Request for Simplify3D gcode test

Posted by Firefox3D

|

Request for Simplify3D gcode test July 15, 2015 08:20AM |

Registered: 8 years ago Posts: 105 |

Hi,

After seeing some good comparison pics of Sli3er vs Simplify3D in an old thread I have seen a banding "feature" in a print that I see in mine, which I think may be down to the way Sli3er deals with sections that have a small gap between inside and outside perimeters.

I would like to send someone who owns Simplify3D a small STL file so they could create a gcode file for a test print. If it prints ok it would be reason enough for me to invest in Simplify3D.

I know how to tweak stuff directly in the gcode so it would just be a straightforward 0.2mm layer print.

Thanks

Jon

After seeing some good comparison pics of Sli3er vs Simplify3D in an old thread I have seen a banding "feature" in a print that I see in mine, which I think may be down to the way Sli3er deals with sections that have a small gap between inside and outside perimeters.

I would like to send someone who owns Simplify3D a small STL file so they could create a gcode file for a test print. If it prints ok it would be reason enough for me to invest in Simplify3D.

I know how to tweak stuff directly in the gcode so it would just be a straightforward 0.2mm layer print.

Thanks

Jon

|

Re: Request for Simplify3D gcode test July 15, 2015 08:50AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Firefox3D

..I would like to send someone who owns Simplify3D a small STL file so they could create a gcode file for a test print....

no problem, a lot of owner will be happy to - just attach the STL to your post

Quote

..if it prints ok it would be reason enough for me to invest in Simplify3D...

before you spend you hard earned, please notice Slic3r is catching up fast, that being said, I have no regrets investing in SF3D

Erik

|

Re: Request for Simplify3D gcode test July 15, 2015 09:37AM |

Registered: 8 years ago Posts: 105 |

Sli3er is better than it was, certainly the interface, but I think it might be something to do with the infill overlap that maybe isn't being honoured in certain situations, I have changed it from 15% to 5% or 0% and it doesn't seem to change the print or gcode when inside and outside walls have a spacing between them of just over 1 line of infill, if you can turn infill off it almost disappears so I think it is related.

I might be purely a limitation of a 0.5mm print head, but if I know then I can decide.

Settings 0.5mm head, 0.3mm starting layer, 0.2mm layer, 3 perimeters from Sli3er 1.2mm I think?, and If I could have 2 files one with infill one without that would be great. With the wall thickness it shouldn't need infill base layers with the no infill option.

Thanks

Jon

I might be purely a limitation of a 0.5mm print head, but if I know then I can decide.

Settings 0.5mm head, 0.3mm starting layer, 0.2mm layer, 3 perimeters from Sli3er 1.2mm I think?, and If I could have 2 files one with infill one without that would be great. With the wall thickness it shouldn't need infill base layers with the no infill option.

Thanks

Jon

|

Re: Request for Simplify3D gcode test July 15, 2015 09:39AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

but we need some information like the print temperature, maybe print speed and so on.

Generating is no problem as long as you do not request 20 files.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

but we need some information like the print temperature, maybe print speed and so on.

Generating is no problem as long as you do not request 20 files.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 10:21AM |

Registered: 8 years ago Posts: 105 |

Sorry had that and forgot to paste it in

Perimeters 50mm/s

External Perimeters 40mm/s

Infill 40mm/s

The speed is not that important, tried it faster and slower with the same result.

Print temps I can paste from Sli3er gcode or manually alter but go with 190 first layer 170 for the rest.

The problems I think are caused by extrusion factors at certain points, not anything else.

Perimeters 50mm/s

External Perimeters 40mm/s

Infill 40mm/s

The speed is not that important, tried it faster and slower with the same result.

Print temps I can paste from Sli3er gcode or manually alter but go with 190 first layer 170 for the rest.

The problems I think are caused by extrusion factors at certain points, not anything else.

|

Re: Request for Simplify3D gcode test July 15, 2015 10:27AM |

Registered: 9 years ago Posts: 1,699 |

And bed temperature? The part should be able to stik on bed, shouldn't it?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 10:30AM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 11:03AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

you have to look if that is okay for you. I had to ZIP them.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

you have to look if that is okay for you. I had to ZIP them.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 11:15AM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 11:17AM |

Registered: 9 years ago Posts: 1,699 |

You are welcome. My Ormerord is "dead" for the moment as I am commissioning it and get rid of the damn connection of the hot-end thermistor.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 11:23AM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 12:02PM |

Registered: 10 years ago Posts: 2,472 |

Quote

ormerod168

... before you spend you hard earned, please notice Slic3r is catching up fast, that being said, I have no regrets investing in SF3D

Erik

Yes, but reading the Slic3r forum it still appears to be plagued with at least one serious bug. The reason I decided to splash out on S3D was the fact that every Slic3r version came with a different set of bugs. Note that S3D also brings out updates with new features from time to time. The latest version now supports different infill patterns (just as Slic3r has always done). Personally I find rectilinear infill to be the fastest and just as good as any other (after all, it is hidden from view, and I am not convinced that other patterns provide any significant strength advantage), but the other patterns are amusing to try out. Perhaps the biggest advantage of S3D is the quality and versatility of the support structures that it generates, which is unmatched by any other slicing software that I know of. Having access to proper technical support is also an advantage that commercial products have over the freebies (not that all companies have adequate technical support of course, but S3D appears to one of those that do).

Dave

|

Re: Request for Simplify3D gcode test July 15, 2015 12:07PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 02:23PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 02:45PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 03:38PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 15, 2015 03:54PM |

Registered: 9 years ago Posts: 1,699 |

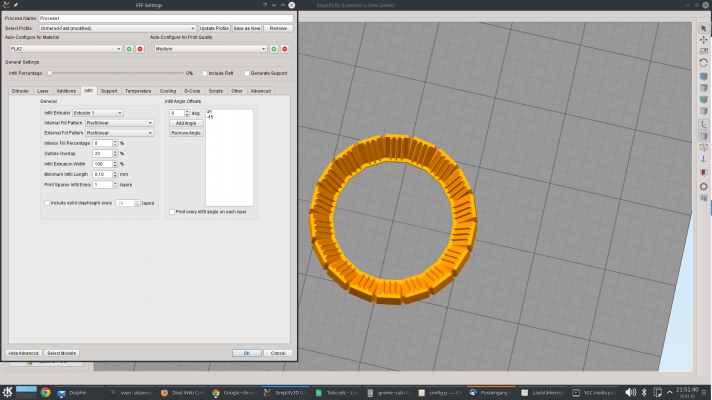

I am not sure if I got the question right but I would say yes: As you can see here:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 05:19PM |

Registered: 8 years ago Posts: 105 |

Thanks Treito, that's what I meant.

I was going to print the 20% infill also but looking at it in Repetier-Host the top "problem" section is exactly the same, not surprising as it shouldn't require infill.

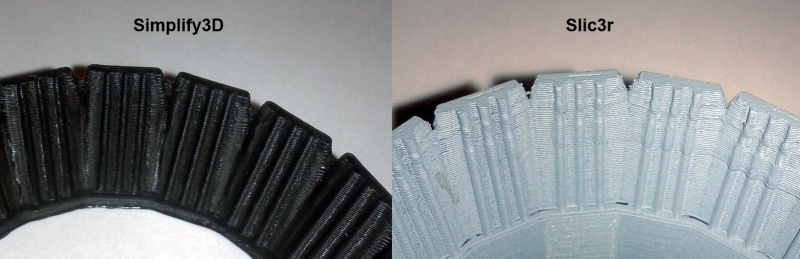

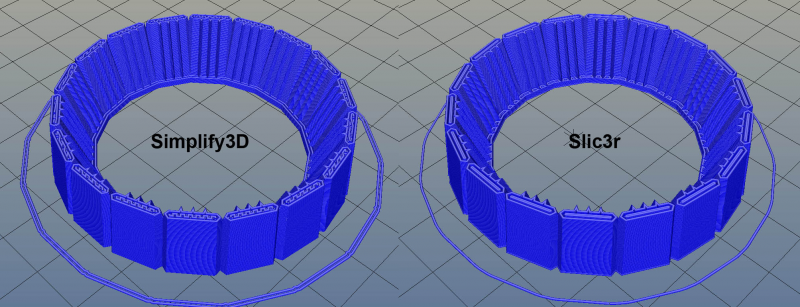

Conclusion Simplify3D wins hands down, no banding, no glitches, being extremely picky - tiny bit of stringing between the really small V cuts at the top, but that's ok as it's a very quick needle file removal, not major sanding work to remove the banding unevenness. Also this is with no tweaking for my printer, although Treito seems to know what he is doing so it probably is pretty spot on

Same filament for both, the Slic3r one just has a coat of primer. The first lower temp setting one I did looked basically the same, just the first layer wasn't brilliant.

Actually if I didn't know I would say it had been printed with a finer nozzle.

The interesting thing is what happens at the layer 66 where the banding occurs with Slic3r

Simplify3D does a thin squiggle, Slic3r does a double line. Also when it gets near the narrow end layer points, it does look like Slic3r is adding about 20% dimensionally in X and Y.

I would say if you are picky about detail prints Simplify3D is worth the money, I would have probably saved about £10 already.

Having said that considering Slic3r is free, really shouldn't be moaning about it, I mean even if it was $1, for 99% of prints it's not 100 odd times better.

Jon

Edited 3 time(s). Last edit at 07/15/2015 05:24PM by Firefox3D.

I was going to print the 20% infill also but looking at it in Repetier-Host the top "problem" section is exactly the same, not surprising as it shouldn't require infill.

Conclusion Simplify3D wins hands down, no banding, no glitches, being extremely picky - tiny bit of stringing between the really small V cuts at the top, but that's ok as it's a very quick needle file removal, not major sanding work to remove the banding unevenness. Also this is with no tweaking for my printer, although Treito seems to know what he is doing so it probably is pretty spot on

Same filament for both, the Slic3r one just has a coat of primer. The first lower temp setting one I did looked basically the same, just the first layer wasn't brilliant.

Actually if I didn't know I would say it had been printed with a finer nozzle.

The interesting thing is what happens at the layer 66 where the banding occurs with Slic3r

Simplify3D does a thin squiggle, Slic3r does a double line. Also when it gets near the narrow end layer points, it does look like Slic3r is adding about 20% dimensionally in X and Y.

I would say if you are picky about detail prints Simplify3D is worth the money, I would have probably saved about £10 already.

Having said that considering Slic3r is free, really shouldn't be moaning about it, I mean even if it was $1, for 99% of prints it's not 100 odd times better.

Jon

Edited 3 time(s). Last edit at 07/15/2015 05:24PM by Firefox3D.

|

Re: Request for Simplify3D gcode test July 15, 2015 05:31PM |

Registered: 9 years ago Posts: 1,699 |

For the moment I only collect proved working improvements but this will change soon when my last parts for my "selfmade" Ormerod MK2 arrives and I am able to print the last parts. Then I will develop some own Improvements. At the moment I have a little problem If you not use all improvements... Both proximity sensors are too low (as they use the same connection) and then they crashes into the printed part. There are improvements to lower the nozzle or other proximity sensors and I would not have that problem.

BTT As I bought S3D the difference were quite bigger. Slic3r could improve the quality and has some nice new features like auto speed and correction of hole sizes..

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

BTT As I bought S3D the difference were quite bigger. Slic3r could improve the quality and has some nice new features like auto speed and correction of hole sizes..

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 06:07PM |

Registered: 8 years ago Posts: 105 |

Funnily enough I moved my Z-sensor as I has having collision problems, I filed about 0.5mm of the bottom of the board, fixed it with super strong double sided tape as the holes in the board wouldn't let me relocate it higher up, and filed about 1mm or more off bottom of the plastic surround. I now have about 2mm+ clearance so no hitting issues.

I have tried 3 different version of Slic3r and the banding "glitch" happens with all of them, in fact looking now I can see it in other parts I have printed, I think it happens with thin or complex geometry.

Now I have a good starting point going to try the colorfabb XT filament I bought.

Thanks again Treito.

Jon

Edited 1 time(s). Last edit at 07/15/2015 06:38PM by Firefox3D.

I have tried 3 different version of Slic3r and the banding "glitch" happens with all of them, in fact looking now I can see it in other parts I have printed, I think it happens with thin or complex geometry.

Now I have a good starting point going to try the colorfabb XT filament I bought.

Thanks again Treito.

Jon

Edited 1 time(s). Last edit at 07/15/2015 06:38PM by Firefox3D.

|

Re: Request for Simplify3D gcode test July 15, 2015 06:45PM |

Registered: 9 years ago Posts: 1,699 |

You are welcome - no problem. The decision to buy S3d was really hard so I waited until night (like now) and I was getting tired I simply bought it. You (not personal, common meant) spend much money for the printer so you really should consider to spent the money as you get better quality. But Slic3r tries to come back.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 15, 2015 08:09PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 16, 2015 05:22AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Firefox3D

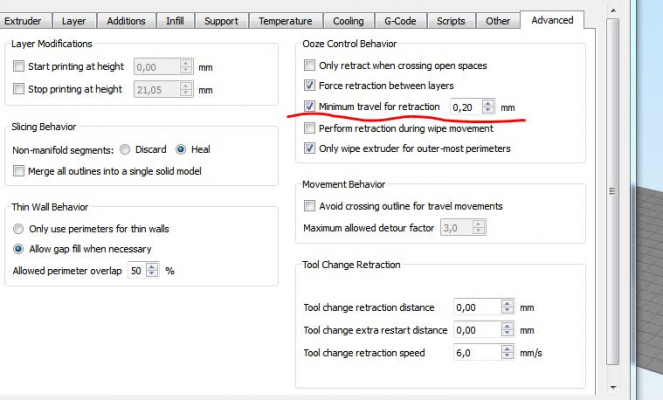

...being extremely picky - tiny bit of stringing between the really small V cuts at the top, but that's ok as it's a very quick needle file removal...

..reducing the minimal travel distance before retraction might make a difference

Erik

|

Re: Request for Simplify3D gcode test July 16, 2015 05:32AM |

Registered: 8 years ago Posts: 443 |

I bought Simplify3d for my Mendle 3 Tricolour as I was having a lot of problems with ooze when printing three colours on each level, but have been having problems setting up the settings, also the Dual Extruder feature of Simplify3d doesn't extend to three extruder and appears to only work with certain printers.

Anyone got a setting file that may help?

Anyone got a setting file that may help?

|

Re: Request for Simplify3D gcode test July 16, 2015 08:51AM |

Registered: 9 years ago Posts: 1,699 |

Quote

ormerod168

Quote

Firefox3D

...being extremely picky - tiny bit of stringing between the really small V cuts at the top, but that's ok as it's a very quick needle file removal...

..reducing the minimal travel distance before retraction might make a difference

[attachment 58181 SF3D_retraction.JPG]

Erik

Thanks for this advice. I just changed this in my settings. What about your speed settings? (Others tab)

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 16, 2015 01:37PM |

Registered: 9 years ago Posts: 638 |

|

Re: Request for Simplify3D gcode test July 16, 2015 01:39PM |

Registered: 8 years ago Posts: 105 |

Well I bought it, copied most of Trieto's settings from the gcode file, couple of amendments, mainly just retraction speed which sounded a bit viscous on my printer and overall speed a little slower.

Plus the minimum travel for retraction to stop the stringing, remembered I changed this in Slic3r down to the 1mm minimum, printing now.

Also using colorfabb XT filament, which from two quick tests last night looks very good.

Edited 1 time(s). Last edit at 07/16/2015 01:51PM by Firefox3D.

Plus the minimum travel for retraction to stop the stringing, remembered I changed this in Slic3r down to the 1mm minimum, printing now.

Also using colorfabb XT filament, which from two quick tests last night looks very good.

Edited 1 time(s). Last edit at 07/16/2015 01:51PM by Firefox3D.

|

Re: Request for Simplify3D gcode test July 16, 2015 01:50PM |

Registered: 8 years ago Posts: 105 |

|

Re: Request for Simplify3D gcode test July 16, 2015 01:53PM |

Registered: 9 years ago Posts: 1,699 |

Quote

Darathy

On their Ormerod is not under its supported printers ,will it work with no problems?

That should not be a problem. Only choose "Others", RepRap Merlin and enter the bed size, nozzle diameter and check that you have a heated bed. I am using this software without any problems. The only restriction is that some supported printers (not all) are supported with more functions.

@Firefox3D I am experimenting with the speed at the moment. I have to lower the first layer speed to approx. 15mm/s and the maximum speed to 50mm/s.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 16, 2015 04:03PM |

Registered: 8 years ago Posts: 105 |

Printed fine, perimeters still a little too fast, little too much ringing from the fast direction change, 2nd attempt going now.

Discovered it doesn't add end code to move the head off the print and move the bed forward as Slic3r does, so you want to put this in Scripts > Ending Script section

G91

G1 Z5

G90

G1 X0 Y200 F6000

M104 S0 ; turn off extruder

M140 S0 ; turn off bed

Discovered it doesn't add end code to move the head off the print and move the bed forward as Slic3r does, so you want to put this in Scripts > Ending Script section

G91

G1 Z5

G90

G1 X0 Y200 F6000

M104 S0 ; turn off extruder

M140 S0 ; turn off bed

Sorry, only registered users may post in this forum.