Printing PETG & Motor Voltage

Posted by atheimer

|

Printing PETG & Motor Voltage August 08, 2015 10:12AM |

Registered: 9 years ago Posts: 101 |

Hi Everyone,

Fine tuning my Duet i3 printer and had a couple questions. I've got PLA printing consistent with the addition of the IR proximity sensor. So I moved on to PETG. Everything almost works but I can't get consistant prints and have been running into trouble

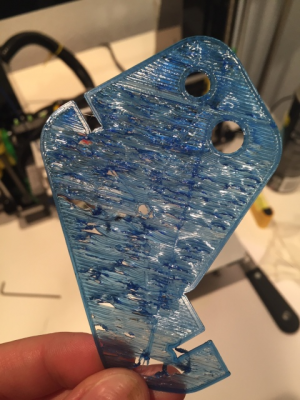

with my extruder drive (Bulldog Lite direct) skipping steps. On the Duet I've got the E voltage set to 850 this was where it seemed to work well for PLA but with PETG this results in lots of skipped steps and my first layer looks like:

On my old RAMPs board I just turned up the voltage, measured, and tested to find the spot where the E didn't skip is there any issue with the same approach in the config file w. the Duet? I assume I shouldn't go higher than 1000? Which I believe is 1A right?

For the rest of my rig, I'm using a e3d6 hotend @ 250 and heated bed @ 75. In looking at the above picture I feel like my hotend might be too hot, the PETG extrudes ok at 230 but skips steps ALOT until around 250 then its just occassional but still noticable.

I'll be trying to play with the E voltage more today but thought I'd post.

Thanks as always!

Fine tuning my Duet i3 printer and had a couple questions. I've got PLA printing consistent with the addition of the IR proximity sensor. So I moved on to PETG. Everything almost works but I can't get consistant prints and have been running into trouble

with my extruder drive (Bulldog Lite direct) skipping steps. On the Duet I've got the E voltage set to 850 this was where it seemed to work well for PLA but with PETG this results in lots of skipped steps and my first layer looks like:

On my old RAMPs board I just turned up the voltage, measured, and tested to find the spot where the E didn't skip is there any issue with the same approach in the config file w. the Duet? I assume I shouldn't go higher than 1000? Which I believe is 1A right?

For the rest of my rig, I'm using a e3d6 hotend @ 250 and heated bed @ 75. In looking at the above picture I feel like my hotend might be too hot, the PETG extrudes ok at 230 but skips steps ALOT until around 250 then its just occassional but still noticable.

I'll be trying to play with the E voltage more today but thought I'd post.

Thanks as always!

|

Re: Printing PETG & Motor Voltage August 08, 2015 11:25AM |

Registered: 9 years ago Posts: 638 |

|

Re: Printing PETG & Motor Voltage August 08, 2015 01:34PM |

Registered: 10 years ago Posts: 14,672 |

It is the motor current you set in the M906 command, not the motor voltage. You can go up to at least 1200mA on the Duet, probably more especially if you cool the Duet with a fan. What is the rated current of your extruder motor?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Printing PETG & Motor Voltage August 09, 2015 10:39AM |

Registered: 9 years ago Posts: 101 |

Darathy,

The more I'm reading it seems like this type of print is associated with moisture in the filiment rather than a temperature issue. I switched back to PLA and saw the same type of "junk" in the print. I've had my printer for almost a year now and never seen this type of issue perhaps thanks to the summer? Is there some way to dry the filiment out for testing?

Thanks

The more I'm reading it seems like this type of print is associated with moisture in the filiment rather than a temperature issue. I switched back to PLA and saw the same type of "junk" in the print. I've had my printer for almost a year now and never seen this type of issue perhaps thanks to the summer? Is there some way to dry the filiment out for testing?

Thanks

|

Re: Printing PETG & Motor Voltage August 09, 2015 10:53AM |

Registered: 9 years ago Posts: 638 |

you can put it in the oven at 50C for a few hours but i just put all my fillaments in a zip bag(even ones i had moisture in them) and [www.amazon.com] ( i use a huge vacumm zip bag for clothes ,it fits abaut 6 spools inside ,but i no longer vacumm it ,it punctures too easly).

the silica will turn green when too full of water and u just put it in microweave(withouht the metal container) for 30 sec or so and its reusable(but i find it does not last as long as first time i opened the dry pack) or u can put it in an oven for 2-3hours with the canister at 120C or 250F ( i will try this and see if it lasts longer).

Edited 2 time(s). Last edit at 08/09/2015 10:57AM by Darathy.

the silica will turn green when too full of water and u just put it in microweave(withouht the metal container) for 30 sec or so and its reusable(but i find it does not last as long as first time i opened the dry pack) or u can put it in an oven for 2-3hours with the canister at 120C or 250F ( i will try this and see if it lasts longer).

Edited 2 time(s). Last edit at 08/09/2015 10:57AM by Darathy.

|

Re: Printing PETG & Motor Voltage August 10, 2015 07:33AM |

Registered: 10 years ago Posts: 2,472 |

Moisture would not cause the extruder to skip. I think the photo is showing the effect of a skipping extruder rather than moisture - note the shorter infill lines are OK - I am assuming that the extruder starts skipping on longer infill lines (which is very typical).

You can safely increase the current to 1000mA (1A), and then reduce the print speed until the motor no longer skips. Other things that cause skipping are low hotend temperature, too low Z height on first layer, and a partially blocked nozzle. Thicker layers need slower print speeds as there is more plastic being extruded.

Dave

You can safely increase the current to 1000mA (1A), and then reduce the print speed until the motor no longer skips. Other things that cause skipping are low hotend temperature, too low Z height on first layer, and a partially blocked nozzle. Thicker layers need slower print speeds as there is more plastic being extruded.

Dave

|

Re: Printing PETG & Motor Voltage August 10, 2015 01:11PM |

Registered: 9 years ago Posts: 638 |

Quote

dmould

Moisture would not cause the extruder to skip. I think the photo is showing the effect of a skipping extruder rather than moisture - note the shorter infill lines are OK - I am assuming that the extruder starts skipping on longer infill lines (which is very typical).

You can safely increase the current to 1000mA (1A), and then reduce the print speed until the motor no longer skips. Other things that cause skipping are low hotend temperature, too low Z height on first layer, and a partially blocked nozzle. Thicker layers need slower print speeds as there is more plastic being extruded.

Dave

Could be inapropriate Z0 making the nozzle too close to bed and make the extruder to skip or simply overextrusion, To me it looks like 0.1mm layer hight which could make a big diference in Z0 or overextruding. or both combined.

|

Re: Printing PETG & Motor Voltage August 10, 2015 01:47PM |

Registered: 10 years ago Posts: 2,472 |

Unless your bed is very level or bed compensation is *really* accurate, 0.1mm as a first layer height is not likely to be attainable for anything other than very small prints. The thicker the first layer, the more tolerant the print is of differences in bed height. I cannot see any significant disadvantage of a thicker base layer - you have to print that first layer more slowly, but that is compensated by the fact that you are printing what would otherwise be more than one layer so the total print time will not change much.

Dave

Dave

|

Re: Printing PETG & Motor Voltage August 11, 2015 02:41PM |

Registered: 8 years ago Posts: 150 |

|

Re: Printing PETG & Motor Voltage August 12, 2015 07:21PM |

Registered: 8 years ago Posts: 105 |

I have been doing some testing with Colorfabb XT which is similar to PETG as far as I know, the maximum print speed for a high quality print is around 30mm/s. It behaves in a much more viscous elastic manner than PLA, can't compare to ABS as I have never used it, don't want to poison myself!

Jon

Jon

|

Re: Printing PETG & Motor Voltage September 04, 2015 09:07AM |

Registered: 9 years ago Posts: 101 |

Thanks for all the great comments, really helpful!

The skipping in my case was due to the nozzle being partially blocked in the middle of the print bed. Re-calibrated + remembering to use auto-bed-compensation fixed that. Printing cleanly @ 140 now. While inspecting the print closer the printer will lay down a nice solid think line but when it somes back to lay the next line it "pulls" the previous line a little causing the ripples. To me this means the previous layer is too hot or perhaps didn't have enough time to fully adhere to the bed? My temps are currently 140(e3dv6) and 85(bed IR temp)

I'm going to run a test right now slowing the print speed down the 30mm and see how that goes perhaps more time = more adhesion?

Also, I thought the following post was useful as well: [forum.makergear.com]

Playing with the infill settings seems relevant as my outlines look perfect and appear to adhere perfectly as well.

The skipping in my case was due to the nozzle being partially blocked in the middle of the print bed. Re-calibrated + remembering to use auto-bed-compensation fixed that. Printing cleanly @ 140 now. While inspecting the print closer the printer will lay down a nice solid think line but when it somes back to lay the next line it "pulls" the previous line a little causing the ripples. To me this means the previous layer is too hot or perhaps didn't have enough time to fully adhere to the bed? My temps are currently 140(e3dv6) and 85(bed IR temp)

I'm going to run a test right now slowing the print speed down the 30mm and see how that goes perhaps more time = more adhesion?

Also, I thought the following post was useful as well: [forum.makergear.com]

Playing with the infill settings seems relevant as my outlines look perfect and appear to adhere perfectly as well.

|

Re: Printing PETG & Motor Voltage September 04, 2015 03:39PM |

Registered: 9 years ago Posts: 638 |

it could mean your Z0 is too low it would also couse ripples i usualy get them then, check before each print(if you turn off the printer) ,home z and then lower/highen by 0.1mm steps till the nozzle bearly touches the paper then send G92 Z0.

Just realised Dc already wrothe this.

Do you print on Kapton tape?

Edited 4 time(s). Last edit at 09/04/2015 03:54PM by Darathy.

Just realised Dc already wrothe this.

Do you print on Kapton tape?

Edited 4 time(s). Last edit at 09/04/2015 03:54PM by Darathy.

|

Re: Printing PETG & Motor Voltage September 05, 2015 02:49AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Printing PETG & Motor Voltage September 26, 2015 07:47PM |

Registered: 8 years ago Posts: 475 |

There is no valid reason for skipping steps with PETG if it does not skip in PLA, as extrusion of PETG is far easier than PLA.

However, temperature shall be much higher. The ease of extrusion is not the good parameter, which is the good adhesion. Good adhesion is obtained for temperature much higher than an easy extrusion > 30 C.

Particularly, esun PETG needs quite high temperature, up to it became stringy.

The easiest mean to detect adhesion is translucent part. You shall see the former layer through the last one.

Moisture is a problem with PETG, as it is not quite easy to detect but it will make the PETG hydrolising, which will make part brittle.

So, instead of what I have read on other topics, store your PETG properly to avoid humidity.

The print speed is not limited if you heat a lot. It depends from your hotend. PETG needs longer heat zone than PLA. For 'ordinary' heat zone, you shall heat more.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

However, temperature shall be much higher. The ease of extrusion is not the good parameter, which is the good adhesion. Good adhesion is obtained for temperature much higher than an easy extrusion > 30 C.

Particularly, esun PETG needs quite high temperature, up to it became stringy.

The easiest mean to detect adhesion is translucent part. You shall see the former layer through the last one.

Moisture is a problem with PETG, as it is not quite easy to detect but it will make the PETG hydrolising, which will make part brittle.

So, instead of what I have read on other topics, store your PETG properly to avoid humidity.

The print speed is not limited if you heat a lot. It depends from your hotend. PETG needs longer heat zone than PLA. For 'ordinary' heat zone, you shall heat more.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

Sorry, only registered users may post in this forum.

) but I would guess that different polymers have different viscosity when they are melted so you simply can't print some as fast as others.

) but I would guess that different polymers have different viscosity when they are melted so you simply can't print some as fast as others.