I'm getting pointy ears on the corners of my prints

Posted by OCLarson13

|

I'm getting pointy ears on the corners of my prints August 15, 2015 08:23AM |

Registered: 8 years ago Posts: 3 |

Hi,

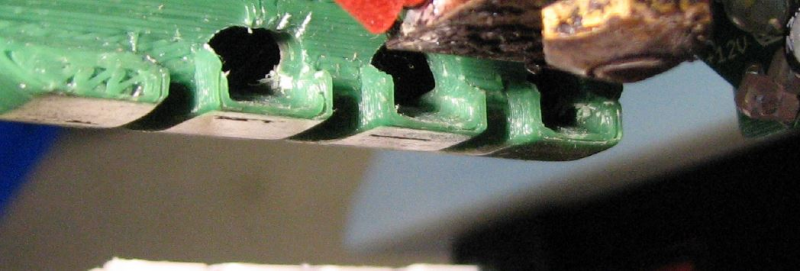

I'm printing replacement parts for my Ormerod 1, but I keep getting pointy ears on the corners of my prints.

I'm printing with PLA at 180 degrees with a bed temparature of 75 degrees. My layer height is set to 0.2mm.

It seems like the hot end might be touching the piece while printing.

Do you guys have any pointers for me please?

Thanks

I'm printing replacement parts for my Ormerod 1, but I keep getting pointy ears on the corners of my prints.

I'm printing with PLA at 180 degrees with a bed temparature of 75 degrees. My layer height is set to 0.2mm.

It seems like the hot end might be touching the piece while printing.

Do you guys have any pointers for me please?

Thanks

|

Re: I'm getting pointy ears on the corners of my prints August 15, 2015 09:37AM |

Registered: 8 years ago Posts: 443 |

|

Re: I'm getting pointy ears on the corners of my prints August 15, 2015 12:01PM |

Registered: 9 years ago Posts: 1,699 |

Your heated bed temperature is far too high and without pictures it is hard to say. These pictures should include the skirt and maybe also the skirt parameters. But I would guess your nozzle is too deep. Also the PLA temperature is a little bit too low. And what is the material you print on? As a beginner you should not try to print directly on glass. This is very hard and depending on the material it can work or not.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I'm getting pointy ears on the corners of my prints August 15, 2015 12:15PM |

Registered: 8 years ago Posts: 3 |

|

Re: I'm getting pointy ears on the corners of my prints August 15, 2015 12:36PM |

Registered: 9 years ago Posts: 638 |

Quote

OCLarson13

Thanks Treito,

I'm printing on Kapton Tape. What bed temperature would you recommend?

What can I do if the nozzle is too deep?

I'd appreciate it if you could have a look at the attached photo.

It looks to me like warping ,you will need more cooling with that part as it is small if you can mount a extra fan to blow below the nozzle. or another solution is print 2 of them and put a bit of a distance between them and slow down print speed a bit

|

Re: I'm getting pointy ears on the corners of my prints August 15, 2015 12:37PM |

Registered: 9 years ago Posts: 1,699 |

Oh yes your nozzle is definitely to deep as you get blobs at the skirt. Probably your Extruder motor skips. Did you read the capital of calibration? You have to change your G31 parameter. Decrease the value after the Z by 0.2 or maybe even 0.3. The skirt (the line outside your object) should be smooth. I print at a maximum bed temperature of 65°C as my glass surface (including Kapton or PET tape) does not reach more then 60°C and that should be the maximum for PLA. You are not allowed to go further for the most of the PLA variants but this is also written in the commissioning chapter and in the datasheet of your PLA.

And I also do not think that the angle of your nozzle is the right one. It seems to be skewed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

And I also do not think that the angle of your nozzle is the right one. It seems to be skewed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I'm getting pointy ears on the corners of my prints August 16, 2015 01:15PM |

Registered: 10 years ago Posts: 1,230 |

yes looks like warping caused by too hot material, if you watch closely you will see the nozzle wade though the molten plastic of the former layers, the cure, as said is to let the print cool, either printing more items in same session or ad more cooling, slowing down the print might help a bit but then again the nozzle will radiate more heat to the print

Yes your nozzle may be too low, hard to see if you only have one starting perimeter, but a too low nozzle will only influence the first layer

If you ad more cooling you should raise the nozzle temperature a bit, 180 degrees is a bit low for PLA, I would not go under 185 and usually prints at 195 - 205 degrees depending of the color

Bed temperature printing on kapton, AFAIK RepRapPro run their business printing at 57 degrees (and so do I) that must mean something

Kapton tape works very well for me, if anythings gives I find its always the glue of the kapton tape

To get more cooling you can open the air vents of the fan duct with a drill bit, drill very very slow or the plastic will melt and leave a mess, to play it safe you can turn the drill by hand

..or print one of the alternative fan ducts, e.g. ianburny's version with the 90 degree turned heat sink and much better air flow

..or just ad a secondary stand alone fan

Erik

Yes your nozzle may be too low, hard to see if you only have one starting perimeter, but a too low nozzle will only influence the first layer

If you ad more cooling you should raise the nozzle temperature a bit, 180 degrees is a bit low for PLA, I would not go under 185 and usually prints at 195 - 205 degrees depending of the color

Bed temperature printing on kapton, AFAIK RepRapPro run their business printing at 57 degrees (and so do I) that must mean something

Kapton tape works very well for me, if anythings gives I find its always the glue of the kapton tape

To get more cooling you can open the air vents of the fan duct with a drill bit, drill very very slow or the plastic will melt and leave a mess, to play it safe you can turn the drill by hand

..or print one of the alternative fan ducts, e.g. ianburny's version with the 90 degree turned heat sink and much better air flow

..or just ad a secondary stand alone fan

Erik

|

Re: I'm getting pointy ears on the corners of my prints August 16, 2015 01:20PM |

Registered: 10 years ago Posts: 1,230 |

|

Re: I'm getting pointy ears on the corners of my prints August 16, 2015 01:50PM |

Registered: 8 years ago Posts: 2 |

HI.

What infill percentage do you use. It could be that you are over extruding. If you use 100% infill. Try to lower the infill to 40%. If the problem disappear it can be that you are over extruding. If the infill is 100% and you over extruding the material is building up and as no where to go. That causes bumps. Very often in the corner where the layer change is done.

If so you have to calibrate your extruding or lower your infill percentage.

/M

What infill percentage do you use. It could be that you are over extruding. If you use 100% infill. Try to lower the infill to 40%. If the problem disappear it can be that you are over extruding. If the infill is 100% and you over extruding the material is building up and as no where to go. That causes bumps. Very often in the corner where the layer change is done.

If so you have to calibrate your extruding or lower your infill percentage.

/M

|

Re: I'm getting pointy ears on the corners of my prints August 16, 2015 10:22PM |

Registered: 8 years ago Posts: 443 |

|

Re: I'm getting pointy ears on the corners of my prints August 17, 2015 03:00AM |

Registered: 8 years ago Posts: 3 |

|

Re: I'm getting pointy ears on the corners of my prints August 19, 2015 04:30PM |

Registered: 10 years ago Posts: 51 |

Quote

Treito

As a beginner you should not try to print directly on glass. This is very hard and depending on the material it can work or not.

Disagree. I've used glass from the start, and never had any problems with PLA. ABS is bit more tricky, but no fault of the glass.

If your glass is clean (I use meths), your bed temp and nozzle temp are reasonable, and (most importantly) your height is correct, glass is no problem.

Wrt to the lifting corners, do all corners lift, or just one side? In my case lifting corners was resolved by putting an anti-backwash went on my hotend fan. The fan backwash was causing my corners to lift.

|

Re: I'm getting pointy ears on the corners of my prints August 20, 2015 02:04AM |

Registered: 9 years ago Posts: 1,699 |

I have material here that prints on glass (from 3dfilaments.ie and some others) and others not (from other suppliers). I never got ABS to stick on glass and I will not use hairspray or an aceton soup. That is fact. And as I told this is nothing for beginners. Fact is that the material stick on glass not as good as on Kapton or Blue Painters Tape.

As you have to level your bed exactly and set up the height correctly (last one you can probe if in doubt) you should have gain some experience and that is what I said.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

As you have to level your bed exactly and set up the height correctly (last one you can probe if in doubt) you should have gain some experience and that is what I said.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I'm getting pointy ears on the corners of my prints August 20, 2015 03:03AM |

Registered: 10 years ago Posts: 51 |

Quote

Treito

I have material here that prints on glass (from 3dfilaments.ie and some others) and others not (from other suppliers). I never got ABS to stick on glass and I will not use hairspray or an aceton soup. That is fact. And as I told this is nothing for beginners. Fact is that the material stick on glass not as good as on Kapton or Blue Painters Tape.

As you have to level your bed exactly and set up the height correctly (last one you can probe if in doubt) you should have gain some experience and that is what I said.

You make it sound like printing on glass is some black art. It has nothing to do with the glass. If your height is wrong or bed is not level, Kapton or Painters tape is not going to fix it. Frankly I find applying Kapton, tape or BuildTak witthout bubbles MUCH harder than wiping my glass with spirits.

Printing PLA on glass is dead easy, printing ABS on anything (including Kapton and BuildTak) is a PITA.

So I would say printing ABS is not for beginners, for a number of reasons, not just sticking to the bed. But the filament is the deciding factor, not the glass.

|

Re: I'm getting pointy ears on the corners of my prints August 20, 2015 03:43AM |

Registered: 9 years ago Posts: 1,699 |

For me at the beginning it was much easier to print on Kapton tape instead of glass as the delivered filament did not stick on glass very good (this filament is not supllied anymore). The strange thing is that I had better results printing ABS than PLA at the beginning (warping excluded) as long as the contact surface was not too big (like this little cute elephant). So you cannot say a common message. But the most here in the forum did have different experience and mostly the filament won't stick on glass in the most cases without special help like hairspray.

If you have made another experience than congratulation but you cannot generalize this as even experienced users did not made it to print directly on glass without support in any kind.

Myself for example has no problem to print ABS on BuildTak. Okay I cannot exclude warping everytimes but I have much less warping using BuildTak. So I would say printing ABS on BuildTak is the easiest thing in the world. I hope you get it with the last sentence what I want to say.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

If you have made another experience than congratulation but you cannot generalize this as even experienced users did not made it to print directly on glass without support in any kind.

Myself for example has no problem to print ABS on BuildTak. Okay I cannot exclude warping everytimes but I have much less warping using BuildTak. So I would say printing ABS on BuildTak is the easiest thing in the world. I hope you get it with the last sentence what I want to say.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I'm getting pointy ears on the corners of my prints August 20, 2015 03:59AM |

Registered: 10 years ago Posts: 14,672 |

I used to print PLA on glass after wiping it with vinegar before each print, and it worked well for some filaments and not at all for others. But a week ago, based on a post in this forum (sorry, I can't remember who I have to thank for it), I tried wiping the bed with sugar solution instead of vinegar. I haven't cleaned or wiped the bed since then, and all my PLA prints stick perfectly during printing and fall off when the bed cools to room temperature. The thin sugar film on the bed might be a problem if you get a lot of wasps though!

I've give up printing ABS until I have an enclosure for my printer, because I believe the particulates emitted are likely to be a health hazard - they certainly made me cough for a while.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I've give up printing ABS until I have an enclosure for my printer, because I believe the particulates emitted are likely to be a health hazard - they certainly made me cough for a while.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: I'm getting pointy ears on the corners of my prints August 20, 2015 06:50AM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

I've give up printing ABS until I have an enclosure for my printer, because I believe the particulates emitted are likely to be a health hazard - they certainly made me cough for a while.

I am looking for a good air refresh during printing ABS and I only print it if really really needed. Mainly only for the extruder parts to have the capability to print ABS and otherwise I use PLA as it is stronger and do not suffer on much warping. At the end it is even cheaper as you have not as much broken prints as with using PLA (caused by less warping). Besides the color selection is even much better. You have more options, more color tones and also opaque colors.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I'm getting pointy ears on the corners of my prints August 23, 2015 08:31AM |

Registered: 9 years ago Posts: 183 |

Hello OCLarson13,

I think there could also be a problem with your hotend-setup.

take a look at the attached photo, the drawn lines should normally be approximately parallel.

This has possibly nothing to do with your actual question, but could in the future lead to difficulties.

greetings

Steffen

PS: --- Translated with Google ;-) ---

I think there could also be a problem with your hotend-setup.

take a look at the attached photo, the drawn lines should normally be approximately parallel.

This has possibly nothing to do with your actual question, but could in the future lead to difficulties.

greetings

Steffen

PS: --- Translated with Google ;-) ---

|

Re: I'm getting pointy ears on the corners of my prints August 23, 2015 02:42PM |

Registered: 9 years ago Posts: 1,699 |

Quote

Treito

And I also do not think that the angle of your nozzle is the right one. It seems to be skewed.

As I said before and I think it was even the second time. With this kind of angle all prints fail at me.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.