nozzle keeps on blocking

Posted by redblunt

|

nozzle keeps on blocking September 13, 2015 04:49PM |

Registered: 10 years ago Posts: 112 |

hi there

i just switched back from ABS to PLA. print started off good. speeding up at the second layer

made some loud cracking noises from the extruder. so i checked it out - the extruder keeps on running

an grinding but no force in the world can push the filament further. so i took the hotend apart to clean

it with aceton worked out pretty well.

next try filament stucks again. so tried to reverse it, stuck too. time to screw of the bowden tube - finaly

i was able to pull the filament out. it kinda expanded in the hotend tip but didnt melt any further?

i tried more and less heat midprint but more heat didnt seem to change much but a little, i stopped raising

the temperature at 230° because it smelled to bad.

so im in doubt what to do. when i check the temperature of the aluminium block where the boden tube

reaches in it seems ok - can touch it witch my fingers. has anyone some idea how to fix this?

kind regards

red

Edited 1 time(s). Last edit at 09/13/2015 04:55PM by redblunt.

i just switched back from ABS to PLA. print started off good. speeding up at the second layer

made some loud cracking noises from the extruder. so i checked it out - the extruder keeps on running

an grinding but no force in the world can push the filament further. so i took the hotend apart to clean

it with aceton worked out pretty well.

next try filament stucks again. so tried to reverse it, stuck too. time to screw of the bowden tube - finaly

i was able to pull the filament out. it kinda expanded in the hotend tip but didnt melt any further?

i tried more and less heat midprint but more heat didnt seem to change much but a little, i stopped raising

the temperature at 230° because it smelled to bad.

so im in doubt what to do. when i check the temperature of the aluminium block where the boden tube

reaches in it seems ok - can touch it witch my fingers. has anyone some idea how to fix this?

kind regards

red

Edited 1 time(s). Last edit at 09/13/2015 04:55PM by redblunt.

|

Re: nozzle keeps on blocking September 14, 2015 07:06AM |

Registered: 10 years ago Posts: 2,472 |

Sounds like it may be a blocked or partially blocked nozzle. You can try the standard methods for unblocking, but they did not work all that well for me, so I just bought a new nozzle (and a couple of spares).

I found that if plastic is left "cooking" in the nozzle for some time, the chances are you will suffer a blocked nozzle. That can happen if the filament stops feeding for some reason during a print, and you don't notice for a while.

I will also guess (pure speculation) that when changing from ABS to PLA, you need to extrude a fair bit of PLA at ABS nozzle temperature in order to flush out the residual ABS which will otherwise remain semi-solid and create a partial blockage at PLA temperatures.

Dave

I found that if plastic is left "cooking" in the nozzle for some time, the chances are you will suffer a blocked nozzle. That can happen if the filament stops feeding for some reason during a print, and you don't notice for a while.

I will also guess (pure speculation) that when changing from ABS to PLA, you need to extrude a fair bit of PLA at ABS nozzle temperature in order to flush out the residual ABS which will otherwise remain semi-solid and create a partial blockage at PLA temperatures.

Dave

|

Re: nozzle keeps on blocking September 14, 2015 07:17AM |

Registered: 10 years ago Posts: 112 |

|

Re: nozzle keeps on blocking September 14, 2015 07:33AM |

Registered: 10 years ago Posts: 112 |

|

Re: nozzle keeps on blocking September 14, 2015 07:54AM |

Registered: 10 years ago Posts: 2,472 |

Quote

redblunt

ok here is where i loose my mind right now detaching the bowden tube to get te filament out

i came up with the idea of pushing filament through the nozzle by hand:

this works great but why does it keep on sticking in the hotend ? does it mean the cooling is too good?

You did say that the cool block did not feel very hot to the touch, so I doubt that's the problem in your case. If it were hot enough to allow plastic to melt up the tube, you would burn your finger on the cold block. It is possible that there is an intermittent blockage such as a small bit of PTFE or grit that is sometimes blocking the nozzle and sometimes not (e.g. pulled out of the way after a retraction). If so, the normal clearing method of heating the nozzle to a low temperature where the plastic is soft but not fully molten, and then unloading the filament so it pulls out the dirt will probably work. Chop the potentially dirty end off the extracted filament before reloading.

I am assuming that the problem occurs on all layers. If it only happens on the first layer (and sometimes the second), it is likely caused by the Z zero height being too low (nozzle blocked by the glass).

Other things to look out for:

(1) Make sure that your hobbed bolt is not clogged with plastic dust in case that is the reason it is slipping on the filament.

(2) Filament binding on the reel

(3) The filament has cut through the curved lead-in tube of the printed part on the extruder and is binding in the slot it has cut. You can look at the top part of the curved lead-in section - many of us have noticed that the filament had worn right through the part. I replaced it with a part that takes a PTFE lining tube.

Dave

|

Re: nozzle keeps on blocking September 14, 2015 08:22AM |

Registered: 9 years ago Posts: 177 |

Replacing the nozzle if you have the older one-piece nozzles isn't really an option anymore....

RRP has stopped ordering the one-piece nozzles, although it looks like the 0.3mm ones are still in stock. The PDF schematics for the nozzles are available in a previous branch of Github, if you knew a shop that could make them you could give them this file.

Or you can get a kit to upgrade to the quick-set nozzles I think, but it costs a bit, and some printed parts would need to be changed.

Something to consider, some places have started selling purging polymers in filament form. The one I'm most aware of is Dyna-Purge, simply because a seller near me in the USA just started selling it.

These are supposed to be able to clear out particulates, trace amount of the previous filament, and carbonized filament residue.... I haven't tried them myself, but I know in industry it's common practice to use a purging polymer (i.e. Ultra Purge), to clean out equipment. If you think it's a blocked nozzle it might be worth a try, this stuff usually isn't too expensive.

RRP has stopped ordering the one-piece nozzles, although it looks like the 0.3mm ones are still in stock. The PDF schematics for the nozzles are available in a previous branch of Github, if you knew a shop that could make them you could give them this file.

Or you can get a kit to upgrade to the quick-set nozzles I think, but it costs a bit, and some printed parts would need to be changed.

Something to consider, some places have started selling purging polymers in filament form. The one I'm most aware of is Dyna-Purge, simply because a seller near me in the USA just started selling it.

These are supposed to be able to clear out particulates, trace amount of the previous filament, and carbonized filament residue.... I haven't tried them myself, but I know in industry it's common practice to use a purging polymer (i.e. Ultra Purge), to clean out equipment. If you think it's a blocked nozzle it might be worth a try, this stuff usually isn't too expensive.

|

Re: nozzle keeps on blocking September 14, 2015 08:47PM |

Registered: 10 years ago Posts: 859 |

I have a theory about the Nozzle blockages. More often than not I've just snapped the filament to get a fresh end to feed in to the machine.

The actual end then becomes quite sharp edged. When this is fed into the machine it scrapes its way down to the nozzle and deposits the PTFE dust in the nozzle it's self.

After a few filament changes like that, eventually you end up with enough PTFE dust to block the nozzle.

I heat to 118' and do a rapid withdraw(1000). It seems to work. (Our Mr Ian told me about that... And it works.

I try to remember to file the edge off the filament now.

I'm just completing a Mod/rebuild of my Ormerod. The screw holes of the Lower Z axis lower mount had pulled through and broken the mount. It had the same affect as a blocked nozzle,

I've reprinted most of my PLA fittings now using an infill of 70% and the prints are as strong as houses now... I also print using a higher temp to make the layers Meld together.

When rebuilding, it's made a Very Big difference now, and I can really tighten the screws.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The actual end then becomes quite sharp edged. When this is fed into the machine it scrapes its way down to the nozzle and deposits the PTFE dust in the nozzle it's self.

After a few filament changes like that, eventually you end up with enough PTFE dust to block the nozzle.

I heat to 118' and do a rapid withdraw(1000). It seems to work. (Our Mr Ian told me about that... And it works.

I try to remember to file the edge off the filament now.

I'm just completing a Mod/rebuild of my Ormerod. The screw holes of the Lower Z axis lower mount had pulled through and broken the mount. It had the same affect as a blocked nozzle,

I've reprinted most of my PLA fittings now using an infill of 70% and the prints are as strong as houses now... I also print using a higher temp to make the layers Meld together.

When rebuilding, it's made a Very Big difference now, and I can really tighten the screws.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: nozzle keeps on blocking September 15, 2015 01:12AM |

Registered: 9 years ago Posts: 1,699 |

For the Z axis lower mount there is a redesign by ZPL using Caphead screws to prevent breaking. However this one also broke before I could finish my MK2. That was my first time that this part broke but I often read about that. I guess that I printed with too low temperature or with too less infill. Now I reprinted this part with 100% infill and higher temperature using another PLA and it is very strong now. Mostly parts I printed with 100% infill.

Maybe you should try the ZPL variant as the countersunk screws can easily damage the plastic parts. Either they get loose or you damage the parts as you tighten them too much.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Maybe you should try the ZPL variant as the countersunk screws can easily damage the plastic parts. Either they get loose or you damage the parts as you tighten them too much.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: nozzle keeps on blocking September 15, 2015 08:37AM |

Registered: 10 years ago Posts: 112 |

well i tried your method kim and came with with the next problem: stuck in reverse gear -.-

took the hotend apart for the fithhundred time (wondering when the threads will wear off)

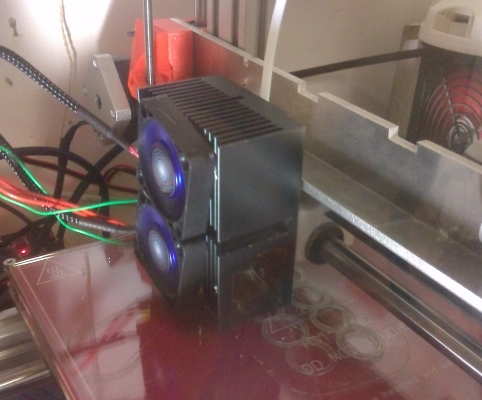

and found this: see picture

how is that even possible?

i messured the hole of the threaded brass union and its about 1.8mm

i kinda tend towards enlarging it or will this make all worse?

kind regards

red

took the hotend apart for the fithhundred time (wondering when the threads will wear off)

and found this: see picture

how is that even possible?

i messured the hole of the threaded brass union and its about 1.8mm

i kinda tend towards enlarging it or will this make all worse?

kind regards

red

|

Re: nozzle keeps on blocking September 15, 2015 08:54AM |

Registered: 10 years ago Posts: 14,672 |

Perhaps the heatsink didn't stay cool enough. Is the hot end fan working properly? When you have finished a print, do you leave the printer turned on (so that the fan runs) until the hot end has cooled to below 40C?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: nozzle keeps on blocking September 15, 2015 09:44AM |

Registered: 10 years ago Posts: 275 |

Hi Red

from your photo it seems that it is not cooled enough....

with some filament I have to clean the hot end after several kilograms (I'm using a filament oilier/cleaner)

with bamboo filament I have to clean the hot end nearly every print ....

Regards

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

from your photo it seems that it is not cooled enough....

with some filament I have to clean the hot end after several kilograms (I'm using a filament oilier/cleaner)

with bamboo filament I have to clean the hot end nearly every print ....

Regards

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: nozzle keeps on blocking September 15, 2015 10:58AM |

Registered: 10 years ago Posts: 2,472 |

Yes - although I dismissed that as the cause because you had said that it did not feel hot to the touch, your photo would suggest that the upper block is not cooling adequately. Possible causes are fan not working, blocked airflow over the heatsink, or bad mechanical (thermal) contact between the cold block and the heatsink.

Dave

Dave

|

Re: nozzle keeps on blocking September 16, 2015 05:18AM |

Registered: 10 years ago Posts: 112 |

|

Re: nozzle keeps on blocking September 16, 2015 08:03AM |

Registered: 10 years ago Posts: 2,472 |

Quote

redblunt

well i can touch the cooling block for several minutes with the topside of my pinky.

i hjave a modulated fansystem so i guess ill change it back to normal when i get the

parts and ill retry.

also thought of decoupling the bowden from the coolingblock

You must not modulate the hotend fan. That fan must always run at full speed while printing otherwise the filament will melt too far up and cause a blockage. I guess you just found that out :-)

Not sure what you mean when you say you will decouple the Bowden from the cooling block. The whole purpose of the cooling block is to keep the filament above the nozzle cool & solid.

The modulated fan output should only be used for a separate print cooling fan.

Dave

|

Re: nozzle keeps on blocking September 16, 2015 08:46AM |

Registered: 9 years ago Posts: 1,699 |

I can only support Dave. Do not modify or try to optimize the process settings unless you really know what you are doing. The newer Ormerod even have two fans. One is permanently on for cooling the nozzle and the other one is for cooling the printed parts. Do not even try to decouple the bowden tube from the cooling block. That is no goo idea. Besides that I have no idea how you want to do it practically but I can only say: Do not do it. Or you can do this and the shop would be happy to sell you a new hot-end.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: nozzle keeps on blocking September 16, 2015 01:08PM |

Registered: 10 years ago Posts: 112 |

no not again

well i guess ill give a try for an old cpu cooler ill the spareparts reach me

i suppose you cant cool too much ?!

@dmould

i tought of an thermic segregation by using different materials

id propably make another mess - so thats off the table

thanks you guys helped me learn - again

well i guess ill give a try for an old cpu cooler ill the spareparts reach me

i suppose you cant cool too much ?!

@dmould

i tought of an thermic segregation by using different materials

id propably make another mess - so thats off the table

thanks you guys helped me learn - again

|

Re: nozzle keeps on blocking September 16, 2015 01:52PM |

Registered: 9 years ago Posts: 177 |

Quote

redblunt

no not again

well i guess ill give a try for an old cpu cooler ill the spareparts reach me

i suppose you cant cool too much ?!

@dmould

i tought of an thermic segregation by using different materials

id propably make another mess - so thats off the table

thanks you guys helped me learn - again

For the hotend cooling block, there is no such thing as overcooling.... but there is such a thing as overkill as well — if the hotend fan causes too much 'backwash' (basically a bunch of turbulence behind the fan, because it's trying to force too much air though the heatsink) it can cause your print to cool too quickly and warp on the fan side (Y high I think).

If you ever had backwash issues, there are some printable vent covers that can go over the fan - they really help a lot.

|

Re: nozzle keeps on blocking September 16, 2015 02:49PM |

Registered: 9 years ago Posts: 1,699 |

ABS is really sensitive to this backwash but you can even achieve that you are not be able to print anything because of the backwash. So why you do not use your original euqipment? Otherwise you have to study the printer and its behaviour and needs before you modify it. But without any knowledge you will always fail.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: nozzle keeps on blocking September 16, 2015 05:38PM |

Registered: 10 years ago Posts: 112 |

why did i mod it?

well more than a year back there were several mods for the fan

like kim browns big blue. and one called cathullu or similiar

i liked the design and it was one of my first working prints so

i wanted to use it of course proud as i was. unfurtunatly i cut

off one third of the original aluminium skeleton *stupid*

some months ago the fan died and i got two instead:

Noiseblocker XM2 40x40x10mm

blessed with fortune my messed up cooling system worked till last week.

today i came up with another "great" idea. i know you'd say dont, but

till the spare parts are here i will try out this beast. at least for the

first three layers it works right now. still have one of dc42's fan backwash

guards, that will be implemented soon.

regards red

well more than a year back there were several mods for the fan

like kim browns big blue. and one called cathullu or similiar

i liked the design and it was one of my first working prints so

i wanted to use it of course proud as i was. unfurtunatly i cut

off one third of the original aluminium skeleton *stupid*

some months ago the fan died and i got two instead:

Noiseblocker XM2 40x40x10mm

blessed with fortune my messed up cooling system worked till last week.

today i came up with another "great" idea. i know you'd say dont, but

till the spare parts are here i will try out this beast. at least for the

first three layers it works right now. still have one of dc42's fan backwash

guards, that will be implemented soon.

regards red

|

Re: nozzle keeps on blocking September 16, 2015 10:32PM |

Registered: 9 years ago Posts: 1,699 |

The Noiseblocker fans are way too slow. How I know this? After only one month the original fan of my Ormerod died because of a bearing fault. As this was a cheap fan I did not want to replace the fan with the same. So I was looking for a similiar one. i studied several datasheets and so on until I found one that seems to be a good choice. I have to say that this is part of my education. Today I know that this airflow is not needed but the Noiseblocker fans do not reach enough power even in this case as they are trimmed to be quiet and not to cool. You would need two of them to get a good result. BTW I used several of this type of fan and all did not last long. Okay in my case I used them horizontally to cool down a CPU on an ITX-Board and I think that was the fault but I am not sure.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: nozzle keeps on blocking September 17, 2015 04:19AM |

Registered: 10 years ago Posts: 859 |

Quote

Treito

For the Z axis lower mount there is a redesign by ZPL using Caphead screws to prevent breaking.

I made my standard replacement on my Prusa i3 with a 0.4mm nozzle and an infill setting of 70% in Slic3r, with a temp of 210' (a hotter temp allow the filament to bond better (Meld). I found I could tighten up the standard countersink

screws very tightly without problem. I also use UHU now as a thread locking agent, as it seems to do the job, and requires less force to undo the screws.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: nozzle keeps on blocking September 17, 2015 04:35AM |

Registered: 9 years ago Posts: 1,699 |

I used 100% also 210°C ans Simplify3D 3.0.2

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.