New firmware 1.09k-dc42

Posted by dc42

|

Re: New firmware 1.09k-dc42 November 05, 2015 09:18AM |

Registered: 8 years ago Posts: 105 |

Thanks Dave,

Good lookin' web interface and the 10X? faster file upload means I don't lose the will to live waiting for a file to upload, plus the ability to cancel, brilliant.

Before I realised you have moved the Motors off button to the send gcode option (M84) I added a macro for Motors off (M18)

Is there difference between M84 and M18 on an Ormerod, doesn't seem to be?

Edited 2 time(s). Last edit at 11/05/2015 09:38AM by Firefox3D.

Good lookin' web interface and the 10X? faster file upload means I don't lose the will to live waiting for a file to upload, plus the ability to cancel, brilliant.

Before I realised you have moved the Motors off button to the send gcode option (M84) I added a macro for Motors off (M18)

Is there difference between M84 and M18 on an Ormerod, doesn't seem to be?

Edited 2 time(s). Last edit at 11/05/2015 09:38AM by Firefox3D.

|

Re: New firmware 1.09k-dc42 November 05, 2015 03:13PM |

Registered: 10 years ago Posts: 14,672 |

M18 and M84 do exactly the same thing in my fork.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware 1.09k-dc42 November 06, 2015 02:32AM |

Registered: 9 years ago Posts: 1,699 |

Using the webinterface my upload speed is only slightly faster. Using FileZilla my upload speed is about 1.5 to 2.0 times faster. Maybe this is caused as my card is a really fast one with the Duets. (I tested several cards and took at least the fastest using the old FW). However I have one card UHS-1 and of one well known brand which is much slower now and achieves only 75 kb/s. Now I do not know if the fault is to find at the card or inside the FW. However I use exactly the same card type in my Android phone and sometimes (6..12 times per year) it does not recognize the card anymore. But the problem is that the FW version I use (it was an update from 4.2 to 4.4) is known to have issues with microSD cards using my smartphone model and according to other forums I have really slightly problems with the card recognition. However I do not know if the manufacturer did reduce the problems with an update. So questions over questions.

@dc42 You know my fast card as we already talked about it. With my Toshiba 8 GB UHS-1 I reach an average speed of 400..500 kb/s and a peak speed of 750 kb/s. Besides if the file size is bigger than 2 MB the speed drops to a maximum of 350 kb/s

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

@dc42 You know my fast card as we already talked about it. With my Toshiba 8 GB UHS-1 I reach an average speed of 400..500 kb/s and a peak speed of 750 kb/s. Besides if the file size is bigger than 2 MB the speed drops to a maximum of 350 kb/s

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 November 06, 2015 05:52AM |

Registered: 8 years ago Posts: 105 |

Perhaps 10 times faster is overstating it, maybe around 5 or 6 times, with a large file 15MiB it averages 160Kib/s with the supplied Kingston card. It was so slow before I usually transferred the card to the pc rather than wait.

Edited 1 time(s). Last edit at 11/06/2015 05:52AM by Firefox3D.

Edited 1 time(s). Last edit at 11/06/2015 05:52AM by Firefox3D.

|

Re: New firmware 1.09k-dc42 November 06, 2015 01:33PM |

Registered: 9 years ago Posts: 1,699 |

Using the old firmware I already achieved 220..240 kb/s. I like my SD card

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 November 08, 2015 11:55AM |

Registered: 8 years ago Posts: 105 |

I will post this here as it's relevant to firmware settings, although also effected by the print material.

Been using Colorfabb XT which is a type of PETG filament. Bed adhesion is proving to be a bit flaky for big parts so might swap to PEI? But it prints well and you can wet sand it to quality surface.

I started printing a test cube with infill so I could optimise the basics for successful printing, found at 0.12mm layers a max print speed for perimeters of around 50mm/s and 30mm/s at 150% for infill so it doesn't miss bits. What I couldn't get rid of were "tears" on the 90 degree corners.

Played with all the obvious settings, improved it but didn't completely stop it. I thought it was just a "feature" of the filament type, unlike PLA which will stay in rubbery lumps at about 100 degrees such that you can peel it off the head after a mishap, this stuff needs around 200. It also "glasses" faster, which is a benefit as small overhangs stay sharp.

Finally worked out what is going on and the reason for this post. I had increased the M201 acceleration settings for X and Y to 600 as it seemed to be a good thing, this was printing PLA. Have found reducing this to 400 at 45mm/s perimeters causes the printer to slow down into corners so it lays a bit more material/heat and the corners now look near perfect. I also dropped the M203 minimum speed settings to 100 for X and Y, not sure this is required but I had already dropped it when lowering the acceleration settings so left it there.

I realise now it's down to the mechanics of printing, when you turn a corner you have to slow down at least with this type of material as you need proportionally more plastic on the outside edge of the corner.

I can provide pics if an anyone is interested to see the effect on corners.

Edited 1 time(s). Last edit at 11/08/2015 12:04PM by Firefox3D.

Been using Colorfabb XT which is a type of PETG filament. Bed adhesion is proving to be a bit flaky for big parts so might swap to PEI? But it prints well and you can wet sand it to quality surface.

I started printing a test cube with infill so I could optimise the basics for successful printing, found at 0.12mm layers a max print speed for perimeters of around 50mm/s and 30mm/s at 150% for infill so it doesn't miss bits. What I couldn't get rid of were "tears" on the 90 degree corners.

Played with all the obvious settings, improved it but didn't completely stop it. I thought it was just a "feature" of the filament type, unlike PLA which will stay in rubbery lumps at about 100 degrees such that you can peel it off the head after a mishap, this stuff needs around 200. It also "glasses" faster, which is a benefit as small overhangs stay sharp.

Finally worked out what is going on and the reason for this post. I had increased the M201 acceleration settings for X and Y to 600 as it seemed to be a good thing, this was printing PLA. Have found reducing this to 400 at 45mm/s perimeters causes the printer to slow down into corners so it lays a bit more material/heat and the corners now look near perfect. I also dropped the M203 minimum speed settings to 100 for X and Y, not sure this is required but I had already dropped it when lowering the acceleration settings so left it there.

I realise now it's down to the mechanics of printing, when you turn a corner you have to slow down at least with this type of material as you need proportionally more plastic on the outside edge of the corner.

I can provide pics if an anyone is interested to see the effect on corners.

Edited 1 time(s). Last edit at 11/08/2015 12:04PM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 18, 2015 04:05PM |

Registered: 8 years ago Posts: 105 |

|

Re: New firmware 1.09k-dc42 December 18, 2015 06:02PM |

Registered: 10 years ago Posts: 14,672 |

M999 has the same effect on the microcontroller as a power down reboot in that it resets it. It won't reset the stepper motor current controller chips, but they will get reprogrammed when the M906 command in config.g is processed. It also won't reset the stepper driver chips, or the PanelDue if you have one attached.

What is the random issue you are seeing?

Edited 1 time(s). Last edit at 12/18/2015 06:02PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What is the random issue you are seeing?

Edited 1 time(s). Last edit at 12/18/2015 06:02PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware 1.09k-dc42 December 18, 2015 07:11PM |

Registered: 8 years ago Posts: 105 |

So the reset command effectively clears all setting and reloads the config.g file which is what I thought it would do.

I have been getting a banding effect as if the print is shrinking then growing a very small amount in the X Y axis which repeats every 1mm or so. I am printing thin layers 0.12 and 0.16mm.

I have driven myself mad for about 3 days because I thought it was inaccurate drive on the Z axis, but have made new herringbone Z gears (and swapped back to the originals) and checking with a micrometer that the layer height is not varying.

I'm trying to pin down what is causing it, it might be I was printing relatively slow at around 20mm/s and the M566 minimum speeds were set at 800 which is too high, I don't think it can be that, but after lowering it to 300 it seems to have stopped.

Will report back if I get a definite answer.

Edited 2 time(s). Last edit at 12/18/2015 07:17PM by Firefox3D.

I have been getting a banding effect as if the print is shrinking then growing a very small amount in the X Y axis which repeats every 1mm or so. I am printing thin layers 0.12 and 0.16mm.

I have driven myself mad for about 3 days because I thought it was inaccurate drive on the Z axis, but have made new herringbone Z gears (and swapped back to the originals) and checking with a micrometer that the layer height is not varying.

I'm trying to pin down what is causing it, it might be I was printing relatively slow at around 20mm/s and the M566 minimum speeds were set at 800 which is too high, I don't think it can be that, but after lowering it to 300 it seems to have stopped.

Will report back if I get a definite answer.

Edited 2 time(s). Last edit at 12/18/2015 07:17PM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 19, 2015 02:28AM |

Registered: 10 years ago Posts: 14,672 |

Try printing a test cube, then see whether the banding lines up with the threads on the threaded rod. Also watch for the end of the X arm wobbling when you command the head up 10mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware 1.09k-dc42 December 19, 2015 02:55AM |

Registered: 9 years ago Posts: 1,699 |

Please also check the belts if they are tight. They should sound like a musical instrument.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 19, 2015 10:20AM |

Registered: 8 years ago Posts: 105 |

It's sure it's none of those things as I printed a cube with banding, then after a full reboot no banding.

The answer for the moment is a full power down reboot before a long print, but I will try and track down what has been causing it. I have a feeling that other people reporting banding problems might be down to the same issue.

Edited 1 time(s). Last edit at 12/19/2015 10:20AM by Firefox3D.

The answer for the moment is a full power down reboot before a long print, but I will try and track down what has been causing it. I have a feeling that other people reporting banding problems might be down to the same issue.

Edited 1 time(s). Last edit at 12/19/2015 10:20AM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 19, 2015 11:39AM |

Registered: 8 years ago Posts: 105 |

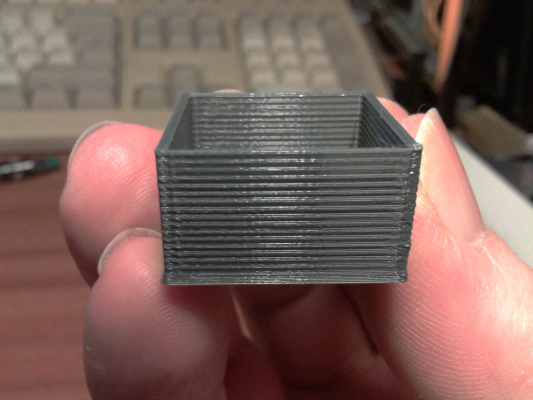

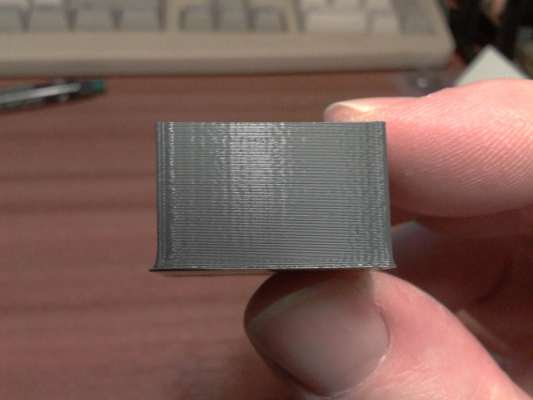

Just to prove I'm not over emphasising the issue at 0.12mm layer height.

Banding

Reboot no banding

Banding

Reboot no banding

|

Re: New firmware 1.09k-dc42 December 19, 2015 12:31PM |

Registered: 10 years ago Posts: 14,672 |

Very odd! Let me know what you find.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware 1.09k-dc42 December 19, 2015 12:39PM |

Registered: 9 years ago Posts: 1,699 |

Sorry if some questions may have answered. You have a very strange problem. Which slic3r software do you use? Can you please provide your config.g, your start and ending G-Code? If I understood correctly you can print one object normally and the second object is bad? I would guess that there is a faulty G-code somewhere.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 19, 2015 01:28PM |

Registered: 8 years ago Posts: 105 |

Sliced with Simplify3D 3.0.2

It's exactly the same g-code file run on the printer.

I'm sure it's something to do with a setting not clearing by using reset from the web interface, at the moment I have things to print but will report back when I pin down what it is, or whether it was just a temporary bug.

Edited 1 time(s). Last edit at 12/19/2015 01:29PM by Firefox3D.

It's exactly the same g-code file run on the printer.

I'm sure it's something to do with a setting not clearing by using reset from the web interface, at the moment I have things to print but will report back when I pin down what it is, or whether it was just a temporary bug.

Edited 1 time(s). Last edit at 12/19/2015 01:29PM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 20, 2015 12:53AM |

Registered: 9 years ago Posts: 1,699 |

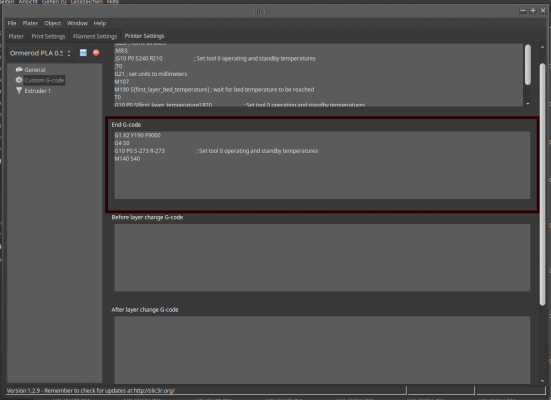

You did get me wrong. I guess your settings in Slic3r are faulty. Probably the G-code batch which is run after the print has finished. Customized G-code settings in Slic3r? Config.g? Stop.g? Post.g?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 20, 2015 05:55AM |

Registered: 9 years ago Posts: 638 |

|

Re: New firmware 1.09k-dc42 December 20, 2015 07:38AM |

Registered: 9 years ago Posts: 1,699 |

Nobody understands me!

Assume his file on the SD-card, he wants to print is called banding.g. Here is the think what I guess. He selects banding.g for printig. The file is printed well. At finishing some additionally g-commands will be executed like moving the head to the park position etc.. Maybe here is one command which is causing is trouble. When he selects banding.g again the printer is already "weird".

There is also some g-code-macros which will be automatically executed after a print has finished. I do not know how this files are named. I guess something like pre.g. Maybe there is a problematic G-code inside.

I guess somewhere there is a problem with a G-Code which drives the printer crazy. So the next print will be faulty.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Assume his file on the SD-card, he wants to print is called banding.g. Here is the think what I guess. He selects banding.g for printig. The file is printed well. At finishing some additionally g-commands will be executed like moving the head to the park position etc.. Maybe here is one command which is causing is trouble. When he selects banding.g again the printer is already "weird".

There is also some g-code-macros which will be automatically executed after a print has finished. I do not know how this files are named. I guess something like pre.g. Maybe there is a problematic G-code inside.

I guess somewhere there is a problem with a G-Code which drives the printer crazy. So the next print will be faulty.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 20, 2015 09:56AM |

Registered: 8 years ago Posts: 105 |

|

Re: New firmware 1.09k-dc42 December 20, 2015 10:20AM |

Registered: 9 years ago Posts: 1,699 |

Can you please post your config.g and one problematic .g-file as attachment?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 20, 2015 10:33AM |

Registered: 8 years ago Posts: 105 |

The g-code file isn't the problem, I have seen the artefact in other things I have printed.

However I think I might just have realised something, using half Z movements in the web interface moves 0.05mm is that a full number of motor steps?

Config,g

; Ormerod 2 config file for dc42 Duet firmware

M111 S0 ; Debug off

M555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M574 X0 Y1 Z0 S1 ; set endstop configuration (Y endstop only, at low end, active high)

M906 X800 Y1000 Z1000 E1100 ; Set motor currents (mA)

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

M92 E424 ; Set extruder steps per mm (single nozzle)

M558 P2 ; change to P1 for an intelligent Z probe

G31 Z2.3 P575 ; Set the probe height and threshold

M305 P0 R4700 H0 L0 ; Put your own H and/or L values bed thermistor ADC correction

M305 P1 R4700 H0 L0 ; Put your own H and/or L values nozzle thermistor ADC correction

M556 S74 X-0.08 Y-0.713 Z-0.41 ; Axis compensation here

M201 X1200 Y1200 Z10 E1000 ; Accelerations (mm/s^2) 1500 for ngen

M203 X15000 Y15000 Z150 E3600 ; Maximum speeds (mm/min) Z was 250

M566 X800 Y800 Z30 E20 ; Minimum speeds mm/minute 800 for ngen

M208 X230 Y205 ; set axis maxima (adjust to suit your machine)

M208 X-13 Y0 S1 ; set axis minimum (adjust to make X=0 the edge of the bed)

T0

Edited 1 time(s). Last edit at 12/20/2015 10:35AM by Firefox3D.

However I think I might just have realised something, using half Z movements in the web interface moves 0.05mm is that a full number of motor steps?

Config,g

; Ormerod 2 config file for dc42 Duet firmware

M111 S0 ; Debug off

M555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M574 X0 Y1 Z0 S1 ; set endstop configuration (Y endstop only, at low end, active high)

M906 X800 Y1000 Z1000 E1100 ; Set motor currents (mA)

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

M92 E424 ; Set extruder steps per mm (single nozzle)

M558 P2 ; change to P1 for an intelligent Z probe

G31 Z2.3 P575 ; Set the probe height and threshold

M305 P0 R4700 H0 L0 ; Put your own H and/or L values bed thermistor ADC correction

M305 P1 R4700 H0 L0 ; Put your own H and/or L values nozzle thermistor ADC correction

M556 S74 X-0.08 Y-0.713 Z-0.41 ; Axis compensation here

M201 X1200 Y1200 Z10 E1000 ; Accelerations (mm/s^2) 1500 for ngen

M203 X15000 Y15000 Z150 E3600 ; Maximum speeds (mm/min) Z was 250

M566 X800 Y800 Z30 E20 ; Minimum speeds mm/minute 800 for ngen

M208 X230 Y205 ; set axis maxima (adjust to suit your machine)

M208 X-13 Y0 S1 ; set axis minimum (adjust to make X=0 the edge of the bed)

T0

Edited 1 time(s). Last edit at 12/20/2015 10:35AM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 20, 2015 10:40AM |

Registered: 9 years ago Posts: 1,699 |

I am asking for a problematic .g-file to get your complete settings in Slic3r. the standard settings do not work for the Ormerod for example, but you would get other problems.

Using half z-movements could be indeed a problem. I cannot imagine how your problem is related to this instead of a bug somewhere, but to find your issue you should use standard settings and add special settings step by step until the problem occurs.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Using half z-movements could be indeed a problem. I cannot imagine how your problem is related to this instead of a bug somewhere, but to find your issue you should use standard settings and add special settings step by step until the problem occurs.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:00AM |

Registered: 8 years ago Posts: 105 |

I am running Simplify3D, I can post the settings but I have seen similar banding on other prints in the past although that might have been my Z drive gears which were not optimal.

It's not showing up on parts I have printed yesterday, but I have been homing all axis then cold rebooting.

If Dave can answer whether the 0.05mm Z movement is a possible issue and if so can it be changed to 0.04mm which is a complete step?

Edited 1 time(s). Last edit at 12/20/2015 11:10AM by Firefox3D.

It's not showing up on parts I have printed yesterday, but I have been homing all axis then cold rebooting.

If Dave can answer whether the 0.05mm Z movement is a possible issue and if so can it be changed to 0.04mm which is a complete step?

Edited 1 time(s). Last edit at 12/20/2015 11:10AM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:02AM |

Registered: 9 years ago Posts: 638 |

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:32AM |

Registered: 9 years ago Posts: 1,699 |

If you provide a .g-file I would get all settings as they are provided in the file.

Like I said above please unchecked the half z-movements and use only standard settings.

Why you want to change the z-movement? This will be all done inside the firmware.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Like I said above please unchecked the half z-movements and use only standard settings.

Why you want to change the z-movement? This will be all done inside the firmware.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:34AM |

Registered: 10 years ago Posts: 14,672 |

Setting half Z steps on the web interface does not affect how the firmware processes gcodes. It only affects the values displayed on the Z movement buttons and the gcodes it sends when you press them.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:36AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: New firmware 1.09k-dc42 December 20, 2015 11:52AM |

Registered: 8 years ago Posts: 105 |

So the 0.05mm jog step from the web interface doesn't put the Z motor out-of-step so to speak?

I really don't want to make a big deal out of this as I think it's maybe something I have been doing as a routine that might be causing it.

Just to expand on that my Z probe seemed to be a bit variable possibly ambient lighting, or the fact I moved it up about 2mm to stop it clipping prints. This was a while ago when I had original Z gears with play in them which was probably the actual culprit.

So now as I have my bed manually levelled to about 0.05mm at worse variance and use a 0.2mm shim that I put on the bed and when I feel it just touching remove it, move the Z down 0.2mm and home, very consistent.

Edited 1 time(s). Last edit at 12/20/2015 12:00PM by Firefox3D.

I really don't want to make a big deal out of this as I think it's maybe something I have been doing as a routine that might be causing it.

Just to expand on that my Z probe seemed to be a bit variable possibly ambient lighting, or the fact I moved it up about 2mm to stop it clipping prints. This was a while ago when I had original Z gears with play in them which was probably the actual culprit.

So now as I have my bed manually levelled to about 0.05mm at worse variance and use a 0.2mm shim that I put on the bed and when I feel it just touching remove it, move the Z down 0.2mm and home, very consistent.

Edited 1 time(s). Last edit at 12/20/2015 12:00PM by Firefox3D.

|

Re: New firmware 1.09k-dc42 December 20, 2015 12:28PM |

Registered: 9 years ago Posts: 1,699 |

Maybe I saw too often "shark tank".

I offer you may help. I do not have to do this, but somehow I am also interested what is causing your problem. Personally I have sometimes a really weird thinking but for my process I need some information like the complete settings of S3D. Simplify3D and also Slic3r provides these complete settings inside the .g-file. That is why I am asking for a file which is causing problems. But my mood is starting to let this case fall down. Maybe there is a problematic setting in your g-code who knows?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I offer you may help. I do not have to do this, but somehow I am also interested what is causing your problem. Personally I have sometimes a really weird thinking but for my process I need some information like the complete settings of S3D. Simplify3D and also Slic3r provides these complete settings inside the .g-file. That is why I am asking for a file which is causing problems. But my mood is starting to let this case fall down. Maybe there is a problematic setting in your g-code who knows?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.