Switches for x,y,z

Posted by Joar107

|

Switches for x,y,z September 24, 2015 04:06AM |

Registered: 10 years ago Posts: 94 |

Hi long time ago I was here, first of all a big thanks to dc42 and other that have made the firmware and web controll awsome!

I have changed to micro switches for all my homing and it works great on x and y, but I cant figure out have to fix z.

This is my config.g

M111 S0 ; Debug off

M550 PFlexoart ; Machine name (can be anything you like). With DHCP enabled connect to (example) [reprapproormerod1] (machine name with no spaces).

M551 Preprap ; Machine password (currently not used)

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;M552 P0.0.0.0 ; Un-comment for DHCP

M552 P192.168.175.50 ; IP address, comment for DHCP

M553 P255.255.255.0 ; Netmask

M554 P192.168.175.1 ; Gateway, comment for DHCP

M555 P2 ; Set output to look like Marlin

M558 P0 X0 Y0 Z4 ; x egen switch y egen switch z switch ansluts till e0 anslutning för switch

anslutning för switch

M574 X2 Y1 Z1 S1 ; var den ska nolla samt S1 aktiv när inte intrycks???

G21 ; Work in millimetres

G90 ; Send absolute corrdinates...

M83 ; ...but relative extruder moves

M906 X1200 Y1200 Z800 E800 ; Set motor currents (mA)

M92 X80 Y80 Z400 ; Set extruder steps per mm

M92 E496:496 ; om man sätter : efter kan vi läga in värdet för nästa extruder steg per 100 mm matning

M569 P0 S1 ; Set X axis direction om man skriver S0 istället vänder man riktningen kan användas på alla axlar P0 x P1 yP2 z P3 e1 p4 e2

M201 X800 Y800 Z15 E2000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z180 E3600 ; Maximum speeds (mm/min)

M566 X600 Y600 Z30 E20 ; Minimum speeds mm/minute

M305 P0 R4700 ; Set the heated bed thermistor series resistor to 4K7

M305 P1 R1000 B4267 ; Set the hot end thermistor series resistor to 4K7

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

M563 P1 D1 H2 ; Define tool 1 Uncomment if you have a dual colour upgrade

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures Uncomment if you have a dual colour upgrade

M208 X220 Y220 Z200 ; set axis maxima (adjust to suit your machine)

M208 X-20 Y-20 Z-1 S1 ; set axis minimum (adjust to make X=0 the edge of the bed)

T0 ; select first hot end

and this is my homez.g

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G1 z-250 F2000 S1 ; home z

G92 Z0 ; set position to z=0

G1 z+3 F200 ; move z axis away from endstop

G1 z-5 F200 S1 ; home z again, slower

G90 ; set movement to absolute mode

G92 Z0 ; set position to Z=0

G1 Z5 F200 ; move Z up 5mm

Kind regards Joar

I have changed to micro switches for all my homing and it works great on x and y, but I cant figure out have to fix z.

This is my config.g

M111 S0 ; Debug off

M550 PFlexoart ; Machine name (can be anything you like). With DHCP enabled connect to (example) [reprapproormerod1] (machine name with no spaces).

M551 Preprap ; Machine password (currently not used)

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;M552 P0.0.0.0 ; Un-comment for DHCP

M552 P192.168.175.50 ; IP address, comment for DHCP

M553 P255.255.255.0 ; Netmask

M554 P192.168.175.1 ; Gateway, comment for DHCP

M555 P2 ; Set output to look like Marlin

M558 P0 X0 Y0 Z4 ; x egen switch y egen switch z switch ansluts till e0

anslutning för switch

anslutning för switchM574 X2 Y1 Z1 S1 ; var den ska nolla samt S1 aktiv när inte intrycks???

G21 ; Work in millimetres

G90 ; Send absolute corrdinates...

M83 ; ...but relative extruder moves

M906 X1200 Y1200 Z800 E800 ; Set motor currents (mA)

M92 X80 Y80 Z400 ; Set extruder steps per mm

M92 E496:496 ; om man sätter : efter kan vi läga in värdet för nästa extruder steg per 100 mm matning

M569 P0 S1 ; Set X axis direction om man skriver S0 istället vänder man riktningen kan användas på alla axlar P0 x P1 yP2 z P3 e1 p4 e2

M201 X800 Y800 Z15 E2000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z180 E3600 ; Maximum speeds (mm/min)

M566 X600 Y600 Z30 E20 ; Minimum speeds mm/minute

M305 P0 R4700 ; Set the heated bed thermistor series resistor to 4K7

M305 P1 R1000 B4267 ; Set the hot end thermistor series resistor to 4K7

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

M563 P1 D1 H2 ; Define tool 1 Uncomment if you have a dual colour upgrade

G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures Uncomment if you have a dual colour upgrade

M208 X220 Y220 Z200 ; set axis maxima (adjust to suit your machine)

M208 X-20 Y-20 Z-1 S1 ; set axis minimum (adjust to make X=0 the edge of the bed)

T0 ; select first hot end

and this is my homez.g

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G1 z-250 F2000 S1 ; home z

G92 Z0 ; set position to z=0

G1 z+3 F200 ; move z axis away from endstop

G1 z-5 F200 S1 ; home z again, slower

G90 ; set movement to absolute mode

G92 Z0 ; set position to Z=0

G1 Z5 F200 ; move Z up 5mm

Kind regards Joar

|

Re: Switches for x,y,z September 24, 2015 04:24AM |

Registered: 10 years ago Posts: 14,672 |

Your M558 command should have Z0 in it instead of Z4.

Edited 1 time(s). Last edit at 09/24/2015 04:25AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/24/2015 04:25AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z September 26, 2015 01:04PM |

Registered: 10 years ago Posts: 859 |

Hi, I use Microswitches. I prefer them... It's a personal choice, and I'm not saying that other methods aren't good.

OK well I use the tilt of my Big Blue to trigger the Z axis. It means lowering the the nozzle on to the Glass, but as I use plain glass to print on

it works well. Again a personal preference. It also means that I can use glass of any thickness.

I've attached my config.g file and homez.g file if it helps... You can run them, but you will have to set the Homez.g to your microswitch height.

All the Best,

Kim..

config.g

homez.g

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

OK well I use the tilt of my Big Blue to trigger the Z axis. It means lowering the the nozzle on to the Glass, but as I use plain glass to print on

it works well. Again a personal preference. It also means that I can use glass of any thickness.

I've attached my config.g file and homez.g file if it helps... You can run them, but you will have to set the Homez.g to your microswitch height.

All the Best,

Kim..

config.g

homez.g

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z September 26, 2015 01:39PM |

Registered: 9 years ago Posts: 1,699 |

But how does this work in practice as the microswitch has to be lower than the nozzle or can you flip your nozzle or something like this? If I understood you correctly you can even use the auto bed levelling so what is the trick?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z September 28, 2015 08:46AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

But how does this work in practice as the microswitch has to be lower than the nozzle or can you flip your nozzle or something like this? If I understood you correctly you can even use the auto bed levelling so what is the trick?

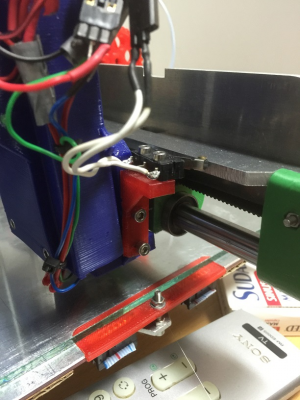

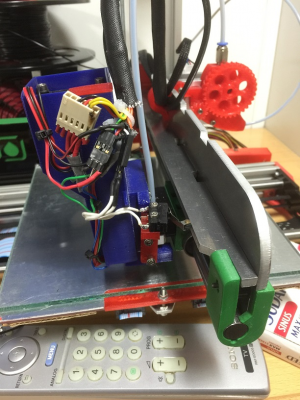

Kim uses the fact that the hotend tilts when it is driven below the bed. His microswitch is way above the nozzle (and bed) oriented horizontally and is activated by pressing against the X-arm as the whole hotend tilts. The microswitch will therefore activate when the nozzle is resting on the bed and tilts as the Z screw tries to lower it more, and so the trigger distance is set to be a negative height. In effect the nozzle is an extension of the button of the microswitch and the hotend assembly acts as a lever to translate the movement through 90 degrees, so nothing needs to be at or below nozzle height. Perhaps he will upload a photo of the arrangement as my explanation is perhaps not that clear.

It seems a very good way to determine Z zero, and I have been meaning to make a similar modification - just waiting for a round tooit.

Dave

|

Re: Switches for x,y,z September 28, 2015 12:01PM |

Registered: 10 years ago Posts: 859 |

Hi, sorry for the late reply.... Dave you know my machine better than me I think....lol Dave is right....

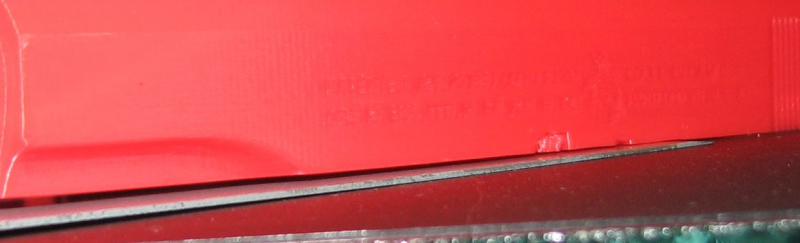

Sometime ago I noticed I could watch the TILT of the BigBlue on my machine to get a reliable point of Z0....

I noticed that when the Nozzle was HOT, and lowered below glass surface level, the BigBlue tilted to the right (please see the pictures).

By raising the Z axis by 0.1 at a time I could watch the BB slowly tilt back to the normal running position, with the next movement LIIFTING the nozzle.

You can see it happening, as the distance between the top rear corner of the BB and the X axis bar (the pivot) is greater than the distance from the X axis to the nozzle....

Therefore it Magnifies the effect. I just sit still concentrate on the top rear corner, and tick away with the mouse until I see the tilting stop.

Very crude.... But it works every time....

I run a totally level Bed, so no compensation is required. (My Bed is within +/- 0.05mm measured with my DTI in place of the extruder).

When the nozzle is lowered the BB eventually tilts to the RIGHT... At some point in the tilt the switch is activated.

But this is a repeatable point.... So you first wire it up and set it on the Nozzle cooling trunking (BigBlue in my case).

Then work out what the offset is from Z0, and edit the homez.g file to suit.

After which it then does it effortlessly every time. You only have to re-edit the homez.g file if you remove the HotEnd assembly to say mount the DTI to level the bed.

Hope that helps......

Excuse the tatty looking wiring.. Invariably a connector will fail with the repeated twisting the connection gets, and it nearly always happends when I'm away at sea on the ship, and haven't got my shrink wrap with me. I'm trying to migrate the connectors to RC servo plugs and sockets when I have time, but I'm not sure if they will handle the current of the Heater...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Sometime ago I noticed I could watch the TILT of the BigBlue on my machine to get a reliable point of Z0....

I noticed that when the Nozzle was HOT, and lowered below glass surface level, the BigBlue tilted to the right (please see the pictures).

By raising the Z axis by 0.1 at a time I could watch the BB slowly tilt back to the normal running position, with the next movement LIIFTING the nozzle.

You can see it happening, as the distance between the top rear corner of the BB and the X axis bar (the pivot) is greater than the distance from the X axis to the nozzle....

Therefore it Magnifies the effect. I just sit still concentrate on the top rear corner, and tick away with the mouse until I see the tilting stop.

Very crude.... But it works every time....

I run a totally level Bed, so no compensation is required. (My Bed is within +/- 0.05mm measured with my DTI in place of the extruder).

When the nozzle is lowered the BB eventually tilts to the RIGHT... At some point in the tilt the switch is activated.

But this is a repeatable point.... So you first wire it up and set it on the Nozzle cooling trunking (BigBlue in my case).

Then work out what the offset is from Z0, and edit the homez.g file to suit.

After which it then does it effortlessly every time. You only have to re-edit the homez.g file if you remove the HotEnd assembly to say mount the DTI to level the bed.

Hope that helps......

Excuse the tatty looking wiring.. Invariably a connector will fail with the repeated twisting the connection gets, and it nearly always happends when I'm away at sea on the ship, and haven't got my shrink wrap with me. I'm trying to migrate the connectors to RC servo plugs and sockets when I have time, but I'm not sure if they will handle the current of the Heater...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z September 29, 2015 12:05AM |

Registered: 9 years ago Posts: 1,699 |

That looks very interesting and I had no idea that the firmware supports negative values for the z-homing-value. It is probably more ccurate than the proximity sensor but I am wondering how precise such a microswitch is according to the repeatability especially if you use such kind of lever as we ware taking about accuracies of 0.1mm. What I really like is that you can use different build surfaces without changing any settings. I think that I will add this feature in some weeks. But what about BuildTak? In the instruction manual they are warning to get the hot nozzle in touch with the surface but probably it is the meovement that reduces the life of it. My idea is to switch to BuildTak for higher objects but for flat objects I will keep at Kapton/ BlueTape as it is heart to release big and not so high objects from BuildTak but maybe this is because I was never in the stage to level the bed full correctly. There is another advantage: You have definitely no offset of the nozzle to the position of the calibration. Do you use the same switch for homing the x-axis or what do you do? Why you do not use micro-mate or mini-mate for your connections? Especially mini-mate can handle high currents and the micro-mate is similiar to the original connectors (different manufacturer, different name but compatible locking mechanism).

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z September 29, 2015 03:08AM |

Registered: 8 years ago Posts: 24 |

Hi All,

This is a great idea and very simple.

At this point I wonder if there is some pin table/layout plan for Duet available (pin numbering; pin usage). I want to connect a small external servo to my Ormerod; I do not only want to use it for a z-Probe but for a "homemade" application. I tried to contact dc-42 if there is a way to actually connect it - however the answer was quite short and dismissive that this is not possible ... (sorry Dave, but as I said, I do not want to interfere with your existing z-Probe).

This kind of answer surprised me: I do not run the Duet extension board (and only "one head" setup") with an additional 2 Cable fan that I regulate through the second fan connector. However, there are still tons of pins unused and I wonder if there is the one or the other "Pin" for "free usage" available. Therefore, I would be very happy if someone could point me to the right direction (the wiki on the v0.6 duet is quite "basic" and does not show the usage of the other pins (or am I missing here something)?

Thanks for your help.

Chris.

This is a great idea and very simple.

At this point I wonder if there is some pin table/layout plan for Duet available (pin numbering; pin usage). I want to connect a small external servo to my Ormerod; I do not only want to use it for a z-Probe but for a "homemade" application. I tried to contact dc-42 if there is a way to actually connect it - however the answer was quite short and dismissive that this is not possible ... (sorry Dave, but as I said, I do not want to interfere with your existing z-Probe).

This kind of answer surprised me: I do not run the Duet extension board (and only "one head" setup") with an additional 2 Cable fan that I regulate through the second fan connector. However, there are still tons of pins unused and I wonder if there is the one or the other "Pin" for "free usage" available. Therefore, I would be very happy if someone could point me to the right direction (the wiki on the v0.6 duet is quite "basic" and does not show the usage of the other pins (or am I missing here something)?

Thanks for your help.

Chris.

|

Re: Switches for x,y,z September 29, 2015 03:19AM |

Registered: 10 years ago Posts: 14,672 |

Hi Chris, sorry if my answer seemed dismissive. What I actually said was that RepRapFirmware does not have any support for servos. My answer was brief because I was writing it in a smartphone (as I am now). Of course you could connect a servo to one of the expansion pins, but you would need to modify the firmware yourself to drive it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z September 30, 2015 02:08AM |

Registered: 8 years ago Posts: 24 |

@dc42: Hi David, thanks for your answer ... mobile communications has sometimes its "flaws" :=)

Modifying the firmware is on thing ... (maybe a patch might be a good thing).

BUT: Before changing anything in the firmware I need to know which pins are usable (what are the pin numbers, what pins can be used (functions) and their corresponding locations on the board). Here I do not have any information at all?

With a small servo I probably need to step up the voltage to 5V? But once more - where could the power connector cables go? Where shall the data cable go.

Thanks for your help.

All the best,

Chris.

Modifying the firmware is on thing ... (maybe a patch might be a good thing).

BUT: Before changing anything in the firmware I need to know which pins are usable (what are the pin numbers, what pins can be used (functions) and their corresponding locations on the board). Here I do not have any information at all?

With a small servo I probably need to step up the voltage to 5V? But once more - where could the power connector cables go? Where shall the data cable go.

Thanks for your help.

All the best,

Chris.

|

Re: Switches for x,y,z September 30, 2015 03:21AM |

Registered: 10 years ago Posts: 14,672 |

I have never driven a servo and I don't have time to research it at present, so I can't help much. But AFAIK you need a PWM pin to drive a servo. All the PWM pins on the Duet are allocated to driving heaters and the fan. So I suggest you pick the pin on the expansion connector that is assigned to the 4th heater on the DueX4 board, which is the one labelled PC21_PWML4. If you need to drive any pins on/off without PWM, see [reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z September 30, 2015 07:52AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

That looks very interesting and I had no idea that the firmware supports negative values for the z-homing-value. It is probably more ccurate than the proximity sensor but I am wondering how precise such a microswitch is according to the repeatability especially if you use such kind of lever as we ware taking about accuracies of 0.1mm. What I really like is that you can use different build surfaces without changing any settings. I think that I will add this feature in some weeks. But what about BuildTak? In the instruction manual they are warning to get the hot nozzle in touch with the surface but probably it is the meovement that reduces the life of it.

To home you drive the axis slowly toward the microswitch until it operates (using the S1 parameter at the end of a G1 move command will cause it to stop when the switch trips), and then set the known position of that trip point with a G92 command - which will accept negative values. To get better accuracy the usual way is to drive the axis at a reasonable speed until the microswitch operates (so you don't wait for hours for the axis to home), then drive back the other way for a few mm, then drive toward the switch again much more slowly until it trips. I don't know the positional repeatability of the trip point of a microswitch - it probably differs from one type of microswitch to another, but they are routinely used for Z homing so should be good enough (the lever action using the tilt method is about 1:1 so should not reduce the accuracy). If it is not accurate enough then you could make or find a simple spring contact which will definitely make contact accurately enough at the same place every time - the output may need inverting which is simple to do using a FET or transistor (or even a relay). Or mount the switch higher up so the lever action amplifies the movement and use a long arm on the switch to engage the X arm.

Regarding using with BuildTak - there is no need to heat the nozzle before homing, and I would be very surprised if the relatively low weight of the nozzle contacting vertically (i.e. no X or Y movement) would cause any damage.

Dave

|

Re: Switches for x,y,z September 30, 2015 08:01AM |

Registered: 9 years ago Posts: 1,699 |

I often have a wrong high when starting a print job so I have to redefine the z-value while the nozzle is hot.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z September 30, 2015 11:27AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

I often have a wrong high when starting a print job so I have to redefine the z-value while the nozzle is hot.

Redefine, yes - but surely you don't re-home the Z axis after the print has started? (Not sure that would be possible in any case). If you want to re-home between prints or when re-starting a failed print and you don't want a hot nozzle to touch the build plate, just wait 1 minute for it to cool down sufficiently.

Anyway - if you can get a more accurate Z homing you probably won't be starting a print at the wrong height.

Dave

|

Re: Switches for x,y,z September 30, 2015 03:11PM |

Registered: 9 years ago Posts: 1,699 |

I often re-home between two prints with the hot-nozzle. I do not want to wait to let the nozzle cool down so that I would lost even more time when I try to near the nozzle to the perfect high with steps of 0.1mm? Besides the proximity sensor may affected by infrared light caused by heat so I will get more accurate readings with the same temperature. So now you can imagine why I am interested in this solution.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z September 30, 2015 03:41PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treito

... Besides the proximity sensor may affected by infrared light caused by heat so I will get more accurate readings with the same temperature...

It would take a far higher temperature than the nozzle temperature to generate enough infrared to affect the sensor.

I always home Z (at the centre of the bed, using my sensor) just before printing, when the nozzle and bed are close to printing temperature, so that the Z=0 setting allows for thermal expansion of the nozzle and the bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 01, 2015 01:52AM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

I always home Z (at the centre of the bed, using my sensor) just before printing, when the nozzle and bed are close to printing temperature, so that the Z=0 setting allows for thermal expansion of the nozzle and the bed.

That is the additional part of course. May values varies a little bit between cold/ hot. But as I switch the bed surface I think the microswitch idea would be the best solution for me. Unfortunately your firmware does not support both so you can use the proximity sensor for speed switch and the microswitch for the final positioning. Okay mabe it is possible to hit the bed with 80mm/min and then use a similiar procedur like x/y-homing as suggested above.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 01, 2015 02:53AM |

Registered: 10 years ago Posts: 14,672 |

You can use both a Z switch and a proximity sensor if you want, just use M574 to enable or disable the switch. You could also set up macro files to change the Z probe trigger height to handle different bed surfaces. You may find the trigger height varies less if you put black paper under the glass, or paint the aluminium heat spreader black.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 01, 2015 03:40AM |

Registered: 9 years ago Posts: 1,699 |

The problem is that I also use Blue Painters tape for example. Macros could be indeed one option but regarding my Ormerod 1 the height often changed by some hundred µm.

The usage of the bed surface depends on the material, the object height and the contact surface. Normally I would like to completely switch to BuildTak but if I have object with a small height I do not know how to remove them properly without damaging the BuildTak. So I will have to test and learn. Meanwhile I found one shop where the BuildTak is a little bit cheaper while covering the whole glass (even more as originally for the K8400), but the among is high enough so it would be way to cheap to replace the BuildTak after less than 10 prints. I think that the microswitch option would give the best possible accuracy. But as my Ormerod 2 do not use an original nozzle I have to check where I can mount it and how. (But for the moment I have no working printer yet)

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

The usage of the bed surface depends on the material, the object height and the contact surface. Normally I would like to completely switch to BuildTak but if I have object with a small height I do not know how to remove them properly without damaging the BuildTak. So I will have to test and learn. Meanwhile I found one shop where the BuildTak is a little bit cheaper while covering the whole glass (even more as originally for the K8400), but the among is high enough so it would be way to cheap to replace the BuildTak after less than 10 prints. I think that the microswitch option would give the best possible accuracy. But as my Ormerod 2 do not use an original nozzle I have to check where I can mount it and how. (But for the moment I have no working printer yet)

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 01, 2015 03:44AM |

Registered: 10 years ago Posts: 14,672 |

Does the print come off the BuildTak more easily if you put the glass+print in the freezer?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 01, 2015 03:47AM |

Registered: 9 years ago Posts: 1,699 |

I did not test this yet but I heard from it that it should be easier. That would be of course an option. As I wrote above I will have to test and learn step by step. I have 3 BuildTaks for 2 printers so I can damage one.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 01, 2015 07:16AM |

Registered: 10 years ago Posts: 2,472 |

In my experience the Z height will change (very slightly) between a hot & a cold bed, but there is no perceptible change between a hot and cold nozzle. Therefore I do my Z homing after the bed has heated but without heating the hotend. If homing with a hot nozzle you'll probably get some plastic drooling out, which will affect manual or microswitch homing. The nozzle does not take very long to cool, so if you need to re-home between prints I should think the nozzle will be pretty cool by the time you have removed the previous print from the bed and wiped it down.

Dave

Dave

|

Re: Switches for x,y,z October 01, 2015 01:28PM |

Registered: 10 years ago Posts: 94 |

|

Re: Switches for x,y,z October 01, 2015 01:30PM |

Registered: 9 years ago Posts: 1,699 |

Especially using BuildTak means that you may have to re-adjust the z-height ten or even twenty times if you are afraid like me. To cool down and reheat the nozzle will take some time so in sum I would loose 20 or even 60 minutes. Alternatively I could use a G92 of course but if something goes wrong it is hard to get the parameters you have to re-enter so I use indeed the homing. The proximity switch is not affected by any small plastic parts at the nozzle and after each pause I clean the nozzle. May printer is not good calibrated at the moment so it is hard to compare your and my requirements for printing. Something is definitely wrong with my MK1 so as soon as my MK2 is working I will demount my MK1 completely and remount it again maybe even as MK2. But in my case the microswitch seems to be a good and stable solution.

Edited 1 time(s). Last edit at 10/01/2015 01:31PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Edited 1 time(s). Last edit at 10/01/2015 01:31PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 02, 2015 07:14AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Especially using BuildTak means that you may have to re-adjust the z-height ten or even twenty times if you are afraid like me.

I don't understand how you are operating. Surely it is only the final adjustment prior to staring the print that makes any difference and all others are redundant?

Dave

|

Re: Switches for x,y,z October 02, 2015 08:00AM |

Registered: 9 years ago Posts: 1,699 |

The BuildTak is very sensitive of a too low nozzle height. As it is much more expensive than Kapton tape I am very careful using it. Secondly it is another philosophy. As in normal circumstances you squeeze the first layer a little bit you have to keep the nozzle a little bit higher. If you squeeze the first layer you already my have damaged the BuildTak already in a way that it is not usable anymore (at some areas). For that reason I am very careful finding this starting point. As I wrote above I had some trouble with my MK1 so it is not redundant. The parameters for the probe sensors changed day by day sometimes even after one print. But as I said there is a problem with my MK1 but I cannot locate the source. And as the BuildTak is very expensive I am trying to find the right layer height sometimes by 0.1mm steps that means in total that I sometimes start 2.0mm too high to find the right starting point. The switch solution is in my eyes the best option as you really have a constant value that is independent from light, temperature, wire connections, wire lengths, contact resistance and so on. Especially the independence from the surface makes this most interesting for me.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 02, 2015 08:35AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

The BuildTak is very sensitive of a too low nozzle height. As it is much more expensive than Kapton tape I am very careful using it. Secondly it is another philosophy. As in normal circumstances you squeeze the first layer a little bit you have to keep the nozzle a little bit higher. If you squeeze the first layer you already my have damaged the BuildTak already in a way that it is not usable anymore (at some areas)..

I print with same nozzle hight as kapton tape, to remove the print I place the 4mm glass with buildtak on one edge, then remove the printed part with hammer and chisel, don't see any damage to the surface or function - it is of cause important to use a flexible sharp chisel with a long sloping edge - and to buff the flat side that goes against the buildtak slightly to make sure it do not dig in

I find this to be the best way to remove prints as there will be no strain on the glue holding the buildtak and it will stay flat

Erik

|

Re: Switches for x,y,z October 02, 2015 01:30PM |

Registered: 9 years ago Posts: 1,699 |

I ordered a special tool. I did not get the name for now but it is similiar like the one the manufacturer of BuildTak suggests. But currently they are on holidays. It is a little bit more wide as your chisel and much less brutal. And there is the difference: I print on BuildTak slightly higher. It prevents mostly warping and I can remove it more easily than you. The only problem I have is to get one small area or edge loose. After that you can use a big screw driver and the part comes off easily but the beginning is the problem. But this does only work as long as you print higher than with Kapton tape. According to the manual you should lower the nozzle until it starts staying on the bed. But nevermind I will test this microswitch method as it seems to be the most stable methos and my MK1 was not able to level the bed properly. I would gues that at least the error of the microswitch is always the same and there is no influence from the outside that can effect the accuracy of the switch or at least I hope so...

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 03, 2015 05:03AM |

Registered: 9 years ago Posts: 1,699 |

Hi Kim,

and how did you solve the x-homing?

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

and how did you solve the x-homing?

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 03, 2015 10:23AM |

Registered: 9 years ago Posts: 49 |

Hi, I was impressed with bigblue and made my own version (a mix of the tilt from bb and iamburneys fanmount) - [www.thingiverse.com]

I have described wiring and mount on thingeverse. Check it out and see if it can solve some of the challenges / i use the same ms for both homing z and x.

Br

I have described wiring and mount on thingeverse. Check it out and see if it can solve some of the challenges / i use the same ms for both homing z and x.

Br

Sorry, only registered users may post in this forum.