Switches for x,y,z

Posted by Joar107

|

Re: Switches for x,y,z October 03, 2015 11:50AM |

Registered: 9 years ago Posts: 1,699 |

That design would only match my MK1 or maybe not as I have other MS. On my MK2 I also have another nozzle. I already thought of this bulb at one area of the x-arm (my printed version also supports this bulb). But in this case the x-homing extremly depends on the nozzle angle as there is no possibility to adjust the distance between the MS and the x-arm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 05, 2015 10:46AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Switches for x,y,z October 06, 2015 07:23AM |

Registered: 10 years ago Posts: 859 |

Hi Sven, I use a microswitch for the X axis homing.... If you look at printed parts at that end of the X axis, you will see two small holes that RepRap included for their Microswitches. I didn't have one of theirs so printed an adapter plate to suit. Unfortunately I don't think my little microswitch mount is on thingiverse any more, and I lost the design ages ago...

My preferance is towards simple microswitches all round, and I run a very level Bed so don't need compensation (I use the 3 point Ally bed, and set it up with a DTI. So it's within 0.05mm all over).

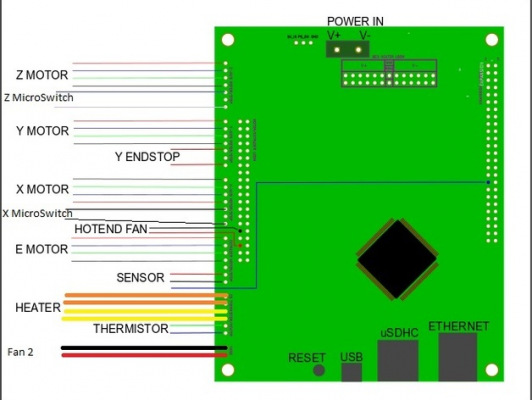

The wiring for the microswitches is easy....

All the Best,

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

My preferance is towards simple microswitches all round, and I run a very level Bed so don't need compensation (I use the 3 point Ally bed, and set it up with a DTI. So it's within 0.05mm all over).

The wiring for the microswitches is easy....

All the Best,

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 06, 2015 11:44AM |

Registered: 9 years ago Posts: 1,699 |

Hello Kim,

thanks for your answer. Indeed I was not looking for the electrical connection. I was looking for the position and how it is pushed. The problem is that I do not have any microswitches with lever at home but I got some cheap without lever, but I do not think I can use them maybe only for x-homing but not for the z-axis.

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

thanks for your answer. Indeed I was not looking for the electrical connection. I was looking for the position and how it is pushed. The problem is that I do not have any microswitches with lever at home but I got some cheap without lever, but I do not think I can use them maybe only for x-homing but not for the z-axis.

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 06, 2015 01:06PM |

Registered: 10 years ago Posts: 859 |

Hello Sven, you don't say which HotEnd your using,,,,, I suspect it's the original design....

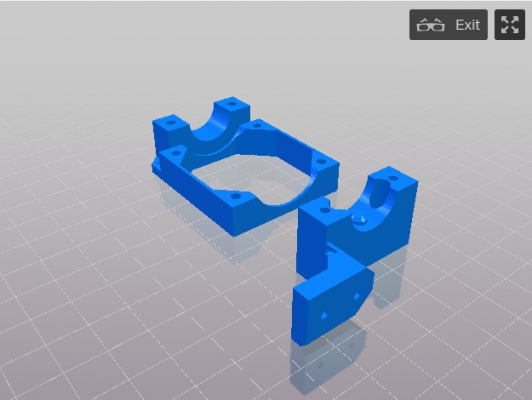

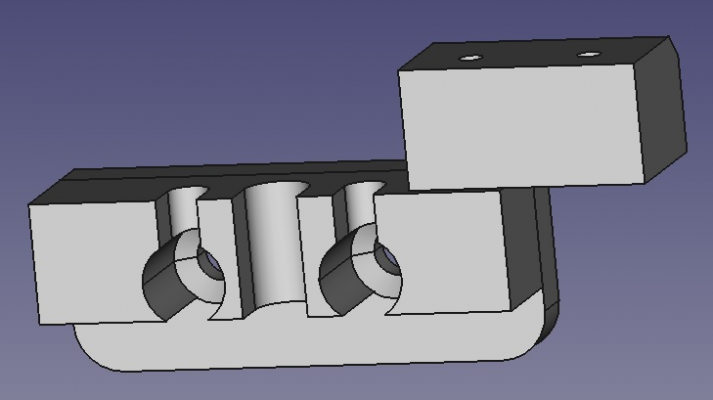

In the picture above is my latest design for the cheap J Head HotEnds from China... £7 inc postage.... How they do them for that price I don't know...

There is an arm on the HotEnd mounting here, that accept a standard micro size microswitch. If you are using the standard Hotend then a similar arm would suit you.

My design goes in place of the HotEnd assembly, and the Nozzle mount. If you can wait a few days I will design you an arm if you need one to print....

As I say it's a standard switch with no lever (arm), just the button. When the printer is running there is 2mm clearance between the button, and X axis arm, so the only wear is when the Z axis is homed...

So next to none really.

As for the X axis switch I used one with out an arm, and the X carriage activates it.. I have lost the design, but if you can wait a couple of days, I'll measure mine, and do a replacement

for you to print out.

The microswitches I use are 20mm wide, 10mm deep, (about 5 or 6mm thick), just with buttons, not arms... (ie the same as on the Y axis)...

I work on a ship and going home tomorrow, so the printer is crated up now, and in the boot of the car. But I can soon get it all sorted out for you, hopefully tomorrow....

Hope that helps.

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 06, 2015 01:21PM |

Registered: 9 years ago Posts: 1,699 |

So what should I say? Yes and no. My Ormerod MK1 (currently broken) uses the standard nozzle. My Ormerod MK2 which is working now uses indeed these cheap nozzles. As I am satisfied with the results (even slightly better than the original one) I ordered some spares. I saw your design already at thingiverse as I published an own design some time ago (and I had to redesign it unfortunately) I cannot use your design for several reasons:

- In my eyes it is too open and no enclosure so there is maybe a problem with the cooling

- There is no option to add a second fan

- My MK2 will soon get a second nozzle as I have the needed Duet Shield already here

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

- In my eyes it is too open and no enclosure so there is maybe a problem with the cooling

- There is no option to add a second fan

- My MK2 will soon get a second nozzle as I have the needed Duet Shield already here

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 06, 2015 02:20PM |

Registered: 10 years ago Posts: 859 |

LoL..... Oh well I thought of a way to design a Nozzle Mount with a microswitch mount with out my printer to hand so have just finished the design for you..........

I'll place it on thingiverse in a minute..... As for the X axis switch I can't do that until I can get to my printer for you....

Kim

Stl Here

Edited 1 time(s). Last edit at 10/06/2015 02:40PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I'll place it on thingiverse in a minute..... As for the X axis switch I can't do that until I can get to my printer for you....

Kim

Stl Here

Edited 1 time(s). Last edit at 10/06/2015 02:40PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 07, 2015 06:44AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

did you see this design?

[www.thingiverse.com]

I formerly use a E3D chines replika and I am really considering to exchange the nozzle of my MK1 to one of that.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

did you see this design?

[www.thingiverse.com]

I formerly use a E3D chines replika and I am really considering to exchange the nozzle of my MK1 to one of that.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 07, 2015 10:52AM |

Registered: 10 years ago Posts: 859 |

Hi, yes it's similar.... I was going to do another version with the switch vertical like that so you had an easy choice....

But as someone has already done it I won't bother re-inventing the Wheel.... Only comment I would make is I'm not sure how much clearance he has allowed

between the switch and the X-axis arm... I gave it 2mm so the switch wouldn't rub on the arm during a printing session.

I dare say he has done similar...

With my J head clamp (it uses a similar method), I will be adding a shroud around the Hot End cooling fins (not that it needs it, it's cool enough when running,

but with the idea of directing any air away from the print area. I will also be adding an LED indocator to the design at the same time now I'm Home...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

But as someone has already done it I won't bother re-inventing the Wheel.... Only comment I would make is I'm not sure how much clearance he has allowed

between the switch and the X-axis arm... I gave it 2mm so the switch wouldn't rub on the arm during a printing session.

I dare say he has done similar...

With my J head clamp (it uses a similar method), I will be adding a shroud around the Hot End cooling fins (not that it needs it, it's cool enough when running,

but with the idea of directing any air away from the print area. I will also be adding an LED indocator to the design at the same time now I'm Home...

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 08, 2015 01:15AM |

Registered: 9 years ago Posts: 1,699 |

Mostly design (including yours) have one or more of the following issues:

- Partly opened so the airflow goes elsewhere - backlash

- Nozzle too deep - loosing printing high and sometimes every mm counts. I lowered the nozzle, too, but only slightly

- Does not fit my design that is why I remixed one design.

So I decided to make my own design. It includes mounting holes for DC42's sensors (height not tested) and one holder for an LED and it is prepared for a second fan which will follow soon. Also all designs are missing a holder for a second nozzle so I will have to extend my design for using one.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

- Partly opened so the airflow goes elsewhere - backlash

- Nozzle too deep - loosing printing high and sometimes every mm counts. I lowered the nozzle, too, but only slightly

- Does not fit my design that is why I remixed one design.

So I decided to make my own design. It includes mounting holes for DC42's sensors (height not tested) and one holder for an LED and it is prepared for a second fan which will follow soon. Also all designs are missing a holder for a second nozzle so I will have to extend my design for using one.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 08, 2015 04:00AM |

Registered: 10 years ago Posts: 859 |

Glad your doing your own design, it's always best....

My time is very limited with working the other side of the country and doing hospital visits now I'm home (the wife tried free fall parachute jumping down the stairs without the parachute...... it didn't go well)....

Good Luck..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

My time is very limited with working the other side of the country and doing hospital visits now I'm home (the wife tried free fall parachute jumping down the stairs without the parachute...... it didn't go well)....

Good Luck..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 08, 2015 06:50AM |

Registered: 9 years ago Posts: 1,699 |

Oh I hope she get well soon.

My design is missing the micro switch yet but I also do not have a suitable MS at home. This other design on thingiverse is not adjustable. It may be that the operating mechanism especially the distance may vary between different manufacturers. I only have ones without lever so the bulb at the arm would be a big problem. But I have one idea for a different x-carriage version 528.4 (counter bearing on the side not on the down-side). Maybe I could use a rotating mechanism. As long as the nozzle is up and the bearing on the arm the MS switch is operated but as soon as the nozzle hits the bed and the bearing looses contact the switch is not operated anymore. As the spring of the switch tries to push the rod away from the arm it even may give better accurancy. The problem is that it seems to be no space for the switch.

May I ask you in which country-region you are on sea and maybe you have even a hull-number? I am a little bit curious as we are a supplier for ship systems. Maybe your ship is party equipped with one of our system or actuators/ valves or whatever.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

My design is missing the micro switch yet but I also do not have a suitable MS at home. This other design on thingiverse is not adjustable. It may be that the operating mechanism especially the distance may vary between different manufacturers. I only have ones without lever so the bulb at the arm would be a big problem. But I have one idea for a different x-carriage version 528.4 (counter bearing on the side not on the down-side). Maybe I could use a rotating mechanism. As long as the nozzle is up and the bearing on the arm the MS switch is operated but as soon as the nozzle hits the bed and the bearing looses contact the switch is not operated anymore. As the spring of the switch tries to push the rod away from the arm it even may give better accurancy. The problem is that it seems to be no space for the switch.

May I ask you in which country-region you are on sea and maybe you have even a hull-number? I am a little bit curious as we are a supplier for ship systems. Maybe your ship is party equipped with one of our system or actuators/ valves or whatever.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 08, 2015 07:24AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Maybe I could use a rotating mechanism. As long as the nozzle is up and the bearing on the arm the MS switch is operated but as soon as the nozzle hits the bed and the bearing looses contact the switch is not operated anymore. As the spring of the switch tries to push the rod away from the arm it even may give better accuracy.

One idea from way back was to use the bearing itself as the switch. Use an aluminium X-arm or place a metal strip on the X-arm for the bearing to run along and connect a wire to the bolt holding the bearing (if the bearing has electrical conductivity between its inner and outer rings, otherwise use a brush on the outer ring). A metal X-arm can safely be connected to the ground side of the Z switch input. IIUC it sounded better in theory than it worked out in practice - but maybe it could be got to work.

Dave

|

Re: Switches for x,y,z October 08, 2015 10:25AM |

Registered: 9 years ago Posts: 1,699 |

I also had this idea before but it would only make sense if there is a conductive connection between bold and bearing but a slightly contact loss would trigger the switch. I think this would not be practicable.

I have two new ideas. Maybe you could use the proximity switch which is mounted upside down and triggered by the horizontally part of the x-arm or an self-made light triggered switch which is interrupted by the horizontally part of the x-arm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I have two new ideas. Maybe you could use the proximity switch which is mounted upside down and triggered by the horizontally part of the x-arm or an self-made light triggered switch which is interrupted by the horizontally part of the x-arm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 08, 2015 12:52PM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

I also had this idea before but it would only make sense if there is a conductive connection between bold and bearing but a slightly contact loss would trigger the switch. I think this would not be practicable.

I have two new ideas. Maybe you could use the proximity switch which is mounted upside down and triggered by the horizontally part of the x-arm or an self-made light triggered switch which is interrupted by the horizontally part of the x-arm.

That would then reference the Z height to the arm rather than the bed - you might as well put a switch on the Z extrusion and operate it with the X-arm if the bed does not move relative to the frame, thus keeping completely away from the hotend assembly.

Dave

|

Re: Switches for x,y,z October 08, 2015 01:13PM |

Registered: 9 years ago Posts: 1,699 |

No you did not get me right. I would use the tilt effect. As long as the nozzle is over the bed the sensor is looking to the ceiling slightly passing the x-arm. As soon as the sensor hits the bed and the nozzle tilts the sensor is going under the horizontally part of the arm. The light will be reflected and the setting is done. You would need the 4-pin-sensor.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 08, 2015 02:35PM |

Registered: 10 years ago Posts: 859 |

Julie is getting better now, thanks. She shattered both sides of her left ankle, so now has a steel plate and long screws inside her ankle... I'm looking forward to the next holiday when she sets off the metal detectors in the air port....lol...

I thought about the bearing on the back of the X axis arm after installing a metal X axis arm. Initially I thought of using the 12mm rod as the conductor, linking that to the bearing, and the X axis arm as the other switch conductor. The only problem is the possibility of false trigger by grease in the bearings. Then I thought of the risk that if the power cable to the HotEnd or Fan broke and touched the metal work, that it might kill the Duet board. So I decided against it..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I thought about the bearing on the back of the X axis arm after installing a metal X axis arm. Initially I thought of using the 12mm rod as the conductor, linking that to the bearing, and the X axis arm as the other switch conductor. The only problem is the possibility of false trigger by grease in the bearings. Then I thought of the risk that if the power cable to the HotEnd or Fan broke and touched the metal work, that it might kill the Duet board. So I decided against it..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 08, 2015 02:41PM |

Registered: 9 years ago Posts: 1,699 |

It is good to hear that.

I hope I can run some tests this weekend using the proximity sensor. I think this would be a good alternative. Contactless and precise.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I hope I can run some tests this weekend using the proximity sensor. I think this would be a good alternative. Contactless and precise.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 09, 2015 02:27PM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

No you did not get me right. I would use the tilt effect. As long as the nozzle is over the bed the sensor is looking to the ceiling slightly passing the x-arm. As soon as the sensor hits the bed and the nozzle tilts the sensor is going under the horizontally part of the arm. The light will be reflected and the setting is done. You would need the 4-pin-sensor.

Oh - OK, yes now I understand, it sounds like a good plan. You could also put a lip (bit of white card) under the X-arm at the X home position so that it reflects when the hotend is not tilted and use the existing X-homing method.

Dave

|

Re: Switches for x,y,z October 09, 2015 05:08PM |

Registered: 9 years ago Posts: 1,699 |

Hello Dave,

I was thinking about the little bulb to use as x-homing position. At first overtravel and then slowly nearing to it from the other side. But it depends on the position of the proximity sensor. I am afraid that the original homing position will not work without further modification- The question is what kind of readings can I expect using my (for the moment) black printed x-arm and what readings could I get using the aluminium arm of my MK1? But the value does not matter I think as long as I use the modulated switch. Standard readings are about 19 and I do not really want to know the distance so I will use the maximum reading minus 20. I expect something about 150. Maybe even the slowing down mechanism can work at the last µm. If this does not work I will build my own photo sensor (no idea if analog or digital) with the IR-LED over the horizontally x-arm-part (z-axis) and the IR-transistor above this area. The sensitivity would be adjustable.

Why does the old proximity sensor not work? When turning it upside down it is exposed to the environmental lights so you get higher readings even if there is no obstacle. So you could use it only in darkness. Some sort of covering mechanism would not help properly so the modulated sensor is needed because the environmental light will be calculated down by the Duet.

I think this solution could be slightly more procise than the microswitch method and the bulb is no big deal.

For the moment I am using a wrong x-carriage. I think I can replace it on Saturday or Sunday. After that I can look for a mounting possibility and run the first tests. I am curious about the results especially how much the values differs if you repeat auto bed leveling several times.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I was thinking about the little bulb to use as x-homing position. At first overtravel and then slowly nearing to it from the other side. But it depends on the position of the proximity sensor. I am afraid that the original homing position will not work without further modification- The question is what kind of readings can I expect using my (for the moment) black printed x-arm and what readings could I get using the aluminium arm of my MK1? But the value does not matter I think as long as I use the modulated switch. Standard readings are about 19 and I do not really want to know the distance so I will use the maximum reading minus 20. I expect something about 150. Maybe even the slowing down mechanism can work at the last µm. If this does not work I will build my own photo sensor (no idea if analog or digital) with the IR-LED over the horizontally x-arm-part (z-axis) and the IR-transistor above this area. The sensitivity would be adjustable.

Why does the old proximity sensor not work? When turning it upside down it is exposed to the environmental lights so you get higher readings even if there is no obstacle. So you could use it only in darkness. Some sort of covering mechanism would not help properly so the modulated sensor is needed because the environmental light will be calculated down by the Duet.

I think this solution could be slightly more procise than the microswitch method and the bulb is no big deal.

For the moment I am using a wrong x-carriage. I think I can replace it on Saturday or Sunday. After that I can look for a mounting possibility and run the first tests. I am curious about the results especially how much the values differs if you repeat auto bed leveling several times.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 10, 2015 06:35PM |

Registered: 9 years ago Posts: 1,699 |

After running some improvised (really improvised) tests I do not think that a reflective photo sensor can work. Only a classical photo sensor can work where the transmitter and receiver are counterpart. The question is should it be a sensor or a switch. The slowing down mechanism worked really good but I did not get constant values for the bed positions. Maybe it could have been the test rig but I had deviations of more than 1mm. The sensor is not sensitive enough that is why a direct sensor pair would be better. And there would be no difference between acrylic, aluminium and printed x-arm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 11, 2015 05:41AM |

Registered: 10 years ago Posts: 859 |

That's why I like using my microswitches. And I can use what ever thickness glass I want, when I want, or any material I like.... Right now I'm using 4mm glass..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z October 11, 2015 07:23AM |

Registered: 9 years ago Posts: 1,699 |

Hello Kim,

you still got me wrong. I tried to use the proximity switch as replacement for the microswitch. The trigger is the same that means the tilt of the nozzle. I tried to catch the horizontally part of the x-arm so I would have been also completely independant of the material or the thickness as the nozzle touching the glass triggers the sensor. It is like your setup only contactless. That was a try as I have no MS with lever here and in my eyes it is even better to use especially when you want to use the bulb in the horizontal part for x-homing. Maybe my setup was wrong and the reflective sensor can work but a direct pair is much better and would be triggered better by the bulb. And at the tlt it would be also better as the measuring range and the scale of the values could be much bigger than with the reflective sensor but the last one would end in less work.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

you still got me wrong. I tried to use the proximity switch as replacement for the microswitch. The trigger is the same that means the tilt of the nozzle. I tried to catch the horizontally part of the x-arm so I would have been also completely independant of the material or the thickness as the nozzle touching the glass triggers the sensor. It is like your setup only contactless. That was a try as I have no MS with lever here and in my eyes it is even better to use especially when you want to use the bulb in the horizontal part for x-homing. Maybe my setup was wrong and the reflective sensor can work but a direct pair is much better and would be triggered better by the bulb. And at the tlt it would be also better as the measuring range and the scale of the values could be much bigger than with the reflective sensor but the last one would end in less work.

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 12, 2015 06:57AM |

Registered: 10 years ago Posts: 2,472 |

The movement of the hotend due to it tilting will be a lot less at the bottom of the arm than at the top of the arm. The bottom of the arm is close to the fulcrum ((X-rod) and so the lever action will decrease the movement. The greater the tilt action, the more accurate the Z height will be sensed, so I think it would be better to try to sense the top of the X arm rather than the bottom.

Dave

Dave

|

Re: Switches for x,y,z October 12, 2015 11:46AM |

Registered: 9 years ago Posts: 1,699 |

Hi Dave,

of course you are right but I have no idea for the moment how to trigger any kind of switch (mechanical or optical) using the top of the X-arm. For example the Extruder would be an obstacle (or at least the clamping mechanism) and the horizontally part is nearly free of obstacles.

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

of course you are right but I have no idea for the moment how to trigger any kind of switch (mechanical or optical) using the top of the X-arm. For example the Extruder would be an obstacle (or at least the clamping mechanism) and the horizontally part is nearly free of obstacles.

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 12, 2015 12:32PM |

Registered: 10 years ago Posts: 14,672 |

I spent some time trying to design a modified X runner bearing mount to incorporate a force sensitive resistor, but I didn't produce a design I was happy with.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 12, 2015 02:25PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

I spent some time trying to design a modified X runner bearing mount to incorporate a force sensitive resistor, but I didn't produce a design I was happy with.

Ah, so it is called in English. I had theoretically thoughts in this direction, too, but I did not find a suitable position for this. What about a resistance strain gauge which is strained under normal condition and compressed during tilt? I know one company which uses such kind of part in another use (unfortunately a compitor of us) for conditioned based monitoring but they can achieve a very high accurancy with this. They are measuring how smooth a motor shaft is rotating and so they check if the bearing of this is unstable (we are talking about a diesel powered engine btw. As I said another use).

Or another idea could be an IR-LED on top of the nozzle and an IR-Receiver at the other end of the X-arm (Z-runner-mount? Nut trap?). As long as the nozzle is not tilt both parts are counterpart and if the arm tilts the IR-LED-beam leaves the registration area of the IR-receiver. This was my latest idea because you would have the most movement but I do not know if this would be practicable as the IR-LED would have different distances to the IR-receiver.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 12, 2015 02:57PM |

Registered: 10 years ago Posts: 2,472 |

Maybe a phototransistor at one end of a fairly long thin tube mounted on the top of the Z extrusion looking along the top of the X-arm. Then a long column from the top of the hotend that is as high as the top of the Z extrusion when the nozzle is on the bed, with an LED on the top facing the phototransistor. Such a long lever would move a huge amount as the hotend tilts, and if the LED were positioned to be in line with the phototransistor when there is no tilt, I think it will have a pretty sensitive off point as soon as the hotend starts to tilt.

Dave

Dave

|

Re: Switches for x,y,z October 12, 2015 03:22PM |

Registered: 9 years ago Posts: 119 |

This conversation reminds me of a simple question I have which I believe I know the answer to, but has anyone got a standard opto-endstop working with the Duet?

The ones I have are driven by 5V which the Duet can provide but the output is also 5v.

Is it ok to just put it through a resistor divider to get it down to 3v?

Alternatively, can the resistors on the endstop PCB be altered to convert it to a 3V device

The ones I have are driven by 5V which the Duet can provide but the output is also 5v.

Is it ok to just put it through a resistor divider to get it down to 3v?

Alternatively, can the resistors on the endstop PCB be altered to convert it to a 3V device

|

Re: Switches for x,y,z October 12, 2015 04:36PM |

Registered: 10 years ago Posts: 14,672 |

Standard opto endstops should work at 3.3V. But my opinion is that my differential IR sensor is entirely adequate for X homing (on the Ormerod/Huxley/Mendel), Z homing and Z probing. I suspect that the RRP modulated sensor is good enough for most users, judging by the way sales of my Ormerod IR sensor have dropped off. More than one 3D printer owner has replaced a microswitch-based Z probe by one of my mini IR sensors and told me that the IR sensor gives better results. E3D abandoned their servo-deployed switch for my IR sensor on their BigBox 3D printer, and at least two other 3D printer kit suppliers seem to be going the same route.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.