Switches for x,y,z

Posted by Joar107

|

Re: Switches for x,y,z October 12, 2015 05:06PM |

Registered: 9 years ago Posts: 1,699 |

Hello David,

our thoughts are not intended in a bad way or anyhow against your sensor board. Your board is indeed a good idea and because of a construction fault by myself I was not able to test the modulated IR-sensor design by RRP. However both variants are dependent on the surface so if I change from BuildTak to Kapton tape for example I would have to change the settings of the z-probe. The idea using the tilt of the nozzle would be completely independant of any surface and it also would not have any offset so in theory it should be more precise. Practically I know that a MS may lack of repeatibility on the trigger point and that could take influence the z-setting and the accuracy. It is hard to say if your sensor board could win the race of accuracy in this case. It may depend on the microswitch but in every case this solution is much cheaper. I found an IR-set consisting of 10 IR-LEDs and 10 IR-transistors for only 0.95€ in total. One part was nearly identical to your used part the other part has a little bit wider beam. I do not know which part was the nearly part but this could be indeed a good and cheap alternative.

But this method sounds god and is a cheap and accurate alternative to the original sensor. I guess there is a method for 500€ for probing the height with an accuracy of 0.01mm. There is always a better and more accurate way but RRP is not helped if the price raises. I think that is way they showed such less interest for your probing method. I have this problem nearly every day at work. Should I spend more money to get a better solution or not? Spending more money lowers the profit but otherwise if there are too much claims the after-sale costs will raise. This is really not an easy task to find the balance in this cases.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

our thoughts are not intended in a bad way or anyhow against your sensor board. Your board is indeed a good idea and because of a construction fault by myself I was not able to test the modulated IR-sensor design by RRP. However both variants are dependent on the surface so if I change from BuildTak to Kapton tape for example I would have to change the settings of the z-probe. The idea using the tilt of the nozzle would be completely independant of any surface and it also would not have any offset so in theory it should be more precise. Practically I know that a MS may lack of repeatibility on the trigger point and that could take influence the z-setting and the accuracy. It is hard to say if your sensor board could win the race of accuracy in this case. It may depend on the microswitch but in every case this solution is much cheaper. I found an IR-set consisting of 10 IR-LEDs and 10 IR-transistors for only 0.95€ in total. One part was nearly identical to your used part the other part has a little bit wider beam. I do not know which part was the nearly part but this could be indeed a good and cheap alternative.

But this method sounds god and is a cheap and accurate alternative to the original sensor. I guess there is a method for 500€ for probing the height with an accuracy of 0.01mm. There is always a better and more accurate way but RRP is not helped if the price raises. I think that is way they showed such less interest for your probing method. I have this problem nearly every day at work. Should I spend more money to get a better solution or not? Spending more money lowers the profit but otherwise if there are too much claims the after-sale costs will raise. This is really not an easy task to find the balance in this cases.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 12, 2015 06:32PM |

Registered: 10 years ago Posts: 14,672 |

Hi Sven,

The trigger height of a nozzle tilt sensor will also depend on the bed surface, in particular between a hard surface such as glass and a soft surface such as glass coated with BuildTak, tape or whatever. I take your point about cost being critical, but as I have said, several companies have.chosen my IR sensor over switch-based alternatives. My mini IR probe costs a lot less than my Ormerod hot end board, because it does just one function (i.e. Z probe) and the demand is much higher, so I manufacture it in larger quantities. If I can work out a way of reducing the variation in trigger height between boards, I could speed up testing and hence reduce the price further.

The paper test is not repeatable between different build surfaces. I thought that my IR sensor was giving a 0.3mm difference in trigger height with a target of PVA glue on glass compared to plain glass. When I checked with feeler gauges, I found that difference was much lower. The increased friction of the PVA glue was causing the nozzle to grip the paper at a higher nozzle height than with plain glass.

I am changing the type of IR LEDs in my new batch of mini IR boards to one with an even narrower beam, and this reduces the variation in trigger height with bed surface by about 50%. The biggest difference in trigger height is when switching from a transparent bed (e.g. plain glass) to an opaque one (e.g. BuildTak).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The trigger height of a nozzle tilt sensor will also depend on the bed surface, in particular between a hard surface such as glass and a soft surface such as glass coated with BuildTak, tape or whatever. I take your point about cost being critical, but as I have said, several companies have.chosen my IR sensor over switch-based alternatives. My mini IR probe costs a lot less than my Ormerod hot end board, because it does just one function (i.e. Z probe) and the demand is much higher, so I manufacture it in larger quantities. If I can work out a way of reducing the variation in trigger height between boards, I could speed up testing and hence reduce the price further.

The paper test is not repeatable between different build surfaces. I thought that my IR sensor was giving a 0.3mm difference in trigger height with a target of PVA glue on glass compared to plain glass. When I checked with feeler gauges, I found that difference was much lower. The increased friction of the PVA glue was causing the nozzle to grip the paper at a higher nozzle height than with plain glass.

I am changing the type of IR LEDs in my new batch of mini IR boards to one with an even narrower beam, and this reduces the variation in trigger height with bed surface by about 50%. The biggest difference in trigger height is when switching from a transparent bed (e.g. plain glass) to an opaque one (e.g. BuildTak).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 12, 2015 06:48PM |

Registered: 9 years ago Posts: 1,699 |

Hi David,

as I mentioned above it is difficult to optimize the costs to the have. If other companies decided to spend more money to get a better quality it is their decision but every company can decide in another way. E3D for example seems to have a high quality standard so I am not astonished that they took your design. I was wondering if some kind of case with only small holes for the light entry or exit could improve your accuracy. And you would not have any need for this big capacitor.

In my case I would change between BuildTak, Kapton tape and Blue Mask Tape as somewhere mentioned before but shortly ago I found a new surface and if all is right that I have read then it could be my only surface in the near future but I am skeptical as I have a similiar surface from Replikeo which is not working well for me but maybe it is needed to adhere and not to clamp? Or it is simply cheap PCB material without copper and does not work as good as the other material, but FR4 should be FR4, shouldn't it?

Regarding your problem with the trigger height difference: Do you have any idea what is the cause? Is it related to the Attiny? Or do you may need a precise power supply for ADC supply? It could be also related to the resistors you are using and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

as I mentioned above it is difficult to optimize the costs to the have. If other companies decided to spend more money to get a better quality it is their decision but every company can decide in another way. E3D for example seems to have a high quality standard so I am not astonished that they took your design. I was wondering if some kind of case with only small holes for the light entry or exit could improve your accuracy. And you would not have any need for this big capacitor.

In my case I would change between BuildTak, Kapton tape and Blue Mask Tape as somewhere mentioned before but shortly ago I found a new surface and if all is right that I have read then it could be my only surface in the near future but I am skeptical as I have a similiar surface from Replikeo which is not working well for me but maybe it is needed to adhere and not to clamp? Or it is simply cheap PCB material without copper and does not work as good as the other material, but FR4 should be FR4, shouldn't it?

Regarding your problem with the trigger height difference: Do you have any idea what is the cause? Is it related to the Attiny? Or do you may need a precise power supply for ADC supply? It could be also related to the resistors you are using and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 12, 2015 07:02PM |

Registered: 10 years ago Posts: 14,672 |

The trigger height difference between different boards is caused by three things I believe:

1. Variation in the angle of the IR LEDs and phototransistors when they are soldered. The LEDs and phototransistors are already soldered while being held in place by a jig. Could perhaps be reduced if I can find some side-looking SMD devices, if the SMD component placement is accurate enough.

2. Variation in the beam direction between different IR LEDs and phototransistors. This depends on the alignment between the chip and he lens.

3. Variation in the amounts of IR power emitted by the two LEDs. Could be reduced by sorting the LEDs into matched pairs, although that would be no good for SMD assembly.

Edited 1 time(s). Last edit at 10/12/2015 07:02PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Variation in the angle of the IR LEDs and phototransistors when they are soldered. The LEDs and phototransistors are already soldered while being held in place by a jig. Could perhaps be reduced if I can find some side-looking SMD devices, if the SMD component placement is accurate enough.

2. Variation in the beam direction between different IR LEDs and phototransistors. This depends on the alignment between the chip and he lens.

3. Variation in the amounts of IR power emitted by the two LEDs. Could be reduced by sorting the LEDs into matched pairs, although that would be no good for SMD assembly.

Edited 1 time(s). Last edit at 10/12/2015 07:02PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 13, 2015 01:24AM |

Registered: 9 years ago Posts: 1,699 |

I am afraid that SMD would cause more trouble in placement. Reducing the beam means that you have to arrange the parts more precisely.

Please take a look at the data sheet of my IR-Komponents again especially the IR-transistor. Ignore the technical data and only take a look at the housing:

[www.pollin.de]

The type of the housing allows you to place it directly to the PCB and if your holes are small enough problem number 1 should be solved. The lens is much smaller and especially the coloring of the IR-transistor should reduce problem 2.

What about reducing the intensity of the beam? I think that could also improve the accuracy.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Please take a look at the data sheet of my IR-Komponents again especially the IR-transistor. Ignore the technical data and only take a look at the housing:

[www.pollin.de]

The type of the housing allows you to place it directly to the PCB and if your holes are small enough problem number 1 should be solved. The lens is much smaller and especially the coloring of the IR-transistor should reduce problem 2.

What about reducing the intensity of the beam? I think that could also improve the accuracy.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 13, 2015 03:43AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treito

I am afraid that SMD would cause more trouble in placement. Reducing the beam means that you have to arrange the parts more precisely.

Please take a look at the data sheet of my IR-Komponents again especially the IR-transistor. Ignore the technical data and only take a look at the housing:

[www.pollin.de]

The type of the housing allows you to place it directly to the PCB and if your holes are small enough problem number 1 should be solved. The lens is much smaller and especially the coloring of the IR-transistor should reduce problem 2.

That package does look better for getting a precise alignment than the one I currently use. Unfortunately the smallest beam half angle they do in that package is 22 degrees, which is much too high.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 13, 2015 06:38AM |

Registered: 9 years ago Posts: 1,699 |

Maybe you can get a different type of transmitter or receiver with a smaller beam. Maybe you can play with the intensity as the highest intensity is in the middle and the outer beam range drops down to 50% of the maximum light intensity as far as I know. As I build a light source consisting of 100 UV-LEDs to expose my PCB to UV-light I overlapped the beams to get an even lighted surface and it works well. Only the duration is a little bit uncomfortable.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 13, 2015 08:04AM |

Registered: 10 years ago Posts: 2,472 |

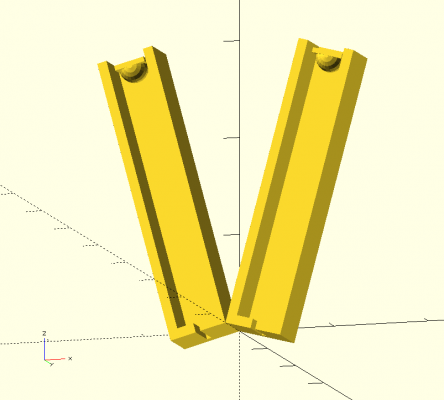

The "dambuster" height determining technique of DC42's sensor board is a good method. You could possibly use tubes or shrouds in front of the LED and photo sensor to give them both a very narrow sight angle. The tube ends closest to the bed would have a very small aperture (probably a thin slot perpendicular to the PCB plane). This would allow the LED and receiver to be mounted on a long base further from the bed for a bigger angle and thus a much sharper trigger height. The tubes I suggest could be built into the printed part that supports the sensor board, so the build cost of the PCB would not increase at all.

Quick SCAD sketch to show what I mean ...

Dave

Quick SCAD sketch to show what I mean ...

Dave

|

Re: Switches for x,y,z October 17, 2015 06:00AM |

Registered: 9 years ago Posts: 1,699 |

I am preparing to test my new design of my nozzle holder for an E3D-Replika. Regarding this design I came to the conclosium that Kims microswitch method can be perfectly work with my holder if I make some small changes. I have to print the holder again as there are some printing issues so the time would be perfect. I found a place where I could use my MS without lever and additionally I can use it for x-homing and the homing position would be only changed by about 2mm (earlier) compared to the original design using the bulb.

Otherwise I am considering to hang the nozzle into the holder and as soon as it touches the bed it would be pushed up triggering a MS. This solution would not be compatible for x-axis homing. Unfortunately both methods are unsuitable for optical endstops.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Otherwise I am considering to hang the nozzle into the holder and as soon as it touches the bed it would be pushed up triggering a MS. This solution would not be compatible for x-axis homing. Unfortunately both methods are unsuitable for optical endstops.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 21, 2015 03:46AM |

Registered: 9 years ago Posts: 1,699 |

I have a new idea. What about the z-axis-nut? I use for example the extended nut trap version and also a nut with a length of 15 mm. So as soon as the nozzle hit the bed the nut is moving down the nut trap. So if you place a MS at the top or at the bottom of the nut the MS would be triggered as soon as the nozzle hits the bed. Maybe 2 mm later. But I think this would be more accurate than the tilt method.

As soon as I got ressources (my MK2 is not working at the moment, too) I will test the tilt method with my MK2 and the nut method with my MK1. Additionally I will add a modified version of dc42s mini sensor board to my MK1 so I can directly compare both.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

As soon as I got ressources (my MK2 is not working at the moment, too) I will test the tilt method with my MK2 and the nut method with my MK1. Additionally I will add a modified version of dc42s mini sensor board to my MK1 so I can directly compare both.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 21, 2015 07:30AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

I have a new idea. What about the z-axis-nut? I use for example the extended nut trap version and also a nut with a length of 15 mm. So as soon as the nozzle hit the bed the nut is moving down the nut trap. So if you place a MS at the top or at the bottom of the nut the MS would be triggered as soon as the nozzle hits the bed. Maybe 2 mm later. But I think this would be more accurate than the tilt method.

As soon as I got ressources (my MK2 is not working at the moment, too) I will test the tilt method with my MK2 and the nut method with my MK1. Additionally I will add a modified version of dc42s mini sensor board to my MK1 so I can directly compare both.

I doubt it would be accurate. The nut does not move in the Z trap as soon as the nozzle hits the bed - initially the X-arm continues to move down while the hotend tilts. Only after the hotend has reached the limit of its tilt and all the slop in the X-arm attachment has been taken up will the nut move in the trap. I doubt that will be at a height that is consistent to within the 0.1mm (minimum) accuracy required, or indeed as accurate as the tilt movement (which is mechanically amplified by the lever action), but maybe do some tests.

Dave

|

Re: Switches for x,y,z October 21, 2015 07:38AM |

Registered: 10 years ago Posts: 14,672 |

I was looking at using an FSR behind the X runner bearing, to detect when the weight of the print head had been taken off the bearing. I didn't get as far as producing a modified X-carriage design incorporating the FSR that I was happy with. But now that the X runner has been moved to be underneath the X arm, perhaps it is worth looking at again.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z October 21, 2015 02:13PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dmould

Quote

Treito

I have a new idea. What about the z-axis-nut? I use for example the extended nut trap version and also a nut with a length of 15 mm. So as soon as the nozzle hit the bed the nut is moving down the nut trap. So if you place a MS at the top or at the bottom of the nut the MS would be triggered as soon as the nozzle hits the bed. Maybe 2 mm later. But I think this would be more accurate than the tilt method.

As soon as I got ressources (my MK2 is not working at the moment, too) I will test the tilt method with my MK2 and the nut method with my MK1. Additionally I will add a modified version of dc42s mini sensor board to my MK1 so I can directly compare both.

I doubt it would be accurate. The nut does not move in the Z trap as soon as the nozzle hits the bed - initially the X-arm continues to move down while the hotend tilts. Only after the hotend has reached the limit of its tilt and all the slop in the X-arm attachment has been taken up will the nut move in the trap. I doubt that will be at a height that is consistent to within the 0.1mm (minimum) accuracy required, or indeed as accurate as the tilt movement (which is mechanically amplified by the lever action), but maybe do some tests.

Dave

Hi Dave,

good point. So let us regard an E3D print head or an E3D replica like I use. They both have in common that they are round (the heatsink is). I was able to rotate my print head inside the holder but the print was always top. So with a slightly modified holder the heat sink would be pushed up as soon as the print head hits the bed. But that should work, shouldn't it?

Okay the time around Halloween will run two tests: dc42's sensor modified sensor model at my MK1 and the tilt option at my MK2. Maybe I can add this new idea at my MK2 and the tilt option also at my MK1. So I could at least compare 3 methods. Maybe I have an idea using a FSR or a straing gauge as this idea sounds really good in theory.

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 22, 2015 10:08AM |

Registered: 10 years ago Posts: 2,472 |

In case it is of use to anyone, I have attached a parametric OpenScad file for an X-carriage that I wrote when playing with various arrangements. This one does not have any bearing runner attached (let me know if you'd like the original arrangement to be added), and nor does it have the Z photo-sensor board attachment mount (these were the things I was changing). The original has the same width belt slot on either side of the grip, but I found this was very tight for the section that holds 2 belts, so there is provision to have different slot widths on either side of the belt grip (increase the variable "SlotWidD" to accomodate the double belt better). Also attached is the original RRP STL of the X-carriage, which the OpenScad file allows you to superimpose (makes designing a tad easier).

For ABS printing I always battle with curlups if the overhang is 45 degrees, so there is also a variable "OverhangAngle" that allows you to steepen it. There are also plenty of other variables to play with to adjust the design - as supplied they have been set to mimic the original part.

Dave

For ABS printing I always battle with curlups if the overhang is 45 degrees, so there is also a variable "OverhangAngle" that allows you to steepen it. There are also plenty of other variables to play with to adjust the design - as supplied they have been set to mimic the original part.

Dave

|

Re: Switches for x,y,z October 22, 2015 03:19PM |

Registered: 9 years ago Posts: 1,699 |

Thanks Dave,

unfortunately I am dependant of the proximity sensor for the moment. If there is no space for a bearing - how should this x-carriage work? Or did I get something wrong? Sorry, I had a really bad day.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

unfortunately I am dependant of the proximity sensor for the moment. If there is no space for a bearing - how should this x-carriage work? Or did I get something wrong? Sorry, I had a really bad day.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 23, 2015 07:13AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Thanks Dave,

unfortunately I am dependant of the proximity sensor for the moment. If there is no space for a bearing - how should this x-carriage work? Or did I get something wrong? Sorry, I had a really bad day.

Hi - I posted it for those wishing to design a different bearing mount incorporating a switch or FSR, - just add a module containing your design, my code will save time by providing the main block and belt slot. Similarly a sensor mount can be easily added by writing a module for that shape and placing it in the appropriate position. I've made each part as a separate module so you can add, subtract or alter the size easily. Attached is the same SCAD design with the original bearing mount design added - you will see how it has been put in as a separate module at the end (and an added set of variables at the top) and so may be altered without needing to adjust anything in the rest of the code. You can modify that module to have a different bearing mount without touching the rest of the code at all.

Dave

Edited 1 time(s). Last edit at 10/23/2015 07:15AM by dmould.

|

Re: Switches for x,y,z October 23, 2015 09:15AM |

Registered: 9 years ago Posts: 1,699 |

Okay, many thanks. I will take a look at it. I am not familiar with OpenSCAD, but I understand the principle as I am writing software at work for PLCs. I will look at it carefully as another design broke apart because of a designing issue (the bearing holder broke). And the modulating switch would not fit either. For these reasons I only wanted to use the original design.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z October 30, 2015 04:15AM |

Registered: 9 years ago Posts: 1,699 |

One small stupid question: Has anyone tested a light reflection switch before? I think this could be a great improvement as it is designed for different surfaces, you have less interference and it is available for different distances. The proximity sensor is for getting distances the other one just simply switches at a given distance, more or less of course.

After reconsidering many things I came to the conclusion to test this with the highest priority. During the next week I will fix my Ormerod 2 and I will use a breadboard to test this solution as it is the simplest way of testing a new device. In parallel I will try to mount a switch for the tilt method but in this case I have to design and print a new part. the light reflective switch I can test easily as I have prepared mounting holes and thanks to the breadboard I can vary the distance between the nozzle and the sensor.

I already ordered this art here:

[cdn-reichelt.de]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

After reconsidering many things I came to the conclusion to test this with the highest priority. During the next week I will fix my Ormerod 2 and I will use a breadboard to test this solution as it is the simplest way of testing a new device. In parallel I will try to mount a switch for the tilt method but in this case I have to design and print a new part. the light reflective switch I can test easily as I have prepared mounting holes and thanks to the breadboard I can vary the distance between the nozzle and the sensor.

I already ordered this art here:

[cdn-reichelt.de]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 03:54AM |

Registered: 9 years ago Posts: 1,699 |

The sensor works indeed better than the original sensor but only partly. It is nearly light independant. Really funny. I put a really bright light source under the sensor and it was still able to detect the height. I only had a difference of 10 digits with light on and off.

Unfortunately this tool is not available in the UK so I have no English site for documentation, German only (Netherlands is also available):

[www.conrad.de]

I only had two problems: I mounted it too high as I use another mounting point and one resistor has to be calibrated as the 4k3 resistor (I used a 4k7 instead) is not sized properly.

As soon as my new print surface arrives or at least the next weekend I will make some other tests: As I said before I would like to test Kim's method but I will use a switch without lever. I am considering of a changed sensor where the contact of the microswitch is in parallel with the sensor output (using a resistor in series) or in parallel with the resistor underneath (again with a smaller resistor than 4k3) to keep the slow down mechanism. As soon as the MS is operated the sensor output would jump to a maximum level of 900 or whatever.

The next thing I would ike to test is a tilt sensor. I would mount it somehow nearby operating angle. But I do not know how precisely the repeatability can be. I am afraid this is not high enough.

Yesterday I saw a video on YT where somebody used a servo to flip down a MS for auto bed leveling. That would be indeed the best idea but I am wondering if I can control an output of the Duet card without modifying the firmware? Is that possible?

Edited 1 time(s). Last edit at 11/08/2015 03:59AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Unfortunately this tool is not available in the UK so I have no English site for documentation, German only (Netherlands is also available):

[www.conrad.de]

I only had two problems: I mounted it too high as I use another mounting point and one resistor has to be calibrated as the 4k3 resistor (I used a 4k7 instead) is not sized properly.

As soon as my new print surface arrives or at least the next weekend I will make some other tests: As I said before I would like to test Kim's method but I will use a switch without lever. I am considering of a changed sensor where the contact of the microswitch is in parallel with the sensor output (using a resistor in series) or in parallel with the resistor underneath (again with a smaller resistor than 4k3) to keep the slow down mechanism. As soon as the MS is operated the sensor output would jump to a maximum level of 900 or whatever.

The next thing I would ike to test is a tilt sensor. I would mount it somehow nearby operating angle. But I do not know how precisely the repeatability can be. I am afraid this is not high enough.

Yesterday I saw a video on YT where somebody used a servo to flip down a MS for auto bed leveling. That would be indeed the best idea but I am wondering if I can control an output of the Duet card without modifying the firmware? Is that possible?

Edited 1 time(s). Last edit at 11/08/2015 03:59AM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 08:53AM |

Registered: 10 years ago Posts: 14,672 |

A light relfection sensor is exactly what the standard Ormerod proximity sensor is. It has two problems:

1. It is sensitive to ambient IR from incandescent light and sunlight. This effect is greatly reduced by adding modulation (as in the Ormerod 2).

2. The trigger height varies depending on the reflectivity of the surface.

My IR sensors use two beams of modulated IR to almost eliminate the sensitivity to bed surface. I don't have any of the Ormerod versions left, but I have plenty of the generic mini IR sensor boards. These are now shipped as standard in the E3D BigBox printer and the Think3DPrint3D Mini Kossel. See [miscsolutions.wordpress.com] for more.

Edited 1 time(s). Last edit at 11/08/2015 08:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. It is sensitive to ambient IR from incandescent light and sunlight. This effect is greatly reduced by adding modulation (as in the Ormerod 2).

2. The trigger height varies depending on the reflectivity of the surface.

My IR sensors use two beams of modulated IR to almost eliminate the sensitivity to bed surface. I don't have any of the Ormerod versions left, but I have plenty of the generic mini IR sensor boards. These are now shipped as standard in the E3D BigBox printer and the Think3DPrint3D Mini Kossel. See [miscsolutions.wordpress.com] for more.

Edited 1 time(s). Last edit at 11/08/2015 08:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z November 08, 2015 10:09AM |

Registered: 9 years ago Posts: 1,699 |

I know about your sensor board you write this very often also in this thread. Your sensor is of course very precise but it is not a cheap variant.

If you would have read my thread above more intensively you would have seen that I wrote that the other sensor I used is nearly light independent. A direct beam with that work light only changes the value by 10 digits with the original sensor it is 800. So I can say that this sensor is not affected by light only by the surface. And you write by yourself that your sensor is not independent from the surface, too.

In one month I will try to create a full printer which costs less than 250€ and using your sensor I would not have any chance to succeed except I reduce the print quality and this is not my goal.

At least the best method seems to be the servo motor method. Using this would beat all other methods but I need to know if there is any output available without changing the FW. Okay I could use at least a Duet shield and a PWM output, but is there no direct switchable output at the expansion board?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

If you would have read my thread above more intensively you would have seen that I wrote that the other sensor I used is nearly light independent. A direct beam with that work light only changes the value by 10 digits with the original sensor it is 800. So I can say that this sensor is not affected by light only by the surface. And you write by yourself that your sensor is not independent from the surface, too.

In one month I will try to create a full printer which costs less than 250€ and using your sensor I would not have any chance to succeed except I reduce the print quality and this is not my goal.

At least the best method seems to be the servo motor method. Using this would beat all other methods but I need to know if there is any output available without changing the FW. Okay I could use at least a Duet shield and a PWM output, but is there no direct switchable output at the expansion board?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 11:03AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treito

At least the best method seems to be the servo motor method. Using this would beat all other methods...

Not according to E3D. They were going to use the servo method for their BigBox printer kit, but they switched to using my mini IR sensor instead.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Switches for x,y,z November 08, 2015 11:12AM |

Registered: 9 years ago Posts: 1,699 |

Do you know what? I would like to do my own test sequence including a modified version of your sensor board but I need an information if I can drive a servo or a relay without modifying the FW. I also have tilt sensors which I will test.

Besides E3D stands for a high quality standard. Of course they prefer a contactless system but that does not mean that the MS method is much worse. I got MS here for only 0.10€ per piece and these MS are of high quality, but they are NC only. Besides I also have cherry switches with changeover contacts for only 0.45€. Both MS have no lever but this option is not expensive.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Besides E3D stands for a high quality standard. Of course they prefer a contactless system but that does not mean that the MS method is much worse. I got MS here for only 0.10€ per piece and these MS are of high quality, but they are NC only. Besides I also have cherry switches with changeover contacts for only 0.45€. Both MS have no lever but this option is not expensive.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 12:10PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

..In one month I will try to create a full printer which costs less than 250€ and using your sensor I would not have any chance to succeed except I reduce the print quality and this is not my goal...

Why go for auto probing then, nobody expect bells and whistles on a dirt cheap printer, manually square up the axises and y-rods and make sure they stay that way (bolt the z-extrusion to the y-extrusion, make a stable console for the printer), mount a star wheel on the treaded rod, mount a micro switch to stop the x-axis half a mm or so over the glass, then zero on paper at the middle of the bed turning the treaded rod with your fingers

Erik

|

Re: Switches for x,y,z November 08, 2015 12:28PM |

Registered: 9 years ago Posts: 1,699 |

Quote

ormerod168

dirt cheap printer

Mind your language.

Honestly I want to create a cheap but precise printer. Maybe it exceeds 250€ we will see. Besides I know many people here at the forum including especially me who did not have any success using the paper method. For me it is definitely not working and I prefer to use the proximity switch for manually leveling and some small adjustments afterwards.

And only because the printer will be cheap this does not mean that I have to resign on comfort. There will be definitely an ABL but I want to keep this printer as cheap as possible with a better resolution then the Ormerod and in relative smaller dimensions with a similar or bigger build volume. That is the idea behind this. One trick is to use a MK3 heated bed as you are not needing an aluminium spreader but you have the same comfort. maybe you even do not need a print surface and can print directly on the bed as the aluminium version is totally even. That is one trick to safe money.

Now I am looking for a cheap solution to fix ABL for my both printers and for the forthcoming one.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 01:43PM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

Quote

ormerod168

dirt cheap printer

Mind your language.

..lets call it a printer on a shoe string budget then :-)

Quote

Honestly I want to create a cheap but precise printer. Maybe it exceeds 250€ we will see. Besides I know many people here at the forum including especially me who did not have any success using the paper method. For me it is definitely not working and I prefer to use the proximity switch for manually leveling and some small adjustments afterwards.

How can it not work?? - the paper is just a proxy to tell you the nozzle is 0,1 mm from ground zero, can't feel nozzle touching paper? - ad more fingerspitz gefühl :-)

Quote

..One trick is to use a MK3 heated bed as you are not needing an aluminium spreader but you have the same comfort. maybe you even do not need a print surface and can print directly on the bed as the aluminium version is totally even. That is one trick to safe money...

..but why use a aluminium spreaderl?, its not needed, I put mine to better use long ago [forums.reprap.org]

Erik

|

Re: Switches for x,y,z November 08, 2015 02:33PM |

Registered: 9 years ago Posts: 1,699 |

So you have reached the gramatically end of your translator but nearly correct. You did find the German umlaut?Quote

ormerod168

fingerspitz gefühl :-)

Maybe my "sense of the fingertips" or just my flair/ intuition is not perfect. I put the paper down under the nozzle and moved it slowly down until I barely could pull out the paper. I noticed the values, entered it and the skirt looked awful. Maybe I am not sensitive enough or maybe it is caused because whether the nozzle nor the bed had reached working temperature as I did this at room temperature. Fact is that some other people (including Prusa I3) also have problems with the paper method. Besides that: We live in the 21st century so I demand from my printer to do this automatically.

Quote

ormerod168

..lets call it a printer on a shoe string budget then :-)

The main idea is to achieve a better result with less money even if I end up at 400€. But I would like to have low-cost model where you do not have to miss something like ABL. Besides regarding my Ormerod 1 the bed leveling seems to change for some reasons but I do not exactly why. One possibility could be if you remove a part and it stucks somewhere and a screw is not 100% tight you may get twisted rods. Or other story maybe a different bed surface needs a different leveling. ABL is done within short time. Manually it needs really much time and in the future I would like to exchange the bed surface after each print to allow the part to cool down as meanwhile the next part is printing so I definitely need an auto level system.

Quote

ormerod168

..but why use a aluminium spreaderl?, its not needed, I put mine to better use long ago [forums.reprap.org]

I know about this but it is a matter of fact that the heat is spreaded better with an aluminium heat spreader as without one. There is also the risk that the glass can break. Besides the additional costs for a MK3 aluminium heated bed to a MK2B or MK2A is less than the cost for the glass if you would like to have a good glass (borosilicate). Did you ever tried a FLIR? I do not believe that the heat is spreaded exactly the same high all over the bed you will have hot spots or you need a damn good insulation which overtakes this job. But as I said it is a cost factor. And at least: Why should I not use the latest and improved version of the heated bed? Using my Ormerod 2 I am totally convinced. If I would have to use the MK2-version I would not use a heat spreader at all, by the way.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 08, 2015 09:46PM |

Registered: 10 years ago Posts: 859 |

I use the tilt method with my microswitch, and it never lets me down. Like Eric I run a level bed, and have bolted my Z to Y axis using a 6mm Gutter bolt (they have a shallow domed head with a 6mm square under it that fits very nicely in the slot of the Ally profile, and the dome gives about 1mm clearance on the Y bearing covers. When I was printing in one colour I used to wash the glass, dry the back with a towel, mount the glass, wipe dry while heating, home, then Print. And I seldom had to wait for the printer to start as it always Printed perfectly. I've found with the Ormerod that once you get the machine setup correctly it becomes very reliable.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Switches for x,y,z November 09, 2015 12:51AM |

Registered: 9 years ago Posts: 1,699 |

@dc42 Besides there are two problems which prevents me to use your switch: What about printing on aluminium and what about printing on PrintBite (as my ones will finally soon arrive). Your sensor needs a dark surface but aluminium is shiny and PrintBite is nearly white, I guess.

@Kim I know about your succeed. That is why I will testing your method with highest priority but I will use a switch without lever. I will construct an adjustable holder for the nozzle of my Ormerod 2. At the place where I will mount the switch I cannot reach the maximum of the bulb so this kind of switch should do the job fine, but as described above I do not know to where I should connect it. A modified proximity sensor (I even have the original sensor part here) would have advantages but I am wondering if you move towards the switch position twice and you reduce the speed the second time results in a better accuracy because of the lower speed. (It would be nice if a good English speaking person could correct this sentence so that I could learn something. )

)

ABL seems to work good if the maximum height difference is less than 0.3mm. I achieved really good results as I leveled the bed manually, but it only lasted for about 5 prints. After that the ABL did a good job for a while.

I will test your method and maybe I will replace the MS with a self-made photoelectric relay (depending on some previously tests). After that I will test a modified version of DC42's sensor. I will keep in mind as I will not use original parts and also not the original design that it may be not as precise as the original one but spending some time I can produce it much cheaper (as I do not need to pay myself).

Besides I am not able to level my Ormerod 1 manually as the height difference is still too high. I still believe this is plywood/ MDF related. I have all non-printed parts here for exchanging the y-axis to the Ormerod 2 version (especially another heated bed for connection purposes and also another power supply). It only lacks on the printed parts. However i need to find the time to design a new case for the Duet and a holder for the PSU and Duet (MK2 style). I am curious if this would make a difference.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

@Kim I know about your succeed. That is why I will testing your method with highest priority but I will use a switch without lever. I will construct an adjustable holder for the nozzle of my Ormerod 2. At the place where I will mount the switch I cannot reach the maximum of the bulb so this kind of switch should do the job fine, but as described above I do not know to where I should connect it. A modified proximity sensor (I even have the original sensor part here) would have advantages but I am wondering if you move towards the switch position twice and you reduce the speed the second time results in a better accuracy because of the lower speed. (It would be nice if a good English speaking person could correct this sentence so that I could learn something.

)

)ABL seems to work good if the maximum height difference is less than 0.3mm. I achieved really good results as I leveled the bed manually, but it only lasted for about 5 prints. After that the ABL did a good job for a while.

I will test your method and maybe I will replace the MS with a self-made photoelectric relay (depending on some previously tests). After that I will test a modified version of DC42's sensor. I will keep in mind as I will not use original parts and also not the original design that it may be not as precise as the original one but spending some time I can produce it much cheaper (as I do not need to pay myself).

Besides I am not able to level my Ormerod 1 manually as the height difference is still too high. I still believe this is plywood/ MDF related. I have all non-printed parts here for exchanging the y-axis to the Ormerod 2 version (especially another heated bed for connection purposes and also another power supply). It only lacks on the printed parts. However i need to find the time to design a new case for the Duet and a holder for the PSU and Duet (MK2 style). I am curious if this would make a difference.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Switches for x,y,z November 09, 2015 02:52AM |

Registered: 10 years ago Posts: 14,672 |

I tested my IR sensor on a sample of Printbite a few weeks ago and it worked well. I am still waiting for my full size PrintBite to arrive.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.