Some questions about the design

Posted by Treito

|

Some questions about the design September 25, 2015 01:51PM |

Registered: 9 years ago Posts: 1,699 |

Hello,

as building an Ormerod 2 from nearly scratch I studied the design and maybe someone can help me with some design questions. I like the newer design of the MK2 more than the MK1. You can really find good choices of making the Ormerod better. So here are the questions:

1) Why a MXL belt was used? It seems that a GT2 belt is much better as it does not suffer from backlash and you get a better amount of steps for millimeters compared to the MXL belt which is more meant for the Americans and their inch system.

2) Theoretically: If I exchange the MXL belt with an GT2 belt would I achieve a better resolution?

3) To think further: If I would use a 16 teeth GT2 pulley and belt I can achieve 100 microsteps per mm so in theory I should achieve a better accuracy. Does this work?

4) And adding on top: Replacing the motors with 0.9° and using 3) I could achieve 200 microsteps per mm so one step gives me an accuracy of 0.005mm in theory.

I think eliminating every error gives a better accuracy so in my eyes point 2 or 3 are good options as I am loosing possible calculation errors, but what do you think?

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

as building an Ormerod 2 from nearly scratch I studied the design and maybe someone can help me with some design questions. I like the newer design of the MK2 more than the MK1. You can really find good choices of making the Ormerod better. So here are the questions:

1) Why a MXL belt was used? It seems that a GT2 belt is much better as it does not suffer from backlash and you get a better amount of steps for millimeters compared to the MXL belt which is more meant for the Americans and their inch system.

2) Theoretically: If I exchange the MXL belt with an GT2 belt would I achieve a better resolution?

3) To think further: If I would use a 16 teeth GT2 pulley and belt I can achieve 100 microsteps per mm so in theory I should achieve a better accuracy. Does this work?

4) And adding on top: Replacing the motors with 0.9° and using 3) I could achieve 200 microsteps per mm so one step gives me an accuracy of 0.005mm in theory.

I think eliminating every error gives a better accuracy so in my eyes point 2 or 3 are good options as I am loosing possible calculation errors, but what do you think?

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Some questions about the design September 25, 2015 03:30PM |

Registered: 10 years ago Posts: 14,672 |

I don't know why they used a MXL belt rather than GT2 either.

The theoretical resolution of the standard Ormerod is about 11 microns in X and Y, and 0.25 microns in Z. In practice it is not as good as this, because you can't expect single-microstep resolution. However, when you are extruding from a nozzle of 500 microns diameter, 11 microns is way more precise than you need anyway.

It's different on a delta printer, because the Z resolution is much lower, e.g. 10 microns using 1.8deg/step motors, GT2 belts and 16 tooth pulleys. Even with 200 micron layer height, the difference between 0.9 and 1.8deg/step motors is observable if you look closely - see the pictures halfway down [miscsolutions.wordpress.com]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The theoretical resolution of the standard Ormerod is about 11 microns in X and Y, and 0.25 microns in Z. In practice it is not as good as this, because you can't expect single-microstep resolution. However, when you are extruding from a nozzle of 500 microns diameter, 11 microns is way more precise than you need anyway.

It's different on a delta printer, because the Z resolution is much lower, e.g. 10 microns using 1.8deg/step motors, GT2 belts and 16 tooth pulleys. Even with 200 micron layer height, the difference between 0.9 and 1.8deg/step motors is observable if you look closely - see the pictures halfway down [miscsolutions.wordpress.com]

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Some questions about the design September 25, 2015 03:58PM |

Registered: 9 years ago Posts: 1,699 |

Many thanks for the answer.

It only was a theoretically thought at first place. I totally know that you cannot achieve the theoretically resolution in practice but if you reduce any error the sum of the errors will be also reduced. For example you have a sensor that has a reading fault. If you transmit the signal via analogue (4..20 mA would be more accurate than voltage) you get an additional error. If you transmit the signal via bus (Modbus, Profibus or whatever) you get a more accurate signal as you eliminate one error source. So that is way I am asking.

Using a GT2 belt should be more robust to loose belts for example and may give you a better accuracy with circles or on short distances. I really had trouble to tense the x-axis. At least I took a screw driver to push the motor to the outer end direction and quickly tightened the screw. My new Ormerod is going to the finish line (okay I have no suitable case for the Duet for example as my Ormerod MK1 failed before I could print it),

At least it seems that the MXL belt is a better choose than the T2.5 but in my eyes the GT2 would have been a much better option. Meanwhile I am really considering exchanging the belts as I have wrong pulleys (20 teeth instead of 18) so I have to exchange them. But should I also try another belt system?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

It only was a theoretically thought at first place. I totally know that you cannot achieve the theoretically resolution in practice but if you reduce any error the sum of the errors will be also reduced. For example you have a sensor that has a reading fault. If you transmit the signal via analogue (4..20 mA would be more accurate than voltage) you get an additional error. If you transmit the signal via bus (Modbus, Profibus or whatever) you get a more accurate signal as you eliminate one error source. So that is way I am asking.

Using a GT2 belt should be more robust to loose belts for example and may give you a better accuracy with circles or on short distances. I really had trouble to tense the x-axis. At least I took a screw driver to push the motor to the outer end direction and quickly tightened the screw. My new Ormerod is going to the finish line (okay I have no suitable case for the Duet for example as my Ormerod MK1 failed before I could print it),

At least it seems that the MXL belt is a better choose than the T2.5 but in my eyes the GT2 would have been a much better option. Meanwhile I am really considering exchanging the belts as I have wrong pulleys (20 teeth instead of 18) so I have to exchange them. But should I also try another belt system?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Some questions about the design September 26, 2015 03:31AM |

Registered: 10 years ago Posts: 275 |

Hi Sven,

maybe can help [prusaprinters.org]

Best

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

maybe can help [prusaprinters.org]

Best

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Some questions about the design September 26, 2015 05:19AM |

Registered: 9 years ago Posts: 1,699 |

Hi Dario,

many thanks for the link. That is only the theory but I try to think further how this is related in a real environment. I have two thoughts or observations that may help to understand what I mean:

My Ormerod 1 has problems with circles. The MXL belt is meant as timing belt that means it is designed for only one direction. Even if you span the belt it may come to a backlash when changing direction. Especially the x-axis belt is hard to span. This would be a reason for my bad circles.

The second observation is about the x-axis of my Ormerod 2. As I mounted the x-carriage and inserted the belt into it I ran a moving test without spanning it. As soon as I changed directions the belt went much down. I used a screw driver to push the motor to the outside to span the belt as much as I could but I did not move the motor that much like the belt went down. So theoretically there could be some backlash left.

According to the Wiki the GT2 belt does not suffer from this problem or it does not suffer that much so the printing results especially circles and probably small areas should be better printed.

As I will soon order new MXL pulleys with 18 teeth I am considering to order GT2 pulleys and a belt too but I am not sure for the moment. I am also thinking of constructing a complete new cartesian printer. In that case I would use GT2 components and then it would not matter if I order two more pulleys as one only costs 1.80$ + VAT + shipping (+ custom?).

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

many thanks for the link. That is only the theory but I try to think further how this is related in a real environment. I have two thoughts or observations that may help to understand what I mean:

My Ormerod 1 has problems with circles. The MXL belt is meant as timing belt that means it is designed for only one direction. Even if you span the belt it may come to a backlash when changing direction. Especially the x-axis belt is hard to span. This would be a reason for my bad circles.

The second observation is about the x-axis of my Ormerod 2. As I mounted the x-carriage and inserted the belt into it I ran a moving test without spanning it. As soon as I changed directions the belt went much down. I used a screw driver to push the motor to the outside to span the belt as much as I could but I did not move the motor that much like the belt went down. So theoretically there could be some backlash left.

According to the Wiki the GT2 belt does not suffer from this problem or it does not suffer that much so the printing results especially circles and probably small areas should be better printed.

As I will soon order new MXL pulleys with 18 teeth I am considering to order GT2 pulleys and a belt too but I am not sure for the moment. I am also thinking of constructing a complete new cartesian printer. In that case I would use GT2 components and then it would not matter if I order two more pulleys as one only costs 1.80$ + VAT + shipping (+ custom?).

Regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Some questions about the design September 26, 2015 06:49AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

....Especially the x-axis belt is hard to span. This would be a reason for my bad circles...

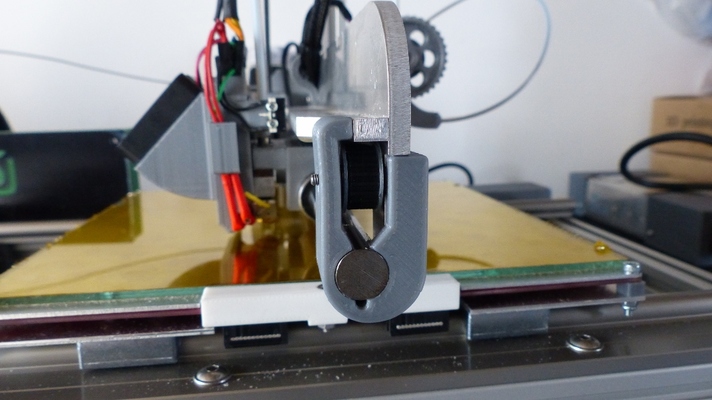

If you use the smooth rod as leverage its no problem

but make sure the belt is centered on the front bearing and not dragging against the x-rib or you might make things worse, rubber against a smooth surface will create a lot of drag

I highly recommend mounting a pulley with belt side guides on the x-axis front bearing, Pointy kindly designed and posted the printed part for that

[forums.reprap.org]

Erik

|

Re: Some questions about the design September 26, 2015 07:00AM |

Registered: 9 years ago Posts: 1,699 |

I put the screw driver between the pulley and the cutout of the x-arm. In theory this was also no problem but I cannot achieve the span that I achieve with the y-belt tensioner.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Some questions about the design September 26, 2015 12:30PM |

Registered: 10 years ago Posts: 14,672 |

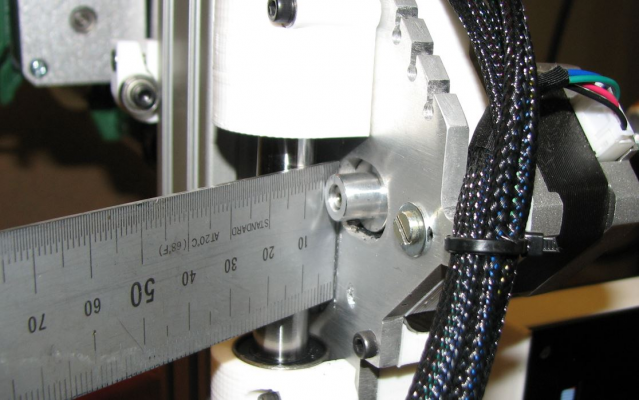

My procedure for tensioning the X belt is:

1. Loosen the X motor screws a lot.

2. With one hand, hold the body of X motor so as to keep the belt taught, while you tighten up the outer X motor screw using the other hand. The belt will be pulling on the pulley so that the X motor is at an angle.

3. Then tighten the inner X motor screw. This will pull the X motor into the correct orientation, tightening the belt as it does so.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Loosen the X motor screws a lot.

2. With one hand, hold the body of X motor so as to keep the belt taught, while you tighten up the outer X motor screw using the other hand. The belt will be pulling on the pulley so that the X motor is at an angle.

3. Then tighten the inner X motor screw. This will pull the X motor into the correct orientation, tightening the belt as it does so.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Some questions about the design September 26, 2015 12:42PM |

Registered: 9 years ago Posts: 1,699 |

Quote

dc42

My procedure for tensioning the X belt is:

1. Loosen the X motor screws a lot.

2. With one hand, hold the body of X motor so as to keep the belt taught, while you tighten up the outer X motor screw using the other hand. The belt will be pulling on the pulley so that the X motor is at an angle.

3. Then tighten the inner X motor screw. This will pull the X motor into the correct orientation, tightening the belt as it does so.

That is nearly the way I did it finally except for step 2 as I used a screw driver. That gave me finally more tension (as far as I could see it). I had to start with the outer screw because the screw driver covered the inner screw. But I am still wondering if a GT2 belt could serve with better results. Okay I soon will commission my Ormerod 2 and according to the print result I may consider it or not.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Some questions about the design September 29, 2015 11:13AM |

Registered: 13 years ago Posts: 1,611 |

Though it's a horrible imperial size (2.032mm/0.08 inch tooth pitch, 6.35mm/0.25 inch width) MXL belt is much, much cheaper than all of the other belt types, as are the pulleys, for no appreciable difference in output. It's cheaper because it's much more widely used than other belt, and unlike proper GT belt and pulleys (Registered trademark of Gates Corporation) you're not paying a premium for copyright/patent. We used to supply T2.5 belt, and T5 belt before that. The most important factor in choosing belt is it's width; narrow belt can be stretchy, and less able to resist the inertia in an axis. The thicker the belt, the less backlash. 10mm width belt would be ideal, but fitting it in becomes the problem...

The belt pitch of MXL is pretty much the same as GT2 (around 2mm) so unless you think GT is a better profile than MXL, or (more importantly) the belt engages better with the pulley, I don't think you'll see much improvement changing belts. My old RepRap still uses T5 belt with a printed 8-tooth pulley, and it prints very well!

I'd tend to agree with dc42, that using 0.9 degree steppers is a better way to go for accuracy.

Ian

RepRapPro tech support

The belt pitch of MXL is pretty much the same as GT2 (around 2mm) so unless you think GT is a better profile than MXL, or (more importantly) the belt engages better with the pulley, I don't think you'll see much improvement changing belts. My old RepRap still uses T5 belt with a printed 8-tooth pulley, and it prints very well!

I'd tend to agree with dc42, that using 0.9 degree steppers is a better way to go for accuracy.

Ian

RepRapPro tech support

|

Re: Some questions about the design September 29, 2015 01:56PM |

Registered: 9 years ago Posts: 1,699 |

Many thanks for this detailed explanation. The cheapest shop I found is Robotdigg at the moment. Actually it seems there is no much difference between MXL and GT2. As David told the 0.9° stepper only makes sense for a Delta-printer so probably the calculation issues using an MXL-belt instead of a GT2 belt is the same.

May problem is that I never was able to print normal circles with my Ormerod MK1 yet and the first question was: What about your tension? So I added an y-belt-tensioner and tried my best to tension the x-belt but the problem staid. So I am wondering if I maybe have still a backlash problem which could be solved with a GT2-belt. That is something nobody can answer exactly.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

May problem is that I never was able to print normal circles with my Ormerod MK1 yet and the first question was: What about your tension? So I added an y-belt-tensioner and tried my best to tension the x-belt but the problem staid. So I am wondering if I maybe have still a backlash problem which could be solved with a GT2-belt. That is something nobody can answer exactly.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.