Ormerod 1 Hot End Replacement

Posted by PeterSimpson

|

Ormerod 1 Hot End Replacement October 21, 2015 06:14PM |

Registered: 8 years ago Posts: 57 |

I need to replace the nozzle in the hot end of my Ormerod 1 because the filament broke inside the bowden tube and jammed. Attempting to remove the nozzle resulted in damaging the thread and it jamming in the heater block!!

I ordered a replacement hot end kit for the Ormerod 1, but it came with a 0.3mm 'Quick-Set nozzle'. I have a few questions about this:

1. What is the significance of the term 'Quick Set'? Does it make any difference to how parts are made on the machine?

2. What was the size of the nozzle in the original Ormerod 1 (0.3mm or 0.5mm)?

3. What are the consequences of using different size nozzles? Does the drawing file determine which nozzle is to be used? Does a parameter need changing in order to use the other nozzle? Should I buy a 0.5mm nozzle?

4. In assembling the hot end on the original ormerod 1 great emphasis was placed in opening up and clearing swarf in the bowden tube where it entered the brass union using a 2mm drill. It does not seem possible to do that with the 'quick-set' nozzle. Is this a problem?

5. The instructions for assembly of the 'quick-set' hot end shows a different cooling block to that used in the ormerod 1. This block was not supplied with the hot end kit. The fan assembly also looks different. I obviously need to buy some more parts/kits! How much more do I need to buy in order to get my ormerod 1 into a working state?

Please note that although this is one of the first 500 printers produced in 2013 I have not yet completely finished it and I have yet to print my first parts (the calibration parts)

I ordered a replacement hot end kit for the Ormerod 1, but it came with a 0.3mm 'Quick-Set nozzle'. I have a few questions about this:

1. What is the significance of the term 'Quick Set'? Does it make any difference to how parts are made on the machine?

2. What was the size of the nozzle in the original Ormerod 1 (0.3mm or 0.5mm)?

3. What are the consequences of using different size nozzles? Does the drawing file determine which nozzle is to be used? Does a parameter need changing in order to use the other nozzle? Should I buy a 0.5mm nozzle?

4. In assembling the hot end on the original ormerod 1 great emphasis was placed in opening up and clearing swarf in the bowden tube where it entered the brass union using a 2mm drill. It does not seem possible to do that with the 'quick-set' nozzle. Is this a problem?

5. The instructions for assembly of the 'quick-set' hot end shows a different cooling block to that used in the ormerod 1. This block was not supplied with the hot end kit. The fan assembly also looks different. I obviously need to buy some more parts/kits! How much more do I need to buy in order to get my ormerod 1 into a working state?

Please note that although this is one of the first 500 printers produced in 2013 I have not yet completely finished it and I have yet to print my first parts (the calibration parts)

|

Re: Ormerod 1 Hot End Replacement October 21, 2015 10:47PM |

Registered: 9 years ago Posts: 1,699 |

Hello,

I try to answer as good as I can.

1. According to this set you should be able to change the nozzle quickly so that is why it is called "Quick set". In theory you can get a better resolution on the parts. Detailed structures could be print more precisely.

2. 0.5mm

3. 0.3mm is more detailed but you can get trouble with filament blockage if you are using bad quality filament. I also would avoid to use special filaments like mixed PLA with carbon, brass and so on. The metal particles can reduce the life of a nozzle and if you are using a small nozzle the risk of a blockage is increased. In every slicing software you have to set the nozzle size. Which nozzle you want to use is up to you.

4. As long as the filament runs smoothly through the tube you will not have any problem. It is even better not to drill because the danger that some rests of the PTFE tube blocks the nozzle is not given.

5. Did you buy this kit? [reprappro.com] Then you should have found a cooling block inside the package. But you will need another printed mounting part.

Sorry I have to ask but you spent much money to buy this printer and then you did not assemble it? I ran my first prints as fast as I could and shortly after that I took a break.

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I try to answer as good as I can.

1. According to this set you should be able to change the nozzle quickly so that is why it is called "Quick set". In theory you can get a better resolution on the parts. Detailed structures could be print more precisely.

2. 0.5mm

3. 0.3mm is more detailed but you can get trouble with filament blockage if you are using bad quality filament. I also would avoid to use special filaments like mixed PLA with carbon, brass and so on. The metal particles can reduce the life of a nozzle and if you are using a small nozzle the risk of a blockage is increased. In every slicing software you have to set the nozzle size. Which nozzle you want to use is up to you.

4. As long as the filament runs smoothly through the tube you will not have any problem. It is even better not to drill because the danger that some rests of the PTFE tube blocks the nozzle is not given.

5. Did you buy this kit? [reprappro.com] Then you should have found a cooling block inside the package. But you will need another printed mounting part.

Sorry I have to ask but you spent much money to buy this printer and then you did not assemble it? I ran my first prints as fast as I could and shortly after that I took a break.

Kind regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 04:26AM |

Registered: 8 years ago Posts: 57 |

Hello Sven

Thank you for your prompt reply and your helpful comments.

I bought the Quickset Nozzle Assembly Kit - [reprappro.com] with a 0.3mm nozzle. I guess I need to buy the Quickset nozzle upgrade kit with 0.5mm nozzle too, as mentioned in your message.

Is the other printed part you mention available in a kit, or as a component from the Reprappro shop? If not, can you suggest where I can obtain one? I would be able to print one myself if the machine was finished and working, but as I need this part to finish the printer that is not possible!!

Despite the introduction to assembly of the Ormerod 1 stating that it should take about 3 hours to assemble, it took me six months to almost finish it, at which time the project for which I bought the printer had disappeared. That, together with more pressing work meant that the printer has been sitting in a corner gathering dust until now!

Thanks again

Peter

Thank you for your prompt reply and your helpful comments.

I bought the Quickset Nozzle Assembly Kit - [reprappro.com] with a 0.3mm nozzle. I guess I need to buy the Quickset nozzle upgrade kit with 0.5mm nozzle too, as mentioned in your message.

Is the other printed part you mention available in a kit, or as a component from the Reprappro shop? If not, can you suggest where I can obtain one? I would be able to print one myself if the machine was finished and working, but as I need this part to finish the printer that is not possible!!

Despite the introduction to assembly of the Ormerod 1 stating that it should take about 3 hours to assemble, it took me six months to almost finish it, at which time the project for which I bought the printer had disappeared. That, together with more pressing work meant that the printer has been sitting in a corner gathering dust until now!

Thanks again

Peter

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 06:49AM |

Registered: 9 years ago Posts: 1,699 |

In this case you will not need to buy the complete set. You will only need the missing parts.

[reprappro.com]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

[reprappro.com]

You may ask the support of the shop for an individual offer for your missing part or maybe you can find someone here who can print your missing part. Maybe someone lives nearby but at least you should someone ask who lives in your country to reduce shipping costs.Quote

Updating an old-style, single hot end to the Quick-set hot end

If you are updating a one-piece stainless steel nozzle hot end to a Quick-set hot end, you will need the Quick-set cooling block, and to print the following parts, as necessary:

I assembled my Ormerod 1 in about 16 hours. My main problem were that some parts needed to be filed and the rods were too long and my printer version was delivered with older parts. I got new parts from the support and I temporarily used washers to extend the aluminium parts but that is another story.

I think that 3 hours are only possible if you have mounted some printers before but if you do this job the first time you need more time as you may have to look more times to find the right parts and I was also very carefully at some points because I was afraid to damage something. Meanwhile I am more experienced as I assembled an Ormerod nearly completely on my own with own parts and without a complete hardware kit.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 07:22AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 10:23AM |

Registered: 9 years ago Posts: 119 |

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 02:15PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

The advertised 3 hours assembly time was always a complete joke...

Dave

wait, there's more...

---------------------------------------------------------------------------

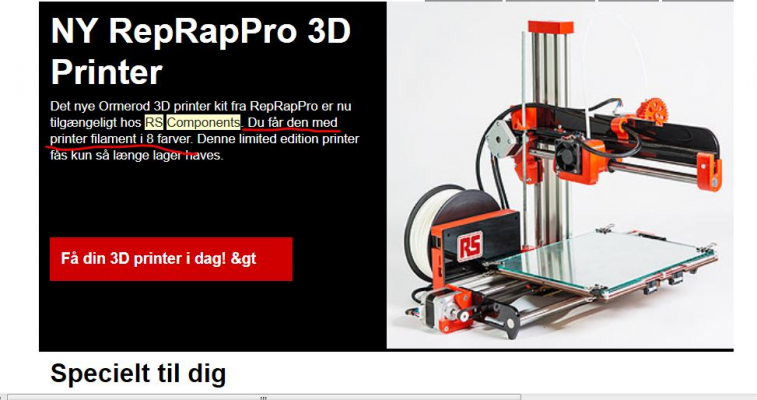

RS Component is a joke, these kids have no honor - this is how I got my ormerod, our firm got a advertisement mail from rs components, "Limited edition, special offer, 8 colors included"

Did not know anything about 3D printers or the RepRap community (and if I had, I would have known that a special limited edition, numbered and signed reprap self reproducing 3D printer is a silly thing), all I could see was the cost of the extra filament (with those RS prices) would amount to about half the cost of the printer itself, so down the basket it went...

Received the package, only one color included, talked to RS about the missing spools, showed them the advert and they agreed, would send the missing items later

Some weeks later we received another mail - "it was a mistake!", the text of the advertisement was wrong, so the missing filament would not be send

..so they they have done the numbers - cost of 7 spools of filament vs loss of goodwill..

Month later we receive a new mail from RS Components - "do you need a trustworthy business partner?" (LOL)

later received two snail mailed postcard from RS noting "long time no do business with us huh??" (more LOL than you can shake a stick at!)

Sorry if I spoiled the atmos, had to get it off my mind :-)

About the printer itself I have no regrets, yes it should have been advertised as a beta edition instead of "Numbered and signed Limited special edition 3D printer" but I enjoyed the build all the way

So my advice would be to buy from RepRapPro directly, those guys and girls are doing all the hard work and deserves all the profit

Erik

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 02:54PM |

Registered: 10 years ago Posts: 2,472 |

My knowledge of Danish is non-existent - did they actually advertise 8 full spools? If not they could have fulfilled their promise & kept some goodwill by sending 8 samples of different colours - 10m filament samples are common for testing a new material or colour.

The only way to get an Ormerod together from a kit in 2 hours is by having the 3 main sections assembled concurrently by 3 different people who are very familiar with the product and so do not need to consult the instructions. Maybe I could put one together in 5 or 6 hours now that I am very familiar with the machine - provided all goes smoothly (which is seldom the case). It took me over 2 hours just to replace the X-carriage, extruder & hotend with ABS parts (albeit including coffee breaks and not working at top speed).

Dave

The only way to get an Ormerod together from a kit in 2 hours is by having the 3 main sections assembled concurrently by 3 different people who are very familiar with the product and so do not need to consult the instructions. Maybe I could put one together in 5 or 6 hours now that I am very familiar with the machine - provided all goes smoothly (which is seldom the case). It took me over 2 hours just to replace the X-carriage, extruder & hotend with ABS parts (albeit including coffee breaks and not working at top speed).

Dave

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 03:11PM |

Registered: 9 years ago Posts: 1,699 |

I am happy to hear that I was not the only one who needed much longer as promised. I do not know how long it took me to assemble my Ormerod 1 as I assembled it in a few days with different amount of time. Especially the faulty Y-bracket took me several hours (!) until i found out that my rods were some mm too long as RepRap changed there manufacturer and there is a new bracket available and my Ormerod was one of the few ones with an old y-bracket as it did not reach a callback.

I cannot compare the building time of my Ormerod 2 as it took me much longer of course as I had no prepared cables for example. Even the heated bed was more complicated as no LED or connection was available, but I am happy about this circumstance as I have a better version of the heated bed which is more effective.

Of course the employees of RepRap could assemble an Ormerod much faster as somebody new to 3D-printing and guess what? Building the Ormerod 2 I found passages which can be improved to make assembling much easier and probably faster, too. I nearly broke my fingers to get the nuts of the heated bed support. Okay to be honest it is not the original one but the situation is probably the same.

Edited 1 time(s). Last edit at 10/22/2015 03:11PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I cannot compare the building time of my Ormerod 2 as it took me much longer of course as I had no prepared cables for example. Even the heated bed was more complicated as no LED or connection was available, but I am happy about this circumstance as I have a better version of the heated bed which is more effective.

Of course the employees of RepRap could assemble an Ormerod much faster as somebody new to 3D-printing and guess what? Building the Ormerod 2 I found passages which can be improved to make assembling much easier and probably faster, too. I nearly broke my fingers to get the nuts of the heated bed support. Okay to be honest it is not the original one but the situation is probably the same.

Edited 1 time(s). Last edit at 10/22/2015 03:11PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 03:19PM |

Registered: 10 years ago Posts: 100 |

Hi Peter

I've gone through this process of upgrade with my Ormerod 1

I bought and tried both the .3mm and the .5mm nozzle. Difference being the print quality. More accurate with the .3mm just like the original nozzle so I guess the original is a .3mm

I purchased .3 and .5mm quick sets. Both work well with the new hot end assembly once you get it all working.

You're a little behind if you.ve not had much time printing.

I try to print most days and have gained better prints by fiddling about and experimenting.

Cheers

jon

Edited 1 time(s). Last edit at 10/22/2015 03:21PM by Jon Steward.

I've gone through this process of upgrade with my Ormerod 1

I bought and tried both the .3mm and the .5mm nozzle. Difference being the print quality. More accurate with the .3mm just like the original nozzle so I guess the original is a .3mm

I purchased .3 and .5mm quick sets. Both work well with the new hot end assembly once you get it all working.

You're a little behind if you.ve not had much time printing.

I try to print most days and have gained better prints by fiddling about and experimenting.

Cheers

jon

Edited 1 time(s). Last edit at 10/22/2015 03:21PM by Jon Steward.

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 03:37PM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

My knowledge of Danish is non-existent - did they actually advertise 8 full spools?...

Dave

Nope

"du (you) får (get) den (it) med (with) printer filament i (in) 8 farver (colors)"

And the link took me to a page with a picture of the printer + spools, don't remember if it there were 7 or 8 spools

Quote

...If not they could have fulfilled their promise & kept some goodwill by sending 8 samples of different colours - 10m filament samples are common for testing a new material or colour...

Yes they could have done that but did not

Erik

|

Re: Ormerod 1 Hot End Replacement October 22, 2015 03:58PM |

Registered: 9 years ago Posts: 1,699 |

Quote

Jon Steward

so I guess the original is a .3mm

Again: The original nozzle is definitely a 0.5mm nozzle. That is for 100% sure! Especially for beginners is a 0.3mm nozzle not suitable as the handling is more complicated. Before I bought my Ormerod 1 I compared it with a Prusa I3 and a Velleman K8200 as these both printers were the other options for me. And of course I took a look at the nozzle size.

Also there are configuration files for Slic3r available. The first files only contained settings for a 0.5mm nozzle. And so on and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement October 23, 2015 10:06AM |

Registered: 8 years ago Posts: 57 |

Thank you all for your replies and comments.

I had been told that the original nozzle was no longer available. However, looking closer at the shop pages I found what looks to me like the original nozzle (https://reprappro.com/shop/components/one-piece-stainless-nozzle/) S I have ordered one which should arrive tomorrow. This nozzle is available in 0.3 and 0.5mm diameters so I still have a little doubt over which was the original. Sven mentioned that the nozzle was set in the Slicing software. There is nothing in the SCAD file for the calibration piece, Calibration.scad, (as far as I can see) to define the nozzle size, but there is a comment in the calibration-200x200.g file (the one specified for the Ormerod and Mendel printers) ';nozzle_diameter = 0.5' so I am fairly confident that 0.5mm is the correct size to use.

If the 'one piece nozzle' is the correct one (I will find out tomorrow!) then hopefully I will be able to finish the machine and start doing some printing!

One of the USPs (Unique Selling Point) for the ormerod was the ability to print any (or all) of the plastic parts for the printer and some improvements (particularly to the Z axis). In order to do this I will obviousl need the design files (.scad or .g) for these parts. I have not been able to find them! Could somebody please point me in the right direction? Are the files for the original Ormerod 1 still available?

Thanks. Peter

I had been told that the original nozzle was no longer available. However, looking closer at the shop pages I found what looks to me like the original nozzle (https://reprappro.com/shop/components/one-piece-stainless-nozzle/) S I have ordered one which should arrive tomorrow. This nozzle is available in 0.3 and 0.5mm diameters so I still have a little doubt over which was the original. Sven mentioned that the nozzle was set in the Slicing software. There is nothing in the SCAD file for the calibration piece, Calibration.scad, (as far as I can see) to define the nozzle size, but there is a comment in the calibration-200x200.g file (the one specified for the Ormerod and Mendel printers) ';nozzle_diameter = 0.5' so I am fairly confident that 0.5mm is the correct size to use.

If the 'one piece nozzle' is the correct one (I will find out tomorrow!) then hopefully I will be able to finish the machine and start doing some printing!

One of the USPs (Unique Selling Point) for the ormerod was the ability to print any (or all) of the plastic parts for the printer and some improvements (particularly to the Z axis). In order to do this I will obviousl need the design files (.scad or .g) for these parts. I have not been able to find them! Could somebody please point me in the right direction? Are the files for the original Ormerod 1 still available?

Thanks. Peter

|

Re: Ormerod 1 Hot End Replacement October 23, 2015 10:39AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Ormerod 1 Hot End Replacement October 23, 2015 10:39AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Ormerod 1 Hot End Replacement October 23, 2015 01:02PM |

Registered: 10 years ago Posts: 14,672 |

The design files are at [github.com]. You will need to look at old versions to find the Ormerod 1 parts where they differ from Ormerod 2.

The standard size nozzle for Ormerod 1 is 0.5mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The standard size nozzle for Ormerod 1 is 0.5mm.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 1 Hot End Replacement October 23, 2015 01:48PM |

Registered: 9 years ago Posts: 1,699 |

The Version 528.4 only differs regarding the mounting place for the proximity switch and version 528.5 put the bearing to the downside but I d not like this option so I use version 528.4.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement October 24, 2015 03:01AM |

Registered: 9 years ago Posts: 1,699 |

It is also a good idea to reslice the calibration test piece. The axes of newer version are marked.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Ormerod 1 Hot End Replacement March 10, 2017 07:11AM |

Registered: 7 years ago Posts: 3 |

|

Re: Ormerod 1 Hot End Replacement March 10, 2017 07:24AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Ormerod 1 Hot End Replacement March 10, 2017 07:56AM |

Registered: 8 years ago Posts: 57 |

Hi Dave (dijgilbert)

It looks as though although the link to the reprappro.com shop which I linked to in my earlier post still exists, it appears to be inactive, however, as Dave (dmould) suggests, the shop still exists at reprapltd.com, which appears to be the same company under a different name.

If you are looking specifically for the nozzle it is on the last page (page 5) at [reprapltd.com]

If you can't find what you are looking for there, try searching on Ebay.

It looks as though although the link to the reprappro.com shop which I linked to in my earlier post still exists, it appears to be inactive, however, as Dave (dmould) suggests, the shop still exists at reprapltd.com, which appears to be the same company under a different name.

If you are looking specifically for the nozzle it is on the last page (page 5) at [reprapltd.com]

If you can't find what you are looking for there, try searching on Ebay.

|

Re: Ormerod 1 Hot End Replacement March 10, 2017 12:32PM |

Registered: 10 years ago Posts: 466 |

Try to find parts here as well.. When RepRap didnt have 0.5 nozzle in stock, Emaker did.

https://emaker.io

Edited 1 time(s). Last edit at 03/10/2017 12:32PM by Sardi.

https://emaker.io

Edited 1 time(s). Last edit at 03/10/2017 12:32PM by Sardi.

Sorry, only registered users may post in this forum.

.

.