Dual Extruder Problems

Posted by KimBrown

|

Dual Extruder Problems October 31, 2015 09:52PM |

Registered: 10 years ago Posts: 859 |

Hi, I've just installed the Dual QuickSet extruder nozzles and having some really stupid problems with one of the extrudes. The right hand Extruder runs fine on the second channel of the expansion board, but the left hand one starts fine then blocks up. I've changed every bit, including nozzles, thermistor, PTFE tube, feeder, heater, even changed the channel it operates on. Why it should block solid has got me beat at the moment. I've even replaced the cabling to the heater In case the original heater cable I was using was breaking down. Changing the cable has improved things a little, and I've even been printing with the bed heater off, in case the 600W ATX power supply couldn't cope. I'm guessing that the only thing left is replacing the power supply, but I don't understand why it should only be the left hot end that is affected Every time. I have a 20Amp power supply waiting to be fitted at home when in a couple of days, but has any one else has this problem? Guessing it's got to be a lack of Amps. Any suggestions welcome. I've tried for 4 days to get this thing going, but it won't play ball, and it's always the same nozzle that blocks. I have a very heavy, 100Amp 12V power supply I can test it with at home, but not keen on lugging that around with the printer (at least I'll be able to monitor the Amps with it. Just wondering if the weak link is that small supply board the ATX power supply plugs in to....

Edited 1 time(s). Last edit at 10/31/2015 10:00PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Edited 1 time(s). Last edit at 10/31/2015 10:00PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 01, 2015 02:06AM |

Registered: 9 years ago Posts: 1,699 |

Hello Kim,

after collecting all information for me as Electrician there are two question left: What happens if you swap the channels? That means what happens if you collect the right hot-end to the left one and the left one to the right? Can you use the left one solely?

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

after collecting all information for me as Electrician there are two question left: What happens if you swap the channels? That means what happens if you collect the right hot-end to the left one and the left one to the right? Can you use the left one solely?

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Dual Extruder Problems November 01, 2015 02:44AM |

Registered: 10 years ago Posts: 14,672 |

Are you sure the problem is caused by the nozzle getting blocked and not by the extruder drive being weak?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dual Extruder Problems November 01, 2015 06:00AM |

Registered: 10 years ago Posts: 859 |

Hi Sven / David, I swapped over the feeder as well. I suspect that the power supply I'm using just can't supply enough Amps, or that the connection box that the ATX power supply is connected to can't handle the current.

When I first tried it, and it blocked just after getting the plastic through the nozzle I tried removing the PTFE tube and feeding it by hand. That didn't work. So had to clean the nozzle.

The nozzle was connected to the old original wiring, so after moving Channels from 1 to 3, it became a little better being powered now from the expansion board instead of the Duet. Then I noticed that the nozzle would try to work but the flow was terrible. So tried running the printer without the Bed heater on... (I tried to print a two colour cone as a test piece). The right hand nozzle was perfect, the left hand nozzle very bad. All ways the same nozzle.

So I then tried replacing the wiring from the Duet box to the HotEnd, and it became a little better. The final test before I packed the printer away (I travel on Wednesday anyway) I am fairly sure I could see the printer brown out as it did the curved section of the cone. So reduced the Amps to the stepper motors from 1000 to 950, and again there seemed to be a tiny improvement, but it was still rubbish.

Things I replaced:-

Nozzle, many times, cleared blocked nozzles using a Blow torch, then quenching, which worked well.

Thermistor, Heater, Feeder (swapped left for right), PTFE Tube (Left for Right), Moved connections from Ch.1 to Ch. 3. Replaced the Power Supply (I'd brought the 600W ATX power supply with me)

and it improved things a great deal, but the print produced by the Left Hand nozzle was rubbish, but it wasn't totally blocking now.

Only thing I wish I'd tried was swapping the Left Nozzle to Ch.2 (the one the right hand nozzle was working well on).

I really think it's a problem with the supply now, just not having enough Amps.

My only puzzle is why always the same Nozzle is blocking up, when the other runs well. I would of thought that it would have affected the other one some times, but no, it's been good.

If I run the nozzle on it's own (after clearing any blockage) it feeds perfectly, but fails soon after it starts to print.

Three days I tried. So given up until I replace the power supply now, as I'm running out of hair. But I thought the 600W ATX would have supplied enough power.

It's been like doing a Rubic Cube after someone has moved the coloured stickers around...... LoL

I'm thinking I might give up on the 2 colour Idea and go back to one nozzle, and get one of the makerbot clones that Hobbyking are selling, especially has it has direct drive HotEnds.... I don't like the

PTFE tubing from the feeders we use, and I'd also like to try Ninga Flex and the like.

Many thanks,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

When I first tried it, and it blocked just after getting the plastic through the nozzle I tried removing the PTFE tube and feeding it by hand. That didn't work. So had to clean the nozzle.

The nozzle was connected to the old original wiring, so after moving Channels from 1 to 3, it became a little better being powered now from the expansion board instead of the Duet. Then I noticed that the nozzle would try to work but the flow was terrible. So tried running the printer without the Bed heater on... (I tried to print a two colour cone as a test piece). The right hand nozzle was perfect, the left hand nozzle very bad. All ways the same nozzle.

So I then tried replacing the wiring from the Duet box to the HotEnd, and it became a little better. The final test before I packed the printer away (I travel on Wednesday anyway) I am fairly sure I could see the printer brown out as it did the curved section of the cone. So reduced the Amps to the stepper motors from 1000 to 950, and again there seemed to be a tiny improvement, but it was still rubbish.

Things I replaced:-

Nozzle, many times, cleared blocked nozzles using a Blow torch, then quenching, which worked well.

Thermistor, Heater, Feeder (swapped left for right), PTFE Tube (Left for Right), Moved connections from Ch.1 to Ch. 3. Replaced the Power Supply (I'd brought the 600W ATX power supply with me)

and it improved things a great deal, but the print produced by the Left Hand nozzle was rubbish, but it wasn't totally blocking now.

Only thing I wish I'd tried was swapping the Left Nozzle to Ch.2 (the one the right hand nozzle was working well on).

I really think it's a problem with the supply now, just not having enough Amps.

My only puzzle is why always the same Nozzle is blocking up, when the other runs well. I would of thought that it would have affected the other one some times, but no, it's been good.

If I run the nozzle on it's own (after clearing any blockage) it feeds perfectly, but fails soon after it starts to print.

Three days I tried. So given up until I replace the power supply now, as I'm running out of hair. But I thought the 600W ATX would have supplied enough power.

It's been like doing a Rubic Cube after someone has moved the coloured stickers around...... LoL

I'm thinking I might give up on the 2 colour Idea and go back to one nozzle, and get one of the makerbot clones that Hobbyking are selling, especially has it has direct drive HotEnds.... I don't like the

PTFE tubing from the feeders we use, and I'd also like to try Ninga Flex and the like.

Many thanks,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 01, 2015 08:12AM |

Registered: 10 years ago Posts: 780 |

Kim

I had a similar problem with the quick set system.

I resolved it by increasing the hot end temperature from 193 to 203.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I had a similar problem with the quick set system.

I resolved it by increasing the hot end temperature from 193 to 203.

Hope that helps

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Dual Extruder Problems November 01, 2015 08:33AM |

Registered: 10 years ago Posts: 859 |

Hi Appjaws, I tried 235' but no good. It'll be Friday before I can unpack it and try anything else...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 01, 2015 01:29PM |

Registered: 10 years ago Posts: 100 |

|

Re: Dual Extruder Problems November 01, 2015 02:52PM |

Registered: 10 years ago Posts: 859 |

Hi Jon, one of the first things I tried was swapping over the filament, as one Nozzle was working perfectly, and the other was blocking all the time.

Only think I noticed after that was that the Heating Up curve wasn't a smooth slope like the good Nozzle, so that's what pointed me towards the wiring and Thermistor.

I'll try to post a picture of the last print I did tomorrow. It's packed away at the moment in the back of the car till we get back to port.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Only think I noticed after that was that the Heating Up curve wasn't a smooth slope like the good Nozzle, so that's what pointed me towards the wiring and Thermistor.

I'll try to post a picture of the last print I did tomorrow. It's packed away at the moment in the back of the car till we get back to port.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 01, 2015 06:52PM |

Registered: 10 years ago Posts: 859 |

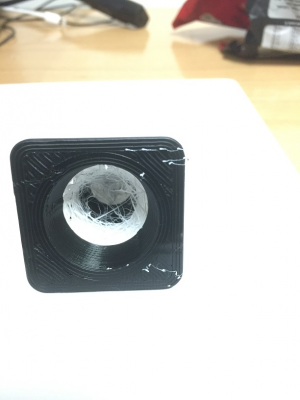

As you can see the White (Left Nozzle) is now too hot (190') but then also the flow is to little...

The Black (right nozzle) is ok, but there is a heavy seam where the layer starts and stops.

This I can tune out (or decrease) later by increasing the retraction, and the feed acceleration.

Edited 1 time(s). Last edit at 11/01/2015 06:56PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The Black (right nozzle) is ok, but there is a heavy seam where the layer starts and stops.

This I can tune out (or decrease) later by increasing the retraction, and the feed acceleration.

Edited 1 time(s). Last edit at 11/01/2015 06:56PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 01, 2015 08:28PM |

Registered: 9 years ago Posts: 1,699 |

Did you try to use the left one solely and leave the right nozzle cold?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Dual Extruder Problems November 03, 2015 10:27AM |

Registered: 10 years ago Posts: 28 |

Hi Kim

I had a lot of problems with blocking when I changed my Ormerod to two nozzles. I tried everything I could think of that might be causing the problem. I'm not sure if the problem effected both nozzles as consistently as you are finding though.

However after many hours of trying various ideas I thought why does it extrude when feeding using the control on the web interface but blocks when it's printing.

My guess (and it was only a guess) was that the original cooling fan duct was causing the heater block to cool as well as the nozzle mounting, so I designed a new fan mounting. I've put it on Thingiverse ( Ormerod fan duct for dc42's PCB )

If you are using RepRapPro's new fan mount (the perspex one) then it probably won't help.

Since I installed my fan duct though I've not had any problems with blocking.

kind regards and good luck

Ray

Ray

I had a lot of problems with blocking when I changed my Ormerod to two nozzles. I tried everything I could think of that might be causing the problem. I'm not sure if the problem effected both nozzles as consistently as you are finding though.

However after many hours of trying various ideas I thought why does it extrude when feeding using the control on the web interface but blocks when it's printing.

My guess (and it was only a guess) was that the original cooling fan duct was causing the heater block to cool as well as the nozzle mounting, so I designed a new fan mounting. I've put it on Thingiverse ( Ormerod fan duct for dc42's PCB )

If you are using RepRapPro's new fan mount (the perspex one) then it probably won't help.

Since I installed my fan duct though I've not had any problems with blocking.

kind regards and good luck

Ray

Ray

|

Re: Dual Extruder Problems November 03, 2015 08:26PM |

Registered: 10 years ago Posts: 859 |

Hi Ray, I've been incredibly busy here onboard ship, so had to pack the Printer away until I can get home on Friday.

I've been thinking about this problem, and the more I think about it the more I'm convinced that it's power related either on the 12V side or the 5V or both.

My Ormerod is one of the earlier ones just outside the first 500 (special edition ones), so it's an earlier Duet. When I get home I will measure the voltages and see what's happening.

I think that when there is allot of demand from the consumers (Heaters, stepper motors), that the machine is starting to Brown Out. When I was watching it working I did notice it stutter

at about the same point producing the Cone. I did actually have my own tiny fan duct fitted, and ended up removing it, to see if for some reason that was compounding the problem.

What I want to try is connecting the USB to my 2.1Amp USB charger or Laptop the next time to see if that helps.

But thanks for telling me about your Fan Duct, I'll try it once I get the Beast working better. I am looking forward to seeing it working properly, but I'm also thinking hard about

biting the bullet and investing in a Dual Nozzle Printer that's enclosed in a steel case, as I think that will put up with the rigors of the vibration and pounding the machine gets here onboard.

I've loved using the Ormerod, and not going to walk away from it. And I've learnt how to print very successfully with the help from others on this Forum, and I must admit that the Web Interface

with DC's firmware is amazing stuff. I also have a Prusa i3 at home. But it's open framework doesn't look as if it will stand up to the hammering it would get here at work. Having learnt

so much from the Ormerod, the Prusa became very easy to setup and I got it printing really well the first time I used it.

I'm very sure it's something minor a miss that I'll find when I get it settled on the Bench (aka as the dinning room table, but I'm trying to convince Julie that we have hinges in our legs to balance

dinner plates on...lol) at home, where I can devote some undisturbed time to it.

All the Best,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I've been thinking about this problem, and the more I think about it the more I'm convinced that it's power related either on the 12V side or the 5V or both.

My Ormerod is one of the earlier ones just outside the first 500 (special edition ones), so it's an earlier Duet. When I get home I will measure the voltages and see what's happening.

I think that when there is allot of demand from the consumers (Heaters, stepper motors), that the machine is starting to Brown Out. When I was watching it working I did notice it stutter

at about the same point producing the Cone. I did actually have my own tiny fan duct fitted, and ended up removing it, to see if for some reason that was compounding the problem.

What I want to try is connecting the USB to my 2.1Amp USB charger or Laptop the next time to see if that helps.

But thanks for telling me about your Fan Duct, I'll try it once I get the Beast working better. I am looking forward to seeing it working properly, but I'm also thinking hard about

biting the bullet and investing in a Dual Nozzle Printer that's enclosed in a steel case, as I think that will put up with the rigors of the vibration and pounding the machine gets here onboard.

I've loved using the Ormerod, and not going to walk away from it. And I've learnt how to print very successfully with the help from others on this Forum, and I must admit that the Web Interface

with DC's firmware is amazing stuff. I also have a Prusa i3 at home. But it's open framework doesn't look as if it will stand up to the hammering it would get here at work. Having learnt

so much from the Ormerod, the Prusa became very easy to setup and I got it printing really well the first time I used it.

I'm very sure it's something minor a miss that I'll find when I get it settled on the Bench (aka as the dinning room table, but I'm trying to convince Julie that we have hinges in our legs to balance

dinner plates on...lol) at home, where I can devote some undisturbed time to it.

All the Best,

Kim..

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Dual Extruder Problems November 04, 2015 04:03PM |

Registered: 10 years ago Posts: 28 |

Hi Kim

I replaced the original ATX power supply with a 33A 12VDC LED unit from ebay £18.80 ( cctvshop_uk ) It works well very well.

The Ormerod 1 ( received mine Christmas 2013 ) has it's faults and it's a bit fragile, but like you I think it's a great way to learn about the problems with 3D printing and I've still got much to learn, but great fun.

I can understand the problems you would have when on-board ship as I was a Shell Tanker engineer apprentice back in the late 1950's and early 1960's and can understand that the Ormerod wouldn't like going to sea.

I agree that without this forum and people like dc42 (and many others) who put so much time in I would probably have thrown the towel in many times.

Kind regards and good luck

Ray

Ray

I replaced the original ATX power supply with a 33A 12VDC LED unit from ebay £18.80 ( cctvshop_uk ) It works well very well.

The Ormerod 1 ( received mine Christmas 2013 ) has it's faults and it's a bit fragile, but like you I think it's a great way to learn about the problems with 3D printing and I've still got much to learn, but great fun.

I can understand the problems you would have when on-board ship as I was a Shell Tanker engineer apprentice back in the late 1950's and early 1960's and can understand that the Ormerod wouldn't like going to sea.

I agree that without this forum and people like dc42 (and many others) who put so much time in I would probably have thrown the towel in many times.

Kind regards and good luck

Ray

Ray

Sorry, only registered users may post in this forum.