Omerod 2 quality issue - uneven walls

Posted by jreut

|

Omerod 2 quality issue - uneven walls November 28, 2015 09:22AM |

Registered: 8 years ago Posts: 10 |

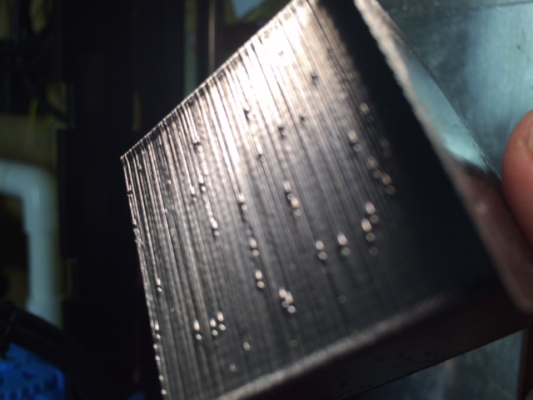

I just noticed that my recent prints have been of poor quality, with a lot of bumps in the walls, as shown in the picture below.

I'm also seeing two other odd things.

1) some skipping of the filament feed when I try to manually feed at more than 10 mm/s

2) some "surging" of the output when I do a manual feed (slow, then fast, then slow, repeat)

I thought it might be a clogged nozzle, so I cleaned out the tip with a microdrill bit when it was hot, with no change.

Omerod 2

ABS, 235-245 deg C

slic3r 1.2.9

.24mm thickness

I've seen this with 3 different rolls of filament

Does anyone have any suggestions on what is causing this?

Thanks,

-Jeff

I'm also seeing two other odd things.

1) some skipping of the filament feed when I try to manually feed at more than 10 mm/s

2) some "surging" of the output when I do a manual feed (slow, then fast, then slow, repeat)

I thought it might be a clogged nozzle, so I cleaned out the tip with a microdrill bit when it was hot, with no change.

Omerod 2

ABS, 235-245 deg C

slic3r 1.2.9

.24mm thickness

I've seen this with 3 different rolls of filament

Does anyone have any suggestions on what is causing this?

Thanks,

-Jeff

|

Re: Omerod 2 quality issue - uneven walls November 28, 2015 04:28PM |

Registered: 9 years ago Posts: 191 |

|

Re: Omerod 2 quality issue - uneven walls November 28, 2015 04:36PM |

Registered: 8 years ago Posts: 10 |

|

Re: Omerod 2 quality issue - uneven walls November 28, 2015 07:34PM |

Registered: 10 years ago Posts: 859 |

Hi, I suspect your Over Extruding slightly. Maybe the filament you are using is slightly thicker this time. In which case decrease the Extrusion Multiplier.

I normally run with a value of 0.84 but adjust this as and when I feel it's needed. We should measure our filament, set the multiplier, and re-slice every time we change it, but I for one don't... Hence my Ball Park figure of 0.84. You would need to do a test print, measure, then calculate the Multiplier figure.

(Or you could do what I do now and adjust the Extrusion amount in the Web page....lol)

I suspect that as your extruder is moving along it's building up a small Bow Wave of molten plastic that it's pushing along in front of the extruder.

It slowly gets bigger in size until it can't be supported by the extruder nozzle and breaks away forming a Blob of plastic. It'll probably sort out your corners

as well....

You could also try an extra 5' as the plastic will become more fluid, and be less likely to form a bow wave, but that won't sort out your corners as much as decreasing the flow would.

Kim..

Edited 3 time(s). Last edit at 11/28/2015 07:42PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

I normally run with a value of 0.84 but adjust this as and when I feel it's needed. We should measure our filament, set the multiplier, and re-slice every time we change it, but I for one don't... Hence my Ball Park figure of 0.84. You would need to do a test print, measure, then calculate the Multiplier figure.

(Or you could do what I do now and adjust the Extrusion amount in the Web page....lol)

I suspect that as your extruder is moving along it's building up a small Bow Wave of molten plastic that it's pushing along in front of the extruder.

It slowly gets bigger in size until it can't be supported by the extruder nozzle and breaks away forming a Blob of plastic. It'll probably sort out your corners

as well....

You could also try an extra 5' as the plastic will become more fluid, and be less likely to form a bow wave, but that won't sort out your corners as much as decreasing the flow would.

Kim..

Edited 3 time(s). Last edit at 11/28/2015 07:42PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Omerod 2 quality issue - uneven walls November 30, 2015 12:47AM |

Registered: 8 years ago Posts: 10 |

Good suggestions.

I reduced the Extrusion Multiplier with no impact.

I increased the nozzle temperature by 5 and then 10 degrees with a slight improvement, but the bumps are still there.

(I'm now running at 255 C, which is the highest I've ever used.)

I then changed the Slic3r setting from random starting points to aligned layer starting point, and the bumps disappeared.

So, problem solved, but I'm still wondering why the start/stop points overextrude so much as to be so noticable. I don't remember seeing this on my old Solidoodle.

Thanks again for the help.

I reduced the Extrusion Multiplier with no impact.

I increased the nozzle temperature by 5 and then 10 degrees with a slight improvement, but the bumps are still there.

(I'm now running at 255 C, which is the highest I've ever used.)

I then changed the Slic3r setting from random starting points to aligned layer starting point, and the bumps disappeared.

So, problem solved, but I'm still wondering why the start/stop points overextrude so much as to be so noticable. I don't remember seeing this on my old Solidoodle.

Thanks again for the help.

|

Re: Omerod 2 quality issue - uneven walls November 30, 2015 02:20AM |

Registered: 10 years ago Posts: 1,230 |

Quote

jreut

So, problem solved, but I'm still wondering why the start/stop points overextrude so much as to be so noticable. I don't remember seeing this on my old Solidoodle.

I had some problems with buildups in corners, as far as I remember a change in acceleration and jerk speed settings fixed that

(RepRapFirmware-1.09c-dc42.bin)

- M111 S0; Debug off

M550 PBigfoot ; Machine name (can be anything you like)

M551 Preprap ; Machine password

M552 P192.168.1.14 ; IP address

M553 P255.255.255.0 ; Netmask

M554 P192.168.1.1 ; Gateway

M555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates

M83 ; relative extruder moves

M906 X1000 Y1200 Z800 E1200 ; Set motor currents (mA)

M563 P0 D0 H1 ; Define tool 1

G10 P0 S-273 R-273 ; Set tool 1 operating and standby temperatures

M92 E420 ; Set extruder steps per mm

M558 P1 ; Use an unmodulated Z probe or an intelligent Z probe

G31 Z0.15 P500 ; Set the probe height and threshold (put your own values here)

M201 X1200 Y1200 Z20 E3600 ; set accelerations (mm/s^2)

M556 S78 X0 Y0 Z0 ; axis compensation

M203 X15000 Y15000 Z250 E3600; Maximum speeds (mm/min)

M566 X1800 Y1800 Z30 E20 ; maximum jerk speed mm/minute(i.e. maximum instantaneous change in speed)

M208 X210 Y205 Z185; set axis travel

M208 X 0 S1 ; set axis minimum

M574 X0 Y2 Z0 S1

T0

Erik

|

Re: Omerod 2 quality issue - uneven walls November 30, 2015 07:01AM |

Registered: 10 years ago Posts: 859 |

Jr that makes sense that the bumps disappeared. You will now have a seam somewhere on the print in that case.

Eriks config file might help reduce it, but also look at your retraction restart extra length. Try a negative number. While the volume of plastic remains the same after the nozzle refills, the length

of the plastic changes (it got stretched when you retracted..... So when it feeds in it will blob, shallow then go to normal. My print is out of commision at the moment at home, else I would try it here.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Eriks config file might help reduce it, but also look at your retraction restart extra length. Try a negative number. While the volume of plastic remains the same after the nozzle refills, the length

of the plastic changes (it got stretched when you retracted..... So when it feeds in it will blob, shallow then go to normal. My print is out of commision at the moment at home, else I would try it here.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Omerod 2 quality issue - uneven walls November 30, 2015 07:43AM |

Registered: 10 years ago Posts: 2,472 |

It is a known issue with Bowden tube extruders. The Bowden tube causes a lag between the extruder motor starting or stopping and the extruded plastic starting or stopping. The Simplify3D slicing program has a setting called "coast at end" which compensates by stopping the extruder slightly before reaching the end of a printed line, and that helps a bit. If you need good quality prints, set the outer perimeter speed very slow, which will greatly reduce the amount of over-extrusion at the end of lines and at corners (at the expense of increased print time). I think Slic3r has a setting "hide seams" where it tries to find a corner to start & end the perimeter so that the blobs are not noticeable. If the perimeters all start in the same place, the blobs (seam) will form a straight line which is usually much easier to file off than the "random" setting.Quote

jreut

I then changed the Slic3r setting from random starting points to aligned layer starting point, and the bumps disappeared.

So, problem solved, but I'm still wondering why the start/stop points overextrude so much as to be so noticable. I don't remember seeing this on my old Solidoodle.

Dave

|

Re: Omerod 2 quality issue - uneven walls December 04, 2015 09:26AM |

Registered: 8 years ago Posts: 10 |

Great advice.

I set

External perimeter speed to half of what it was (now at 15 mm/s).

External perimeters first.

The seam stop/starts are barely visible.

I will also try out the Align Seams: Nearest, which is supposed to choose hidden spots for the stop/start point.

Thanks again. I'm much happier with my print quality.

I set

External perimeter speed to half of what it was (now at 15 mm/s).

External perimeters first.

The seam stop/starts are barely visible.

I will also try out the Align Seams: Nearest, which is supposed to choose hidden spots for the stop/start point.

Thanks again. I'm much happier with my print quality.

|

Re: Omerod 2 quality issue - uneven walls December 04, 2015 04:40PM |

Registered: 8 years ago Posts: 10 |

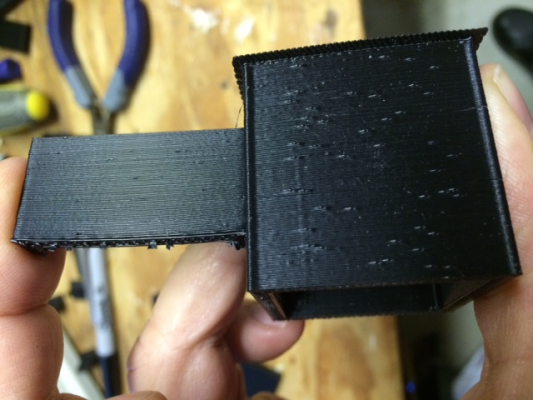

And finally, here is a before and after picture. The large part on the right is the original. The smaller test piece on the right still has the random stop/start points (for test purposes) but you can see that they are barely noticable.

Thanks again.

-Jeff

Edited 1 time(s). Last edit at 12/04/2015 04:40PM by jreut.

Thanks again.

-Jeff

Edited 1 time(s). Last edit at 12/04/2015 04:40PM by jreut.

Sorry, only registered users may post in this forum.