RepRapPro closing down

Posted by ormerod168

|

Re: RepRapPro closing down January 07, 2016 06:35AM |

Registered: 9 years ago Posts: 21 |

I was saddened to hear of RRP's pending closure. I'm sorry to hear you have lost your job Ian, you helped me out on numerous occasions when I was setting up my printer. Also, I am in the process of setting up a business involving 3d printing and the Fisher Delta was going to play a big part in what I had planned. Hopefully RRP China will carry it on. Sadly there are always winners and losers in any decision to be made. Hopefully my Ormerod 2 doesn't have an irreplaceable part failures soon though. I'm glad I bought a few spares a while back.

Magoo

Magoo

|

Re: RepRapPro closing down January 07, 2016 08:50AM |

Registered: 9 years ago Posts: 189 |

Quote

Davek0974

As a busines owner, I know there are many reasons for the sudden closure of a company, none of which I would like to post here as they are not good reasons. Almost every case of closure there is time to make an announcement, time to try and take every penny by selling off stock, time for employees to look for other work, many many opportunities that so far I do not see as being taken.

It is very odd indeed, especially with new products being launched etc.

I think this forum and its users deserves a full and frank statement from RRP at the least.

I would second this

Hi Dave,

Did some enquires about getting the quick-set nozzle engineered, company I approached weren't able to make them, as it uses stainless steel 316.

They suggested needing a small high precision sliding head lathe with back ops and that 316 is mostly used in medical applications.

Would you be able or know anyone that could produce the quick-set nozzle for Ormerod 2?

Chris

|

Re: RepRapPro closing down January 07, 2016 08:59AM |

Registered: 8 years ago Posts: 301 |

|

Re: RepRapPro closing down January 07, 2016 09:14AM |

Registered: 9 years ago Posts: 189 |

Quote

unstable

I have some regulators that I can use to replace the faulty one, but it's the stepper controller that is holding me up at the moment. 3 days now and no replystarting to worry if I will get a replacement before the 15th and don't want to have to return the lot to RS as I doubt they have spares.

Having 82 (was 87 towards the end of last week) complete (printed parts & hardware) Ormerod 2 in stock at RS amounts to having spares.

I wasn't aware that RS stocked them as I always used RepRapPro for parts and bought my hardware kit from them. Did RRP give some to RS?

Now if I was working at RS I would pop open a box and send you the new board but you see RS are just box shifters;

Helped a RS team assemble an early Ormerod 2 maybe a 1 (it's a while ago) and it was the first time that they had put one together, they were shocked as it took time and effort to get right, they had no idea what was inside the box.

RRP LTD UK were a group of people that designed and understood what was in the box, supported it, developed a process to get the parts into bags, bags into boxes so the people could build 3D printers.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: RepRapPro closing down January 07, 2016 09:27AM |

Registered: 9 years ago Posts: 189 |

Quote

DADIY

Perhaps Ian ( ex reprap ) might know who originally manufactured them for RRP. Then we could approach them for a batch.

Maybe, But what mostly happens when people leave a company is that any information about sources and supplier contracts stays within those walls, you take no information with you.

Let see how open RRP Ltd are going to be as there was a company mentioned upon my hardware kit that did the logistics for the kit but I have lost the label :-(

I was told that RRP had 50+ printer farm so able to produce the printed parts needed.

Which could be shipped to a central location where all the parts where boxed and shipped out.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: RepRapPro closing down January 07, 2016 09:28AM |

Registered: 10 years ago Posts: 776 |

Quote

orictosh

Quote

Davek0974

As a busines owner, I know there are many reasons for the sudden closure of a company, none of which I would like to post here as they are not good reasons. Almost every case of closure there is time to make an announcement, time to try and take every penny by selling off stock, time for employees to look for other work, many many opportunities that so far I do not see as being taken.

It is very odd indeed, especially with new products being launched etc.

I think this forum and its users deserves a full and frank statement from RRP at the least.

I would second this

Hi Dave,

Did some enquires about getting the quick-set nozzle engineered, company I approached weren't able to make them, as it uses stainless steel 316.

They suggested needing a small high precision sliding head lathe with back ops and that 316 is mostly used in medical applications.

Would you be able or know anyone that could produce the quick-set nozzle for Ormerod 2?

Chris

Hi

its a job beyond my abilities/setup i fear. 316 is not much fun to machine.

I can look around for a place but can't do it myself i'm afraid.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: RepRapPro closing down January 07, 2016 09:34AM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro closing down January 07, 2016 10:47AM |

Registered: 9 years ago Posts: 177 |

Quote

Davek0974

Quote

orictosh

Quote

Davek0974

As a busines owner, I know there are many reasons for the sudden closure of a company, none of which I would like to post here as they are not good reasons. Almost every case of closure there is time to make an announcement, time to try and take every penny by selling off stock, time for employees to look for other work, many many opportunities that so far I do not see as being taken.

It is very odd indeed, especially with new products being launched etc.

I think this forum and its users deserves a full and frank statement from RRP at the least.

I would second this

Hi Dave,

Did some enquires about getting the quick-set nozzle engineered, company I approached weren't able to make them, as it uses stainless steel 316.

They suggested needing a small high precision sliding head lathe with back ops and that 316 is mostly used in medical applications.

Would you be able or know anyone that could produce the quick-set nozzle for Ormerod 2?

Chris

Hi

its a job beyond my abilities/setup i fear. 316 is not much fun to machine.

I can look around for a place but can't do it myself i'm afraid.

Where did you see that the nozzles are 316? All the schematics I could find for the one-piece nozzles and the quickset nozzles on GitHub say they are stainless steel and don't elaborate on the type.

Is there any reason 316 was chosen? what would happen if we used a different stainless steel?

Right now my O2 is running a single one-piece nozzle. I was planning to get the 2 color upgrade but I guess that's not going to happen. Although the Duex4 is available from think3dprint3d and now that they've fixed the noisy thermistor ground problem...... It's almost better than the expansion board RRP was selling anyways.

If I wanted to do that now I'd have to replace the entire hotend with something else, unless someone's going to be getting supplies of all of the parts unique to the O2(nozzles, tapered brass nuts, hot end blocks etc....)

And since so few of us would actually purchase anything but the nozzles..... I doubt that will be very economical.

I guess my O2 is probably going to stay the way it is, someday I'll have to get/build a different printer.

I feel bad for the people who just got kits, my O2 took a few months + 2 warranty claims on bad parts to get it operational; granted part of that was the shipping time to the US.

Edited 1 time(s). Last edit at 01/07/2016 10:48AM by shadow651.

|

Re: RepRapPro closing down January 07, 2016 11:27AM |

Registered: 10 years ago Posts: 2,472 |

Quote

orictosh

They suggested needing a small high precision sliding head lathe with back ops and that 316 is mostly used in medical applications.

Also extensively used in marine applications because unlike many other stainless steel compositions is will not corrode or discolour in a salt water environment. I cannot think of a good reason why a different type (e.g. 304) could not be used for a nozzle.

Dave

|

Re: RepRapPro closing down January 07, 2016 11:29AM |

Registered: 9 years ago Posts: 189 |

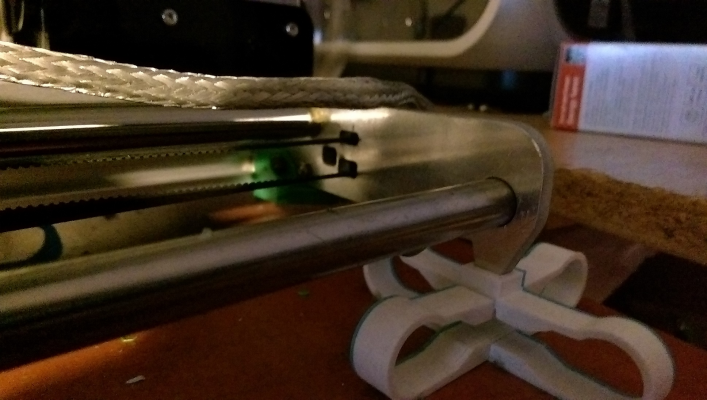

The files for the quick-set hot end are here [github.com]

There is one PDF file named 737 which is the engineering drawing for a 0.3mm quick set nozzle. It marked on the drawing Stainless Steel 316

Most likely uses could be; as 316 regarded as "food safe" and used in medical applications. There is also a BOM in the above which shows which file is which bit, I'm not able to convert the solid works files to PDF so I'm able to send them out to be made into physical objects.

I believe and found it easier to fit than the old single piece, there is no need to have the PTFE liner or butt the bowden tube end to the nozzle. So you could run it higher temperatures, (ex rep rap) Ian did some non public testing, don't have the email to hand or remember the temp value.

As the bowden tube screws straight into the quick-set nozzle and the heat block fixes upon the bottom. Just before this discussion started I sold an quick-set upgrade kit for 0.5mm which replaces the old single nozzle and would like to replace it, its progression from the older and could be regarded as a true one piece nozzle but wasn't sold or mentioned in that way when sold.

Yes it's sad about others buying kits just before this announcement, I went though 3 firmware upgrades (for needed bug fixes) during my build. I was using stock rep rap pro firmware which surprised many, there is DC42 firmware but I rather the printer printed items rather than spend time sorting out installing another firmware version.

I have spent more time fixing it than printing with it, which doesn't help when you are trying to support it's use to average joe.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

There is one PDF file named 737 which is the engineering drawing for a 0.3mm quick set nozzle. It marked on the drawing Stainless Steel 316

Most likely uses could be; as 316 regarded as "food safe" and used in medical applications. There is also a BOM in the above which shows which file is which bit, I'm not able to convert the solid works files to PDF so I'm able to send them out to be made into physical objects.

I believe and found it easier to fit than the old single piece, there is no need to have the PTFE liner or butt the bowden tube end to the nozzle. So you could run it higher temperatures, (ex rep rap) Ian did some non public testing, don't have the email to hand or remember the temp value.

As the bowden tube screws straight into the quick-set nozzle and the heat block fixes upon the bottom. Just before this discussion started I sold an quick-set upgrade kit for 0.5mm which replaces the old single nozzle and would like to replace it, its progression from the older and could be regarded as a true one piece nozzle but wasn't sold or mentioned in that way when sold.

Yes it's sad about others buying kits just before this announcement, I went though 3 firmware upgrades (for needed bug fixes) during my build. I was using stock rep rap pro firmware which surprised many, there is DC42 firmware but I rather the printer printed items rather than spend time sorting out installing another firmware version.

I have spent more time fixing it than printing with it, which doesn't help when you are trying to support it's use to average joe.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: RepRapPro closing down January 07, 2016 12:30PM |

Admin Registered: 17 years ago Posts: 177 |

As you might imagine, we have all been rushed off our feet in the last couple of weeks and will be into the near future. When you close a company, the amount of work multiplies extraordinarily.

However I have been writing a long post for here on what happened, is happening and will happen. As soon as the second two stop changing faster than I can write them down, I will post it. My best guess is that that will be in about a week.

best wishes

Adrian

[reprap.org]

[reprapltd.com]

However I have been writing a long post for here on what happened, is happening and will happen. As soon as the second two stop changing faster than I can write them down, I will post it. My best guess is that that will be in about a week.

best wishes

Adrian

[reprap.org]

[reprapltd.com]

|

Re: RepRapPro closing down January 07, 2016 01:02PM |

Registered: 10 years ago Posts: 776 |

No reason it would need to be 316, any stainless is pretty nasty to machine.

I have no equipment small enough to drill a 0.5 or 0.3mm hole though.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

I have no equipment small enough to drill a 0.5 or 0.3mm hole though.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: RepRapPro closing down January 07, 2016 01:29PM |

Registered: 8 years ago Posts: 45 |

Quote

orictosh

Just before this discussion started I sold an quick-set upgrade kit for 0.5mm

That would be me, a very quick and efficient service it was too. I've been printing in ABS and want to also print in PLA so the idea is to have a hot end for each to save the problems going from ABS to PLA. Just need to find out which thermistor is the right one. Reprappro have been out of stock of 0.5 nozzles for a while and I was getting suspicious because of the amount of kit that was out of stock and the fact they were selling off ex production machines. As soon as I saw the message on Monday I jumped in quick.

I also ordered some hobbed inserts from think3dprint3d and they seem to be the right ones.

[www.think3dprint3d.com]

It was always in my plan to upgrade to two colour printing at some stage so an option now might be a Duet 0.8.5 and something like an e3d Chimera.

What would be useful is if Reprappro could provide a list of suppliers for individual parts as they are no longer in the game.

Now I just have to sort out what I am going to do about my cracked acrylic y axis end plates.

|

Re: RepRapPro closing down January 07, 2016 02:02PM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro closing down January 07, 2016 02:06PM |

Registered: 8 years ago Posts: 164 |

Quote

trevmas

Now I just have to sort out what I am going to do about my cracked acrylic y axis end plates.

I used 5mm HDPE for my y-ends because I couldn't find 5mm acrylic anywhere locally. The bars are a bit loose in the holes, but I was able to use vinyl tape to tighten them up. I've wondered if CNCed aluminium might also work

|

Re: RepRapPro closing down January 07, 2016 02:22PM |

Registered: 9 years ago Posts: 638 |

Quote

trevmas

Quote

orictosh

Just before this discussion started I sold an quick-set upgrade kit for 0.5mm

That would be me, a very quick and efficient service it was too. I've been printing in ABS and want to also print in PLA so the idea is to have a hot end for each to save the problems going from ABS to PLA. Just need to find out which thermistor is the right one. Reprappro have been out of stock of 0.5 nozzles for a while and I was getting suspicious because of the amount of kit that was out of stock and the fact they were selling off ex production machines. As soon as I saw the message on Monday I jumped in quick.

I also ordered some hobbed inserts from think3dprint3d and they seem to be the right ones.

[www.think3dprint3d.com]

It was always in my plan to upgrade to two colour printing at some stage so an option now might be a Duet 0.8.5 and something like an e3d Chimera.

What would be useful is if Reprappro could provide a list of suppliers for individual parts as they are no longer in the game.

Now I just have to sort out what I am going to do about my cracked acrylic y axis end plates.

If you know anyone who can Water jet you a pair in aluminium:

or you can just print them in PLA...

Edited 2 time(s). Last edit at 01/07/2016 02:26PM by Darathy.

|

Re: RepRapPro closing down January 07, 2016 02:38PM |

Registered: 8 years ago Posts: 164 |

|

Re: RepRapPro closing down January 07, 2016 03:04PM |

Registered: 9 years ago Posts: 638 |

I converted it to STL for you : y-axis-end-plate.STL

|

Re: RepRapPro closing down January 07, 2016 03:07PM |

Registered: 8 years ago Posts: 45 |

Quote

0x0000

@darathy, I was actually planning to design a y-axis-end STL file suitable for printing and put it on Thingiverse. I need to import the DXF and extrude the shape to 5mm, just cant find any software that will do it for free! Has someone already made one?

there are a couple already.

ormerod 2 front legs by Le4fy,

[www.thingiverse.com]

and a chunky version by the same person

[www.thingiverse.com]

I like the idea of the chunky one but I'm not sure how you would adjust them.

|

Re: RepRapPro closing down January 07, 2016 03:19PM |

Registered: 9 years ago Posts: 189 |

Quote

trevmas

Quote

orictosh

Just before this discussion started I sold an quick-set upgrade kit for 0.5mm

Quote

trevmas

That would be me, a very quick and efficient service it was too.

I've been printing in ABS and want to also print in PLA so the idea is to have a hot end for each to save the problems going from ABS to PLA. Just need to find out which thermistor is the right one. Reprappro have been out of stock of 0.5 nozzles for a while and I was getting suspicious because of the amount of kit that was out of stock and the fact they were selling off ex production machines. As soon as I saw the message on Monday I jumped in quick.

Many thanks, it was a good start to year, just a shame I didn't have box of them, just that one

Check back often, I plan to sort out what to sell on the site.

Good choice and application for having two nozzles, the right thermistor is a 100k

Quote

trevmas

I also ordered some hobbed inserts from think3dprint3d and they seem to be the right ones.

[www.think3dprint3d.com]

Looks good to me, and using M3 nyloc nuts helps keep the bearing in the right place and tight.

Quote

trevmas

It was always in my plan to upgrade to two colour printing at some stage so an option now might be a Duet 0.8.5 and something like an e3d Chimera.{/quote]

What would be useful is if Reprappro could provide a list of suppliers for individual parts as they are no longer in the game.

Yes, trying to source the machined quick set nozzle has been hard, so knowing where it's produced would help get some in the UK as I think it's made in china or India.

Some of the machined items popped up on a site which linked above and in Switzerland [www.robofun.ch]

I don't mind importing the items into the UK, as long as I'm able to meet the required MOQ and have funds available.

Having it in stock allows me to post it quickly. It's quite tricky get the pricing so it's fair and covers the costs involved.

Quote

trevmas

Now I just have to sort out what I am going to do about my cracked acrylic y axis end plates.

Edited 1 time(s). Last edit at 01/07/2016 03:23PM by orictosh.

Supporting 3D Printers with Parts and Build services.

Printer: Ormerod 2 (528.4) Duel extruder set-up with Aluminium X-Rib, RRPro Firmware v1.11-ch (2016-04-08)

|

Re: RepRapPro closing down January 07, 2016 03:29PM |

Registered: 8 years ago Posts: 89 |

So my kit did not come from them but this all has me wondering about parts and upkeep.

I know I can print parts as needed and buy other parts but what items will wear out or break with usage and need to be replaced that may be hard to find?

I see talk about the hot end but right now that is going right over my head. Should I stock up on anything?

Any help would be great.

I know I can print parts as needed and buy other parts but what items will wear out or break with usage and need to be replaced that may be hard to find?

I see talk about the hot end but right now that is going right over my head. Should I stock up on anything?

Any help would be great.

|

Re: RepRapPro closing down January 07, 2016 03:37PM |

Registered: 9 years ago Posts: 177 |

Quote

orictosh

Quote

trevmas

It was always in my plan to upgrade to two colour printing at some stage so an option now might be a Duet 0.8.5 and something like an e3d Chimera.{/quote]

What would be useful is if Reprappro could provide a list of suppliers for individual parts as they are no longer in the game.

Yes, trying to source the machined quick set nozzle has been hard, so knowing where it's produced would help get some in the UK as I think it's made in china or India.

Some of the machined items popped up on a site which linked above and in Switzerland [www.robofun.ch]

I don't mind importing the items into the UK, as long as I'm able to meet the required MOQ and have funds available.

Having it in stock allows me to post it quickly. It's quite tricky get the pricing so it's fair and covers the costs involved.

orictosh

I would definitely be interested in getting at least a quick set nozzle upgrade kit, if not something simular to the RRP dual color upgrade for the O2's using a duet pre v0.85 (I assume you wouldn't stock the Duet shield or the Duex4 but I could source that from Think3DPrint3D).

I'm in the United States though, would your site sell to me?

Although maybe RRP will sell it's surplus (we can hope) - in which case I'd still need to order spare nozzles etc... from your site

|

Re: RepRapPro closing down January 07, 2016 04:31PM |

Registered: 8 years ago Posts: 45 |

Quote

orictosh

Many thanks, it was a good start to year, just a shame I didn't have box of them, just that one

Check back often, I plan to sort out what to sell on the site.

Good choice and application for having two nozzles, the right thermistor is a 100k

Most axial thermistors I have found are only rated unto 200C. I have found a Honeywell on Farnell that is rated up to 300C [uk.farnell.com] but I'm not sure if this is the right package (DO-35) or the right temperature curve.

|

Re: RepRapPro closing down January 07, 2016 05:00PM |

Registered: 8 years ago Posts: 164 |

|

Re: RepRapPro closing down January 07, 2016 08:48PM |

Registered: 9 years ago Posts: 1,699 |

I switched to a radial thermistor. Those types you can get everywhere already prewired. The big advantage is that there is no wire which has to bypass the heated block.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro closing down January 08, 2016 12:31AM |

Registered: 10 years ago Posts: 14,672 |

Quote

trevmas

Most axial thermistors I have found are only rated unto 200C. I have found a Honeywell on Farnell that is rated up to 300C [uk.farnell.com] but I'm not sure if this is the right package (DO-35) or the right temperature curve.

The thermistor used by RRP is this one [www.digikey.co.uk]. So that one from Farnell has a higher resistance tolerance (5%) and a different beta. Otherwise OK.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro closing down January 08, 2016 01:17AM |

Registered: 9 years ago Posts: 92 |

|

Re: RepRapPro closing down January 08, 2016 02:31AM |

Registered: 8 years ago Posts: 301 |

Quote

dc42

Quote

trevmas

Most axial thermistors I have found are only rated unto 200C. I have found a Honeywell on Farnell that is rated up to 300C [uk.farnell.com] but I'm not sure if this is the right package (DO-35) or the right temperature curve.

The thermistor used by RRP is this one [www.digikey.co.uk]. So that one from Farnell has a higher resistance tolerance (5%) and a different beta. Otherwise OK.

This radial thermistor looks like a good replacement to me - [uk.farnell.com]

|

Re: RepRapPro closing down January 08, 2016 02:34AM |

Registered: 10 years ago Posts: 776 |

Quote

steve0-uk

I am not sure if Dave (makes the aluminium x arm) still makes the dual nozzle blocks. But if we can still at least get the one piece nozzle and block with Dave block we can still have dual nozzle... I am sure Dave will confirm if he is making them

Hi

yes I can still do these.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: RepRapPro closing down January 08, 2016 03:04AM |

Registered: 10 years ago Posts: 14,672 |

Can anyone who has built the Replikeo Ormerod tell us what hot end that kit uses? Maybe we can get nozzles etc. from them. Otherwise we can convert to E3DV6 or Lite for single extrusion, and E3D Chimera or Cyclops for dual.

Edited 1 time(s). Last edit at 01/08/2016 03:06AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 01/08/2016 03:06AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.