Cheap E3D hot end and stuck filament

Posted by appjaws1

|

Cheap E3D hot end and stuck filament January 18, 2016 06:26AM |

Registered: 10 years ago Posts: 780 |

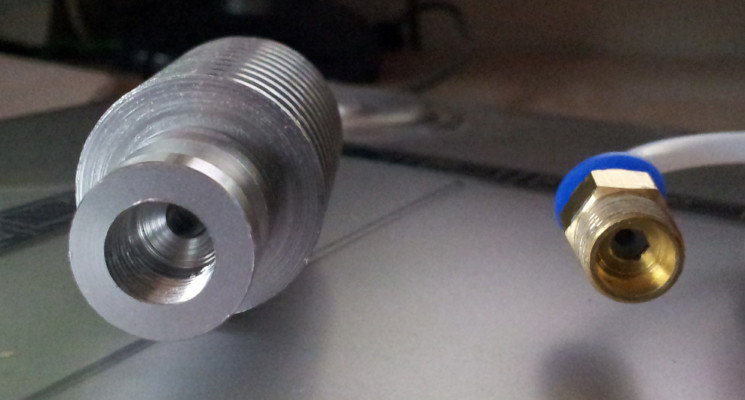

I have been testing a cheap E3D hot end from china. I thought it was V6 but it could be V5, what is the difference?

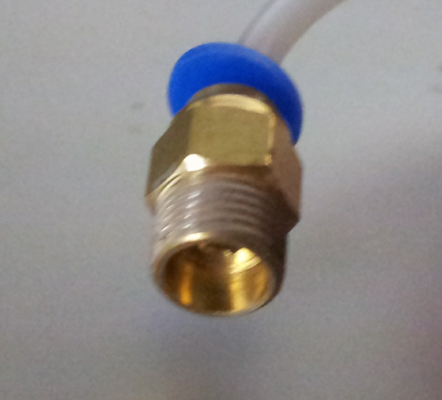

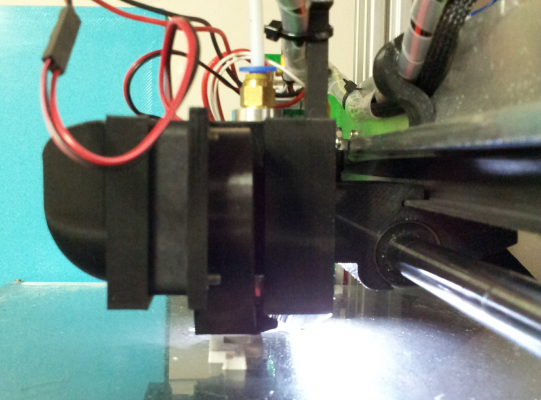

I have a major problem with it trying to feed filament, under the pneumatic fitment there is a gap before the hole that the filament goes through. The filament catches and will not feed.

I tried pushing the bowden tubing all the way in to the stop and that didn't work.

In all other respects it works well if I initially feed the filament into the hole, without the pneumatic fitting or bowden tubing in place and then screw in the pneumatic fitting and insert the bowden tubing.

If I need to change colour or reinsert after removing the filament I am in trouble again.

Has anybody else experienced this problem and how did you solve it?

so the filament has no guide in the gap and this is the problem because the filament naturally has a curve, due to being on a reel, so the filament will not go straight but curves to hit the side where no matter how much force is applied, it will not locate in the filament Chanel The internal gap is approx 15mm

.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I have a major problem with it trying to feed filament, under the pneumatic fitment there is a gap before the hole that the filament goes through. The filament catches and will not feed.

I tried pushing the bowden tubing all the way in to the stop and that didn't work.

In all other respects it works well if I initially feed the filament into the hole, without the pneumatic fitting or bowden tubing in place and then screw in the pneumatic fitting and insert the bowden tubing.

If I need to change colour or reinsert after removing the filament I am in trouble again.

Has anybody else experienced this problem and how did you solve it?

so the filament has no guide in the gap and this is the problem because the filament naturally has a curve, due to being on a reel, so the filament will not go straight but curves to hit the side where no matter how much force is applied, it will not locate in the filament Chanel The internal gap is approx 15mm

.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

|

Re: Cheap E3D hot end and stuck filament January 18, 2016 07:24AM |

Registered: 9 years ago Posts: 57 |

|

Re: Cheap E3D hot end and stuck filament January 18, 2016 07:52AM |

Registered: 10 years ago Posts: 780 |

|

Re: Cheap E3D hot end and stuck filament January 25, 2016 11:44PM |

Registered: 9 years ago Posts: 1,699 |

Unfortunately you did not show the rest of the hot-end to see which version you use. I had similar problems with the first batch, but I do not use them anymore. I now have a newer revision which works fine (but not the latest one),

One hot-end is seriously damaged. I just mounted it without checking it any further and that was a mistake. It was not screwed tight and the PLA went through all holes. I am just getting an idea how to repair it. Using ABS and then I could use Aceton to clean it.

BTT: I get really good looking printouts using them so I decided that I will exchange the nozzle of my Ormerod 1, too. You have to watch out a little bit regarding the cooling. They do not need very much and so the risk of a backwash is high. I attached a fan guard to reduce the air flow and everything is working fine. The bridging is a little bit slow. It will probably get much better if I add a second fan.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

One hot-end is seriously damaged. I just mounted it without checking it any further and that was a mistake. It was not screwed tight and the PLA went through all holes. I am just getting an idea how to repair it. Using ABS and then I could use Aceton to clean it.

BTT: I get really good looking printouts using them so I decided that I will exchange the nozzle of my Ormerod 1, too. You have to watch out a little bit regarding the cooling. They do not need very much and so the risk of a backwash is high. I attached a fan guard to reduce the air flow and everything is working fine. The bridging is a little bit slow. It will probably get much better if I add a second fan.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Cheap E3D hot end and stuck filament January 26, 2016 03:28AM |

Registered: 9 years ago Posts: 1,159 |

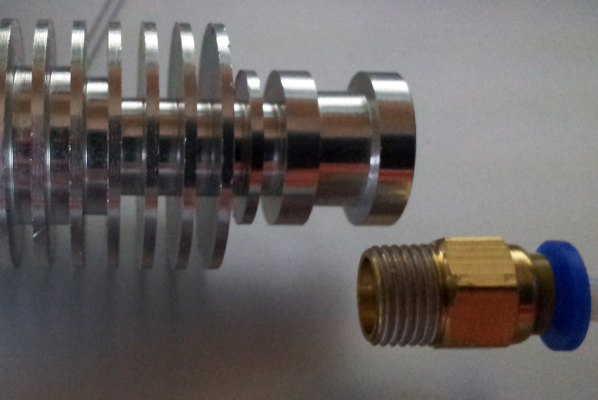

It looks like a V5 from the photos if you look on E3D's website they have the engineering drawing's published on there and it is the Aluminium heatsink you need to compare.

IIRC the V6 is longer and the inner wall of it is tapered whereas I think the V5 is a stepped inner wall.

The reason that the original's are so much better than the clones is in the manufacture and the internal finish on the orig is polished and not just drill as in the clones.

also the original has a very nice Bowden clip design that is very compact and allows the PTFE to go all the way to the heatbreak.

It is also very important to follow the E3D Assembly instruction to avoid any leakage around the nozzle area

Edited 1 time(s). Last edit at 01/26/2016 03:28AM by dougal1957.

IIRC the V6 is longer and the inner wall of it is tapered whereas I think the V5 is a stepped inner wall.

The reason that the original's are so much better than the clones is in the manufacture and the internal finish on the orig is polished and not just drill as in the clones.

also the original has a very nice Bowden clip design that is very compact and allows the PTFE to go all the way to the heatbreak.

It is also very important to follow the E3D Assembly instruction to avoid any leakage around the nozzle area

Edited 1 time(s). Last edit at 01/26/2016 03:28AM by dougal1957.

|

Re: Cheap E3D hot end and stuck filament January 26, 2016 08:27AM |

Registered: 10 years ago Posts: 780 |

Thank you for all your replies.

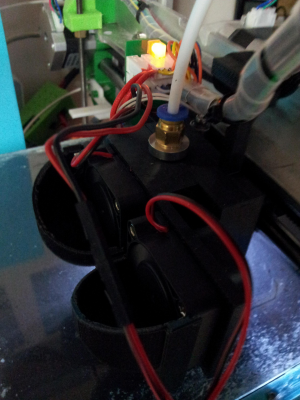

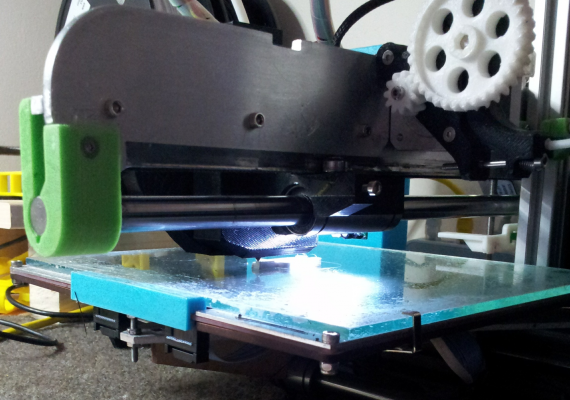

I drilled the pneumatic fitting so that the bowden tube goes all the way to the heatsink.

I now have it working and the print quality is very good. I have designed my own mount to be compatible with my modified X carriage. The mount directs the air from the heatsink onto the extruded filament, which is great for bridging. I have also added a second fan for additional cooling.

I only print in PLA, this setup would probably overheat if using temperatures of 230+C

again, thanks for all the advice.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

I drilled the pneumatic fitting so that the bowden tube goes all the way to the heatsink.

I now have it working and the print quality is very good. I have designed my own mount to be compatible with my modified X carriage. The mount directs the air from the heatsink onto the extruded filament, which is great for bridging. I have also added a second fan for additional cooling.

I only print in PLA, this setup would probably overheat if using temperatures of 230+C

again, thanks for all the advice.

appjaws - Core XYUV Duet Ethernet Duex5

firmware 3.1.1 Web Interface 3.1.1

Ormerod 1-converted to laser engraver, Duet wifi

OpenSCAD version 2020.07

slic3r-1.3.0, Simplify3D 4.1.2, Cura-4.4.1

Sorry, only registered users may post in this forum.