Omerod Wobble?

Posted by MechaBits

|

Omerod Wobble? January 27, 2016 01:17AM |

Registered: 8 years ago Posts: 1,671 |

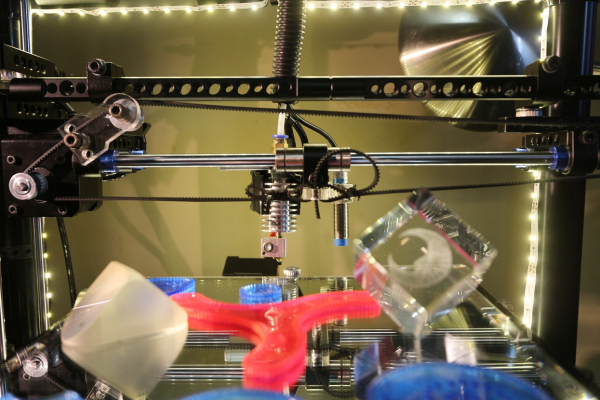

Hi Omerod users, a little survey into wobbles, I was wondering if anyone has any wobble in the design,

mainly X & Z as these are free standing in Z and unsupported on the X in Y direction.

ie with machine at standstill, what happens if you tap the end of X, do you see any wobble, or flick Z,

then what about when carriage is in motion is there any wobble then?

Also in order to minimize any wobble, what do you typically have your speed, accel' & jerk set to.

Thanks

Edited 1 time(s). Last edit at 01/27/2016 02:46AM by MechaBits.

mainly X & Z as these are free standing in Z and unsupported on the X in Y direction.

ie with machine at standstill, what happens if you tap the end of X, do you see any wobble, or flick Z,

then what about when carriage is in motion is there any wobble then?

Also in order to minimize any wobble, what do you typically have your speed, accel' & jerk set to.

Thanks

Edited 1 time(s). Last edit at 01/27/2016 02:46AM by MechaBits.

|

Re: Omerod Wobble? January 27, 2016 07:28AM |

Registered: 10 years ago Posts: 2,472 |

I have no significant wobble on the Z extrusion. The supplied plastic X arm was not all that stable, and the unsupported end could easily be bent (in the Y direction). This could cause issues if the filament did not feed smoothly off the reel - the uneven tension on the extruder via the filament as it came off the reel in jerks would pull the X-arm sideways, causing steps in the print. Fitting the extruder in the slot closest to the Z extrusion helps a lot, and replacing the X-arm with an aluminium part stopped it almost completely.

Dave

Dave

|

Re: Omerod Wobble? January 28, 2016 01:24AM |

Registered: 9 years ago Posts: 176 |

|

Re: Omerod Wobble? January 28, 2016 02:11AM |

Registered: 8 years ago Posts: 1,671 |

No Wobble, good, the movement I'm talking about is more from a deliberate/unnatural tap, eg to the end or table,

things generally move, even my hifi stand has some resonance if tapped(but I have no way to measure how much force i'm adding),

but you can feel the vibrations, not so bad if everything vibrates in sync

or how much it can flex/deviate under a little force around the axis joints

Even with the orig' X bar on, it seems to be able to produce a decent print.

[www.youtube.com]

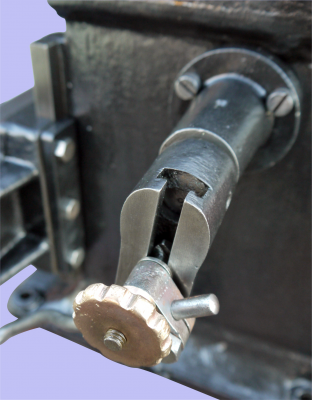

I was aware of the upgrade to increase X stiffness/stability, can't tell from the pics but the aluminium plate looks thick(5+mm?)

does ormerod use 12mm rail all round? if so should be pretty stiff, not as prone to flex/resonance as 8mm,

but it was the link between Z & Y which is plastic, and also on Z - X, that must have some

though I saw an ormerod with 3 heads, looked a little crowded but seemed to hold things up ok.

@VortZA yes the moving mass(which is why I was asking about speeds) looks lighter than say the Printrbot type moving arm, and with 12mm rods, micro wobbles maybe more from bearings or joints, just trying to get a feel for what is acceptable, 0.1 deviation on any axis via a wobble maybe from quick moves, wondering what it might look like(ripple's) in a print.

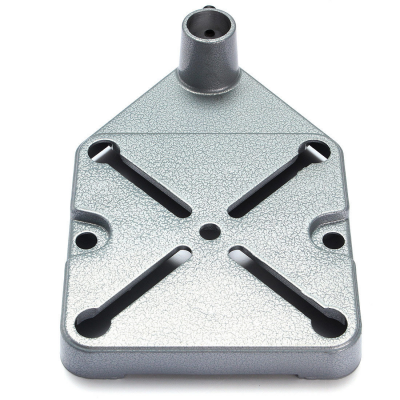

I'm looking for something like this for the base of my Z

but without having to buy the whole drill press, I need this X arrangement of the slots, can anyone recommend a search term, besides face plate, they seem a little expensive.

Edited 4 time(s). Last edit at 01/29/2016 03:16AM by MechaBits.

things generally move, even my hifi stand has some resonance if tapped(but I have no way to measure how much force i'm adding),

but you can feel the vibrations, not so bad if everything vibrates in sync

or how much it can flex/deviate under a little force around the axis joints

Even with the orig' X bar on, it seems to be able to produce a decent print.

[www.youtube.com]

I was aware of the upgrade to increase X stiffness/stability, can't tell from the pics but the aluminium plate looks thick(5+mm?)

does ormerod use 12mm rail all round? if so should be pretty stiff, not as prone to flex/resonance as 8mm,

but it was the link between Z & Y which is plastic, and also on Z - X, that must have some

though I saw an ormerod with 3 heads, looked a little crowded but seemed to hold things up ok.

@VortZA yes the moving mass(which is why I was asking about speeds) looks lighter than say the Printrbot type moving arm, and with 12mm rods, micro wobbles maybe more from bearings or joints, just trying to get a feel for what is acceptable, 0.1 deviation on any axis via a wobble maybe from quick moves, wondering what it might look like(ripple's) in a print.

I'm looking for something like this for the base of my Z

but without having to buy the whole drill press, I need this X arrangement of the slots, can anyone recommend a search term, besides face plate, they seem a little expensive.

Edited 4 time(s). Last edit at 01/29/2016 03:16AM by MechaBits.

|

Re: Omerod Wobble? January 29, 2016 06:07AM |

Registered: 8 years ago Posts: 1,671 |

O' me Rod...is Black!

Looks like my R ain't working, or I been picking up bad pronunciation from china,

Ormerod users feel free to chip in

Looks like my R ain't working, or I been picking up bad pronunciation from china,

Ormerod users feel free to chip in

|

Re: Omerod Wobble? December 19, 2016 04:09AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Omerod Wobble? December 19, 2016 07:20AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Omerod Wobble? December 21, 2016 05:17AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Omerod Wobble? December 29, 2016 03:38AM |

Registered: 10 years ago Posts: 776 |

Quote

MechaBits

I'm looking for something like this for the base of my Z

but without having to buy the whole drill press, I need this X arrangement of the slots, can anyone recommend a search term, besides face plate, they seem a little expensive.

Hi,

I could probably machine something like that from solid for you, would need dimensions etc to get a firm idea of what is needed.

Yes the arms are 5mm plate on the strengthening kits.

Dave

Edited 2 time(s). Last edit at 12/29/2016 03:40AM by Davek0974.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Omerod Wobble? January 03, 2017 02:43PM |

Registered: 8 years ago Posts: 1,671 |

Hi Dave thanks for the reply & offer, this thread was done some time back so the need for that piece has passed(for now), my ideal piece would need to be longer so it can also support Y and allow Z to free stand, but I found some kitchen worktop, 3 pieces, 2" thick, grey n glitter...just right to pimp up my machine base, I'd previously tried getting the 4 holes in wood positioned correct, but didnt end up with perfect drill holes as i have no press drill....but I decided when I got these worktops to get the compass set out and mark things up as good as I could....and it worked great...I would like to add the holes in the base for the Y rails & any motors I wanted to countersink into base...but that's something for the future.

Though I could do with some bed supports, but need something different to what you have listed.

Though I could do with some bed supports, but need something different to what you have listed.

Sorry, only registered users may post in this forum.