I made a belt driven/feeding extruder

Posted by fotomas

|

I made a belt driven/feeding extruder February 24, 2016 03:06AM |

Registered: 9 years ago Posts: 191 |

I few weeks back I read a post about a belt driven extruder:

[forums.reprap.org]

I thought the design looked a bit too complicated so I quickly threw together a simple draft in a CAD program. (pics in the post linked above)

But the idea stuck with me. So I started designing a real extruder based on my idea.

(further down the line I have found designs based on the same concept but with some major differences)

It has been great fun now I have completed the first version and it worked on the first try.

How does it perform then?

I works just fine, it feeds the filament quietly and smoothly. It is easy to feed when changing filament.

I was worried about the grip on the filament but that is more than enough.

The only thing that is worth mentioning is that the torque of the stepper motor just enough when running it at 1200 mA.

To make the design as simple as possible I have skipped any reduction between the the stepper motor and the filament.

So the parameters I have to play with is the size of the pulley and how many Amps is fed to the stepper motor.

I have read on the forum that I can go even higher on the Amps but then I would probably need cooling of the duet,

somthing I do not want. I want it to be as simple as possible.

I have tried to print a smaller pulley to gain som more momentum but did not turn out well due to the small diameter

of the pully and not sharp enough teeth when printing with a .5 mm nozzle. So I have stuck with an aluminium pulley bought on E-bay.

So printing at low temperatures and relatively high speed the stepper motor will skip steps. When the skipping occurs it

so far between the skips that it does not seem to affect the print. (The stepper keeps the pressure up dispite the skipping)

And In all my tests it has been very few time the conditions has been such that it skips.

It has been an interesting experiment and I will keep the extruder running on my second nozzle.

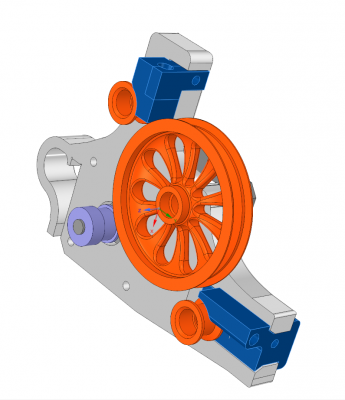

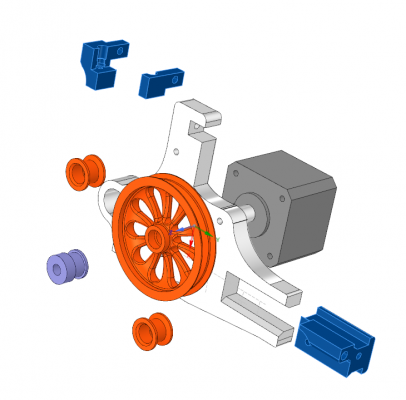

It is constructed of:

7 printed parts,

5 M3 bolts with washers and nuts

4 ball bearings (salvaged from PC cooling fans)

1 212 mm GT2 belt

1 16 teeth GT2 pulley

Assembled view:

Exploded view:

Video of it in action:

[youtu.be]

[forums.reprap.org]

I thought the design looked a bit too complicated so I quickly threw together a simple draft in a CAD program. (pics in the post linked above)

But the idea stuck with me. So I started designing a real extruder based on my idea.

(further down the line I have found designs based on the same concept but with some major differences)

It has been great fun now I have completed the first version and it worked on the first try.

How does it perform then?

I works just fine, it feeds the filament quietly and smoothly. It is easy to feed when changing filament.

I was worried about the grip on the filament but that is more than enough.

The only thing that is worth mentioning is that the torque of the stepper motor just enough when running it at 1200 mA.

To make the design as simple as possible I have skipped any reduction between the the stepper motor and the filament.

So the parameters I have to play with is the size of the pulley and how many Amps is fed to the stepper motor.

I have read on the forum that I can go even higher on the Amps but then I would probably need cooling of the duet,

somthing I do not want. I want it to be as simple as possible.

I have tried to print a smaller pulley to gain som more momentum but did not turn out well due to the small diameter

of the pully and not sharp enough teeth when printing with a .5 mm nozzle. So I have stuck with an aluminium pulley bought on E-bay.

So printing at low temperatures and relatively high speed the stepper motor will skip steps. When the skipping occurs it

so far between the skips that it does not seem to affect the print. (The stepper keeps the pressure up dispite the skipping)

And In all my tests it has been very few time the conditions has been such that it skips.

It has been an interesting experiment and I will keep the extruder running on my second nozzle.

It is constructed of:

7 printed parts,

5 M3 bolts with washers and nuts

4 ball bearings (salvaged from PC cooling fans)

1 212 mm GT2 belt

1 16 teeth GT2 pulley

Assembled view:

Exploded view:

Video of it in action:

[youtu.be]

|

Re: I made a belt driven/feeding extruder February 24, 2016 04:12PM |

Registered: 9 years ago Posts: 638 |

|

Re: I made a belt driven/feeding extruder February 24, 2016 04:29PM |

Registered: 9 years ago Posts: 191 |

So far have seen a few benefits, but nothing major.

- The need of a hobbed insert (there were discussions about getting hold of the correct type of hobbed insert after reprappro closed down)

- No markings in the filament of a hobbed insert (if that counts as a benefit)

- Silent, it almost makes no sound at all.

I bought the belt like that, it is tensioned as hars as the other belts on the printer so putting it together will probably be very difficult.

But the type of belt an pulley makes no difference, I just picked GT2 since that is what is used on the Ormerod.

- The need of a hobbed insert (there were discussions about getting hold of the correct type of hobbed insert after reprappro closed down)

- No markings in the filament of a hobbed insert (if that counts as a benefit)

- Silent, it almost makes no sound at all.

I bought the belt like that, it is tensioned as hars as the other belts on the printer so putting it together will probably be very difficult.

But the type of belt an pulley makes no difference, I just picked GT2 since that is what is used on the Ormerod.

|

Re: I made a belt driven/feeding extruder February 25, 2016 03:04AM |

Registered: 10 years ago Posts: 14,672 |

Nice design! You can increase the torque by using a longer stepper motor. Be sure to get one with a rated current that the Duet can drive.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: I made a belt driven/feeding extruder February 25, 2016 06:59AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Darathy

Looks nice, what would the benefits be? how did you weld the belt together or did you purchease it like that?

The main benefits are:- 1) No hobbed part to get clogged with plastic dust. 2) Slippages will not result in a groove being ground into the filament that prevents further feeding. 3) No high-pressure pinch point that can cause some filaments to become brittle and break if left in the extruder.

You can find many different sizes of toothed belt that are already joined (e.g. [uk.rs-online.com] )

Dave

|

Re: I made a belt driven/feeding extruder February 25, 2016 07:15AM |

Registered: 9 years ago Posts: 191 |

Quote

dc42

Nice design! You can increase the torque by using a longer stepper motor. Be sure to get one with a rated current that the Duet can drive.

That thought has crossed my mind but since I wanted this design to be a simple switch from the original extruder without any expensive parts required.

I already had the bolts, bearings and filament so cost me about 13£ for a pulley, belt and postage. I even tried to print my own pulley, without success.

This left me with software tweaking and smallest avaliable pulley..... or somthing I havent thought of yet that someone will point out in this thread

|

Re: I made a belt driven/feeding extruder February 25, 2016 07:52AM |

Registered: 9 years ago Posts: 1,699 |

The Ormerod uses a MXL-belt by the way, but very nice design.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder February 25, 2016 09:33AM |

Registered: 9 years ago Posts: 638 |

|

Re: I made a belt driven/feeding extruder February 25, 2016 09:38AM |

Registered: 9 years ago Posts: 1,699 |

What is the advantage of gears?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder February 25, 2016 11:08AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

What is the advantage of gears?

Gears would solve the issue stated by the OP that the motor has barely enough power to feed the filament even when driven at 1200mA. It would allow the motor current to be reduced while still having plenty sufficient power to feed even at higher speeds and/or higher viscosities.

Dave

|

Re: I made a belt driven/feeding extruder February 25, 2016 12:55PM |

Registered: 9 years ago Posts: 638 |

I would be interested in testing this extruder ,Would you mind sharing the design or STLs?

Adding gears would probably make the extruder a bit bigger but you could use the original gears from Ormerod and incorporate into the design.

Edited 1 time(s). Last edit at 02/25/2016 12:55PM by Darathy.

Adding gears would probably make the extruder a bit bigger but you could use the original gears from Ormerod and incorporate into the design.

Edited 1 time(s). Last edit at 02/25/2016 12:55PM by Darathy.

|

Re: I made a belt driven/feeding extruder February 25, 2016 01:08PM |

Registered: 9 years ago Posts: 191 |

I wanted to keep things as simple as possible, so I stayed away from gears as long as possible.

I have played with the idea of a worm gear on the stepper motor for a compact solution. Using the original gears would definitely be possible too.

Hmm ideas are starting to grow...

Since there is interest in making one I will post it on thingiverse later (asap) Will post link here.

I have played with the idea of a worm gear on the stepper motor for a compact solution. Using the original gears would definitely be possible too.

Hmm ideas are starting to grow...

Since there is interest in making one I will post it on thingiverse later (asap) Will post link here.

|

Re: I made a belt driven/feeding extruder February 27, 2016 05:49AM |

Registered: 9 years ago Posts: 191 |

|

Re: I made a belt driven/feeding extruder February 27, 2016 07:16AM |

Registered: 9 years ago Posts: 638 |

|

Re: I made a belt driven/feeding extruder February 27, 2016 07:24AM |

Registered: 9 years ago Posts: 638 |

[www.ebay.com]

if anyone does not have any PC cooling fans

Found the above to have expensive shipping....

so heres an alternative: [www.avidrc.com]

Edited 1 time(s). Last edit at 02/27/2016 08:09AM by Darathy.

if anyone does not have any PC cooling fans

Found the above to have expensive shipping....

so heres an alternative: [www.avidrc.com]

Edited 1 time(s). Last edit at 02/27/2016 08:09AM by Darathy.

|

Re: I made a belt driven/feeding extruder February 27, 2016 07:33AM |

Registered: 9 years ago Posts: 191 |

Quote

Darathy

Nice ,thanks. Btw where did u buy that orange Fillament? it looks nice!

Looks like the do not carry that color any more. Here's yellow.

[www.3dprima.com]

|

Re: I made a belt driven/feeding extruder February 28, 2016 08:31AM |

Registered: 9 years ago Posts: 1,699 |

Quote

fotomas

Quote

Darathy

Nice ,thanks. Btw where did u buy that orange Fillament? it looks nice!

Looks like the do not carry that color any more. Here's yellow.

[www.3dprima.com]

You linked to the Orange spool?

What is written on the small label on your spool? PLA or PLA+? 3DPrima switched to PLA+ last summer. You could also look for eSun that is the original brand.

Unfortunately I would have to change your design a little bit before I could try it because I switched to pneumatic fitting and I have no brass connector for the PTFE-tube.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder February 28, 2016 09:48AM |

Registered: 9 years ago Posts: 191 |

I can easily adapt the design for you. Just tell me the size of the hole; diameter and depth.

This is the label on the spool:

This is the label on the spool:

|

Re: I made a belt driven/feeding extruder February 28, 2016 02:14PM |

Registered: 9 years ago Posts: 1,699 |

Okay this spool is not available anymore according to 3DPrima as they changed to PLA+. I have a normal pneumatic fitting with a thread of M5, the length should be something about 2 or 3 mm.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder February 28, 2016 02:50PM |

Registered: 9 years ago Posts: 191 |

Regarding the hole, I will make it 4,5 mm (4.2 is the correct size for tapping M5) plus some margin for the printer making it smaller.

The hole should be shallow enough for the pneumatic fitting to hit the bottom. Otherwise the is a small risk that the filament catches the edge of the pneumatic fitting when loading filament.

I will make it 4.5 x 3 (2 seems too shallow).

--- Edit: Part uploaded to Thingiverse ---

Edited 1 time(s). Last edit at 02/28/2016 02:57PM by fotomas.

The hole should be shallow enough for the pneumatic fitting to hit the bottom. Otherwise the is a small risk that the filament catches the edge of the pneumatic fitting when loading filament.

I will make it 4.5 x 3 (2 seems too shallow).

--- Edit: Part uploaded to Thingiverse ---

Edited 1 time(s). Last edit at 02/28/2016 02:57PM by fotomas.

|

Re: I made a belt driven/feeding extruder February 29, 2016 04:46PM |

Registered: 9 years ago Posts: 638 |

|

Re: I made a belt driven/feeding extruder March 01, 2016 12:37AM |

Registered: 9 years ago Posts: 191 |

Quote

Darathy

I cant seem to find a 212mm GT2 belt

My bad, I am so so sorry. It should be 224 mm.

I bought this one:

[m.ebay.co.uk]

|

Re: I made a belt driven/feeding extruder March 20, 2016 11:59AM |

Registered: 9 years ago Posts: 1,699 |

I ordered the missing parts by today. I need 693ZZ bearings and I bought a 232-2GT-6 belt as it was easier to get.

Even though I have a GT2-pulley I am wondering if a printed one would do the job as well. Maybe I equip my MK1 with the printed version and my MK2 with the aluminum version.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Even though I have a GT2-pulley I am wondering if a printed one would do the job as well. Maybe I equip my MK1 with the printed version and my MK2 with the aluminum version.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder March 20, 2016 12:22PM |

Registered: 9 years ago Posts: 191 |

I have tried to print a pulley. It failed for me, it did not get enough grip. Probably due to the small diameter and a .5 mm nozzle. A bigger pulley would probably work but all avaliable torque is needed. So my conclusion is that an aluminium pulley is required.

Profile of the teeth (MXL, GT2 etc.) does not matter as long as the belt is of proper length and width.

Today I tried to feed TPU filament through and it does NOT work with current design. The filament bends between leaving the big wheel and entering the bowden tube. To make it work the gap has to be reduced to a minimum.

I will try to come up with a design that fixes this, without modifying the frame, just the parts clamping the bowden tube.

Profile of the teeth (MXL, GT2 etc.) does not matter as long as the belt is of proper length and width.

Today I tried to feed TPU filament through and it does NOT work with current design. The filament bends between leaving the big wheel and entering the bowden tube. To make it work the gap has to be reduced to a minimum.

I will try to come up with a design that fixes this, without modifying the frame, just the parts clamping the bowden tube.

|

Re: I made a belt driven/feeding extruder March 20, 2016 12:31PM |

Registered: 9 years ago Posts: 1,699 |

Everybody says in my FB-groups that TPU will not work with a Bowden Extruder. I haven't tested it yet, but I have some filament here with a really nice color. Maybe I should print the belt, too.

I will have to wait for the parts to arrive and meanwhile I can repair both printers. My MK2 with a 0.4mm nozzle may be able to print a pulley and maybe it would be a good idea to print it in PETG.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I will have to wait for the parts to arrive and meanwhile I can repair both printers. My MK2 with a 0.4mm nozzle may be able to print a pulley and maybe it would be a good idea to print it in PETG.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder March 20, 2016 12:46PM |

Registered: 9 years ago Posts: 191 |

I have managed to make it work pretty well. So those saying that is does not maybe not tried for them selves?

Anyway this is one of the things I have printed:

[www.thingiverse.com]

Of course it requires it's own set of settings when slicing.

Edited 1 time(s). Last edit at 03/20/2016 12:48PM by fotomas.

Anyway this is one of the things I have printed:

[www.thingiverse.com]

Of course it requires it's own set of settings when slicing.

Edited 1 time(s). Last edit at 03/20/2016 12:48PM by fotomas.

|

Re: I made a belt driven/feeding extruder March 20, 2016 01:07PM |

Registered: 9 years ago Posts: 1,699 |

Quote

fotomas

Of course it requires it's own set of settings when slicing.

I guess that this is the problem. Probably it's only harder to use it.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

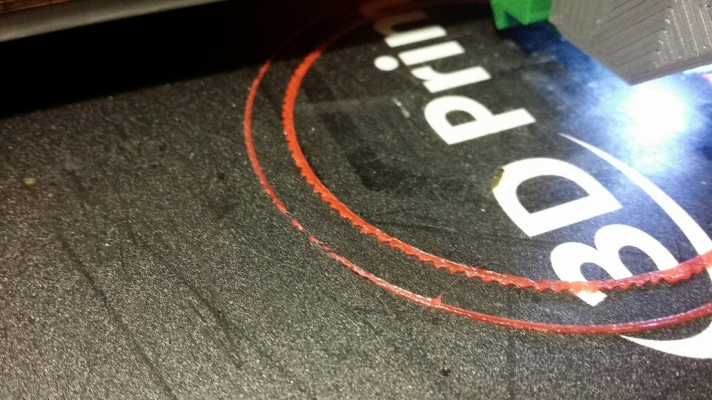

Re: I made a belt driven/feeding extruder March 20, 2016 03:14PM |

Registered: 9 years ago Posts: 191 |

Treito: You got me thinking... why not. So I have to try it, most likely I will fail but maybe, just maybe it could work.

So here goes; printing a GT2 belt:

While printing I got thinking with coarser teeth on the belt a printed pulley may work too, who knows....

If that would work we are down to only bolts and bearings for the whole belt feeder/extruder. That would really be simplistic. One can dream...

So here goes; printing a GT2 belt:

While printing I got thinking with coarser teeth on the belt a printed pulley may work too, who knows....

If that would work we are down to only bolts and bearings for the whole belt feeder/extruder. That would really be simplistic. One can dream...

|

Re: I made a belt driven/feeding extruder March 20, 2016 04:37PM |

Registered: 9 years ago Posts: 1,699 |

You are crazy.

I just disassembled my MK2. I also dreamt about printing too much parts. The bed support looked awful.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I just disassembled my MK2. I also dreamt about printing too much parts. The bed support looked awful.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder March 22, 2016 05:14AM |

Registered: 9 years ago Posts: 191 |

I have made two attempts to print a belt of TPU filament.

The first belt I drew exact to the spec of GT2 2 mm pitch. That looked nice but was to thin so the belt flexed too much under tension. The teeth were not sharp enough so the grip on the aluminium pulley was not good enough.

I then redesigned the belt to be thicker and higher teeth. That gave a much better result in terms of grip and flexing. Unfortunately the TPU caused some trouble. When the printer was changing layer the residual pressure in the nozzle squeezes out extra plastic in the beginning of the next layer, clogging the teeth in the printed belt.

Retraction is not working so well with flexible filaments and a bowden tube so I am thinking of testing dc42's firmware feature that gradually reduces the pressure to the end of the layer.

But over all I am beginning to think that this may actually work. My experiments continue....

The first belt I drew exact to the spec of GT2 2 mm pitch. That looked nice but was to thin so the belt flexed too much under tension. The teeth were not sharp enough so the grip on the aluminium pulley was not good enough.

I then redesigned the belt to be thicker and higher teeth. That gave a much better result in terms of grip and flexing. Unfortunately the TPU caused some trouble. When the printer was changing layer the residual pressure in the nozzle squeezes out extra plastic in the beginning of the next layer, clogging the teeth in the printed belt.

Retraction is not working so well with flexible filaments and a bowden tube so I am thinking of testing dc42's firmware feature that gradually reduces the pressure to the end of the layer.

But over all I am beginning to think that this may actually work. My experiments continue....

Sorry, only registered users may post in this forum.