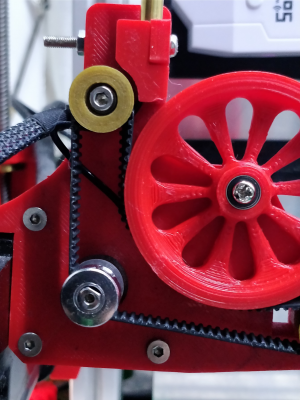

I made a belt driven/feeding extruder

Posted by fotomas

|

Re: I made a belt driven/feeding extruder March 22, 2016 05:20AM |

Registered: 9 years ago Posts: 1,699 |

As far as I know there are two versions of NinjaFlex available with different flexibility. Maybe the one with less flexibility would be more suitable for this job. At the moment I have no good working printer and also only bearings with an outer diameter of 9mm instead of 8mm. Otherwise I would have joined the test with my TPU filament from SainSmart.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder March 22, 2016 05:46AM |

Registered: 9 years ago Posts: 191 |

The design stops me from changing the inner diameter for the roller to 9 mm. Otherwise I would have done that for you.

The roller gets to thin with five mm and a thicker/bigger roller would not fit without modifying the position of the rollers.

The TPU I am testing with I have forgotten the brand of but I have a roll of Torwell TPE that is a bit stiffer but harder to get to stick to the bed. When I have a design and printing method that works I will try that filament. It is easier to fix one problem at the time...

The roller gets to thin with five mm and a thicker/bigger roller would not fit without modifying the position of the rollers.

The TPU I am testing with I have forgotten the brand of but I have a roll of Torwell TPE that is a bit stiffer but harder to get to stick to the bed. When I have a design and printing method that works I will try that filament. It is easier to fix one problem at the time...

|

Re: I made a belt driven/feeding extruder March 22, 2016 06:13AM |

Registered: 9 years ago Posts: 1,699 |

It's not recommended to fix more than one problem at a time. I ordered 30 pieces of 693ZZ bearings in total, but they will arrive in about 3 weeks.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: I made a belt driven/feeding extruder March 22, 2016 08:11AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: I made a belt driven/feeding extruder March 22, 2016 08:46AM |

Registered: 9 years ago Posts: 191 |

|

Re: I made a belt driven/feeding extruder March 22, 2016 08:54AM |

Registered: 9 years ago Posts: 191 |

|

Re: I made a belt driven/feeding extruder March 22, 2016 09:52AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: I made a belt driven/feeding extruder April 10, 2016 12:02PM |

Registered: 9 years ago Posts: 638 |

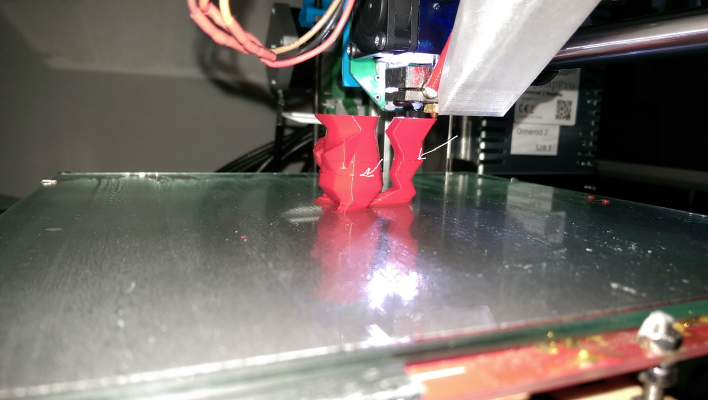

I have made one of these ,and seems to work but i got a few lines where there was sparese layer or something( it could be from overcooling i am not sure, i'll have to retry it)

Edited 3 time(s). Last edit at 04/10/2016 03:37PM by Darathy.

Edited 3 time(s). Last edit at 04/10/2016 03:37PM by Darathy.

|

Re: I made a belt driven/feeding extruder April 12, 2016 02:15PM |

Registered: 9 years ago Posts: 191 |

Wow great to se that it works for you. It brings me great joy that you went through the effort to make one.

My guess is that for some reason at that point in the print the resistance for pushing the filament through the nozze got tio great for the tourqe that the extruder can deliver.

As you are saying it could be cooling and\or the shaoe of the print.

I havet also hade the exact same phenomen in som of my prints.

I would recomend slower and hotter prints and maybe higher current to the stepper motor. What do you have it set to now?

The lack of torque seems to be the weak spot for this design. Do you have any ideas for improvements?

Edited 1 time(s). Last edit at 04/12/2016 02:16PM by fotomas.

My guess is that for some reason at that point in the print the resistance for pushing the filament through the nozze got tio great for the tourqe that the extruder can deliver.

As you are saying it could be cooling and\or the shaoe of the print.

I havet also hade the exact same phenomen in som of my prints.

I would recomend slower and hotter prints and maybe higher current to the stepper motor. What do you have it set to now?

The lack of torque seems to be the weak spot for this design. Do you have any ideas for improvements?

Edited 1 time(s). Last edit at 04/12/2016 02:16PM by fotomas.

|

Re: I made a belt driven/feeding extruder April 12, 2016 02:42PM |

Registered: 9 years ago Posts: 638 |

I dont know i suspect my E3D nozzle is getting blocked somehow ,but i will have to try with my original extruder.

I have set the current to 1200 as you susggested, but it does start to skip steps sometimes and then skips all time when i tried to print 3Dbenchy and ruined the print but as said before it somehow gets cloged or something.

I have set the current to 1200 as you susggested, but it does start to skip steps sometimes and then skips all time when i tried to print 3Dbenchy and ruined the print but as said before it somehow gets cloged or something.

|

Re: I made a belt driven/feeding extruder April 12, 2018 01:59PM |

Registered: 10 years ago Posts: 147 |

Hey,

Thanks for the design.

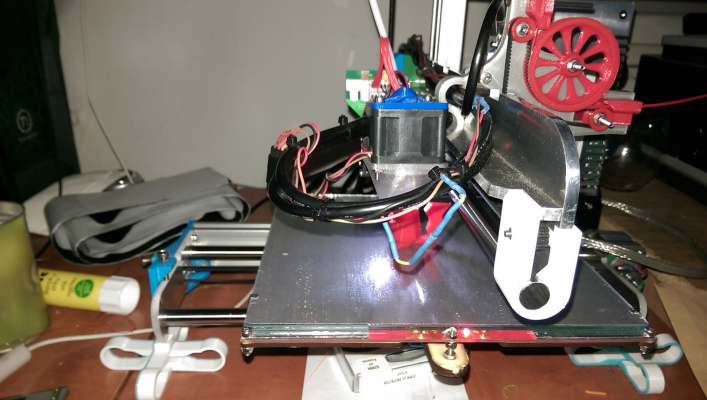

Originally I printed the frame in PLA but due to the heat of my stepper motor the frame soon distorted. I managed to print in ABS and it was alot stronger.

More often now I see that the filament is getting kinked and it stops extruding (please see attached photo)

Do you know of any way to combat this issue?

Thanks for the design.

Originally I printed the frame in PLA but due to the heat of my stepper motor the frame soon distorted. I managed to print in ABS and it was alot stronger.

More often now I see that the filament is getting kinked and it stops extruding (please see attached photo)

Do you know of any way to combat this issue?

Sorry, only registered users may post in this forum.