USB fixed!

Posted by ZeAllan

|

USB fixed! March 25, 2016 07:04PM |

Registered: 10 years ago Posts: 46 |

Hi,

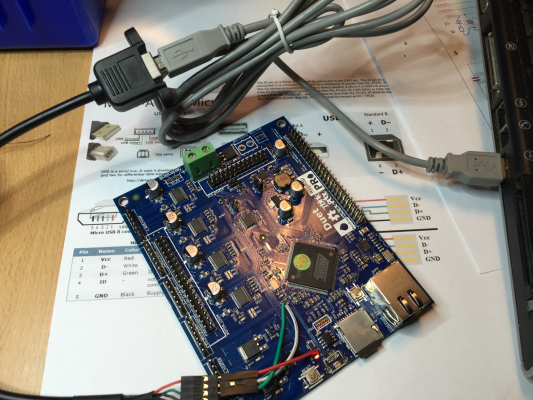

After waiting for ages (since LAN was fine for printing) I finally managed to get my firmware upgraded despite having torn off the USB plug on my Duet ages ago.

Strange thing:The town is full of shops repairing cellphones, which one would assume includes things like USB plugs -- yet whenever I would turn up with my duet and the torn plug to ask if they could solder it back on since they had both the tools and skills, they would look like they had never seen a USB plug before and deny being able to do such black magic.

Anyway, now I am finally ready to upgrade to dual colour. That will teach me to wait I guess. :-/

Is there a way to get the upgrade now that RRP has closed -- or should I just go for a Diamond Hotend instead?

/Allan

After waiting for ages (since LAN was fine for printing) I finally managed to get my firmware upgraded despite having torn off the USB plug on my Duet ages ago.

Strange thing:The town is full of shops repairing cellphones, which one would assume includes things like USB plugs -- yet whenever I would turn up with my duet and the torn plug to ask if they could solder it back on since they had both the tools and skills, they would look like they had never seen a USB plug before and deny being able to do such black magic.

Anyway, now I am finally ready to upgrade to dual colour. That will teach me to wait I guess. :-/

Is there a way to get the upgrade now that RRP has closed -- or should I just go for a Diamond Hotend instead?

/Allan

|

Re: USB fixed! March 26, 2016 04:50AM |

Registered: 10 years ago Posts: 14,672 |

Two suggestions:

1. Ask user deckingman about his experiences with the diamond hot end. He has a Duet powered Mendel fitted with one, see [forums.reprap.org].

2. Ask emakershop whether they can supply the nozzles, heater block etc. for the 2-colour upgrade. For the electronics, you can use either the Duet Shield if there are any still available, or the DueX4 from T3P3.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Ask user deckingman about his experiences with the diamond hot end. He has a Duet powered Mendel fitted with one, see [forums.reprap.org].

2. Ask emakershop whether they can supply the nozzles, heater block etc. for the 2-colour upgrade. For the electronics, you can use either the Duet Shield if there are any still available, or the DueX4 from T3P3.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: USB fixed! March 26, 2016 10:21PM |

Registered: 8 years ago Posts: 68 |

|

Re: USB fixed! March 27, 2016 11:48AM |

Registered: 8 years ago Posts: 123 |

Quote

ZeAllan

Is there a way to get the upgrade now that RRP has closed -- or should I just go for a Diamond Hotend instead?

I made this list of components for a dual extruder for my 528.4 Ormerod 2

I've left the ability to put comments on it, which I can then merge in, if anyone feels like adding to it to develop this into a useful resource.

I was just about to purchase when I saw an Ormerod 2 on eBay with a dual extruder (but no Duet board), so I bought that instead for the extruders and spares.

Edited 1 time(s). Last edit at 03/27/2016 11:55AM by cheeseandham.

|

Re: USB fixed! March 28, 2016 06:10AM |

Registered: 8 years ago Posts: 45 |

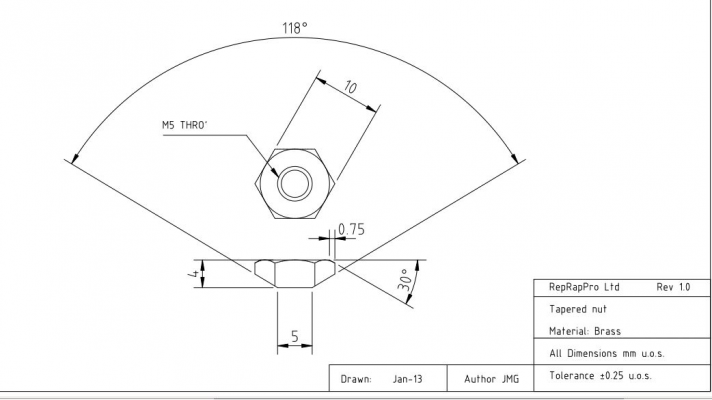

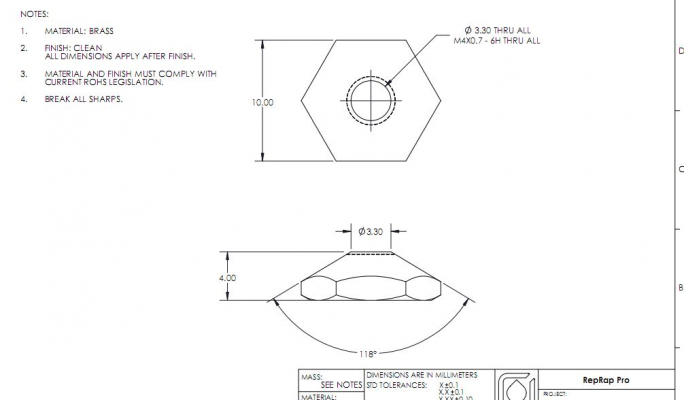

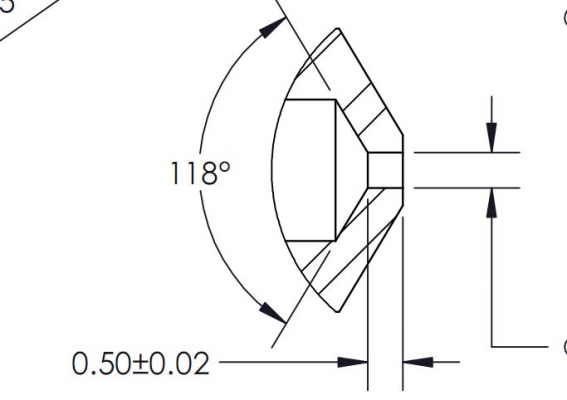

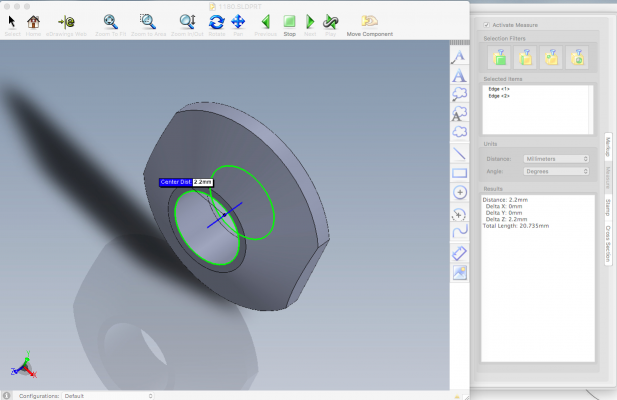

The Quick set brass nut you have shown is for the Fisher not the Ormerod. Whilst they are both M4 thread I think the Ormerod nut is 4mm thick whilst the Fisher is 2.2 mm thick. I've just ordered one to try it out and decided there are two options.

1) Screw the nozzle into the heater block but not all the way in. If using a 0.3 nozzle, which seems to be the only one available, I wonder if that might be a problem as the extrusion rate is quite slow anyway and less efficient heating of the nozzle chamber may either slow it to a crawl or possibly cause blockages.

2) Add a spacer of 1.8mm between the heater block and nozzle. This would need to have good thermal transfer.

Using the 0.3 nozzle I also found that I needed to upgrade the extruder to a spring loaded version, I also added herringbone gears at the same time.

The acrylic spacer (741.2.dxf) can be imported into OpenSCAD and printed in ABS. The command I used was:-

linear_extrude(height = 5)

import("741.dxf");

1) Screw the nozzle into the heater block but not all the way in. If using a 0.3 nozzle, which seems to be the only one available, I wonder if that might be a problem as the extrusion rate is quite slow anyway and less efficient heating of the nozzle chamber may either slow it to a crawl or possibly cause blockages.

2) Add a spacer of 1.8mm between the heater block and nozzle. This would need to have good thermal transfer.

Using the 0.3 nozzle I also found that I needed to upgrade the extruder to a spring loaded version, I also added herringbone gears at the same time.

The acrylic spacer (741.2.dxf) can be imported into OpenSCAD and printed in ABS. The command I used was:-

linear_extrude(height = 5)

import("741.dxf");

|

Re: USB fixed! March 28, 2016 08:13AM |

Registered: 10 years ago Posts: 1,230 |

Quote

trevmas

The Quick set brass nut you have shown is for the Fisher not the Ormerod. Whilst they are both M4 thread I think the Ormerod nut is 4mm thick whilst the Fisher is 2.2 mm thick.

Ormerod tapered nut, one-piece-nozzle..

..and quick-set-nozzle

Quote

..If using a 0.3 nozzle, which seems to be the only one available..

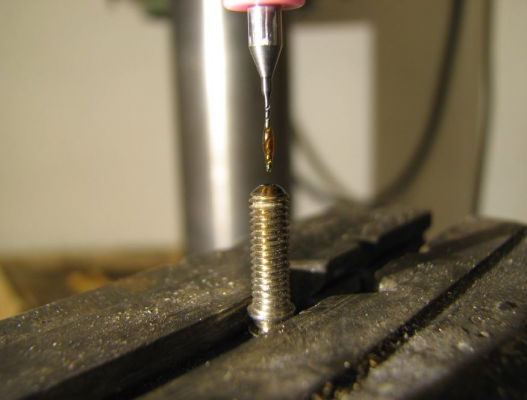

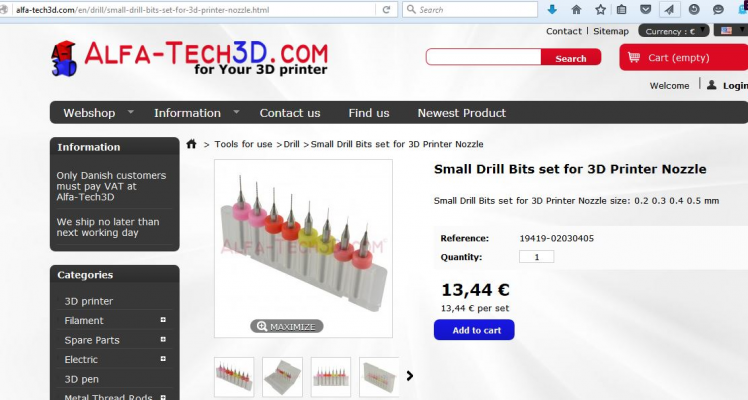

You can easily expand that to 0.5mm with a proper quality drill, the hole is only 0.5mm deep

work slow and ad lots of drilling paste, e.g. Rocol

Erik

|

Re: USB fixed! March 28, 2016 09:46AM |

Registered: 8 years ago Posts: 45 |

Quote

ormerod168

Quote

trevmas

The Quick set brass nut you have shown is for the Fisher not the Ormerod. Whilst they are both M4 thread I think the Ormerod nut is 4mm thick whilst the Fisher is 2.2 mm thick.

Ormerod tapered nut, one-piece-nozzle..

attachment 75477 taperednutone-piece-nozzle.JPG

..and quick-set-nozzle

attachment 75478 taperednutquick-set-nozzle.JPG

But neither of those are the Fisher nut quoted in the spreadsheet which seems to be the only tapered nut available on eMakershop

I couldn't find the drawings for the Fisher tapered nut, only the solidworks file.

As you can see it is only 2.2 mm deep whilst the quickset tapered nut is 4 mm deep as shown on the drawing you attached.

Quote

ormerod168

Quote

..If using a 0.3 nozzle, which seems to be the only one available..

You can easily expand that to 0.5mm with a proper quality drill, the hole is only 0.5mm deep

work slow and ad lots of drilling paste, e.g. Rocol

Erik

Yes I had thought of drilling a compromise nozzle at 0.4 which seems a popular size elsewhere, but you would need to be very accurate in your drilling, very square with next to no runout in your drill. Probably best to mount it in a lathe if you have access to one.

Not everyone feels confident enough to start drilling parts though and would like to use off the shelf components which are not all available.

|

Re: USB fixed! March 29, 2016 05:49AM |

Registered: 8 years ago Posts: 123 |

Quote

trevmas

The Quick set brass nut you have shown is for the Fisher not the Ormerod. Whilst they are both M4 thread I think the Ormerod nut is 4mm thick whilst the Fisher is 2.2 mm thick.

Quote

trevmas

If using a 0.3 nozzle, which seems to be the only one available

Yes, thank you for highlighting that. I was aware of these shortcomings at the time, but I forgot by the time I posted (as the document was originally only intended for me).

I figured I'd have to see if/how it worked and hack from there.

Then a second-hand Ormerod 2 popped up on a search at eBay, and the spreadsheet was abandoned.

Please let us know how it goes!

(edit) P.S. It seems a 0.5mm nozzle has appeared on eMaker - adding to the sheet

Edited 1 time(s). Last edit at 03/29/2016 05:56AM by cheeseandham.

|

Re: USB fixed! March 29, 2016 07:17AM |

Registered: 10 years ago Posts: 2,472 |

Quote

ZeAllan

Strange thing:The town is full of shops repairing cellphones, which one would assume includes things like USB plugs -- yet whenever I would turn up with my duet and the torn plug to ask if they could solder it back on since they had both the tools and skills, they would look like they had never seen a USB plug before and deny being able to do such black magic.

Probably because they don't! The USB plug on cellphones is typically mounted on a separate small PCB (often together with a couple of pushbuttons and some SMD components), and repair shops usually replace the entire PCB assembly. There are few places that do repairs down to component level. Typically a USB connector that has been damaged by rough handling will have torn off the PCB tracks, and so replacement of the connector would not be possible in any case. A friend of mine does cellphone repairs and seldom needs to use a soldering iron. By far the most common repair is a broken screen, which needs special tools to remove the old screen and a UV box to cure the epoxy used to attach the new screen.

Dave

|

Re: USB fixed! March 29, 2016 07:23AM |

Registered: 8 years ago Posts: 45 |

Hmm that isn't a quickset nozzle so it wouldn't be any good to me, though it may be to others.

Also the matching tapered brass nut is sold out by emaker and not offered by reprapltd, the two accounts selling off the reprappro stock

[www.emakershop.com]

|

Re: USB fixed! March 31, 2016 03:14PM |

Registered: 10 years ago Posts: 46 |

Thanks for the replies.

I got a few spare nozzles from emakershop earlier, but it seems like not all of the components for a full quick-set is in the shop right now. I have a Diamond, meant for an i3 clone that has become rather unstable - so I think I'll try mounting that on the Ormerod instead, just so I go with something that I can get spares for later.

The nozzles I got at emakershop were all 0.3mm, but you make it look like it should be relatively easy to drill them -- that has to be tried one day; they can still be used on my SmartRap then. :-)

You are right, it is living dangerously -- however, the original tracks did not take the first soldering experiments too well, so I think it is safter to keep it like this and print a case where I can mount the plug and prevent it from moving. Perhaps hot-glueing the wires just to be sure.

/Allan

Quote

dc42

1. Ask user deckingman about his experiences with the diamond hot end. (...)

2. Ask emakershop whether they can supply the nozzles, heater block etc. (...)

I got a few spare nozzles from emakershop earlier, but it seems like not all of the components for a full quick-set is in the shop right now. I have a Diamond, meant for an i3 clone that has become rather unstable - so I think I'll try mounting that on the Ormerod instead, just so I go with something that I can get spares for later.

Quote

trevmas

You can easily expand that to 0.5mm with a proper quality drill, the hole is only 0.5mm deep

The nozzles I got at emakershop were all 0.3mm, but you make it look like it should be relatively easy to drill them -- that has to be tried one day; they can still be used on my SmartRap then. :-)

Quote

Vuokko

That USB connector looks one which could be easily be found from digikey or mouser or somewhere. Take a good measurements and find fitting connector. You will burn your board when you connect 5V and GND wrong way.

You are right, it is living dangerously -- however, the original tracks did not take the first soldering experiments too well, so I think it is safter to keep it like this and print a case where I can mount the plug and prevent it from moving. Perhaps hot-glueing the wires just to be sure.

/Allan

|

Re: USB fixed! April 15, 2016 11:09AM |

Registered: 8 years ago Posts: 45 |

Quote

ZeAllan

The nozzles I got at emakershop were all 0.3mm, but you make it look like it should be relatively easy to drill them -- that has to be tried one day; they can still be used on my SmartRap then. :-)

/Allan

My decent 0.4mm drills just arrived from RDG tools so I thought I'd try and drill out one of my 0.3 mm nozzles.

I offered up a drill to the nozzle and it easily dropped straight through. Measured the shank of the drill and it was 0.39 mm, so that was Ok. Fished out an old PCB drill that measures 0.42 mm and that wouldn't go through. Tried my two other 0.3 nozzles and found exactly the same result.

So it seems the 0.3 mm nozzles I got from eMaker shop were 0.4 mm all along. Perhaps that explains why I had difficulty getting decent prints from them!

Checked my spare 0.5 mm nozzle and that seems spot on.

Sorry, only registered users may post in this forum.