Building a more accurate Ormerod

Posted by Firefox3D

|

Building a more accurate Ormerod June 02, 2016 05:25AM |

Registered: 8 years ago Posts: 105 |

This is work in progress, but essentially I wanted to fix some of the precision/reliability issues with the Ormerod design. I am not bashing the design here, for £400 it is a brilliant printer, but from a year or two of use and looking at other designs I know it can be better.

I was initially going to just fix certain aspects of the one I have, but when I started looking I realised it made sense to leave the one I have as is and start over. Mainly so I still have a working printer to use.

The main things that have been a pain are the twisting of the Y rods so accurate bed levelling is difficult to maintain and accurate Z axis movements due to the printed gears. I have already re-designed and printed Z gears and altered the mounting method so the drive is more accurate, but printed gears will always have a small amount of eccentricity due to the way the plastic is laid down.

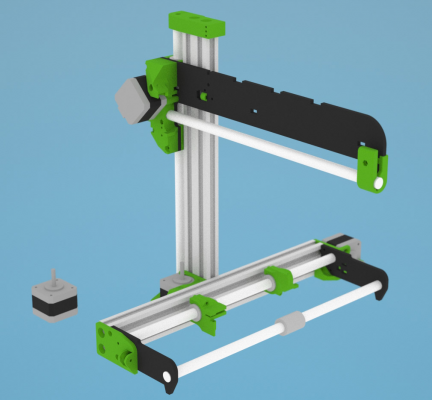

As a start point using the available files I have built a 3D model of the Ormerod 2.

I don't need them but are there dxf files for the bed plywood support parts? I have the complete parts repository but they don't seem to be in there?

Edited 1 time(s). Last edit at 06/02/2016 06:59AM by Firefox3D.

I was initially going to just fix certain aspects of the one I have, but when I started looking I realised it made sense to leave the one I have as is and start over. Mainly so I still have a working printer to use.

The main things that have been a pain are the twisting of the Y rods so accurate bed levelling is difficult to maintain and accurate Z axis movements due to the printed gears. I have already re-designed and printed Z gears and altered the mounting method so the drive is more accurate, but printed gears will always have a small amount of eccentricity due to the way the plastic is laid down.

As a start point using the available files I have built a 3D model of the Ormerod 2.

I don't need them but are there dxf files for the bed plywood support parts? I have the complete parts repository but they don't seem to be in there?

Edited 1 time(s). Last edit at 06/02/2016 06:59AM by Firefox3D.

|

Re: Building a more accurate Ormerod June 02, 2016 07:00AM |

Registered: 10 years ago Posts: 275 |

Hi Firefox3D,

it sounds interesting!

Sure Ormerod can be better

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

it sounds interesting!

Sure Ormerod can be better

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Building a more accurate Ormerod June 02, 2016 08:57AM |

Registered: 8 years ago Posts: 105 |

|

Re: Building a more accurate Ormerod June 02, 2016 10:06AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Firefox3D

Thanks Dario, are those in the repository, did I just miss them?

Latest dxf design should be here:

[github.com]

...according to trevmas:

[forums.reprap.org]

Erik

|

Re: Building a more accurate Ormerod June 02, 2016 11:05AM |

Registered: 9 years ago Posts: 15 |

Dear Firefox3d

One of the cheapest mods that should make your Ormerod more accurate, may be to replace the belts and pulleys with their GT2 equivalent. This means you won't get any rounding errors. Most objects I print and design are using the metric system, so I do find it a bit strange that the printer spends it's time microstepping to the closest imperial value. In reality, it's a small error, and the most that you'll notice is the difference in noise the printer makes.

If you do decide to do this, be careful which GT2 pulleys you buy. Several that I purchased were too large to fit in the hole for the X axis motor drive area. For that pulley specifically, the one place that I managed to get one to fit was from Ooznest. The Y pulley size doesn't matter. (In both cases I bought 20 tooth pulleys). The GT2 tooth profile just about fits in the grooves for the MXL on the printed parts, so you don't have to modify these.

Instead of the printed gears for the Z axis, or even threaded rod at all, it is widely recommended to use trapezoidal leadscrews. You can purchase Nema 17 motors with them built in, in 300mm lengths, which eliminates the need for and any problems that could be caused by the coupler. The latest prusa design by Joseph now has trapezoidal leadscrews.

This isn't so much precision, but reducing wear, which can lead to imprecision. And getting rid of the backlash should make the G32 autocompensation work better. (I've read in a few places that they don't recommend having the autocompensation on when using threaded rod, due to the increased amount of wear it causes).

I have a design on thingiverse where I've started to make up a model of this Z axis mod, and have found a supplier for 8mm diameter, 2mm pitch leadscrew motors which gives a good compromise between speed and accuracy.

If you are designing a printer completely from scratch, then I would recommend looking at the designs for things like lead screen printers etc. One thing that never really caught on in printers is the idea of having the motor on a short loop of belt, and the main belt between two pulleys. This means you can have a much higher tension on the axis, which reduces belt errors. (You need more tension for the length of the belt, and you shouldn't put a lot of axial strain on the motor). This way you can also put a gear ratio on. I've seen 20 tooth and 40 tooth gt2 pulleys going cheaply, so you can easily double the resolution without changing the motors.

Best wishes

Mitch

One of the cheapest mods that should make your Ormerod more accurate, may be to replace the belts and pulleys with their GT2 equivalent. This means you won't get any rounding errors. Most objects I print and design are using the metric system, so I do find it a bit strange that the printer spends it's time microstepping to the closest imperial value. In reality, it's a small error, and the most that you'll notice is the difference in noise the printer makes.

If you do decide to do this, be careful which GT2 pulleys you buy. Several that I purchased were too large to fit in the hole for the X axis motor drive area. For that pulley specifically, the one place that I managed to get one to fit was from Ooznest. The Y pulley size doesn't matter. (In both cases I bought 20 tooth pulleys). The GT2 tooth profile just about fits in the grooves for the MXL on the printed parts, so you don't have to modify these.

Instead of the printed gears for the Z axis, or even threaded rod at all, it is widely recommended to use trapezoidal leadscrews. You can purchase Nema 17 motors with them built in, in 300mm lengths, which eliminates the need for and any problems that could be caused by the coupler. The latest prusa design by Joseph now has trapezoidal leadscrews.

This isn't so much precision, but reducing wear, which can lead to imprecision. And getting rid of the backlash should make the G32 autocompensation work better. (I've read in a few places that they don't recommend having the autocompensation on when using threaded rod, due to the increased amount of wear it causes).

I have a design on thingiverse where I've started to make up a model of this Z axis mod, and have found a supplier for 8mm diameter, 2mm pitch leadscrew motors which gives a good compromise between speed and accuracy.

If you are designing a printer completely from scratch, then I would recommend looking at the designs for things like lead screen printers etc. One thing that never really caught on in printers is the idea of having the motor on a short loop of belt, and the main belt between two pulleys. This means you can have a much higher tension on the axis, which reduces belt errors. (You need more tension for the length of the belt, and you shouldn't put a lot of axial strain on the motor). This way you can also put a gear ratio on. I've seen 20 tooth and 40 tooth gt2 pulleys going cheaply, so you can easily double the resolution without changing the motors.

Best wishes

Mitch

|

Re: Building a more accurate Ormerod June 02, 2016 11:11AM |

Registered: 8 years ago Posts: 105 |

|

Re: Building a more accurate Ormerod June 02, 2016 11:16AM |

Registered: 8 years ago Posts: 105 |

Thanks Mitch, leadscrews were the direction I was heading in for the Z axis for sure.

I did just want a level bed so I can forget about the compensation. Through much fiddling I got my bed to a max deviation of about 0.05mm which is pretty good, but an accidental bump could easily upset it, or just looking at it funny...

Jon

Edited 1 time(s). Last edit at 06/02/2016 11:16AM by Firefox3D.

I did just want a level bed so I can forget about the compensation. Through much fiddling I got my bed to a max deviation of about 0.05mm which is pretty good, but an accidental bump could easily upset it, or just looking at it funny...

Jon

Edited 1 time(s). Last edit at 06/02/2016 11:16AM by Firefox3D.

|

Re: Building a more accurate Ormerod June 02, 2016 12:51PM |

Registered: 9 years ago Posts: 15 |

You're welcome

I have an almost complete cad model of the Ormerod 1, so if you're having trouble converting/finding some parts, I may be able to provide a solution.

Misumi offer several 3d printer designs which it would be good to look at, and igus have several guides on how to design linear axis correctly.

The correct way to do a linear axis is to have one fully constrained rod/bearing setup and one with floating bearings or even floating rod ends. This would reduce the effects of Y twist as much as feasible. Since really, all the second rod does is stop rotation about the first. In an ideal case you'd spend the money and get carriage bearings as they're the most precise.

I have an almost complete cad model of the Ormerod 1, so if you're having trouble converting/finding some parts, I may be able to provide a solution.

Misumi offer several 3d printer designs which it would be good to look at, and igus have several guides on how to design linear axis correctly.

The correct way to do a linear axis is to have one fully constrained rod/bearing setup and one with floating bearings or even floating rod ends. This would reduce the effects of Y twist as much as feasible. Since really, all the second rod does is stop rotation about the first. In an ideal case you'd spend the money and get carriage bearings as they're the most precise.

|

Re: Building a more accurate Ormerod June 02, 2016 06:49PM |

Registered: 8 years ago Posts: 105 |

Thanks again Mitch, never thought of looking for the Nema motors with the leadscrews, seems obvious they exist now.

My head is now swimming with possibilities. My starting point idea is an accurate base, aluminiumwarehouse sell ecocast aluminium sheet which has a surface accuracy of 10 microns and it's not expensive. Linear rails for the X and Y axis would ensure very good accuracy. A quick look around gives prices of around £30 (made in China) to £90 (zappautomation) per rail.

Bed support and non stressed parts I would make from phenolic resin (bakelite/tufnul) as it's stiff but light and is not bothered by heat. Also mainly because a local plastics company use it all the time and sell offcuts cheap

Just to say I have access to a medium sized CNC machine so can make most parts easily.

So a question for the more experienced, are belts a good idea because you can set the gearing, or are leadscrews overall a better idea, but obviously you need the correct type for the resolution needed.

I'm guessing overall max speed and acceleration/directional changes are going to have to be lower with leadscrews, having said that a max print speed of say 40mm/s is fine with me as anything faster seems to create more artefacts. I would rather have better prints than faster.

I realised building the Ormerod model is now probably an exercise in futility as what I am thinking of is so different very little if any part is going to be carried over, oh well.

Jon

Edited 2 time(s). Last edit at 06/02/2016 06:59PM by Firefox3D.

My head is now swimming with possibilities. My starting point idea is an accurate base, aluminiumwarehouse sell ecocast aluminium sheet which has a surface accuracy of 10 microns and it's not expensive. Linear rails for the X and Y axis would ensure very good accuracy. A quick look around gives prices of around £30 (made in China) to £90 (zappautomation) per rail.

Bed support and non stressed parts I would make from phenolic resin (bakelite/tufnul) as it's stiff but light and is not bothered by heat. Also mainly because a local plastics company use it all the time and sell offcuts cheap

Just to say I have access to a medium sized CNC machine so can make most parts easily.

So a question for the more experienced, are belts a good idea because you can set the gearing, or are leadscrews overall a better idea, but obviously you need the correct type for the resolution needed.

I'm guessing overall max speed and acceleration/directional changes are going to have to be lower with leadscrews, having said that a max print speed of say 40mm/s is fine with me as anything faster seems to create more artefacts. I would rather have better prints than faster.

I realised building the Ormerod model is now probably an exercise in futility as what I am thinking of is so different very little if any part is going to be carried over, oh well.

Jon

Edited 2 time(s). Last edit at 06/02/2016 06:59PM by Firefox3D.

|

Re: Building a more accurate Ormerod June 02, 2016 07:20PM |

Registered: 8 years ago Posts: 105 |

Just done a bit more research and the linear rails available from [www.hiwinactuators.co.uk] used in Kossel printers recommend using ballscrews as the lower friction means speed and direction changes should not be an issue. These are used on bigger CNC machines so are maybe overkill, and or expensive.

If anyone thinks I'm an idiot and overdoing this please step in!

Jon

If anyone thinks I'm an idiot and overdoing this please step in!

Jon

|

Re: Building a more accurate Ormerod June 03, 2016 02:33AM |

Registered: 10 years ago Posts: 776 |

Quote

Mitch

Dear Firefox3d

One of the cheapest mods that should make your Ormerod more accurate, may be to replace the belts and pulleys with their GT2 equivalent. This means you won't get any rounding errors. Most objects I print and design are using the metric system, so I do find it a bit strange that the printer spends it's time microstepping to the closest imperial value. In reality, it's a small error, and the most that you'll notice is the difference in noise the printer makes.

Mitch

The belt will not make any difference to the operation, it does not matter if its a metric or imperial pitch system as long as the belt matches the pulleys of course. The important factor is the relationship between the motor steps (usually 200) and the pitch of a lead-screw if used, if the drive is by direct belt then the only part that matters is the motor steps and pulley sizes. I have no idea what micro-step a Duet uses but on my bigger CNC stuff its 1000 so the motor has a resolution of 200*1000 steps, it's not quite that simple but in theory anyway. Lets put a pulley with a pitch diameter of 10mm on that - this will give a theoretical resolution of 0.000157mm per step - ((10 * 3.1415) / 200,000)

The thing with micro stepping is that not all of those steps are available as movement - some are used up in making the motor move to the next step, it's cumulative and the motor may not physically move if you throw say 5 steps at it, throw a couple more steps and it might move, but that's 7 steps for one movement.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Building a more accurate Ormerod June 03, 2016 06:18AM |

Registered: 8 years ago Posts: 105 |

Quote

Davek0974

The belt will not make any difference to the operation, it does not matter if its a metric or imperial pitch system as long as the belt matches the pulleys of course. The important factor is the relationship between the motor steps (usually 200) and the pitch of a lead-screw if used, if the drive is by direct belt then the only part that matters is the motor steps and pulley sizes. I have no idea what micro-step a Duet uses but on my bigger CNC stuff its 1000 so the motor has a resolution of 200*1000 steps, it's not quite that simple but in theory anyway. Lets put a pulley with a pitch diameter of 10mm on that - this will give a theoretical resolution of 0.000157mm per step - ((10 * 3.1415) / 200,000)

The thing with micro stepping is that not all of those steps are available as movement - some are used up in making the motor move to the next step, it's cumulative and the motor may not physically move if you throw say 5 steps at it, throw a couple more steps and it might move, but that's 7 steps for one movement.

What is the geared resolution of the X and Y axes on the Ormerod?

I can work out for the Nema motors with 2mm pitch leadscrew and 1.8 degree (200 step) you get a resolution of 2/200 - 0.01mm which would be ok for Z but not enough for X and Y.

|

Re: Building a more accurate Ormerod June 03, 2016 06:29AM |

Registered: 10 years ago Posts: 776 |

Not got my one here so i don't know the pulley sizes but they are small.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Building a more accurate Ormerod June 03, 2016 06:53AM |

Registered: 8 years ago Posts: 105 |

|

Re: Building a more accurate Ormerod June 03, 2016 07:47AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Davek0974

The belt will not make any difference to the operation, it does not matter if its a metric or imperial pitch system as long as the belt matches the pulleys of course.

The circumference of the pulley must always be an exact multiple of the tooth pitch of the belt (think about it). Every revolution of the motor will move the axis by the belt pitch X number of teeth on the pulley. If the belt pitch is metric, each motor revolution will thus move an exact metric amount, while if the pitch is imperial it will move an exact imperial amount. If the motor has 200 steps per revolution and the belt size is metric, this means that if the part and extrusion widths are in exact multiples of 0.05mm then many of the moves will start and end on an exact step so microsteps will not be needed. The same is not quite so true of imperial belts & imperial designs because designs using imperial measurements will often use fractions of an inch rather than decimals of an inch which thus are not accommodated in terms of 1/200ths of the pulley circumference. I think this was the point being made.

However I disagree that it will make any difference in practice because it will not hold true in most cases, such as when printing curves or where the design dimensions are not oriented along the X & Y axis of the printer (think of a 10mm cube rotated 45 degrees on the build plate, for example). The infill lines inside a shape that is not orthogonal (e.g. inside a circle or triangle) will also not start & stop on an exact multiple of the design unit no matter whether metric or imperial.

Dave

|

Re: Building a more accurate Ormerod June 03, 2016 08:05AM |

Registered: 10 years ago Posts: 776 |

Yes but the Duet uses micro stepping AFIK, even with something minimal like 500 micro-steps, the differences will be way below the possibilities of 3d printing therefore invisible, therefore irrelevant surely. We are after all, printing with a semi liquid plastic which will not always flow exactly where we put it, it also contracts while cooling and so on. What i am saying is, there is little point in making a printer with a resolution of sub microns as it will bring no benefit, I would not look below 0.01mm personally as I doubt it would bring anything to the table.

Also AFIK, Ormerod pulleys and belts are all metric.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Also AFIK, Ormerod pulleys and belts are all metric.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Building a more accurate Ormerod June 03, 2016 09:17AM |

Registered: 8 years ago Posts: 45 |

Quote

Firefox3D

I am not mad they are not in there, certainly not as as DXF's anyway.

It's not obvious where they are. Go to the RepRapPro GitHub. [github.com]

Select the repositories tab.

Scroll down to Ormerod and select it.

Select the tag near the top of the screen that says '3 releases'.

You will see three releases each one with a zip file that describes itself as 'Source code'.

This is the file you want. Download it. Strangely it isn't the firmware source code as you might expect, it's all the design files for that release zipped up.

Inside the zip file you will see a folder dxf and hey presto your files will be in there.

The latest version is by part number, older versions by part description.

Hope that helps. I would suggest you download the three versions for future reference as you never know what will happen now the machine is no longer sold. (I have been caught out before!)

|

Re: Building a more accurate Ormerod June 05, 2016 03:05PM |

Registered: 9 years ago Posts: 1,699 |

The Ormerod uses MXL pulleys whith 18 teeth and a pitch distance of 2.032mm. The Duet provides 16 microsteps so you end up with 89.345 steps for 1mm. I am switching my second Ormerod to 16 teeth GT2-belts. This gives me exactly 100 steps per mm.

I think this is a great improvement especiall, the MXL profile is not designed for direction changes.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I think this is a great improvement especiall, the MXL profile is not designed for direction changes.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Building a more accurate Ormerod June 06, 2016 03:56AM |

Registered: 10 years ago Posts: 275 |

HP Scanjet GXXXX... I'm using this scanner for many years... belt: MXL

It has always been accurate.... and no problems.

I doubt there are belt problems with MXL...

GT2 is better with Tooth Jump Resistance

Dario

Edited 1 time(s). Last edit at 06/06/2016 05:01AM by Ormerod187.

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

It has always been accurate.... and no problems.

I doubt there are belt problems with MXL...

GT2 is better with Tooth Jump Resistance

Dario

Edited 1 time(s). Last edit at 06/06/2016 05:01AM by Ormerod187.

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Building a more accurate Ormerod June 06, 2016 11:21AM |

Registered: 8 years ago Posts: 105 |

I think I really want to get away from belts so to remove belt noise and vibrations from the equation. I am heading in the linear bearing and ballscrews direction, although they are more expensive they are 1 - simpler to implement/very accurate and 2 - why not do something different? and cool

5mm lead (5mm movement per motor rotation) is readily available but not sure if that is enough, simple maths gives something like 6 times higher motor rotational speed vs belts for the same print speed, not sure if that is going to be an issue with direction/speed changes. I guess allowing lower speed and acceleration should make it workable.

Speaking to the guy at zappautomation, they have made a 3D printer with ballscrews (forgot to as what lead) and there is a one on youtube here [www.youtube.com] using massive 16mm lead to be able to print fast but the bigger lead requires more torque.

Regarding the microstepping how many is it per motor step with an Ormerod board?

Jon

5mm lead (5mm movement per motor rotation) is readily available but not sure if that is enough, simple maths gives something like 6 times higher motor rotational speed vs belts for the same print speed, not sure if that is going to be an issue with direction/speed changes. I guess allowing lower speed and acceleration should make it workable.

Speaking to the guy at zappautomation, they have made a 3D printer with ballscrews (forgot to as what lead) and there is a one on youtube here [www.youtube.com] using massive 16mm lead to be able to print fast but the bigger lead requires more torque.

Regarding the microstepping how many is it per motor step with an Ormerod board?

Jon

|

Re: Building a more accurate Ormerod June 06, 2016 01:09PM |

Registered: 9 years ago Posts: 638 |

|

Re: Building a more accurate Ormerod June 06, 2016 02:06PM |

Registered: 8 years ago Posts: 105 |

Not according to the guy at zappautomation, he said the Nema 17's work fine

Also this [carbide3d.com] uses Nema 17's

Edited 2 time(s). Last edit at 06/06/2016 02:08PM by Firefox3D.

Also this [carbide3d.com] uses Nema 17's

Edited 2 time(s). Last edit at 06/06/2016 02:08PM by Firefox3D.

|

Re: Building a more accurate Ormerod June 06, 2016 02:13PM |

Registered: 9 years ago Posts: 1,699 |

Look above. The Duet board allows 16 microsteps per full step.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Building a more accurate Ormerod June 06, 2016 02:28PM |

Registered: 9 years ago Posts: 638 |

|

Re: Building a more accurate Ormerod June 06, 2016 02:37PM |

Registered: 8 years ago Posts: 105 |

|

Re: Building a more accurate Ormerod June 06, 2016 03:42PM |

Registered: 10 years ago Posts: 14,672 |

Firefox3D, here are a few suggestions for your "better Ormerod" build:

- Stay with belts (preferably GT2) for the X and Y axes, or else do a lot of research if you go for leadscrews. I have heard that controlling backlash is difficult with leadscrews, but I have no experience of them. Leadscrew or ballscrew is almost certainly a good idea for the Z axis.

- Consider changing to 0.9deg/step motors for the X and Y axes. They give almost double the torque per unit angular error for small errors, compared to similar 1.8deg/step motors. If you are striving for accuracy, this is probably worth having.

- If you can, budget for upgrading to the forthcoming next-generation Duet controller. You'll realise why when we announce the full details.

- One of my differential IR proximity sensors, if you don't already have one. The mini one will do if you use a fan output on the Duet to control the hot end fan.

Edited 1 time(s). Last edit at 06/06/2016 03:43PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- Stay with belts (preferably GT2) for the X and Y axes, or else do a lot of research if you go for leadscrews. I have heard that controlling backlash is difficult with leadscrews, but I have no experience of them. Leadscrew or ballscrew is almost certainly a good idea for the Z axis.

- Consider changing to 0.9deg/step motors for the X and Y axes. They give almost double the torque per unit angular error for small errors, compared to similar 1.8deg/step motors. If you are striving for accuracy, this is probably worth having.

- If you can, budget for upgrading to the forthcoming next-generation Duet controller. You'll realise why when we announce the full details.

- One of my differential IR proximity sensors, if you don't already have one. The mini one will do if you use a fan output on the Duet to control the hot end fan.

Edited 1 time(s). Last edit at 06/06/2016 03:43PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a more accurate Ormerod June 06, 2016 03:50PM |

Registered: 10 years ago Posts: 776 |

Ball-screws would be good and with the right nuts will be zero backlash, but, they are far heavier. They would be ideal if building a serious size machine like a 450mm sq print area or more. I recently built a mini-mill with 16mm ball-screws and a 400mm bed, the accuracy is amazing.

Don't forget lots of machined aluminium parts

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

Don't forget lots of machined aluminium parts

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Building a more accurate Ormerod June 06, 2016 03:55PM |

Registered: 9 years ago Posts: 15 |

In the industry, when done properly, modern belt systems can compete hand in hand will ball/leadscrews.

To buy professional anti-backlash nuts, it's often well into the £100s just for the nut.

Scanners/2d printers achieve accuracy through the use of optical encoders. This means they achieve accuracy regardless of the belts used. Ideally you would use a closed loop positioning system. A number of the older generation Reprap users manually tune the steps/mm instead of using the calculated value, which they believed increased the precision of their machine.

I've read online that you should at least have 12 teeth engaged at any one time on gt2 systems. This means you should use at least 20 tooth pulleys. The more teeth you have engaged on the pulley, and the wider the belt, should reduce vibrations significantly. You can buy 10mm width gt2 easily in the UK. Belt systems are much more forgiving of misalignment in the design.

I'd also recommend toothed idler pulleys. All the toothed idler pulleys from China tend to come with cheap bearings, and the teeth from experience are not perpendicular to the sides of the pulley, or even cut correctly. I would recommend buying a pulley with 8mm ID, then using some 8mm shaft constrained between two meaty 608 or other bearings. That's sort of the best toothed idler you're going to get, unless you pay around £15 upwards from somewhere like Misumi.

Edited 1 time(s). Last edit at 06/06/2016 03:57PM by Mitch.

To buy professional anti-backlash nuts, it's often well into the £100s just for the nut.

Scanners/2d printers achieve accuracy through the use of optical encoders. This means they achieve accuracy regardless of the belts used. Ideally you would use a closed loop positioning system. A number of the older generation Reprap users manually tune the steps/mm instead of using the calculated value, which they believed increased the precision of their machine.

I've read online that you should at least have 12 teeth engaged at any one time on gt2 systems. This means you should use at least 20 tooth pulleys. The more teeth you have engaged on the pulley, and the wider the belt, should reduce vibrations significantly. You can buy 10mm width gt2 easily in the UK. Belt systems are much more forgiving of misalignment in the design.

I'd also recommend toothed idler pulleys. All the toothed idler pulleys from China tend to come with cheap bearings, and the teeth from experience are not perpendicular to the sides of the pulley, or even cut correctly. I would recommend buying a pulley with 8mm ID, then using some 8mm shaft constrained between two meaty 608 or other bearings. That's sort of the best toothed idler you're going to get, unless you pay around £15 upwards from somewhere like Misumi.

Edited 1 time(s). Last edit at 06/06/2016 03:57PM by Mitch.

|

Re: Building a more accurate Ormerod June 07, 2016 02:39AM |

Registered: 9 years ago Posts: 1,699 |

I am switching my Ormerod 2 to 16teeth GT2 pulleys. The reason is very simple (as I read somewhere): Using 16 teeth pulleys gives me exactly 100 steps per mm or a movement of 0.01mm per step using the standard motors with the Duet. As we use the metric system that is exactly the accuracy of the printer for the x-/y-axis.

Using 18 teeth like the original MXL belts you would end up at 88.889 steps for 1mm including a rounding error. Using 20 teeth you end up with 80 steps per mm. That would be a better choice, but with accuracy losts. Unless you switch the motors the accuracy would be 0.0125mm.

I don't know yet if it changes anything.

But what are you planning? Do you want to keep the main design (optically)? For me it sounds like you want to build a complete different printer like I do.

I hope that the DuetNG will be released soon.

@dc42 If I manage to finish my own printer design (CoreXY) before the DuetNG is released is it a good idea to use a Duet 0.6 temporarily (spare for emergency cases if a Duet will fail) and waiting for the DuetNG? Or should I buy a Duet 0.85 instead?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Using 18 teeth like the original MXL belts you would end up at 88.889 steps for 1mm including a rounding error. Using 20 teeth you end up with 80 steps per mm. That would be a better choice, but with accuracy losts. Unless you switch the motors the accuracy would be 0.0125mm.

I don't know yet if it changes anything.

But what are you planning? Do you want to keep the main design (optically)? For me it sounds like you want to build a complete different printer like I do.

I hope that the DuetNG will be released soon.

@dc42 If I manage to finish my own printer design (CoreXY) before the DuetNG is released is it a good idea to use a Duet 0.6 temporarily (spare for emergency cases if a Duet will fail) and waiting for the DuetNG? Or should I buy a Duet 0.85 instead?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Building a more accurate Ormerod June 07, 2016 09:25AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Treito

I hope that the DuetNG will be released soon.

@dc42 If I manage to finish my own printer design (CoreXY) before the DuetNG is released is it a good idea to use a Duet 0.6 temporarily (spare for emergency cases if a Duet will fail) and waiting for the DuetNG? Or should I buy a Duet 0.85 instead?

That's entirely up to you. The DuetNG uses the same connectors as the Duet 0.8.5, so the conversion would be easier. I think we'll be releasing the specs of the Duet NG within a couple of weeks.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.