Bed Compensation ruins first layer

Posted by jsv555

|

Bed Compensation ruins first layer June 08, 2016 01:20PM |

Registered: 9 years ago Posts: 73 |

Hi everyone.

I've been printing without using the automatic bed levelling without issue. I decided to implement the auto bed compensation and it ruins my first layer. It looks like cottage cheese. Without compensation the first layer it is near perfect, even on large objects.

I've checked all the probe locations and can't see any issue.

I was really just interested to know what people think is the likely cause of this?

I've been printing without using the automatic bed levelling without issue. I decided to implement the auto bed compensation and it ruins my first layer. It looks like cottage cheese. Without compensation the first layer it is near perfect, even on large objects.

I've checked all the probe locations and can't see any issue.

I was really just interested to know what people think is the likely cause of this?

|

Re: Bed Compensation ruins first layer June 08, 2016 01:44PM |

Registered: 9 years ago Posts: 638 |

|

Re: Bed Compensation ruins first layer June 09, 2016 09:26AM |

Registered: 9 years ago Posts: 73 |

Hi Darathy

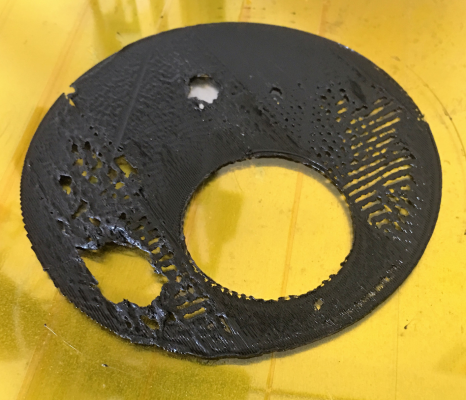

The only photo I have at the minute is this first layer test I did the other day to check the bed was level. It is a 100mm dia circle with another circle within it.

This is using the bed compensation. As you can see there are gaps in the infill and holes all over the place. Without the bed compensation this was near perfect (typically I didn't photo this).

I don't think light level is the issue as this was done at night with indirect lighting to the room. I did wonder whether there was dirt etc. at a probe site so I replaced the targets and Kapton tape. I get similar results whenever I apply the bed compensation. Without it is spot on.

As you say I can just not use the auto bed levelling. I just can't figure out what is going on.

Edited 2 time(s). Last edit at 06/09/2016 09:34AM by jsv555.

The only photo I have at the minute is this first layer test I did the other day to check the bed was level. It is a 100mm dia circle with another circle within it.

This is using the bed compensation. As you can see there are gaps in the infill and holes all over the place. Without the bed compensation this was near perfect (typically I didn't photo this).

I don't think light level is the issue as this was done at night with indirect lighting to the room. I did wonder whether there was dirt etc. at a probe site so I replaced the targets and Kapton tape. I get similar results whenever I apply the bed compensation. Without it is spot on.

As you say I can just not use the auto bed levelling. I just can't figure out what is going on.

Edited 2 time(s). Last edit at 06/09/2016 09:34AM by jsv555.

|

Re: Bed Compensation ruins first layer June 09, 2016 04:06PM |

Registered: 9 years ago Posts: 638 |

Try manualy setting Z0 after you do auto bed compensation ,does look to me like the first layer might be too low(the gaps couse by exturder skipping). Position the nozzle in the middle ,put a peice of paper under it and lower it till it grips the paper and then send G92 Z0. Most of the time i have to do this after bed compensation with DC42s probe and 5 point probes, might be something simular with stock.

Edited 2 time(s). Last edit at 06/09/2016 04:08PM by Darathy.

Edited 2 time(s). Last edit at 06/09/2016 04:08PM by Darathy.

|

Re: Bed Compensation ruins first layer June 10, 2016 02:02AM |

Registered: 9 years ago Posts: 1,699 |

Earlier Firmware-versions suffered indeed from the problem Darathy described. A bed compensation also rehomes the z-axis. This is still so, but if you look at the bed compensation points - the first point is negative (should be nearby zero). If you redo the bed compensation the first value get even more negative. For example -0.142; -0.163; -0.181 and so on. This behaviour was fixed in FW-version 1.10-dc42 or 1.11-dc42 so it would be a good idea to upgrade to FW version 1.12a-dc42 or later.

For me the paper method never worked. From my time using BuildTak (and also using FilaPrint) the suggested procedure is the following: Start at a higher nozzle distance. Than slowly change the value of the sensor and re-home the z-axis until you get the filament to stick.

For several print surfaces the paper method is not allowed: BuildTak, FilaPrint and I guess PEI also. Kapton tape is also a problem. If you are a little bit too deep the tape will be destroyed. It seems like you are in the grey zone where the tape can survive, but if you look at one hole it looks like the Kapton tape has already gone.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

For me the paper method never worked. From my time using BuildTak (and also using FilaPrint) the suggested procedure is the following: Start at a higher nozzle distance. Than slowly change the value of the sensor and re-home the z-axis until you get the filament to stick.

For several print surfaces the paper method is not allowed: BuildTak, FilaPrint and I guess PEI also. Kapton tape is also a problem. If you are a little bit too deep the tape will be destroyed. It seems like you are in the grey zone where the tape can survive, but if you look at one hole it looks like the Kapton tape has already gone.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed Compensation ruins first layer June 10, 2016 03:33AM |

Registered: 9 years ago Posts: 73 |

|

Re: Bed Compensation ruins first layer June 10, 2016 09:58PM |

Registered: 7 years ago Posts: 2 |

Hey Guys,

Exactly the same issue here. I've leveled the bed and can print well without auto bed leveling. However once I turn on the 5 point leveling things get pretty bad, can see the Z axis winding up and down even though I know the bed is flat.

Is anyone else here using this function with success? Using the upgraded differential IR sensor and version 1.13b btw.

Edited 1 time(s). Last edit at 06/10/2016 10:01PM by RoboPicker.

Exactly the same issue here. I've leveled the bed and can print well without auto bed leveling. However once I turn on the 5 point leveling things get pretty bad, can see the Z axis winding up and down even though I know the bed is flat.

Is anyone else here using this function with success? Using the upgraded differential IR sensor and version 1.13b btw.

Edited 1 time(s). Last edit at 06/10/2016 10:01PM by RoboPicker.

|

Re: Bed Compensation ruins first layer June 10, 2016 10:28PM |

Registered: 10 years ago Posts: 14,672 |

The bed may be flat, but unless you have the aluminium arm then the acrylic probably has a slight twist in it. Also the sideways force exerted by the Bowden tube varies with position and typically pushes the head down more near the middle of the X axis. So even though the bed is flat, bed compensation tries to raise the head a little near the middle of the X axis to compensate.

Edited 1 time(s). Last edit at 06/11/2016 06:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 06/11/2016 06:00PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed Compensation ruins first layer June 11, 2016 05:21AM |

Registered: 9 years ago Posts: 1,699 |

Quote

RoboPicker

Hey Guys,

Exactly the same issue here. I've leveled the bed and can print well without auto bed leveling. However once I turn on the 5 point leveling things get pretty bad, can see the Z axis winding up and down even though I know the bed is flat.

Is anyone else here using this function with success? Using the upgraded differential IR sensor and version 1.13b btw.

How you want to know that your bed is flat?

Like dc42 said it is not important that it is angled to the z-axis. The distance between the nozzle and the bed is the thing. Using Firmware 1.12a-dc42 with the mini-height-sensor and PrintBite works perfect. With FilaPrint I have small issues, but it seems that meanwhile there is a bigger problem with my Ormerod 1 - again.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed Compensation ruins first layer June 11, 2016 05:23PM |

Registered: 7 years ago Posts: 2 |

Hey thanks for the reply guys. Yes I'm still running the original X arm, it was twisted but I've made it somewhat straighter by temporarily inserting a washer to flex it back. The thing is though, the nozzle distance to bed is good enough to print with, and the bed sensor is connected to the nozzle mount, but I'm stumped as to why the auto level can be up to half a millimeter out across the bed. Way more than just the x arm twist contributes and even so, a 5 point level would be assumed to automatically counter this twist, not amplify it right?

|

Re: Bed Compensation ruins first layer June 11, 2016 06:02PM |

Registered: 10 years ago Posts: 14,672 |

I'll check out the bed compensation again when I have time, but right now I'm up to my ears in firmware for the Duet WiFi.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bed Compensation ruins first layer June 12, 2016 07:01PM |

Registered: 9 years ago Posts: 1,699 |

The original sensor has big problems if the height difference and therefore the deviation of the angle is too big. The sensor failed for me if two extreme points differed more than 0.6. If I reduced the difference it worked good regarding ABL.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed Compensation ruins first layer June 13, 2016 07:47AM |

Registered: 10 years ago Posts: 2,472 |

If you can get good prints without bed compensation then I strongly suggest you print without it. Bed compensation results in a lot of wear on the Z screw, and also means that the top of your print is warped in the same way as the bed / x-arm. I suggested a while ago that bed compensation should be gradually reduced on each layer so that it is no longer in operation by layer 5 or so, but there is as yet no firmware that implements such a method.

Dave

Dave

|

Re: Bed Compensation ruins first layer June 13, 2016 08:06AM |

Registered: 9 years ago Posts: 1,699 |

Originally my Ormerod 1 had a height difference of more than 1mm which I wasn't able to remove. Why I am telling this? To make you one thing clear: If you put such a feature into your firmware the dimensions will not be accurate.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed Compensation ruins first layer June 13, 2016 10:29AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Originally my Ormerod 1 had a height difference of more than 1mm which I wasn't able to remove. Why I am telling this? To make you one thing clear: If you put such a feature into your firmware the dimensions will not be accurate.

They won't be accurate with normal bed compensation either - think about it.

Dave

|

Re: Bed Compensation ruins first layer June 13, 2016 11:43AM |

Registered: 9 years ago Posts: 1,699 |

Why not?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bed Compensation ruins first layer June 14, 2016 07:02AM |

Registered: 10 years ago Posts: 2,472 |

Quote

Treito

Why not?

Think about an extreme situation where the bed is bowl-shaped with a big dip in the middle. Bed compensation will result in the nozzle dipping in the middle of the print and rising at the edges. This will continue to be the case layer by layer and so the top surface of the print will follow the shape of the bed and also have a bowl-shaped depression in the middle.

Dave

|

Re: Bed Compensation ruins first layer June 14, 2016 08:19AM |

Registered: 9 years ago Posts: 1,699 |

But if you have a situation like I have where the front is 1mm higher than the back the current ABL works but with your method it wouldn't.

The most important thing is that the surface is even of course.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

The most important thing is that the surface is even of course.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.