ABS Settings?

Posted by Pointy

|

ABS Settings? August 18, 2016 04:18PM |

Registered: 10 years ago Posts: 327 |

Hey guys,

I know that there are some long time Ormerod users on here that print with ABS, while I have only ever printed PLA, in the 2+ years I have had my Ormerod. I do have the need to print an ABS part, so I am wondering if some of you experienced ABS guys would be kind enough to share some settings.

For reference I am printing PLA with the bed at 65 deg for the first layer and then 55 deg for the rest. Hotend is 185 deg for the first and then 180 deg for the rest. Speed I can go up to 60mm/s and still get very good results. The bed is glass with Kapton tape and I just wipe over with a 10-1 mix of watered down PVA glue. I have zero adhesion problems with this.

I have never tested my heated bed at higher temps, so I am not sure what it will get up to, so that might be a good thing to test first.

TIA

Les

Pointy's Things

Pointy's Blog

I know that there are some long time Ormerod users on here that print with ABS, while I have only ever printed PLA, in the 2+ years I have had my Ormerod. I do have the need to print an ABS part, so I am wondering if some of you experienced ABS guys would be kind enough to share some settings.

For reference I am printing PLA with the bed at 65 deg for the first layer and then 55 deg for the rest. Hotend is 185 deg for the first and then 180 deg for the rest. Speed I can go up to 60mm/s and still get very good results. The bed is glass with Kapton tape and I just wipe over with a 10-1 mix of watered down PVA glue. I have zero adhesion problems with this.

I have never tested my heated bed at higher temps, so I am not sure what it will get up to, so that might be a good thing to test first.

TIA

Les

Pointy's Things

Pointy's Blog

|

Re: ABS Settings? August 18, 2016 08:37PM |

Registered: 8 years ago Posts: 30 |

Hi Pointy,

The settings that I use are 100 deg bed and 230 deg hotend. I am using a 4 mil kapton sheet on the glass bed, which is much sturdier than the kapton tape that came with my Ormerod 2. I clean it with acetone and use nothing else and get good adhesion.

The first time I printed with abs the hotend fell off of the carriage, as the pla nozzle mount is not able to handle the abs temperature too long. I highly recommend that the first abs print that you attempt is a new nozzle mount, then you should be good to go. Good luck

The settings that I use are 100 deg bed and 230 deg hotend. I am using a 4 mil kapton sheet on the glass bed, which is much sturdier than the kapton tape that came with my Ormerod 2. I clean it with acetone and use nothing else and get good adhesion.

The first time I printed with abs the hotend fell off of the carriage, as the pla nozzle mount is not able to handle the abs temperature too long. I highly recommend that the first abs print that you attempt is a new nozzle mount, then you should be good to go. Good luck

|

Re: ABS Settings? August 19, 2016 04:24AM |

Registered: 9 years ago Posts: 638 |

|

Re: ABS Settings? August 19, 2016 05:42AM |

Registered: 10 years ago Posts: 327 |

Quote

ayudtee

Hi Pointy,

The settings that I use are 100 deg bed and 230 deg hotend. I am using a 4 mil kapton sheet on the glass bed, which is much sturdier than the kapton tape that came with my Ormerod 2. I clean it with acetone and use nothing else and get good adhesion.

The first time I printed with abs the hotend fell off of the carriage, as the pla nozzle mount is not able to handle the abs temperature too long. I highly recommend that the first abs print that you attempt is a new nozzle mount, then you should be good to go. Good luck

Thanks for the reply.

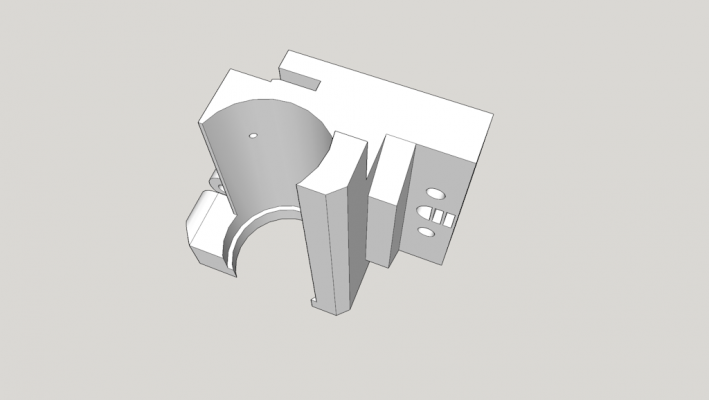

I had forgotten about the heat issue with the nozzle mount. I am using Igus rod and bearing on the X axis and have a custom piece that has the X carriage with the nozzle mount combined (printed in PLA)...

It's quite a long print, so it could be a problem. I will have to have a think about how to proceed.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: ABS Settings? August 19, 2016 09:12AM |

Registered: 8 years ago Posts: 45 |

I had no problems printing the ABS parts following the RepRapPro advice.

Important: all the supplied printer parts are made from PLA. Long term exposure to the heat of ABS printing will cause some of them to fail. If you plan to print a lot of ABS, you should first reprint some of the parts from ABS, specifically (and in this order) the x-carriage, z-runner-mount, extruder-body and the rest of the extruder parts, nozzle-duct, fan-duct.

When printing ABS without upgraded parts, at the start of the print leave the x-axis high above the bed (at least 100mm) so that it is not getting hot while the bed heats up.

I would also raise the x-axis after each print while the bed cools as well.

I print on Kapton tape cleaned with IPA or acetone. Bed temp 100 and the hot end between 220 and 260 depending on the filament.

Important: all the supplied printer parts are made from PLA. Long term exposure to the heat of ABS printing will cause some of them to fail. If you plan to print a lot of ABS, you should first reprint some of the parts from ABS, specifically (and in this order) the x-carriage, z-runner-mount, extruder-body and the rest of the extruder parts, nozzle-duct, fan-duct.

When printing ABS without upgraded parts, at the start of the print leave the x-axis high above the bed (at least 100mm) so that it is not getting hot while the bed heats up.

I would also raise the x-axis after each print while the bed cools as well.

I print on Kapton tape cleaned with IPA or acetone. Bed temp 100 and the hot end between 220 and 260 depending on the filament.

|

Re: ABS Settings? August 19, 2016 04:55PM |

Registered: 10 years ago Posts: 327 |

I have printed off a spare X carriage/nozzle mount just in case!

First attempt failed.

I tried 100 deg bed and 230 deg hot end. It started off very well and then about 3/4 of the way through the print, the print came off the bed. It looks like it has warped up at the front.

The other thing I have noticed is that the part is very brittle and easy to pull apart.

In case it's relevant the ABS is from 3d Filaprint in white.(It's been kicking around for 18 months but was still in it's sealed bag inside an unopened box.

Regards,

Les

Pointy's Things

Pointy's Blog

First attempt failed.

I tried 100 deg bed and 230 deg hot end. It started off very well and then about 3/4 of the way through the print, the print came off the bed. It looks like it has warped up at the front.

The other thing I have noticed is that the part is very brittle and easy to pull apart.

In case it's relevant the ABS is from 3d Filaprint in white.(It's been kicking around for 18 months but was still in it's sealed bag inside an unopened box.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: ABS Settings? August 19, 2016 05:16PM |

Registered: 9 years ago Posts: 638 |

If you have some acetone ,put some in a flask and mix in some of the ABS fillament(the failed part will work aswell) making ABS slurry ,you can apply that to the heated bed with a paint brush in a thin layer. It will help it not to warp. As for brittle try increasing temperature to 235 or 240.

|

Re: ABS Settings? August 19, 2016 05:17PM |

Registered: 10 years ago Posts: 14,672 |

You may need higher temperature than 230C, or perhaps you have some unwanted print cooling. Is it an Ormerod 1? If so, did you block off the air escape vents at the bottom of the fan duct, and drill an escape chimney at the top to let the air out instead?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: ABS Settings? August 19, 2016 06:12PM |

Registered: 10 years ago Posts: 327 |

Quote

Darathy

If you have some acetone ,put some in a flask and mix in some of the ABS fillament(the failed part will work aswell) making ABS slurry ,you can apply that to the heated bed with a paint brush in a thin layer. It will help it not to warp. As for brittle try increasing temperature to 235 or 240.

I might have some acetone lurking in the shed, if so I will give it a try.

Quote

dc42

You may need higher temperature than 230C, or perhaps you have some unwanted print cooling. Is it an Ormerod 1? If so, did you block off the air escape vents at the bottom of the fan duct, and drill an escape chimney at the top to let the air out instead?

It was an Ormerod 1, it doesn't look anything like that now though. I am using my own fan/heatsink ducts, which have the vents blowing towards the print. If this is undesirable for ABS, I will look at how I can block/vent the airflow.

Regards,

Les

Pointy's Things

Pointy's Blog

|

Re: ABS Settings? August 20, 2016 02:43AM |

Registered: 9 years ago Posts: 44 |

|

Re: ABS Settings? August 20, 2016 04:26PM |

Registered: 10 years ago Posts: 327 |

Quote

achaz

except in very limited scenarios this is very undesirable with ABS. Will cause terrible layer bonding and the result will be a very brittle partQuote

Pointy

If this is undesirable for ABS, I will look at how I can block/vent the airflow.

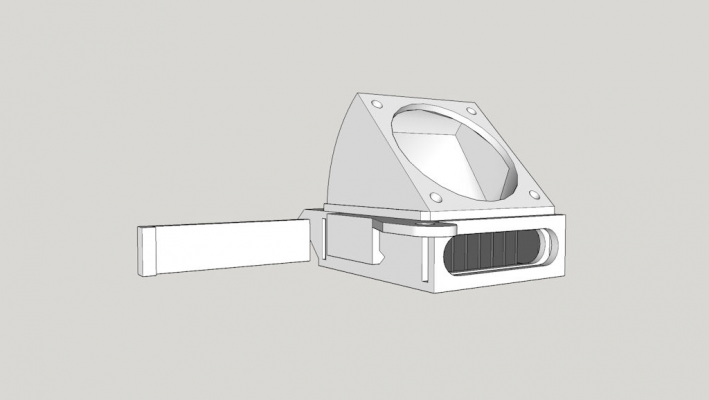

I spent the morning redesigning my heatsink & fan mounts to accommodate a slider panel that can be fitted at the top for PLA or the bottom for ABS...

Just that on it's own made the difference and the next print came out OK at 230 degrees. It's a little blobby/stringy where the was a small overhang, but it's certainly usable.

I then re-printed the X-Carriage/nozzle mount at 240 degrees at that came out better apart from the small column on top, I didn't catch it in time to slow the print down and it's a bit of a melted blob. Again it's still usable, so I am happy.

Does anyone use the ABS from E3D? I have to place an order with them on Monday (I managed to break the thermistor leads on my E3D V6, while fiddling with the delta

) and thought I might try some of the spoolWorks ABS.

) and thought I might try some of the spoolWorks ABS.Thanks for the help guys.

Les

Pointy's Things

Pointy's Blog

Sorry, only registered users may post in this forum.