anyone got experience with using an acme rod for z axis?

Posted by improprietary

|

anyone got experience with using an acme rod for z axis? August 24, 2016 03:23PM |

Registered: 8 years ago Posts: 35 |

oi oi

I've bought an acme rod, brass nut and 5-8mm aluminium coupler for my printer. I've designed, printed, installed and programmed my printer now for the setup but its first now i've been thinking about if any of you got any experience with this setup versus the m5 threaded rod setup that the printer originally came with.

Do you got any experience with other z axis setups than what originally came with the printer? Is a directly driven threaded rod better than a geared rod for the z axis? et cetera.

I've bought an acme rod, brass nut and 5-8mm aluminium coupler for my printer. I've designed, printed, installed and programmed my printer now for the setup but its first now i've been thinking about if any of you got any experience with this setup versus the m5 threaded rod setup that the printer originally came with.

Do you got any experience with other z axis setups than what originally came with the printer? Is a directly driven threaded rod better than a geared rod for the z axis? et cetera.

|

Re: anyone got experience with using an acme rod for z axis? August 25, 2016 05:11AM |

Registered: 8 years ago Posts: 105 |

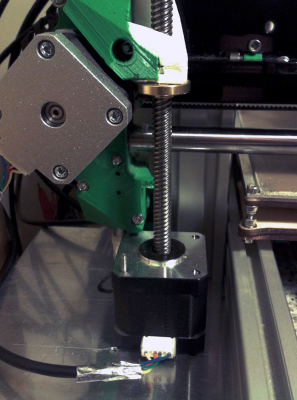

I was tired of getting uneven layer thickness's with printed gears so I changed to a nema 17 with an 8 x 8 acme thread just recently. Also partly rebuilt the printer with a 3mm aluminium baseplate to screw the Z axis and motor onto, this bolts with t-nuts to the Y extrusion. Manually built an extension to the Z-nut trap section to get the alignment right before building and printing a new part. Having said that everything is square and I am able to print 0.08mm and 0.04mm layers so I might just leave it alone for the time being.

Wiring was fun as the pinout on the motor was completely different to the stock motors, with the help of a multimeter worked out how it should be wired up and changed the pins over on the board end, also reversing the drive at the same time. Only other change I had to make was adding M92 Z400 to the config.sys file to correct the stepping.

Edited 1 time(s). Last edit at 08/25/2016 05:36AM by Firefox3D.

Wiring was fun as the pinout on the motor was completely different to the stock motors, with the help of a multimeter worked out how it should be wired up and changed the pins over on the board end, also reversing the drive at the same time. Only other change I had to make was adding M92 Z400 to the config.sys file to correct the stepping.

Edited 1 time(s). Last edit at 08/25/2016 05:36AM by Firefox3D.

|

Re: anyone got experience with using an acme rod for z axis? August 25, 2016 01:28PM |

Registered: 10 years ago Posts: 44 |

|

Re: anyone got experience with using an acme rod for z axis? August 25, 2016 07:40PM |

Registered: 8 years ago Posts: 35 |

|

Re: anyone got experience with using an acme rod for z axis? August 30, 2016 01:13PM |

Registered: 9 years ago Posts: 44 |

I'm driving a TR-8 direct.

[pinshape.com]

Shifted the stepper away from the junction of the Z and Y extrusions to accomodate this, rebuilt the lower parts and the nut-trap to accommodate. I had a little misalignment in V1, so the v2 files were designed to move the nut trap out to allow shimming for a better alignment. I did the original numbers back of a cocktail-napkin style some I was surprised that the v1 fit as well as it did.

Later I put a heavier motor on the X axis and discovered the original Z axis motor needed more juice to drive the axis consistently after the increased weight.

[pinshape.com]

Shifted the stepper away from the junction of the Z and Y extrusions to accomodate this, rebuilt the lower parts and the nut-trap to accommodate. I had a little misalignment in V1, so the v2 files were designed to move the nut trap out to allow shimming for a better alignment. I did the original numbers back of a cocktail-napkin style some I was surprised that the v1 fit as well as it did.

Later I put a heavier motor on the X axis and discovered the original Z axis motor needed more juice to drive the axis consistently after the increased weight.

|

Re: anyone got experience with using an acme rod for z axis? August 31, 2016 09:01AM |

Registered: 10 years ago Posts: 2,472 |

Thanks achaz. I bought a Nema17 with a 200mm TR-8 many months ago but have never got around to fitting it. My main concern is that my designs for the printed parts needed to fit it would be unlikely to work without tweaking, so I'd end up pulling my Ormerod apart to fit the trial modification then reverting back to print updated parts multiple times until I achieved a design that worked, so I have been putting off all that hassle. Now (after finally figuring out how to download from pinshape) I can use your "known good" design which makes me more motivated to get it done - I just need to make up a new connector to fit the motor (the connector is different to the existing motors).

The main reason for wanting to do this mod is that while I can adjust my bed to be very close to flat, I cannot achieve better than 0.15mm across the whole surface, probably due to slight misalignment between front & back ground rods, and that's only if I adjust the bed immediately before starting the print as the Ormerod is not solid enough to retain its adjustment well. This is good enough to print parts that fit in the centre 100mm area which is flat to within 0.08mm or so, but larger parts or collections of parts would benefit from bed compensation to get a good all-important first layer. I do not want to use bed compensation with the existing Z arrangement as I fear the continuous Z movement will soon result in wear & failure of the threaded rod and nut.

Dave

The main reason for wanting to do this mod is that while I can adjust my bed to be very close to flat, I cannot achieve better than 0.15mm across the whole surface, probably due to slight misalignment between front & back ground rods, and that's only if I adjust the bed immediately before starting the print as the Ormerod is not solid enough to retain its adjustment well. This is good enough to print parts that fit in the centre 100mm area which is flat to within 0.08mm or so, but larger parts or collections of parts would benefit from bed compensation to get a good all-important first layer. I do not want to use bed compensation with the existing Z arrangement as I fear the continuous Z movement will soon result in wear & failure of the threaded rod and nut.

Dave

|

Re: anyone got experience with using an acme rod for z axis? August 31, 2016 09:25AM |

Registered: 9 years ago Posts: 44 |

if you use the v2 you will need a spacer between the nut trap and motor mount. I've been just using an ad hoc one i tossed together out of 'stuff', but I think the number is about 4mm. I will try to remember to generate a few spacers and upload them. I'm also using a motor mount that includes a longer/larger sensor target. Will hunt down that file too.

|

Re: anyone got experience with using an acme rod for z axis? August 31, 2016 06:43PM |

Registered: 9 years ago Posts: 44 |

motor brackets should be printable w\o support or brim if you use the w-discs version (I print mostly ABS, so planning for warp is a normal thing) (do check your slicer's preview on the modeled supports though, i made this back when I wasn't real great at modelling in supports so YMMV)

the shim piece I would suggest printing a couple of, if you want thicker single piece shims just resize it on the Z axis but hold X and Y constant.

Edited 1 time(s). Last edit at 08/31/2016 06:45PM by achaz.

the shim piece I would suggest printing a couple of, if you want thicker single piece shims just resize it on the Z axis but hold X and Y constant.

Edited 1 time(s). Last edit at 08/31/2016 06:45PM by achaz.

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 07:35AM |

Registered: 10 years ago Posts: 2,472 |

Thanks for the update. I printed your motor mount last night in ABS and it came out perfect using 0.25mm layer height, no warping at all, and the chamfers on the bottom are small enough that they did not cause any curl-up except a trivial amount at the corner of the thin foot where the overhang angle is a bit steeper than the other chamfers. I used a reasonably slow print speed, so it took about 3 hours to complete. I reduced the hotend temperature and speed when it got to the layer of the Z-rod collar as that is a small area per layer and can overheat and deform if you are not careful. The STL needed to be flipped over to put the flat side down, but that's trivial. I'll probably print the other parts tonight and might manage to fit it over the weekend (depending on how my other weekend jobs go).

Do I need any different fasteners? If so I probably have them in my nuts & bolts box, but it would be good to make sure.

Good job!

Dave

Do I need any different fasteners? If so I probably have them in my nuts & bolts box, but it would be good to make sure.

Good job!

Dave

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 09:13AM |

Registered: 9 years ago Posts: 44 |

yeah those chamfers are annoying. I'd get rid of them and just clean up any elephant foot by hand if I were to redesign the parts again.

I don't think you should need any different hardware, pretty sure in all cases I designed it to reuse the parts in their original locations since I didn't want to go buying a small handful of oddball pieces. This choice I think leaves the design a little weak in some places though.

I don't think you should need any different hardware, pretty sure in all cases I designed it to reuse the parts in their original locations since I didn't want to go buying a small handful of oddball pieces. This choice I think leaves the design a little weak in some places though.

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 10:08AM |

Registered: 10 years ago Posts: 2,472 |

I just looked at your Z-nut trap. It has a very long and steep overhang that is not going to print in ABS without a separate print cooling fan (which I don't have). So I'll modify it by putting a couple of thin walls under each side of the overhang for support - they can be broken off afterwards.

Dave

Dave

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 10:48AM |

Registered: 10 years ago Posts: 2,472 |

Modified your nut trap design a little ...

The "teardrops" on the holes on your design would suggest an orientation that could not print (without lots and lots of support!), so I have removed those teardrops and turned the part to what I think is the best orientation for printing, then added 2 x 1mm walls to support the steep overhang. I've found I can get away with 3mm horizontal holes without needing a teardrop at the top. There is still an unsupported overhang, but it is fully supported on one side and I think the overhang is shallow enough that it should print OK - I might have to baby it using a hand-held fan while those layers are printing.

I've also included the OpenScad file that applies the modifications - use it from the same directory you have your original STL.

Dave

The "teardrops" on the holes on your design would suggest an orientation that could not print (without lots and lots of support!), so I have removed those teardrops and turned the part to what I think is the best orientation for printing, then added 2 x 1mm walls to support the steep overhang. I've found I can get away with 3mm horizontal holes without needing a teardrop at the top. There is still an unsupported overhang, but it is fully supported on one side and I think the overhang is shallow enough that it should print OK - I might have to baby it using a hand-held fan while those layers are printing.

I've also included the OpenScad file that applies the modifications - use it from the same directory you have your original STL.

Dave

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 11:15AM |

Registered: 9 years ago Posts: 44 |

Quote

dmould

I just looked at your Z-nut trap. It has a very long and steep overhang that is not going to print in ABS without a separate print cooling fan (which I don't have). So I'll modify it by putting a couple of thin walls under each side of the overhang for support - they can be broken off afterwards.

Dave

Interesting. I don't have a parts cooling fan and I've printed it in ABS without supports several times.

They're artifacts from the original RRP part. I cut it down to the minimum I needed to guarantee bore positions and lengths and then built the new nut trap arm from there. I could have filled in the teardrops I guess but it just wasn't overly important to me at the time.Quote

The "teardrops" on the holes on your design would suggest an orientation that could not print (without lots and lots of support!),

I intended for the part to be printed upside down such that the large flat on the top of the trap is against the bed.

If you're printing ABS I would discourage use of additional cooling. These are parts you want strong and cooling layers will weaken the bonds of the next layer. I can tell you that all these parts I printed without any additional cooling (and without generated support)Quote

I might have to baby it using a hand-held fan while those layers are printing.

Also, if any of the overhangs do get a bit funky on the nut trap, none of them are actually located in a place on the O2 where it matters. Just user a razor and needle file to clean up any edges that have to mate cleanly to another part.

|

Re: anyone got experience with using an acme rod for z axis? September 01, 2016 11:19AM |

Registered: 9 years ago Posts: 44 |

I think I lied about one thing on the hardware question... I recall that you do need 2 longer bolts for the z nut trap mount. 5mm longer than whatever is there right now iirc. The original v1 design didn't have that problem but once I rebuilt it to stand further out (and need to be shimmed accordingly) longer bolts were in order.

|

Re: anyone got experience with using an acme rod for z axis? September 02, 2016 07:48AM |

Registered: 10 years ago Posts: 2,472 |

Quote

achaz

Interesting. I don't have a parts cooling fan and I've printed it in ABS without supports several times.

Printed it last night - the shallow overhang definitely needed walls - in fact the first attempt curled up so hard it pulled up the walls so I had to add a base for the walls to keep it down - printed OK after that, and the other overhang was OK without cooling.

Quote

achaz

If you're printing ABS I would discourage use of additional cooling. These are parts you want strong and cooling layers will weaken the bonds of the next layer. I can tell you that all these parts I printed without any additional cooling (and without generated support)

Also, if any of the overhangs do get a bit funky on the nut trap, none of them are actually located in a place on the O2 where it matters. Just user a razor and needle file to clean up any edges that have to mate cleanly to another part.

The problem is that the curl-up can catch the nozzle and either pull the part off the bed or cause missed steps. What I do if I can't modify the STL is blow a gentle stream of air at the base of the nozzle *only when the perimeter of the overhang is being printed* (so just for a few seconds on each layer). It is tedious, but stops the curl-up without weakening the layer bonds anywhere else. I have blocked off all print cooling as I only print in ABS. I used to blow air from my mouth using a straw, but have since got a cheap hand-held battery fan I have fitted with a crude nozzle.

After printing your part, I discovered that it doesn't quite fit my TR-8, which has 4 holes threaded to take an M3 bolt, so the 4 pins of your part are too fat to fit into the holes. The pins would need to be much thinner to fit the holes, which would make them too fragile. I could easily drill out the threaded holes of the TR-8 carriage and use your part (which was my first thought), but what I will do instead is fit some M3 bolts through the TR-8 carriage so that they act as pins (facing upwards), and have 4 holes in the Z nut trap instead of 4 pins. Your part already has blind holes opposite the pins, so I can just drill those out (which will remove the pins) rather than printing a new part.

Dave

|

Re: anyone got experience with using an acme rod for z axis? September 02, 2016 12:07PM |

Registered: 9 years ago Posts: 44 |

|

Re: anyone got experience with using an acme rod for z axis? September 04, 2016 12:43PM |

Registered: 10 years ago Posts: 2,472 |

Just finished the update. Apart from the fiddly recessed bolts, it went smoothly, everything lined up without needing the shims. Just doing my first print with it - looking good. I did not have a lot of Z banding previously, but it seems to have gone completely after this mod. I'm a lot happier with this leadscrew than the M5 threaded rod, Z movement is completely silent and looks smoother - I'm sure I could also put the speed way up if I remove the present firmware limit so as to move 100mm+ in a couple of seconds. The X homing tab didn't fit, so I took that off and home X by hand until I get around to making a modified tab.

I will however be modifying it. The motor I bought has a 200mm leadscrew which means my maximum height is 150mm. Not a problem as I have only once printed anything taller than that, but I could buy a motor with a longer leadscrew & easily replace it if needed. A bigger issue however is that the hotend hits the leadscrew at about X=10mm, so I lose 10mm off the maximum X dimension. That is a concern because I often make use of the maximum bed area. It will be perfectly possible to set the motor & nut-trap back further. The limit will be where the leadscrew hits the X-motor, and it is presently over 20mm away.

A worthwhile mod - thankyou very much for publishing the parts and giving me the impetus to do something I have been procrastinating about for nearly a year!

Dave

I will however be modifying it. The motor I bought has a 200mm leadscrew which means my maximum height is 150mm. Not a problem as I have only once printed anything taller than that, but I could buy a motor with a longer leadscrew & easily replace it if needed. A bigger issue however is that the hotend hits the leadscrew at about X=10mm, so I lose 10mm off the maximum X dimension. That is a concern because I often make use of the maximum bed area. It will be perfectly possible to set the motor & nut-trap back further. The limit will be where the leadscrew hits the X-motor, and it is presently over 20mm away.

A worthwhile mod - thankyou very much for publishing the parts and giving me the impetus to do something I have been procrastinating about for nearly a year!

Dave

|

Re: anyone got experience with using an acme rod for z axis? September 04, 2016 12:49PM |

Registered: 9 years ago Posts: 44 |

Sorry, only registered users may post in this forum.