Stabilizing Ormerod 2

Posted by Treito

|

Re: Stabilizing Ormerod 2 September 22, 2016 02:33AM |

Registered: 10 years ago Posts: 776 |

They are used on high-end milling machines which use flood coolant, that said, they do have way covers and forced lubrication etc but i have seen them covered in muck and swarf.

They have wipers on each end, I fitted dual wipers just to make sure

The coolant is generally oil based even the water soluble ones so its never just plain water.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

They have wipers on each end, I fitted dual wipers just to make sure

The coolant is generally oil based even the water soluble ones so its never just plain water.

Another RS Ormerod Mk1 meets the world

Retired now but I used to make....

CNC Machined Mk1 aluminium bed support plates for the Ormerod

CNC machined X-plates and ribs for Mk1 & Mk2 Ormerods

CNC machined bed support arms for the Mk2 Ormerod.

Dual Hot-End heatsink blocks.

|

Re: Stabilizing Ormerod 2 September 23, 2016 06:10AM |

Registered: 9 years ago Posts: 1,699 |

I would like to give the DryLin N a try. They are cheap, "Made in Germany", easy to mount on an extrusion. They are used at a bq hephestos 2 for the z-axis. The manufacturer names this as a refernce.

They are probably very calm, but I am still unsure what is causing my ghosting.

I need to fix my OM1, since my OM2 is also broken, but it can print with some limitations, but I have no idea if these limitations may have influence on the ghosting. For some reasons the y-axis is not operating smoothly if moved by hand, Maybe this is caused by the GT2 belt as I use a 16 teeth pulley and the belt may touch some parts, but I need to check, where the problem is related. I also use another type of bearings and maybe this is causing the problem, but I can check this as soon as the OM1 works again.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

They are probably very calm, but I am still unsure what is causing my ghosting.

I need to fix my OM1, since my OM2 is also broken, but it can print with some limitations, but I have no idea if these limitations may have influence on the ghosting. For some reasons the y-axis is not operating smoothly if moved by hand, Maybe this is caused by the GT2 belt as I use a 16 teeth pulley and the belt may touch some parts, but I need to check, where the problem is related. I also use another type of bearings and maybe this is causing the problem, but I can check this as soon as the OM1 works again.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Stabilizing Ormerod 2 January 16, 2017 03:41AM |

Registered: 8 years ago Posts: 164 |

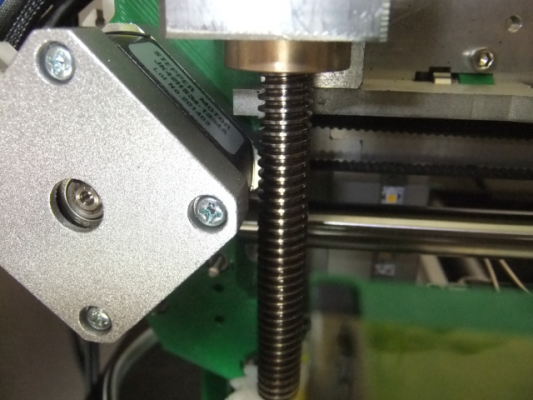

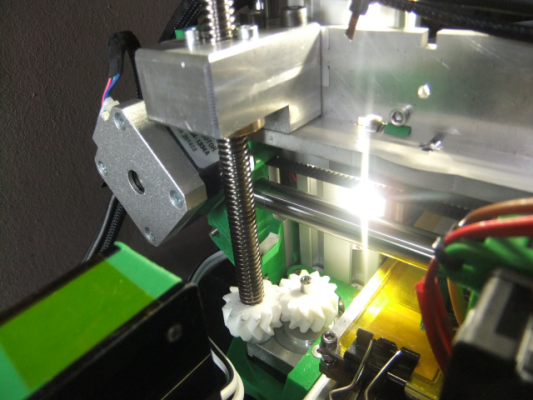

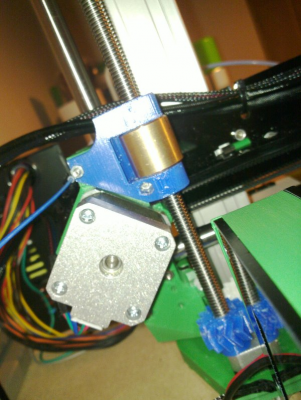

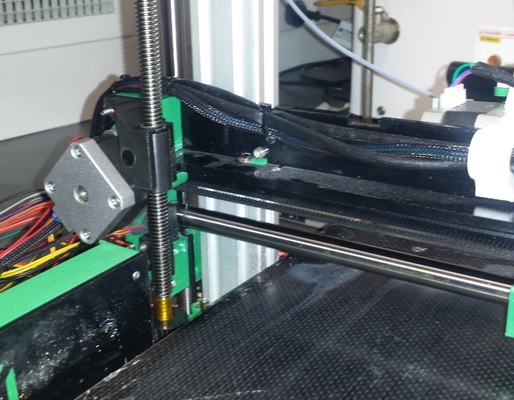

I'm doing some repairs on my z-axis at the moment, and my M5 threaded rod keeps popping off of the bearing on the corner of the Z stepper motor. The threaded rod isn't straight anymore after 1 year of driving the printer, and I suspect friction at the z-nut-trap is greater than the friction keeping the gear on the bearing. Rather than use the same threaded rod, I thought I'd explore other options.

What modifications need to be done to the printer to accept an ACME or ball screw? Naturally the captured M5 nut at the tip of the z-nut-trap isn't going to cut the mustard if the drive screw is larger. Does anybody have a modified STL they could share? One other idea I had was to slightly enlarge the end of the laser-cut x-rib where the x-axis meets the z. I can't make something from nothing but since my parts are HDPE, I need to get them re-cut anyway. For example, if I left a patch of metal at the end of the x-rib, I could also cut holes for the lead screw and any mounts for the bearing. This would eliminate the existing captive nut, and possibly even the entire z-nut-trap part. What are the downsides to this approach?

Apologies for the crude illustration, I'll put some more effort into Inkscape later!

What modifications need to be done to the printer to accept an ACME or ball screw? Naturally the captured M5 nut at the tip of the z-nut-trap isn't going to cut the mustard if the drive screw is larger. Does anybody have a modified STL they could share? One other idea I had was to slightly enlarge the end of the laser-cut x-rib where the x-axis meets the z. I can't make something from nothing but since my parts are HDPE, I need to get them re-cut anyway. For example, if I left a patch of metal at the end of the x-rib, I could also cut holes for the lead screw and any mounts for the bearing. This would eliminate the existing captive nut, and possibly even the entire z-nut-trap part. What are the downsides to this approach?

Apologies for the crude illustration, I'll put some more effort into Inkscape later!

|

Re: Stabilizing Ormerod 2 January 16, 2017 08:38AM |

Registered: 10 years ago Posts: 1,230 |

Quote

0x0000

..For example, if I left a patch of metal at the end of the x-rib, I could also cut holes for the lead screw and any mounts for the bearing.......

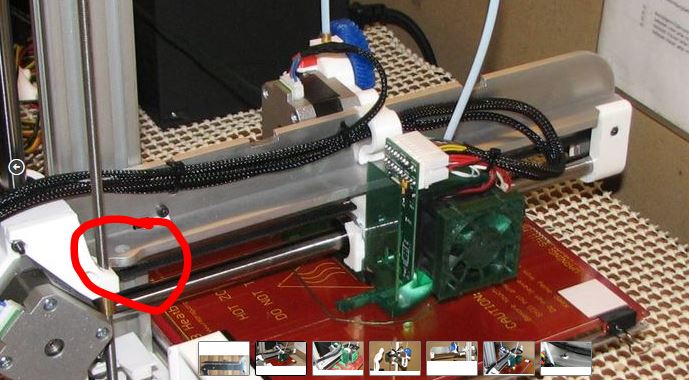

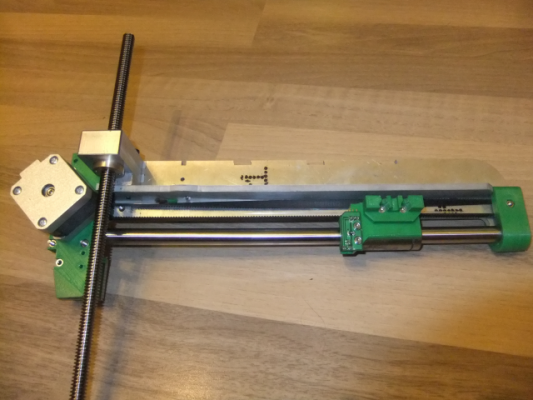

The first version of Dave's alu - x-arm was prepared for such a lead screw, see 2. picture from his web site (my ormerod1 as it looked some time ago), the hole is positioned directly over and in-line with the stepper axle

[ddmetalproducts.co.uk]

...and IFAIR the dfx file is downstream in this string:

[forums.reprap.org]

Erik

|

Re: Stabilizing Ormerod 2 January 17, 2017 04:07AM |

Registered: 8 years ago Posts: 164 |

|

Re: Stabilizing Ormerod 2 January 17, 2017 09:55AM |

Registered: 10 years ago Posts: 1,230 |

Quote

0x0000

..How large is the hole? Is it threaded or just drilled straight through?

6,50mm, straight through - finally found the post with the files Joar107 shared:

[forums.reprap.org]

Erik

Edited 1 time(s). Last edit at 01/17/2017 09:56AM by ormerod168.

|

Re: Stabilizing Ormerod 2 January 17, 2017 12:30PM |

Registered: 10 years ago Posts: 1,230 |

Quote

0x0000

How large is the hole? Is it threaded or just drilled straight through?

..and notice Joar107's direct drive mod was with the original 5mm threaded rod that clears the x-axis smooth rod by a hair, so if you plan to use a bigger diameter ball screw you will have to move the stepper a bit or use gears

Here's another take, Melmie's mod:

[forums.reprap.org]

..and epninety:

[forums.reprap.org]

..and zeb00:

[forums.reprap.org]

Erik

|

Re: Stabilizing Ormerod 2 January 17, 2017 04:06PM |

Registered: 9 years ago Posts: 44 |

Sorry, only registered users may post in this forum.