Ormerod 2 problems

Posted by kpapr1

|

Ormerod 2 problems December 27, 2016 01:32PM |

Registered: 8 years ago Posts: 60 |

Hi all and Merry Xmas!

I've absent for quite some time, almost a year now. I had also abandoned my printer all this period but now I need to print some designs. To be honest, I never managed to make any decent prints despite all the time I spent last year calibrating and this was the main reason for stopping the 3D prints. After spending a few days reading my old posts to see where I left off, I began again today, but the old nightmares appeared right from the start. I currently have 2 problems:

1) Layers don't stick well together (or better say very poorly). Low extruder temp? It's set to 200 degrees, PLA filament I use says 190-220.

2) Printer stops extruding in the middle of the print (my old nightmare...). The filament gets filed at the hobbed insert, I assume that something goes wrong at the extruder end. Possible reasons:

a) Extruder temp too low?

b) Extruder nose too low, so filament cannot be extruded?

c) Extruder clogged (I really doubt this because if I stop printing, lift the head and push the filament by hand, then the filament comes out OK)

d) something else I cannot understand

PLA filament reel rotates freely so I don't think that the motor cannot pull the filament. Doing manual extrudes and retracts I don't see any slips. I also add a bit of extra resistance with my hand by holding the filament - no problem for motor or hobbed part.

I must also let you know that I now print outside (into a small storage room at the back of the house). I had problems with sore throat and itchy eyes when printing inside the house, so I stopped. The storage room has no heating and currently temp is fairly low (around 10 degrees), but I remember last year same period I used a portable heating element, but same results.

So far (I mean last year when I did a lot of calibration) I have manually leveled the bed to within 0.2mm and calibrated the z-axis (the routine with the piece of paper under the extruder nose). I use dc42 firmware (1.09o-dc42 I think but maybe 1.09k-dc42, how can I find out?) but not the dc42 additional IR sensor board. Also, I use 4 point bed auto leveling every time before I print (have also tried without... same thing).

Any thoughts or ideas that could help me are welcome :-)

I've absent for quite some time, almost a year now. I had also abandoned my printer all this period but now I need to print some designs. To be honest, I never managed to make any decent prints despite all the time I spent last year calibrating and this was the main reason for stopping the 3D prints. After spending a few days reading my old posts to see where I left off, I began again today, but the old nightmares appeared right from the start. I currently have 2 problems:

1) Layers don't stick well together (or better say very poorly). Low extruder temp? It's set to 200 degrees, PLA filament I use says 190-220.

2) Printer stops extruding in the middle of the print (my old nightmare...). The filament gets filed at the hobbed insert, I assume that something goes wrong at the extruder end. Possible reasons:

a) Extruder temp too low?

b) Extruder nose too low, so filament cannot be extruded?

c) Extruder clogged (I really doubt this because if I stop printing, lift the head and push the filament by hand, then the filament comes out OK)

d) something else I cannot understand

PLA filament reel rotates freely so I don't think that the motor cannot pull the filament. Doing manual extrudes and retracts I don't see any slips. I also add a bit of extra resistance with my hand by holding the filament - no problem for motor or hobbed part.

I must also let you know that I now print outside (into a small storage room at the back of the house). I had problems with sore throat and itchy eyes when printing inside the house, so I stopped. The storage room has no heating and currently temp is fairly low (around 10 degrees), but I remember last year same period I used a portable heating element, but same results.

So far (I mean last year when I did a lot of calibration) I have manually leveled the bed to within 0.2mm and calibrated the z-axis (the routine with the piece of paper under the extruder nose). I use dc42 firmware (1.09o-dc42 I think but maybe 1.09k-dc42, how can I find out?) but not the dc42 additional IR sensor board. Also, I use 4 point bed auto leveling every time before I print (have also tried without... same thing).

Any thoughts or ideas that could help me are welcome :-)

|

Re: Ormerod 2 problems December 27, 2016 04:38PM |

Registered: 10 years ago Posts: 14,672 |

1. The main reasons for layers not bonding to each other are nozzle temperature too low and too much cooling air. Your temperature reading may not be accurate. Your low ambient temperature won't help.

2. Reduce the extruder motor current so that if the nozzle becomes obstructed, the extruder drive motor will skip steps instead of grinding the filament. Temporary obstructions are quite common, blobs and curl-up can cause them.

Your firmware is old. Version 1.17 is current.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2. Reduce the extruder motor current so that if the nozzle becomes obstructed, the extruder drive motor will skip steps instead of grinding the filament. Temporary obstructions are quite common, blobs and curl-up can cause them.

Your firmware is old. Version 1.17 is current.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod 2 problems December 28, 2016 03:15AM |

Registered: 8 years ago Posts: 60 |

Thanks a lot dc42. I will upgrade the firmware, reduce extruder motor current, increase nozzle temp + ambient temp and see how it goes.

My config file says extruder motor current is 900mA, reduce this to 700mA say?

I may not remember well, but I think that a new duet board was out some months ago and your newer firmwares (after 1.09) supported only that. So, is this the case or will your new 1.17 firmware do for my duet board?

Thanks :-)

My config file says extruder motor current is 900mA, reduce this to 700mA say?

I may not remember well, but I think that a new duet board was out some months ago and your newer firmwares (after 1.09) supported only that. So, is this the case or will your new 1.17 firmware do for my duet board?

Thanks :-)

|

Re: Ormerod 2 problems December 28, 2016 10:18AM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

Thanks a lot dc42. I will upgrade the firmware, reduce extruder motor current, increase nozzle temp + ambient temp and see how it goes.

My config file says extruder motor current is 900mA, reduce this to 700mA say?

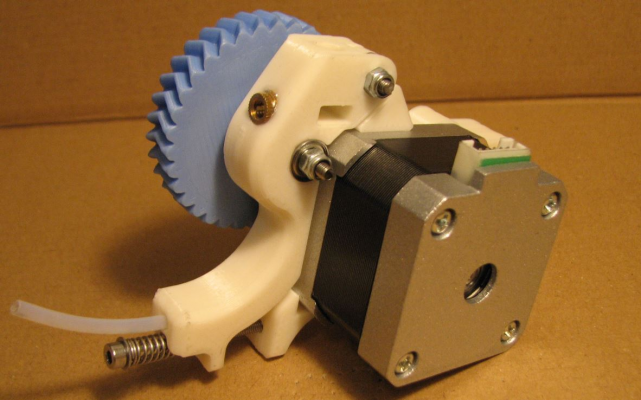

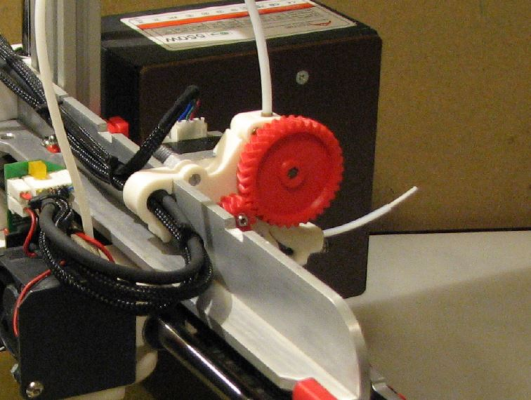

The original setting is 800mA so should work, but when you get printing I highly recommend you print and use the brilliant spring loaded extruder designed by MasonStonehenge, chose the PTFE version and use a proper spring - then you can forget all about slipping filament - with my setting at E1200 it stops the stepper without losing grip of the filament

[www.thingiverse.com]

Erik

|

Re: Ormerod 2 problems December 28, 2016 10:25AM |

Registered: 8 years ago Posts: 60 |

|

Re: Ormerod 2 problems December 28, 2016 10:33AM |

Registered: 8 years ago Posts: 60 |

Hi,

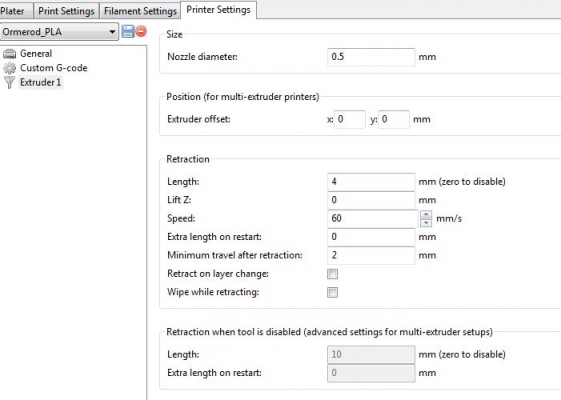

I have changed to firmware 1.17 now. I used bed temp of 65 degrees and nozzle temp of 210, I also heated the room to around 15 degrees. I went back to zero and printed the snowman. I have attached 2 pics of it (from & back). Any thoughts would be welcome.

I have also noticed that printing speed was slower that my other prints, so any recommendations on printing speed is welcome. I currently use slic3r and default settings (see pic). Also, my config file part for speed is below.

M556 S75 X0 Y0 Z0 ; Axis compensation here

M201 X500 Y500 Z15 E500 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X200 Y200 Z30 E20 ; Minimum speeds mm/minute

I have changed to firmware 1.17 now. I used bed temp of 65 degrees and nozzle temp of 210, I also heated the room to around 15 degrees. I went back to zero and printed the snowman. I have attached 2 pics of it (from & back). Any thoughts would be welcome.

I have also noticed that printing speed was slower that my other prints, so any recommendations on printing speed is welcome. I currently use slic3r and default settings (see pic). Also, my config file part for speed is below.

M556 S75 X0 Y0 Z0 ; Axis compensation here

M201 X500 Y500 Z15 E500 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X200 Y200 Z30 E20 ; Minimum speeds mm/minute

|

Re: Ormerod 2 problems December 28, 2016 12:25PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

I went back to zero and printed the snowman. I have attached 2 pics of it (from & back). Any thoughts would be welcome.

Looks like you are extruding too little filament, could be that your settings for M92, extruder steps per mm is off - or your filament is way thinner than you settings in slic3r, get this right first, then you can fine adjust your extrusion multiplier settings in Slic3r

Quote

I have also noticed that printing speed was slower that my other prints, so any recommendations on printing speed is welcome.

The perimeter speed of the original snowman.g is 20mm/s, my normal setting is 50mm/s

; generated by Slic3r 0.9.10b on 2013-12-05 at 21:07:27

; perimeter_speed = 20

Quote

I currently use slic3r and default settings (see pic). Also, my config file part for speed is below.

M556 S75 X0 Y0 Z0 ; Axis compensation here

M201 X500 Y500 Z15 E500 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X200 Y200 Z30 E20 ; Minimum speeds mm/minute

Here are my ditto settings:

M556 S78 X0 Y0 Z0 ; axis compensation

M201 X1200 Y1200 Z20 E3600 ; set accelerations (mm/s^2)

M203 X15000 Y15000 Z250 E3600; Maximum speeds (mm/min)

M566 X1800 Y1800 Z30 E20 ; maximum jerk speed mm/minute(i.e. maximum instantaneous change in speed)

Notice M566: Set allowable instantaneous speed change:

[reprap.org]

Erik

|

Re: Ormerod 2 problems December 28, 2016 12:33PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

Thanks a lot for the info, if I get the printer to print decent I will invest on a spring loader. Can you please tell me where I can get it from? Thanks!

Nothing to invest but filament and time :-) - just print the two parts and re-use the hardware from the original extruder + ad a spring, e.g. from a empty soap dispenser

Erik

|

Re: Ormerod 2 problems December 28, 2016 01:36PM |

Registered: 8 years ago Posts: 60 |

Hi all,

Thank you very much for your help!

I will print the spring loaded extruder once I manage to make decent prints :-)

I remember calibrating the extruder motor and looking at my config file it now reads M92 E431.

Snowman is a ready-made gcode file, maybe I should download the STL and play with the slic3r settings? Or what else can I change to make a decent snowman print? My current filament is 1.75mm

Thank you very much for your help!

I will print the spring loaded extruder once I manage to make decent prints :-)

I remember calibrating the extruder motor and looking at my config file it now reads M92 E431.

Snowman is a ready-made gcode file, maybe I should download the STL and play with the slic3r settings? Or what else can I change to make a decent snowman print? My current filament is 1.75mm

|

Re: Ormerod 2 problems December 28, 2016 02:33PM |

Registered: 9 years ago Posts: 638 |

|

Re: Ormerod 2 problems December 29, 2016 06:31AM |

Registered: 8 years ago Posts: 60 |

I downloaded snowman's STL and used slic3r to generate the gcode. I checked that nozzle diameter was 0.5mm and filament 1.75. The result is better that the first one but it seems that it still needs a bit of work. Should I increase the extrusion factor from the web interface? Maybe set it to 115% ???

|

Re: Ormerod 2 problems December 29, 2016 07:23AM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

Should I increase the extrusion factor from the web interface? Maybe set it to 115% ???

You could re-slice it with a skirt, e.g. 10mm from model running 10 loops, this will give you time to adjust the exstusion factor from web interface and get it just right before the actual print starts - adjust until you see the loops touching, ad to that a tiny bit (first layer get extra heat from the bed)

..and it looks like your Z0 is off, the first layer should be flat at the underside of the print, should be squeezed out against the bed

what I would do: zero the nozzle manually before printing at the center of the print - go to center of printing area, lower clean nozzle on a piece of 80gram copy paper (0.1mm), move the paper around while you lower the nozzle, and with a bit of fingerspitzgefühl you should be able to feel when the clean nozzle is very very slightly touching the paper, then lower the nozzle 0.1mm and send "G92 Z0"

...and I think you should lower the temperature a bit, you can also do that on the fly

Erik

|

Re: Ormerod 2 problems December 29, 2016 07:26AM |

Registered: 8 years ago Posts: 60 |

|

Re: Ormerod 2 problems December 29, 2016 01:23PM |

Registered: 8 years ago Posts: 60 |

Hi Erik, I did the G92 Z0 thing and things got better! I think I'm on the right track now, thanks a lot for your help!

Still not perfect but that's OK, it's really cold now (it's snowing) and the heating element can't increase temp to more than 10 degrees.

Still not perfect but that's OK, it's really cold now (it's snowing) and the heating element can't increase temp to more than 10 degrees.

|

Re: Ormerod 2 problems December 29, 2016 02:21PM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

Hi Erik, I did the G92 Z0 thing and things got better! I think I'm on the right track now, thanks a lot for your help!

Yes much better!

Quote

Still not perfect but that's OK, it's really cold now (it's snowing) and the heating element can't increase temp to more than 10 degrees.

You sure picked a fine time to print a snowman :-) - no not perfect but way better than my first snowman, yes I think those low 10 degrees (and draft maybe?) is adding to the problem, the bottom of the print should be mirror flat and I doubt that you printing bed surface is up to temperature, you could try to raise it 10 or so, also bring the bed up to temp. before printing and then wait a bit for the temp. to surface on the top of the glass

Erik

|

Re: Ormerod 2 problems December 29, 2016 03:15PM |

Registered: 8 years ago Posts: 60 |

Hi Erik,

Yes, I did pick up the right time to print the snowman :-D

Thanks for the tip, I will try again tomorrow and wait a bit more for the glass to heat up before I start printing. By the end of the year I will have a huge collection of snowmen :-P

I will also try to print something different/bigger/taller and see how it will go.

Yes, I did pick up the right time to print the snowman :-D

Thanks for the tip, I will try again tomorrow and wait a bit more for the glass to heat up before I start printing. By the end of the year I will have a huge collection of snowmen :-P

I will also try to print something different/bigger/taller and see how it will go.

|

Re: Ormerod 2 problems December 30, 2016 12:16PM |

Registered: 8 years ago Posts: 60 |

Hello again,

Today I managed to print a 10x10x1 cm object and it went fairly well. I think I have to make some trial-and-error adjustment to make the print better and better. So, 2 last questions if I may:

1) at the point where the beginning and end of a circle come together there is always a bit more material (it looks like a bump), does this have to do with the retraction setting?

2) some very small holes - 1mm diameter - where partially or almost fully covered with material, is 1mm too much to ask for, or is it related to temperature and fine adjustment of extraction factor?

I feel the need to thank you all again for your help, I was about to throw my printer away!

Today I managed to print a 10x10x1 cm object and it went fairly well. I think I have to make some trial-and-error adjustment to make the print better and better. So, 2 last questions if I may:

1) at the point where the beginning and end of a circle come together there is always a bit more material (it looks like a bump), does this have to do with the retraction setting?

2) some very small holes - 1mm diameter - where partially or almost fully covered with material, is 1mm too much to ask for, or is it related to temperature and fine adjustment of extraction factor?

I feel the need to thank you all again for your help, I was about to throw my printer away!

|

Re: Ormerod 2 problems December 30, 2016 03:11PM |

Registered: 12 years ago Posts: 548 |

|

Re: Ormerod 2 problems December 31, 2016 05:35AM |

Registered: 8 years ago Posts: 60 |

|

Re: Ormerod 2 problems December 31, 2016 06:18AM |

Registered: 10 years ago Posts: 1,230 |

Quote

kpapr1

1) at the point where the beginning and end of a circle come together there is always a bit more material (it looks like a bump), does this have to do with the retraction setting?

Yes most likely, can be a bit of a fiddle to get it right, will always be a compromise (short vs. long nozzle travel), my standard setting in Slic3r and Simplyfy3D is 4mm at 60mm/sec and works very well for me (on two Ormerods)

Quote

2) some very small holes - 1mm diameter - where partially or almost fully covered with material, is 1mm too much to ask for, or is it related to temperature and fine adjustment of extraction factor?

Small holes is a slicing problem as stephenrc notes and you cannot do anything about that, all you can do is not to ad to the problem - when small hole dimensions is important, print outer perimeters first so they solidify and make a hedge against the next perimeters, get the temperature right (not to high), ad proper cooling

To better understand the problem with small holes, read this brilliant blog post by Nophead

Quote

http://hydraraptor.blogspot.fi/2011/02/polyholes.html

Polyholes

When Reprap machines print holes they tend to come out undersized, even if the linear dimensions of an object are spot on. There are several effects that all make holes smaller than they should be: -

Faceting error

When CAD systems convert cylinders to triangles they produce a polygonal prism, so holes represented in an STL file are polygons with their vertices on the circumference of the original circle. That means the sides of the polygon are inside the circle, shrinking it by cos(π / n).

[hydraraptor.blogspot.fi]

Quote

I feel the need to thank you all again for your help, I was about to throw my printer away!

Glad to pay back a little, been in the same situation, one post from dc42 saved me from throwing my printer away - and his firmware, probe and PanelDue has made it better than I could ever imagine

Erik

|

Re: Ormerod 2 problems December 31, 2016 10:06AM |

Registered: 8 years ago Posts: 60 |

Thank you both for your replies. It's good to know about the holes so that I'm not hunting ghosts :-)

My retraction length is currently set to 2mm, I will play a bit with this and see if I can get any improvement.

The most important thing is that now the printer works and I can play with the settings! The bad news are that the temp outside is about -1 degrees and the heating element is inadequate. I have to wait a few days for the weather to improve. So...

HAPPY NEW YEAR EVERYONE :-)

My retraction length is currently set to 2mm, I will play a bit with this and see if I can get any improvement.

The most important thing is that now the printer works and I can play with the settings! The bad news are that the temp outside is about -1 degrees and the heating element is inadequate. I have to wait a few days for the weather to improve. So...

HAPPY NEW YEAR EVERYONE :-)

|

Re: Ormerod 2 problems January 05, 2017 02:10PM |

Registered: 8 years ago Posts: 60 |

Hi,

This is really embarrassing...

Trying to print a 190mm x 190mm x20mm object, printing stops after a few layers like it always has when printing anything larger than snowman. It just won't extract any filament, although the motor still tries to...

I don't know what to look for... if at that point where the printer stops extruding I stop printing, raise the nozzle (z-axis) and try to extrude from the web interface it won't even if I push the filament by hand. I have to set nozzle temp to 0 degrees, wait until the nozzle goes down to around 110 degrees, retract the filament - which in most cases won't come out from the extruder motor side because the filament's diameter at the very end is larger due to melting - so I have to unscrew the metal bit off the tube, pull the filament out and cut the end - re-install the filament, wait for the nozzle to reach 200 degrees or so and then if I try to extract the filament it would again go out just fine.

Any input would be great at this point as I'm completely hands up :-(

This is really embarrassing...

Trying to print a 190mm x 190mm x20mm object, printing stops after a few layers like it always has when printing anything larger than snowman. It just won't extract any filament, although the motor still tries to...

I don't know what to look for... if at that point where the printer stops extruding I stop printing, raise the nozzle (z-axis) and try to extrude from the web interface it won't even if I push the filament by hand. I have to set nozzle temp to 0 degrees, wait until the nozzle goes down to around 110 degrees, retract the filament - which in most cases won't come out from the extruder motor side because the filament's diameter at the very end is larger due to melting - so I have to unscrew the metal bit off the tube, pull the filament out and cut the end - re-install the filament, wait for the nozzle to reach 200 degrees or so and then if I try to extract the filament it would again go out just fine.

Any input would be great at this point as I'm completely hands up :-(

|

Re: Ormerod 2 problems January 06, 2017 08:08AM |

Registered: 10 years ago Posts: 2,472 |

Sounds like either the cool-end is not cooling sufficiently (is the fan mounted the correct way around?), the heat-break between the nozzle and the cold block is defective (hotend block is touching the cold block and/or heat insulator missing) or there is poor thermal contact between the heat sink and the cold block (ensure screws are tight and surfaces flush - maybe add some heat compound).

A poor heat-break is a common issue with the quick-release hotend arrangement, and caused by incorrect assembly - check the drawings and assembly notes carefully. There have also been a few people using the quick-release system with that problem who have posted here, so if that's what you are using maybe check past threads.

What's happening is that the filament gradually starts melting too high up before it reaches the nozzle. This results in it swelling and blocking further extrusion.

Dave

Edited 2 time(s). Last edit at 01/06/2017 08:10AM by dmould.

A poor heat-break is a common issue with the quick-release hotend arrangement, and caused by incorrect assembly - check the drawings and assembly notes carefully. There have also been a few people using the quick-release system with that problem who have posted here, so if that's what you are using maybe check past threads.

What's happening is that the filament gradually starts melting too high up before it reaches the nozzle. This results in it swelling and blocking further extrusion.

Dave

Edited 2 time(s). Last edit at 01/06/2017 08:10AM by dmould.

|

Re: Ormerod 2 problems January 06, 2017 12:08PM |

Registered: 8 years ago Posts: 60 |

Hi Dave,

I think you are right, most probably the filament gradually starts melting too high. I thought initially that printing speed was too fast and that the nozzle was locally becoming cold and unable to melt the filament, but I tried printing at half speed and things got worse! I was printing at 210 degrees to compensate for low ambient temp, which proved to be a wrong approach. Lowering temp to 205 for the first layer and then to 200 for the rest did the trick! I will also check screws and heat-sink/cold block connection and maybe add a bit of thermal compound. Thank you very much for your help and for pointing me to the right direction!

Costas

I think you are right, most probably the filament gradually starts melting too high. I thought initially that printing speed was too fast and that the nozzle was locally becoming cold and unable to melt the filament, but I tried printing at half speed and things got worse! I was printing at 210 degrees to compensate for low ambient temp, which proved to be a wrong approach. Lowering temp to 205 for the first layer and then to 200 for the rest did the trick! I will also check screws and heat-sink/cold block connection and maybe add a bit of thermal compound. Thank you very much for your help and for pointing me to the right direction!

Costas

Sorry, only registered users may post in this forum.