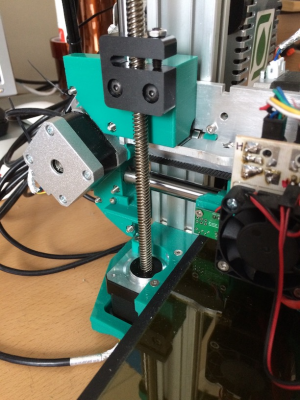

Z Axis Direct Drive upgrade

Posted by trevmas

|

Z Axis Direct Drive upgrade August 05, 2017 09:29AM |

Registered: 8 years ago Posts: 45 |

The Ormerod threaded rod with the method of mounting the gears for the z-axis always seemed a bit problematic for me even with upgraded gears, so I decided to upgrade it for a lead screw. To avoid using a shaft connector where space is tight, I decided to use a lead screw integral to the motor and bought this one from Oooznest.

[ooznest.co.uk]

Initially I went with the standard brass nut but was not happy with the backlash so changed it out for the Openbuilds delrin anti-backlash block.

[ooznest.co.uk]

The nut block was far too tight so I screwed it onto an offcut of the lead screw and gently heated the lead screw until it ran free. I left it quite tight, but if you overdo it you can take up any resulting slack with the tensioner.

Clearances are tight and if you use a different solution for the your sensor you may need to make adjustments.

My sensor mount can be found at [www.thingiverse.com]

The lead screw is on the same plane as the original Y Axis but is further away from the motor in the X Axis. To accommodate this I had to make a slightly longer homing pad.

The lead screw is 8mm Pitch, Tr8*8 4 Start

16x microstepping

200 steps per revolution,

so according to the Prusa Calculator [www.prusaprinters.org] the changes to the config were:

M569 P2 S0 ; Set Z motor direction

M92 X87.4890 Y87.4890 Z400 ; Set axis steps/mm for TR 8*8 (Changed from Z4000 to Z400)

WARNING! The original Ormerod solution allowed the Z nut to pop free if you crashed the head into the bed. This solution means that is no longer the case, all you have is the small amount of lift allowed by the rotation of the head on the rail.

The files can be found on Thingsverse at

[www.thingiverse.com]

|

Re: Z Axis Direct Drive upgrade August 07, 2017 08:30AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Z Axis Direct Drive upgrade August 07, 2017 09:38AM |

Registered: 8 years ago Posts: 45 |

Quote

dmould

I have done a similar mod to my Ormerod. Z backlash is not a problem because the weight of the X arm ensures that it is always pushing in one direction (down), so no matter how loose the nut, there is no backlash.

Dave

While printing I 100% agree, but... I was getting a very small inconsistency when setting the z height with the z-axis being raised and lowered. Normally it wouldn't be a problem but I was printing some gliders [www.thingiverse.com] in ABS and the difference between not sticking and wrinkling the single layer was very very small. Since using the anti-backlash nut I've had no problems at all. To be honest it's probably getting to the limits of the mechanics and other factors probably make as much difference but it's chip away one bit at a time.

|

Re: Z Axis Direct Drive upgrade August 08, 2017 02:29PM |

Registered: 10 years ago Posts: 466 |

|

Re: Z Axis Direct Drive upgrade August 09, 2017 09:40AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Z Axis Direct Drive upgrade August 09, 2017 12:06PM |

Registered: 10 years ago Posts: 466 |

Quote

dmould

AFAICS that part of the Ormerod is the same on both models, so I should think so.

Dave

Yeah, I thought so but wanted to be sure. I always thought direct drive would work better (or if anything - simpler) then the one with two gears.

There is also this option to convert the ormerod to a direct drive but it requires to modify the x rib in order to keep the z motor in the same place.

|

Re: Z Axis Direct Drive upgrade August 09, 2017 05:10PM |

Registered: 8 years ago Posts: 45 |

Quote

Sardi

Quote

dmould

AFAICS that part of the Ormerod is the same on both models, so I should think so.

Dave

Yeah, I thought so but wanted to be sure. I always thought direct drive would work better (or if anything - simpler) then the one with two gears.

There is also this option to convert the ormerod to a direct drive but it requires to modify the x rib in order to keep the z motor in the same place.

It's basically the same mod but using a bronze nut. Whilst the Z-axis rod stays in the same plane in the Y direction it moves forward about 15mm(?) in the X direction. This means you have to adjust the homing tab. I decided a few mods ago to cut off the pip and mount a tab using the holes that I think were provided for a mechanical end stop. I had already modified the X carriage [www.thingiverse.com] to accommodate the DC42 sensor which made it easier. Get one if you haven't already, it's well worth the small outlay, it's so much more accurate and getting rid of the homing pads is a big bonus. [escher3d.com]

If you find like me the holes in the motor bracket get too big for the screws after taking them in and out a few times, put a length of filament into a dremel and spin weld up the hole before drilling a new one.

With an Ormerod 1 you shouldn't have any problem hitting the edge of the bed because of the changed homing position but with a quickset nozzle in the normal position, furthest from the Z axis it's a bit tight.

Also have a look at [forums.reprap.org] and [pinshape.com] Never re-invent what you can beg steal or borrow!

|

Re: Z Axis Direct Drive upgrade August 11, 2017 02:31AM |

Registered: 6 years ago Posts: 174 |

Quote

trevmas

WARNING! The original Ormerod solution allowed the Z nut to pop free if you crashed the head into the bed. This solution means that is no longer the case, all you have is the small amount of lift allowed by the rotation of the head on the rail.

Can you not also wire in a conventional limit switch as a failsafe for if the carriage would crash into the bed?

By the way, great job on this upgrade!

Edited 1 time(s). Last edit at 08/11/2017 02:32AM by Karoo Klong.

|

Re: Z Axis Direct Drive upgrade August 11, 2017 03:03PM |

Registered: 8 years ago Posts: 45 |

Quote

Karoo Klong

Quote

trevmas

WARNING! The original Ormerod solution allowed the Z nut to pop free if you crashed the head into the bed. This solution means that is no longer the case, all you have is the small amount of lift allowed by the rotation of the head on the rail.

Can you not also wire in a conventional limit switch as a failsafe for if the carriage would crash into the bed?

By the way, great job on this upgrade!

Thanks. It would be possible but for me it's not an issue. I've only ever crashed the head once anyway and the mains switch on the back helps..... When testing upgrades etc I often put a piece of thick black corrugated card over the bed just in case.

Sorry, only registered users may post in this forum.