Hot End Direct Feed Extruder Drive

Posted by PlasticPogle

|

Hot End Direct Feed Extruder Drive August 28, 2017 03:12AM |

Registered: 8 years ago Posts: 10 |

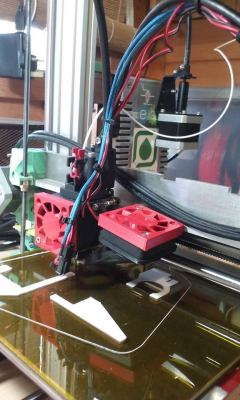

After switching to the E3D V6 hotend, I fitted a Bowden connection to the standard Ormerod extruder drive. This started proving unreliable, so I searched for a direct way of mounting the extruder over the hot end. I opted for the Zesty Nimble, purely because of the weight issue which is advertised as 37grams. Although I originally thought it was a bit pricey (+£15 postage from Australia) especially if it didn't work out ! It has proved an excellent investment. The support from Lykle at Zesty Technologies has been amazing in designing the adapter (FOC) [www.thingiverse.com]

As for reliability...only time will tell but I really recommend this as an alternative to the Bowden extruder drive.

Edited 4 time(s). Last edit at 08/28/2017 06:55AM by PlasticPogle.

PlasticPogle@COSMIC3D

Ormerod2

As for reliability...only time will tell but I really recommend this as an alternative to the Bowden extruder drive.

Edited 4 time(s). Last edit at 08/28/2017 06:55AM by PlasticPogle.

PlasticPogle@COSMIC3D

Ormerod2

|

Re: Hot End Direct Feed Extruder Drive August 28, 2017 11:01AM |

Registered: 10 years ago Posts: 1,230 |

How stiff is the cable compared to the PTFE tube?, the variation in down pressure on the Ormerod's hinged hotend is know to give the illusion of a bulged glass plate

And also the gear ratio of 30:1, do you find this to be a problem?, I seem to remember dc42 noting something about 10:1 would be max for the Duet (mass to higher speed, jerk speed, acceleration)

Erik

And also the gear ratio of 30:1, do you find this to be a problem?, I seem to remember dc42 noting something about 10:1 would be max for the Duet (mass to higher speed, jerk speed, acceleration)

Erik

|

Re: Hot End Direct Feed Extruder Drive August 28, 2017 03:14PM |

Registered: 10 years ago Posts: 14,672 |

You will have to use lower E acceleration when using a large gear ratio. However, the main reason for using a large E acceleration is to get high retraction speeds; but as you need very little retraction when using a remote direct drive extruder, that shouldn't matter.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hot End Direct Feed Extruder Drive August 28, 2017 07:44PM |

Registered: 7 years ago Posts: 62 |

@omerod168

Both Lykle and myself that developed the Nimble use the Duet board, no issues at all, just need to make sure you have settings set correctly which we have well documented, we also hapily help people that get stuck with the docs.

[zestytechnology.readthedocs.io]

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

Both Lykle and myself that developed the Nimble use the Duet board, no issues at all, just need to make sure you have settings set correctly which we have well documented, we also hapily help people that get stuck with the docs.

[zestytechnology.readthedocs.io]

Co-creator of the Zesty Nimble, worlds lightest direct drive extruder.

[zesty.tech]

|

Re: Hot End Direct Feed Extruder Drive August 29, 2017 03:30AM |

Registered: 8 years ago Posts: 10 |

...ditto to all above...thanks guys. As you say Erik, my main concern was the rotational force outwards on the hot end from the natural spring of the drive cable. So I settled on mounting the stepper (temporarily) high so to induce a small positive force as the height of the print increases to keep the nozzle at 90ᵒ to the bed. This works well and I'll print out a mounting bracket for the motor to finish the mod. I can now start printing flexible filaments which was always pain trying to push it down a PTFE tube.

PlasticPogle@COSMIC3D

Ormerod2

PlasticPogle@COSMIC3D

Ormerod2

|

Re: Hot End Direct Feed Extruder Drive August 29, 2017 05:45AM |

Registered: 8 years ago Posts: 312 |

We just uploaded a short video of a Nimble printing with X60.

X60 is one of the most flexible filaments available and the Nimble prints it fine.

This is the first print I tried with X60, so no tuning or optimising is done just yet. Only had a small sample so next it to buy a spool and start tweaking.

[youtu.be]

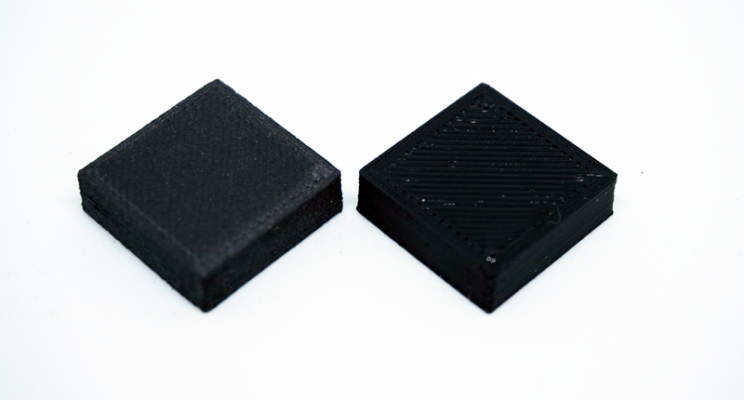

Also, here is a photo of two blocks I printed. The left one is Carbonfil, one of the hardest filaments to print. The right one is the X60 filament. All printed with the same printer, just changed the temp and speed settings. Goes to show that the Nimble is a very flexible extruder (pun intended).

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

X60 is one of the most flexible filaments available and the Nimble prints it fine.

This is the first print I tried with X60, so no tuning or optimising is done just yet. Only had a small sample so next it to buy a spool and start tweaking.

[youtu.be]

Also, here is a photo of two blocks I printed. The left one is Carbonfil, one of the hardest filaments to print. The right one is the X60 filament. All printed with the same printer, just changed the temp and speed settings. Goes to show that the Nimble is a very flexible extruder (pun intended).

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

Sorry, only registered users may post in this forum.