The Alumarod needs manual mesh bed leveling

Posted by Karoo Klong

|

The Alumarod needs manual mesh bed leveling November 14, 2018 11:00AM |

Registered: 6 years ago Posts: 174 |

I have been a bad boy and hijacked a thread or two so here goes my own atempt at dedicating a thread to my problem.

The Alumarod is working fine and I am able to reproduce very neat parts from ABS but the unevenness in the glass bed is causing larger parts to warp still.

I think the glass bed warps due to the clamping system I am using so 4 point leveling does not work.

Till now I have tried to level the bed out as best I could on the three corner screws and then just seting Z 0 at the centre of the bed. Howeer I still keep geting deviations of about 0.2 mm from side to side on the X and Y axes respectively. The glass is definately not flat and I have tried others. Its definately the tension from the frame clamps.

I remember from seting up the Ormerod when I first commisioned it that there is a Mesh Bed Leveling procedure with the infra sensor. But it seems my google-fu is weak.

dc42 suggested "Just set the Z probe type to 0 in the M558 command, set up the grid using M557, send G29, and follow the prompts on DWC or PanelDue."

Alas I don't fully grasp the procedure and researching trying to grasp the procedure has only left me feeling even more incompetent. No results under youtube and searchig other sites also left me more confused.

Mr cheeseandham left me this reply

"[[url=https://duet3d.dozuki.com/]duet3d.dozuki.com[/url]]

You're looking for this with M558 P0 mesh leveling"

I believe this is what I am wanting but again reading through the duet3d.dozuki.com I could still not find this section quoted.

Boy I feel really incapable now

It might also be the flu that is making my head denser than a brick.

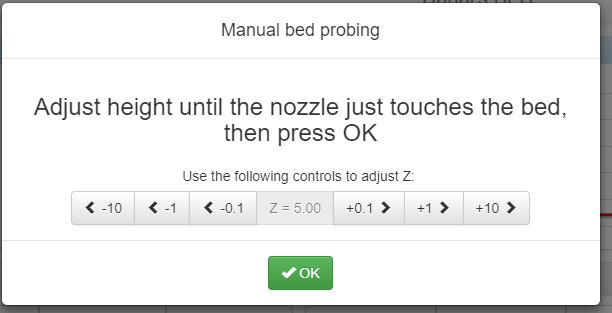

I just want to be able to understand how to define my own leveling mesh grid. Then be able to manually at each point have the printer pause and allow me to control the z height with the Duet Web Interfavce until it hits the zero height and store that point. Then the printer will move to the next point waiting for my next participation.

The printer is quite rigid now and I travel with it alot so the need for me to be able to mesh bed level is quite a necessity.

Would any of you please consider helping me trough the procedure step by step?

I saw another Ormerod 2 up for sale on Monday and I am considering buying it in order build another printer design that will be left at home. Posibly a cubic style printer.

This is The Alumerod

Edited 2 time(s). Last edit at 11/14/2018 11:25AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

The Alumarod is working fine and I am able to reproduce very neat parts from ABS but the unevenness in the glass bed is causing larger parts to warp still.

I think the glass bed warps due to the clamping system I am using so 4 point leveling does not work.

Till now I have tried to level the bed out as best I could on the three corner screws and then just seting Z 0 at the centre of the bed. Howeer I still keep geting deviations of about 0.2 mm from side to side on the X and Y axes respectively. The glass is definately not flat and I have tried others. Its definately the tension from the frame clamps.

I remember from seting up the Ormerod when I first commisioned it that there is a Mesh Bed Leveling procedure with the infra sensor. But it seems my google-fu is weak.

dc42 suggested "Just set the Z probe type to 0 in the M558 command, set up the grid using M557, send G29, and follow the prompts on DWC or PanelDue."

Alas I don't fully grasp the procedure and researching trying to grasp the procedure has only left me feeling even more incompetent. No results under youtube and searchig other sites also left me more confused.

Mr cheeseandham left me this reply

"[[url=https://duet3d.dozuki.com/]duet3d.dozuki.com[/url]]

You're looking for this with M558 P0 mesh leveling"

I believe this is what I am wanting but again reading through the duet3d.dozuki.com I could still not find this section quoted.

Boy I feel really incapable now

It might also be the flu that is making my head denser than a brick.

I just want to be able to understand how to define my own leveling mesh grid. Then be able to manually at each point have the printer pause and allow me to control the z height with the Duet Web Interfavce until it hits the zero height and store that point. Then the printer will move to the next point waiting for my next participation.

The printer is quite rigid now and I travel with it alot so the need for me to be able to mesh bed level is quite a necessity.

Would any of you please consider helping me trough the procedure step by step?

I saw another Ormerod 2 up for sale on Monday and I am considering buying it in order build another printer design that will be left at home. Posibly a cubic style printer.

This is The Alumerod

Edited 2 time(s). Last edit at 11/14/2018 11:25AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 14, 2018 11:16AM |

Registered: 6 years ago Posts: 174 |

I did find this Using the manual bed levelling assistant but it refers to having adjustment screws and my adjustment screws are locked at the points were they are all equal to zero. But the rest of the print bed does not always have all other points at zero.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 14, 2018 12:29PM |

Registered: 9 years ago Posts: 383 |

|

Re: The Alumarod needs manual mesh bed leveling November 14, 2018 02:05PM |

Registered: 6 years ago Posts: 174 |

|

Re: The Alumarod needs manual mesh bed leveling November 14, 2018 05:42PM |

Registered: 9 years ago Posts: 383 |

Ok, from what I can see in order to do probing completely manually then you need the following lines in your config file:

M558 P0 H5.0 F120 T3000

The critical parts of this are H which defines the height that the probe should be above it's trigger value before it displays the pop up to drop the nozzle to zero. F usually defines the speed that the head dives when it is auto-probing. I'm guessing that this may be the jog speed in your case but I'm not sure. Keep it low to start. Slow enough to hit the emergency stop if all goes weird!

G31 T0 X0.0 Y0.0 Z0.0

I'm not sure if this is needed but the above line says there is zero offset between the probe trigger value and the nozzle location. I'm not sure what would happen if you had 0.1mm in the Z parameter. In an ideal world the pop up would ask you to drop until the nozzle is 0.1mm above the bed and then automatically calculate the z=0 level from that for you. That might not make much sense unless you are dropping the nozzle onto a feeler gauge of a known thickness. The T0 sets the offsets to be applied to manual probing.

M557 X0.0:200.0 Y0.0:210.0 S100.0:105.0

This defines the grid that will be probed. Looking at the X0.0:200.0 section this defines the start of the grid at a x value of 0 and the grid ends at a grid value of 200. The S section defines the gap between the points in X and Y axis. In an ideal world we would just tell the Duet how many steps to break down the distance between min and max but we have to be explicit and tell it the step size. The example given says use a 100mm spacing in x and 105 in y. In a nut shell we've defined a 3 x 3 grid of 9 points that will be probed. The gotcha here is if you accidentally put 101 in the x spacing it would only probe at 2 x co-ordinates rather than 3 resulting in a grid of 6 points; 2 in x, 3 in y.

Once the above is in the config file and the duet has been restarted you should be able to run the probe just by sending the G29 command.

I have not checked through the above as my machines are running at the moment. I do need to convert my machines to run an automatic 4 point probe as the use of bed.g is potentially being removed from the the firmware judging by comments that dc42 has made on the Duet forums.

Take care with this and read through the links that I have provided. There are certain circumstances where the duet will happily drive beyond your axis limits set in the config file and I think this is one of them. Go slow and hit the emergency stop on DWC if the machine does something unexpected.

The specific x and y values you will need depend on the set up of your machine. For example I've set up my mendel to have 0,0 at the centre of the bed but my Ormerod is still 0,0 at the lower left of the build plate.

Edited 1 time(s). Last edit at 11/14/2018 05:47PM by WesBrooks.

M558 P0 H5.0 F120 T3000

The critical parts of this are H which defines the height that the probe should be above it's trigger value before it displays the pop up to drop the nozzle to zero. F usually defines the speed that the head dives when it is auto-probing. I'm guessing that this may be the jog speed in your case but I'm not sure. Keep it low to start. Slow enough to hit the emergency stop if all goes weird!

G31 T0 X0.0 Y0.0 Z0.0

I'm not sure if this is needed but the above line says there is zero offset between the probe trigger value and the nozzle location. I'm not sure what would happen if you had 0.1mm in the Z parameter. In an ideal world the pop up would ask you to drop until the nozzle is 0.1mm above the bed and then automatically calculate the z=0 level from that for you. That might not make much sense unless you are dropping the nozzle onto a feeler gauge of a known thickness. The T0 sets the offsets to be applied to manual probing.

M557 X0.0:200.0 Y0.0:210.0 S100.0:105.0

This defines the grid that will be probed. Looking at the X0.0:200.0 section this defines the start of the grid at a x value of 0 and the grid ends at a grid value of 200. The S section defines the gap between the points in X and Y axis. In an ideal world we would just tell the Duet how many steps to break down the distance between min and max but we have to be explicit and tell it the step size. The example given says use a 100mm spacing in x and 105 in y. In a nut shell we've defined a 3 x 3 grid of 9 points that will be probed. The gotcha here is if you accidentally put 101 in the x spacing it would only probe at 2 x co-ordinates rather than 3 resulting in a grid of 6 points; 2 in x, 3 in y.

Once the above is in the config file and the duet has been restarted you should be able to run the probe just by sending the G29 command.

I have not checked through the above as my machines are running at the moment. I do need to convert my machines to run an automatic 4 point probe as the use of bed.g is potentially being removed from the the firmware judging by comments that dc42 has made on the Duet forums.

Take care with this and read through the links that I have provided. There are certain circumstances where the duet will happily drive beyond your axis limits set in the config file and I think this is one of them. Go slow and hit the emergency stop on DWC if the machine does something unexpected.

The specific x and y values you will need depend on the set up of your machine. For example I've set up my mendel to have 0,0 at the centre of the bed but my Ormerod is still 0,0 at the lower left of the build plate.

Edited 1 time(s). Last edit at 11/14/2018 05:47PM by WesBrooks.

|

Re: The Alumarod needs manual mesh bed leveling November 15, 2018 04:37AM |

Registered: 6 years ago Posts: 174 |

From what I have read so far it seems that I will have to go back to the basics.

The problem with my Auto Z Probing is that the position it goes to is at an offset where the probe isnt even over the bed and thus the probe cannot read the height.

I manually moved the print head to where it should be reading heights and they are as follow.

X20:100:170 Y0:100:190 (That would form the 9 points I have to probe)

The probe reading at 0.05mm above bed is 395 (strenth of the refraction I think) This is the G31

I opened the RRF CONFIG TOOL but at probing points it only allows up to 5 points to be defined.

Maybe I should first try and get this grid sorted before I give up on the existing sensor?

Or does this mean that I have to start from scratch and redo the whole firmware installation? Or can I just change the parameters somewhere else?

I see that there is no bed.g file in my sd card.

My level of confusion cannot be described.

I need to start at one point and move through this whole procedure. as I start with the https://duet3d.dozuki.com/ I read to a certain point then I fall down a rabit hole of sidetracking.

This is my config.g

M111 S0 ; Debug off

M550 PAlumarod ; Machine name (can be anything you like)

M551 Preprap ; Machine password

M552 P192.168.1.240 ; IP address

M553 P255.255.255.0 ; Netmask

M554 P192.168.1.1 ; Gateway

M555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates

M83 ; relative extruder moves

M569 P0 S1 ; direction of X motor

M906 X1000 Y1200 Z800 E1200 ; Set motor currents (mA)

M563 P0 D0 H1 ; Define tool 1

G10 P0 S-273 R-273 ; Set tool 1 operating and standby temperatures

M92 E421 ; Set extruder steps per mm

;M558 P0 ; Manually adjust the nozzle down to the bed (Using the paper feeler test or similar)

M558 P1 ; Use an unmodulated Z probe or an intelligent Z probe

G31 Z0.05 P395 ; Set the probe height and threshold (put your own values here)

M305 P0 T10000 ; added

M305 P1 T100000 R1000 B4138 C0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M201 X1200 Y1200 Z20 E3600 ; set accelerations (mm/s^2)

M556 S78 X0 Y0 Z0 ; axis compensation

M203 X15000 Y15000 Z250 E3600 ; Maximum speeds (mm/min)

M566 X1800 Y1800 Z30 E20 ; maximum jerk speed mm/minute(i.e. maximum instantaneous change in speed)

M208 X210 Y205 Z185 ; set axis travel

M208 X 0 S1 ; set axis minimum

M574 X0 Y2 Z0 S1

T0

Edited 4 time(s). Last edit at 11/15/2018 05:55AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

The problem with my Auto Z Probing is that the position it goes to is at an offset where the probe isnt even over the bed and thus the probe cannot read the height.

I manually moved the print head to where it should be reading heights and they are as follow.

X20:100:170 Y0:100:190 (That would form the 9 points I have to probe)

The probe reading at 0.05mm above bed is 395 (strenth of the refraction I think) This is the G31

I opened the RRF CONFIG TOOL but at probing points it only allows up to 5 points to be defined.

Maybe I should first try and get this grid sorted before I give up on the existing sensor?

Or does this mean that I have to start from scratch and redo the whole firmware installation? Or can I just change the parameters somewhere else?

I see that there is no bed.g file in my sd card.

My level of confusion cannot be described.

I need to start at one point and move through this whole procedure. as I start with the https://duet3d.dozuki.com/ I read to a certain point then I fall down a rabit hole of sidetracking.

This is my config.g

M111 S0 ; Debug off

M550 PAlumarod ; Machine name (can be anything you like)

M551 Preprap ; Machine password

M552 P192.168.1.240 ; IP address

M553 P255.255.255.0 ; Netmask

M554 P192.168.1.1 ; Gateway

M555 P2 ; Set output to look like Marlin

G21 ; Work in millimetres

G90 ; Send absolute coordinates

M83 ; relative extruder moves

M569 P0 S1 ; direction of X motor

M906 X1000 Y1200 Z800 E1200 ; Set motor currents (mA)

M563 P0 D0 H1 ; Define tool 1

G10 P0 S-273 R-273 ; Set tool 1 operating and standby temperatures

M92 E421 ; Set extruder steps per mm

;M558 P0 ; Manually adjust the nozzle down to the bed (Using the paper feeler test or similar)

M558 P1 ; Use an unmodulated Z probe or an intelligent Z probe

G31 Z0.05 P395 ; Set the probe height and threshold (put your own values here)

M305 P0 T10000 ; added

M305 P1 T100000 R1000 B4138 C0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M201 X1200 Y1200 Z20 E3600 ; set accelerations (mm/s^2)

M556 S78 X0 Y0 Z0 ; axis compensation

M203 X15000 Y15000 Z250 E3600 ; Maximum speeds (mm/min)

M566 X1800 Y1800 Z30 E20 ; maximum jerk speed mm/minute(i.e. maximum instantaneous change in speed)

M208 X210 Y205 Z185 ; set axis travel

M208 X 0 S1 ; set axis minimum

M574 X0 Y2 Z0 S1

T0

Edited 4 time(s). Last edit at 11/15/2018 05:55AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 15, 2018 06:02AM |

Registered: 10 years ago Posts: 14,672 |

Have you read [duet3d.dozuki.com] ?

Edited 1 time(s). Last edit at 11/15/2018 06:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/15/2018 06:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 15, 2018 09:10AM |

Registered: 6 years ago Posts: 174 |

Yes I have and it made no sense to me.

I read through all my older posts and I am now a bit closer to understanding the coding process again. So reading it now does make a bit more sense.

This is how I interpret what I am reading

1. I read that you can have G29 wich is Auto Bed Leveling (What des the S0 and S1 signify?)

2. First you must Home all axes G28 (mine does the X and Y and on Z it moves the X to 0 and thus the probe cannot scan the top of the glass since it only ligns up at X50.So i need to figure out where and how to change that. Currently I only go to X100Y100 and manualy set z G92 Z0)

3. Defining a grid using the M557 command. (My probe projects over the bed at these locations: X50 to X170 and Y0 to Y190)

(So then I have to input M557 X50:170 Y10:190 S30 ; probe from X=50 to 170, Y=10 to 190mm with a mesh spacing of 30mm)

(But here lies another problem, my defined grid is not a square but a rectangle so how do I define the mesh spacing then? {170-50}=150x180={190-10})

(Or should I make it M557 X50:170 Y50:170 S30 ?)

4. "You run G29 S0 (or just G29) to probe the bed at the mesh points. If probing is successful, the bed height map is saved in a file on the SD card and is or can be displayed in Duet Web Control"

(Is this refering to the bed.g that will be created?)

5. RepRapFirmware 1.17 or later - (Got that covered)

6. Viewing the height map in the web interface requires Duet Web Control 1.14 or later - (Must confir that. Think I have 1.2.11 or something like that)

7. Using the manual bed levelling assistant. (This looks like what I want but... This feature is implemented in firmware version 1.19 and later and I am on 1.17) Now here I get Sidetracked and confused...

8. Back here. If you are using a Z probe, make sure it is correctly configured and working. (G31 Z0.05 P365 )

This includes the trigger height and the X and Y offsets of the probe relative to the nozzle this I am not sure about, how do I input that offset? (Or is that the X50Y0 that I mentioned in #3?)

(So it should look like this

G31 Z0.05 P365

G31 X50 Y0

or should it be like this

G31 X50 Y0 Z0.05 P365 or G31 P365 X50 Y0 Z0.05)

Especially if using manual probing z height adjustment, Should you only use G31 X50 Y0 of do you leave it there with M558 P0 in order to disable the probe??

9. M558 - Still need to read up bout this

10. G32 - Stil need to read up about this

Any Feedback on these items that I do not completely grasp would be very helpfull.

Edited 2 time(s). Last edit at 11/16/2018 05:23AM by Karoo Klong.

I read through all my older posts and I am now a bit closer to understanding the coding process again. So reading it now does make a bit more sense.

This is how I interpret what I am reading

1. I read that you can have G29 wich is Auto Bed Leveling (What des the S0 and S1 signify?)

2. First you must Home all axes G28 (mine does the X and Y and on Z it moves the X to 0 and thus the probe cannot scan the top of the glass since it only ligns up at X50.So i need to figure out where and how to change that. Currently I only go to X100Y100 and manualy set z G92 Z0)

3. Defining a grid using the M557 command. (My probe projects over the bed at these locations: X50 to X170 and Y0 to Y190)

(So then I have to input M557 X50:170 Y10:190 S30 ; probe from X=50 to 170, Y=10 to 190mm with a mesh spacing of 30mm)

(But here lies another problem, my defined grid is not a square but a rectangle so how do I define the mesh spacing then? {170-50}=150x180={190-10})

(Or should I make it M557 X50:170 Y50:170 S30 ?)

4. "You run G29 S0 (or just G29) to probe the bed at the mesh points. If probing is successful, the bed height map is saved in a file on the SD card and is or can be displayed in Duet Web Control"

(Is this refering to the bed.g that will be created?)

5. RepRapFirmware 1.17 or later - (Got that covered)

6. Viewing the height map in the web interface requires Duet Web Control 1.14 or later - (Must confir that. Think I have 1.2.11 or something like that)

7. Using the manual bed levelling assistant. (This looks like what I want but... This feature is implemented in firmware version 1.19 and later and I am on 1.17) Now here I get Sidetracked and confused...

8. Back here. If you are using a Z probe, make sure it is correctly configured and working. (G31 Z0.05 P365 )

This includes the trigger height and the X and Y offsets of the probe relative to the nozzle this I am not sure about, how do I input that offset? (Or is that the X50Y0 that I mentioned in #3?)

(So it should look like this

G31 Z0.05 P365

G31 X50 Y0

or should it be like this

G31 X50 Y0 Z0.05 P365 or G31 P365 X50 Y0 Z0.05)

Especially if using manual probing z height adjustment, Should you only use G31 X50 Y0 of do you leave it there with M558 P0 in order to disable the probe??

9. M558 - Still need to read up bout this

10. G32 - Stil need to read up about this

Any Feedback on these items that I do not completely grasp would be very helpfull.

Edited 2 time(s). Last edit at 11/16/2018 05:23AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 15, 2018 05:42PM |

Registered: 6 years ago Posts: 174 |

I have now repeatedly read through all the feedback and now I understand a bit better what WesBrooks explained to me so neatly. I was just not able to understand the terms and implementation that well.

Thank you WesBrooks and dc42 for setting me on the right track.

However there now are still a few more questions that I need some help with please.

Edited 1 time(s). Last edit at 11/15/2018 05:43PM by Karoo Klong.

Thank you WesBrooks and dc42 for setting me on the right track.

However there now are still a few more questions that I need some help with please.

Edited 1 time(s). Last edit at 11/15/2018 05:43PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 04:21AM |

Registered: 6 years ago Posts: 174 |

I read through all the .g files in the sys folder and I noticed this in the homez.g

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G90 ; set movement to absolute mode

;M558 P1 ; UNCOMMENT this line if you upgrade to a 4-wire probe

G1 X20 Y0 F12000

G30 ; home Z, using values from G31 in config.g

G1 Z5 F200 ; Move Z up to Z=5

G1 X0 Y0 F2000 ; Move to X=0 Y=0

G1 Z2 F200 ; Move to Z=2

Looking at the config.g it is clear that the G31 infrmation does not correlate with where the probe should be in order to successfully home the z-axis

I will start by changing this and see how it reacts.

G31 P365 X50 Y0 Z0.05

Edited 2 time(s). Last edit at 11/16/2018 05:25AM by Karoo Klong.

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G90 ; set movement to absolute mode

;M558 P1 ; UNCOMMENT this line if you upgrade to a 4-wire probe

G1 X20 Y0 F12000

G30 ; home Z, using values from G31 in config.g

G1 Z5 F200 ; Move Z up to Z=5

G1 X0 Y0 F2000 ; Move to X=0 Y=0

G1 Z2 F200 ; Move to Z=2

Looking at the config.g it is clear that the G31 infrmation does not correlate with where the probe should be in order to successfully home the z-axis

I will start by changing this and see how it reacts.

G31 P365 X50 Y0 Z0.05

Edited 2 time(s). Last edit at 11/16/2018 05:25AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 05:15AM |

Registered: 6 years ago Posts: 174 |

Good!

I got home.z sorted

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G90 ; set movement to absolute mode

;M558 P1 ; UNCOMMENT this line if you upgrade to a 4-wire probe

G1 X50 Y0 F12000 ; The probe was not aligned at X20

G30 ; home Z, using values from G31 in config.g

G1 Z5 F200 ; Move Z up to Z=5

G1 X0 Y0 F2000 ; Move to X=0 Y=0

G1 Z2 F200 ; Move to Z=2

So finaly all axes homing works.

But alas, mesh bed compensasion is still not working. The x carridge just straight on runs into the endstop without trigering it... That is if I press Auto bed compensation.

( The printer uses the z-probe as x-axis endstop so when disabling the probe,how do you set x endstop? Even if you do preset your x-value, the moment you type in G29 it automaticaly wants to find x-endstop.)

I remember now that I still havent created the bed.g file

Edited 1 time(s). Last edit at 11/16/2018 05:28AM by Karoo Klong.

I got home.z sorted

G91 ; set movement to relative mode

G1 Z5 F200 ; move Z up 5mm

G90 ; set movement to absolute mode

;M558 P1 ; UNCOMMENT this line if you upgrade to a 4-wire probe

G1 X50 Y0 F12000 ; The probe was not aligned at X20

G30 ; home Z, using values from G31 in config.g

G1 Z5 F200 ; Move Z up to Z=5

G1 X0 Y0 F2000 ; Move to X=0 Y=0

G1 Z2 F200 ; Move to Z=2

So finaly all axes homing works.

But alas, mesh bed compensasion is still not working. The x carridge just straight on runs into the endstop without trigering it... That is if I press Auto bed compensation.

( The printer uses the z-probe as x-axis endstop so when disabling the probe,how do you set x endstop? Even if you do preset your x-value, the moment you type in G29 it automaticaly wants to find x-endstop.)

I remember now that I still havent created the bed.g file

Edited 1 time(s). Last edit at 11/16/2018 05:28AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 06:23AM |

Registered: 6 years ago Posts: 174 |

The moment I set these in the config.g

M557 X50:170 Y10:170 S10 ; Define Mesh Bed Leveling Grid

M558 P0 ; Manually adjust the nozzle

and I go with G29

I can't homex and when i predefne x with G92 X0 then it still doesnt recognise the x endstop when I want to Auto bedlevel.

What am I missing.

Everywhere i read it just say to define M558 P0

and set the M5578 X0:200 Y0:200 S20 but that does not work.

I get the following warning on G29: Probing did not work Probe did not trigger (But how is it supposed to trigger iff its supposed to be off?)

Is it because my Web interface is HTML 1.11, JS: 1.11 ?

Edited 2 time(s). Last edit at 11/16/2018 06:33AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

M557 X50:170 Y10:170 S10 ; Define Mesh Bed Leveling Grid

M558 P0 ; Manually adjust the nozzle

and I go with G29

I can't homex and when i predefne x with G92 X0 then it still doesnt recognise the x endstop when I want to Auto bedlevel.

What am I missing.

Everywhere i read it just say to define M558 P0

and set the M5578 X0:200 Y0:200 S20 but that does not work.

I get the following warning on G29: Probing did not work Probe did not trigger (But how is it supposed to trigger iff its supposed to be off?)

Is it because my Web interface is HTML 1.11, JS: 1.11 ?

Edited 2 time(s). Last edit at 11/16/2018 06:33AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 06:36AM |

Registered: 8 years ago Posts: 123 |

Hey Karoo,

I wonder if you're getting a bit mixed up here.

G29 requires M557 (putting this in your config.g is a good place) and is the mesh

G32 uses bed.g and is the 3-5 (usually 4 with ormerod) point bed compensation.

1. Read [duet3d.dozuki.com] for the G29 parameters. It explains it better than I can.

2. home all axes is in homeall.g

3. Start simple and small, and in the middle of the bed and see what happens e.g. M557 X50:150 Y50:150 S50

4. bed.g is not created by the Duet, you need to make it. so for G32 (not G29) you will need as an example (and this is intentionally smaller than your bed once again)

7. you should get your firmware to latest if you can, if can potentially solve issues.

8. Yes, the X offset is via G31 e.g.

9. M558 should be something like for an Ormerod

Go through the RepRapFirmware Configuration tool (Version 1) for firmware 1.17 - download it and compare each file to your own and see if anything is missing or different and try to identify why. (or you can use v2, but that is new and has no bed.g)

I wonder if you're getting a bit mixed up here.

G29 requires M557 (putting this in your config.g is a good place) and is the mesh

G32 uses bed.g and is the 3-5 (usually 4 with ormerod) point bed compensation.

1. Read [duet3d.dozuki.com] for the G29 parameters. It explains it better than I can.

2. home all axes is in homeall.g

3. Start simple and small, and in the middle of the bed and see what happens e.g. M557 X50:150 Y50:150 S50

4. bed.g is not created by the Duet, you need to make it. so for G32 (not G29) you will need as an example (and this is intentionally smaller than your bed once again)

; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool on Fri Nov 16 2018 11:24:50 GMT+0000 (Greenwich Mean Time) M561 ; clear any bed transform ; Probe the bed at 4 points G30 P0 X25 Y25 H0 Z-99999 G30 P1 X25 Y175 H0 Z-99999 G30 P2 X175 Y175 H0 Z-99999 G30 P3 X175 Y25 H0 Z-99999 S

7. you should get your firmware to latest if you can, if can potentially solve issues.

8. Yes, the X offset is via G31 e.g.

G31 P500 X30 Y0 Z0.8

9. M558 should be something like for an Ormerod

M558 P1 X1 Y0 Z1 H5 F120 T6000(but I can't check this as I'm at work at the moment and I have an Ormerod 2 anyway so may be different)

Go through the RepRapFirmware Configuration tool (Version 1) for firmware 1.17 - download it and compare each file to your own and see if anything is missing or different and try to identify why. (or you can use v2, but that is new and has no bed.g)

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 06:53AM |

Registered: 6 years ago Posts: 174 |

This time I tried something diferent.

Every time I enter G29 it goes to X0 Y0 for the first probe. I have defined M557 X0:200 Y0:200 S50 But even if I change the X value it still goes to X0

I hold a piece of paper to triger the probe while it is off the bed at X0

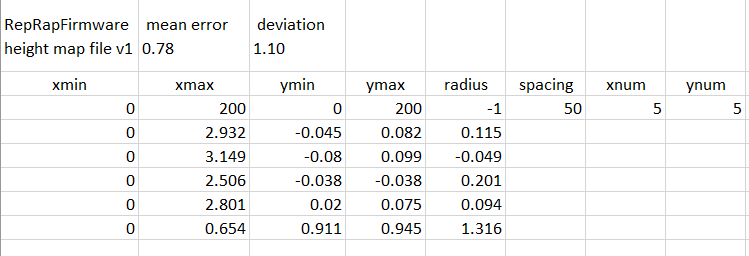

Finaly I got through the probing process and managed to get a heightmap.csv file generated.

RepRapFirmware height map file v1 mean error 0.78 deviation 1.10

xmin xmax ymin ymax radius spacing xnum ynum

0 200 0 200 -1 50 5 5

0 2.932 -0.045 0.082 0.115

0 3.149 -0.08 0.099 -0.049

0 2.506 -0.038 -0.038 0.201

0 2.801 0.02 0.075 0.094

0 0.654 0.911 0.945 1.316

Ok...

Now why does it start the mesh bed leveling at X0 and not at X50?

Edited 3 time(s). Last edit at 11/16/2018 07:04AM by Karoo Klong.

Every time I enter G29 it goes to X0 Y0 for the first probe. I have defined M557 X0:200 Y0:200 S50 But even if I change the X value it still goes to X0

I hold a piece of paper to triger the probe while it is off the bed at X0

Finaly I got through the probing process and managed to get a heightmap.csv file generated.

RepRapFirmware height map file v1 mean error 0.78 deviation 1.10

xmin xmax ymin ymax radius spacing xnum ynum

0 200 0 200 -1 50 5 5

0 2.932 -0.045 0.082 0.115

0 3.149 -0.08 0.099 -0.049

0 2.506 -0.038 -0.038 0.201

0 2.801 0.02 0.075 0.094

0 0.654 0.911 0.945 1.316

Ok...

Now why does it start the mesh bed leveling at X0 and not at X50?

Edited 3 time(s). Last edit at 11/16/2018 07:04AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 07:00AM |

Registered: 6 years ago Posts: 174 |

|

Re: The Alumarod needs manual mesh bed leveling November 16, 2018 11:05AM |

Registered: 8 years ago Posts: 123 |

|

Re: The Alumarod needs manual mesh bed leveling November 17, 2018 05:47AM |

Registered: 6 years ago Posts: 174 |

Quote

cheeseandham

Karoo,

Zip up your whole sys directory and attach it here, I'll be happy to take a look this weekend at some point.

(you should be able to do it from the web interface, just select all the files and right click , save as zip)

Thank you cheeseandham

Here is the zipped sys folder.

Edited 1 time(s). Last edit at 11/17/2018 05:47AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 20, 2018 01:47PM |

Registered: 8 years ago Posts: 123 |

Karoo,

I've had a look, please remember I'm not an expert, just an enthusiastic amateur!

I've not seen you specify exactly which Ormerod, I get the impression that you are using an Ormerod 1, and my information is based on this assumption.

There are 3 config.g files here, so I'm just going on the main config.g

i) I note your G31 has a P value of 365 and 0.2 - this IMHO is a biggie. The sensors I am familiar with require a P value of 500 or 600 and typically are not sensitive at lower values.

ii) you have no bed.g for G32. While this is deprecated, before mesh leveling I feel you need to get (i) sorted, and G32 working (as it is simpler IMO)

iii) a very bare config.g with little errors such as "M208 X 0 S1" (shouldn't be a space there) and no M557 mesh levelling nor a lot of other values.

using your values in your config.g and putting it through the Reprap configurator, you get a much nicer config.g with which to work with (and bed.g , homeall.g etc)

The whole thing is here karooconfig.zip

Edited 1 time(s). Last edit at 11/20/2018 01:48PM by cheeseandham.

I've had a look, please remember I'm not an expert, just an enthusiastic amateur!

I've not seen you specify exactly which Ormerod, I get the impression that you are using an Ormerod 1, and my information is based on this assumption.

There are 3 config.g files here, so I'm just going on the main config.g

i) I note your G31 has a P value of 365 and 0.2 - this IMHO is a biggie. The sensors I am familiar with require a P value of 500 or 600 and typically are not sensitive at lower values.

ii) you have no bed.g for G32. While this is deprecated, before mesh leveling I feel you need to get (i) sorted, and G32 working (as it is simpler IMO)

iii) a very bare config.g with little errors such as "M208 X 0 S1" (shouldn't be a space there) and no M557 mesh levelling nor a lot of other values.

using your values in your config.g and putting it through the Reprap configurator, you get a much nicer config.g with which to work with (and bed.g , homeall.g etc)

; Configuration file for Duet 0.6 (firmware version 1.17 to 1.19) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Tue Nov 20 2018 18:26:14 GMT+0000 (Greenwich Mean Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 PMichiel Ormerod 1 ; Set machine name M552 P192.168.1.240 ; IP address M553 P255.255.255.0 ; Netmask M554 P192.168.1.1 ; Gateway M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M92 X87.489 Y87.489 Z4000 E420 ; Set steps per mm M566 X1800 Y1800 Z30 E20 ; Set maximum instantaneous speed changes (mm/min) M203 X15000 Y15000 Z250 E3600 ; Set maximum speeds (mm/min) M201 X500 Y500 Z20 E250 ; Set accelerations (mm/s^2) M906 X1000 Y1200 Z800 E1200 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X210 Y205 Z185 S0 ; Set axis maxima ; Endstops M574 X0 Z0 S0 ; Set active low endstops M574 Y2 S1 ; Set active high endstops ; Z-Probe M558 P1 X1 Y0 Z1 H5 F120 T6000 ; Set Z probe type to unmodulated, the axes for which it is used and the dive height + speeds G31 P500 X0 Y0 Z0.2 ; Set Z probe trigger value, offset and trigger height M556 S0 X0 Y0 Z0 ; Set orthogonal axis compensation parameters M557 X15:215 Y15:195 S20 ; Define mesh grid ; Heaters M305 P0 T10000 B3988 C0 R1000 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 C0 R1000 ; Set thermistor + ADC parameters for heater 1 M143 H1 S280 ; Set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R-273 S-273 ; Set initial tool 0 active and standby temperatures to 0C ; Custom settings are not configured

The whole thing is here karooconfig.zip

Edited 1 time(s). Last edit at 11/20/2018 01:48PM by cheeseandham.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 12:38PM |

Registered: 6 years ago Posts: 174 |

I understand and appreciate your time and effort to try and help me very much.Quote

cheeseandham

I've had a look, please remember I'm not an expert, just an enthusiastic amateur!

That is correct, I have an Ormerod 1, of the origional RS branded modelsQuote

cheeseandham

I've not seen you specify exactly which Ormerod, I get the impression that you are using an Ormerod 1, and my information is based on this assumption.

Yes the config.g was one that I started editing and has the Home Z sorted outQuote

cheeseandham

There are 3 config.g files here, so I'm just going on the main config.g

No you may have misread that, G31 has a P value of 365 at 0.05mm (I am assuming the 0.2 should be in mm right?)Quote

cheeseandham

i) I note your G31 has a P value of 365 and 0.2 - this IMHO is a biggie. The sensors I am familiar with require a P value of 500 or 600 and typically are not sensitive at lower values.

Yes that was the main problem I did not have a bed.g and did not know how to get hold of one.Quote

cheeseandham

ii) you have no bed.g for G32. While this is deprecated, before mesh leveling I feel you need to get (i) sorted, and G32 working (as it is simpler IMO)

Thank you for this, I tried using the RepRap configurator but got stuck at some of the requeted information. I did not know how and where to find all that information.Quote

cheeseandham

using your values in your config.g and putting it through the Reprap configurator, you get a much nicer config.g with which to work with (and bed.g , homeall.g etc)

I copied the sys folder over to an sd card and inserted it into my printer. I tried connecting via Duet Web Controld and get the following Ajax Communication Error;

An AJAX error has been reported, so the current session has been terminated.

Please check if your printer is still on and try to connect again.

Error reason: SyntaxError: Unexpected token a in JSON at position 65

Any Idea what this might mean?

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 01:06PM |

Registered: 8 years ago Posts: 123 |

Quote

Karoo Klong

No you may have misread that, G31 has a P value of 365 at 0.05mm (I am assuming the 0.2 should be in mm right?)

As per Setting the Z probe ,

"7. Repeat the above until G31 reports a value of around 600, +/-20"

to my knowledge a P value of 365 (and 0.05mm) to me means that your probe is too high (or possibly too low, I can't remember) compared to your hot-end , and you will have massive issues with levelling.

Quote

Karoo Klong

I copied the sys folder over to an sd card and inserted it into my printer. I tried connecting via Duet Web Controld and get the following Ajax Communication Error;

An AJAX error has been reported, so the current session has been terminated.

Please check if your printer is still on and try to connect again.

Error reason: SyntaxError: Unexpected token a in JSON at position 65

Any Idea what this might mean?

No, although this post by dc42 indicates that it may be a firmware issue.

If it were me, I really would spend the time to

a) sort out the hotend so you get a P600 value (usually at 1-2mm)

b) upgrade to the last firmware for the Duet 0.6

before you go anywhere else.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 02:42PM |

Registered: 6 years ago Posts: 174 |

Ok Thanks for clearing that up.

I will bite the bullet and update the firmare and the web interface as well.

I found the problem with the P500 value that my printer does not return.

I loosened the probe and found that it had been set all the way to the top.

So I homed the axes and set the nozzle to centre of bed and dropped it all the way according to the paper feel method. then dropped 0.05mm to achieve zero

Then I adjusted the IR probe untill it returned a value of 500 on the Duet Web Control interface.

Finaly, one fault found.

I will bite the bullet and update the firmare and the web interface as well.

I found the problem with the P500 value that my printer does not return.

I loosened the probe and found that it had been set all the way to the top.

So I homed the axes and set the nozzle to centre of bed and dropped it all the way according to the paper feel method. then dropped 0.05mm to achieve zero

Then I adjusted the IR probe untill it returned a value of 500 on the Duet Web Control interface.

Finaly, one fault found.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 03:45PM |

Registered: 8 years ago Posts: 123 |

Karoo

P500?

As above:-

"7. Repeat the above until G31 reports a value of around 600, +/-20"

580-620 is where the sensitivity of the Ormerod sensor lies (I said "500-600" because I meant "500 for dc42's sensor and 600 for the RepRapPro sensor" and shortened it badly).

Outside of this range you are going to still have inaccuracies.

Regarding the firmware update.

There is a reason that the reprapro documentation says in the commissioning pages "Update your firmware" and the next section says "No, really, update your firmware!". It's also the first thing Duet support says when someone has a problem.

Yes, you may have a teething issue or two as you have to reconfigure your homing files/config.g, but you'll thank yourself at a later date.

Some of my biggest issues have been because I've not wanted to change things because it'll "be an effort", to my own detriment. In the end it's worth doing everything properly.

P500?

As above:-

"7. Repeat the above until G31 reports a value of around 600, +/-20"

580-620 is where the sensitivity of the Ormerod sensor lies (I said "500-600" because I meant "500 for dc42's sensor and 600 for the RepRapPro sensor" and shortened it badly).

Outside of this range you are going to still have inaccuracies.

Regarding the firmware update.

There is a reason that the reprapro documentation says in the commissioning pages "Update your firmware" and the next section says "No, really, update your firmware!". It's also the first thing Duet support says when someone has a problem.

Yes, you may have a teething issue or two as you have to reconfigure your homing files/config.g, but you'll thank yourself at a later date.

Some of my biggest issues have been because I've not wanted to change things because it'll "be an effort", to my own detriment. In the end it's worth doing everything properly.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 04:09PM |

Registered: 6 years ago Posts: 174 |

That's my problem with the infrared sensor.

I don't get anything beter than P521 vaue and thats with the sensor face 0.2mm above the bed (I had to bend it down) and with the print nozzle on Z0

I don't know how to get the value any closer to 600.

Edited 2 time(s). Last edit at 11/21/2018 04:12PM by Karoo Klong.

I don't get anything beter than P521 vaue and thats with the sensor face 0.2mm above the bed (I had to bend it down) and with the print nozzle on Z0

I don't know how to get the value any closer to 600.

Edited 2 time(s). Last edit at 11/21/2018 04:12PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 04:11PM |

Registered: 8 years ago Posts: 123 |

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 04:13PM |

Registered: 9 years ago Posts: 383 |

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 06:48PM |

Registered: 6 years ago Posts: 174 |

With white paper under the sensor I remember seeing a reading of close to 900.

No I do not have paper targets on the glass bed since having those will render mesh bed leveling useless as you cannot have targets on the printing surface.

Do you propose I put a sheet of paper under the glass bed. Would'nt that pose a burning hazard since I use the heated bed at 120°C

Edited 2 time(s). Last edit at 11/21/2018 06:51PM by Karoo Klong.

No I do not have paper targets on the glass bed since having those will render mesh bed leveling useless as you cannot have targets on the printing surface.

Do you propose I put a sheet of paper under the glass bed. Would'nt that pose a burning hazard since I use the heated bed at 120°C

Edited 2 time(s). Last edit at 11/21/2018 06:51PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 07:03PM |

Registered: 9 years ago Posts: 383 |

Are you running the standard RepRap heated bed? If so I'd prepare it as per the instructions. Here's the build surface prep instructions for the Ormerod2:

[reprapltd.com]

Edited 1 time(s). Last edit at 11/21/2018 07:15PM by WesBrooks.

[reprapltd.com]

Edited 1 time(s). Last edit at 11/21/2018 07:15PM by WesBrooks.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 07:07PM |

Registered: 9 years ago Posts: 383 |

Auto ignition temperature of paper would appear to be over 200C

[en.wikipedia.org]

I've moved to using spray bed adhesive called 3DLac, which seems not much more than hairspray. Because I moved away form the Kapton tape I couldn't use plain paper. I now use printer envelope labels trimmed to 25mm square, but only run my bed at 60C for PLA.

[en.wikipedia.org]

I've moved to using spray bed adhesive called 3DLac, which seems not much more than hairspray. Because I moved away form the Kapton tape I couldn't use plain paper. I now use printer envelope labels trimmed to 25mm square, but only run my bed at 60C for PLA.

|

Re: The Alumarod needs manual mesh bed leveling November 21, 2018 07:37PM |

Registered: 6 years ago Posts: 174 |

White paper tabs ontop of the glass will work but then I have to forget a out mesh bed leveling as having extra targets all over the print surface will interfere with the print footing. Has anybody tried mirror beds? I see alot of Youtubers reccomend the use of mirrors for print surfaces.

Yes it is still the RepRap heated bed that came with the kit.

The powersupply however is set for 15.7V so it heats up the bed quite a bit quicker. I did solder in diodes as dc42 proposed for the cooling fan. I am not sure what other impact that will have on the IR sensor.

I also looked at the latest firmware available. It seems I need to go for Firmware 1.22 with the 0.6 Board I have. Or are there higher versions to look for. Then, do I also only use the web interface for that same version of firmware?

I don't use any kind of sprays or adhesives any more. The 120°C bed makes abs stick like a dream to the new glass plate.

I also don't use any stickers or stuff on the glass. It's just the plain aluminium sheet ontop of the heated plate with mdf sheet under the heated bed for insulation since it looses heat very quickly without it. Then the plain glass sheet ontop of the aluminium sheet. All is held together by four photo frame spring clips.

I have an LED strip stuck to the underside of the X-arm rib. Will that interfere with the IR sensor P value?

Is there a pinout on the Duet bord that I can use for switching the led strip on and off? I only know of the part cooling fan pinout that supports that.

Edited 5 time(s). Last edit at 11/21/2018 08:01PM by Karoo Klong.

Yes it is still the RepRap heated bed that came with the kit.

The powersupply however is set for 15.7V so it heats up the bed quite a bit quicker. I did solder in diodes as dc42 proposed for the cooling fan. I am not sure what other impact that will have on the IR sensor.

I also looked at the latest firmware available. It seems I need to go for Firmware 1.22 with the 0.6 Board I have. Or are there higher versions to look for. Then, do I also only use the web interface for that same version of firmware?

I don't use any kind of sprays or adhesives any more. The 120°C bed makes abs stick like a dream to the new glass plate.

I also don't use any stickers or stuff on the glass. It's just the plain aluminium sheet ontop of the heated plate with mdf sheet under the heated bed for insulation since it looses heat very quickly without it. Then the plain glass sheet ontop of the aluminium sheet. All is held together by four photo frame spring clips.

I have an LED strip stuck to the underside of the X-arm rib. Will that interfere with the IR sensor P value?

Is there a pinout on the Duet bord that I can use for switching the led strip on and off? I only know of the part cooling fan pinout that supports that.

Edited 5 time(s). Last edit at 11/21/2018 08:01PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 01:57AM |

Registered: 9 years ago Posts: 383 |

At the moment your bed compensation or level check is likely to be incorrect. As cheeseandham pointed out your trigger value is much lower than the sweet spot for the sensor that it's designers have indicated. This will mean the the system will attempt to find your trigger value but the level at which it does will be inconsistent and have large error. I'd say get the system working as standard and lets have a look at the picture the duet web contol shows you after a four point check. You may not need a full mesh bed compensation.

The standard IR sensor is a fussy thing that is very sensitive to environmental lighting. It can get very confused by a filament light. I found out a couple of days ago that a little 12v halogen light raised the home level by ~5mm! That said a strong flouresent light in the room had no effect. It really depends on the light being given off. Move the nozzle close to the build surface and turn the light on and off and see if it has a strong effect on the current sensor value. If it's in a position of strong sunlight it would be worth moving it to the shade.

Just go for the latest release of the duet web control software. Not sure about the versions you are on at the moment but the current release has a live read out of the sensot value.

The standard IR sensor is a fussy thing that is very sensitive to environmental lighting. It can get very confused by a filament light. I found out a couple of days ago that a little 12v halogen light raised the home level by ~5mm! That said a strong flouresent light in the room had no effect. It really depends on the light being given off. Move the nozzle close to the build surface and turn the light on and off and see if it has a strong effect on the current sensor value. If it's in a position of strong sunlight it would be worth moving it to the shade.

Just go for the latest release of the duet web control software. Not sure about the versions you are on at the moment but the current release has a live read out of the sensot value.

Sorry, only registered users may post in this forum.