The Alumarod needs manual mesh bed leveling

Posted by Karoo Klong

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 02:05AM |

Registered: 9 years ago Posts: 383 |

Detecting glass build surfaces is notoriously difficult for IR sensors and they get reflections ftom the top and bottom surface of the glass sheet that creates a significant error.

If you really wanted an alternative build surface then a commercial build surface that is not transparent and has a matt surface finish would work best.

Edit: I was asking about you abs because I wanted to understand better how you came to the conclusion the bed level was the cause of your warping issue. On another machine I had no luck with large ABS parts until I worked in an enclosure.

Edited 1 time(s). Last edit at 11/22/2018 02:08AM by WesBrooks.

If you really wanted an alternative build surface then a commercial build surface that is not transparent and has a matt surface finish would work best.

Edit: I was asking about you abs because I wanted to understand better how you came to the conclusion the bed level was the cause of your warping issue. On another machine I had no luck with large ABS parts until I worked in an enclosure.

Edited 1 time(s). Last edit at 11/22/2018 02:08AM by WesBrooks.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 04:15AM |

Registered: 8 years ago Posts: 123 |

Karoo,

Now I'm beginning to understand the picture. You are trying to use the standard Ormerod sensor on glass, without white stickers and with mesh leveling! Arrgh!

The Ormerod sensor is simply not designed for mesh leveling with glass/kapton. It really does need the white stickers.

Please, do yourself a favour and forget mesh leveling for now. Go with 4 point compensation with white stickers. Glass is a flat surface and you will get decent results, I promise.

(to add to this, me and a number of other people in the Railcore group are using BLTouch , IR probes, and piezo sensors with PrintBite+,glass,LokBuild, PEI and other surfaces. Everything points to mesh leveling being extremely finicky at best, and at worst a huge waste of time for the person trying to get it working)

Perhaps you can get away with it on a very hot summers day in SA, but ABS needs an enclosure and about 40-50 degrees C within. You can make an enclosure with something as simple as a large cardboard box. (which was my first enclosure)

Now I'm beginning to understand the picture. You are trying to use the standard Ormerod sensor on glass, without white stickers and with mesh leveling! Arrgh!

The Ormerod sensor is simply not designed for mesh leveling with glass/kapton. It really does need the white stickers.

Please, do yourself a favour and forget mesh leveling for now. Go with 4 point compensation with white stickers. Glass is a flat surface and you will get decent results, I promise.

(to add to this, me and a number of other people in the Railcore group are using BLTouch , IR probes, and piezo sensors with PrintBite+,glass,LokBuild, PEI and other surfaces. Everything points to mesh leveling being extremely finicky at best, and at worst a huge waste of time for the person trying to get it working)

Perhaps you can get away with it on a very hot summers day in SA, but ABS needs an enclosure and about 40-50 degrees C within. You can make an enclosure with something as simple as a large cardboard box. (which was my first enclosure)

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 04:51AM |

Registered: 10 years ago Posts: 14,672 |

Quote

WesBrooks

Detecting glass build surfaces is notoriously difficult for IR sensors and they get reflections ftom the top and bottom surface of the glass sheet that creates a significant error.

Detecting the surface is very easy for the differential IR sensor that I make. But as you say, the reflection from the back surface of the glass interferes with the reflection from the front surface, causing a change in trigger height. This is manageable under some conditions. My Ormerod uses 3mm float glass and the aluminium bed plate is painted matt black. I get acceptable results from the differential IR sensor. However, I only print PLA on it, which means I don't need to to use any kind of coating on the surface of the glass. Using a coating changes the balance of the reflections from top and bottom surfaces, and because the coating won't be uniform, this leads to inconsistent trigger height.

Using black glass might resolve this, however I've been unable to find black glass that isn't toughened (the toughening process usually causes warping) and doesn't have a textured surface.

Edited 1 time(s). Last edit at 11/22/2018 05:31AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 05:03AM |

Registered: 6 years ago Posts: 174 |

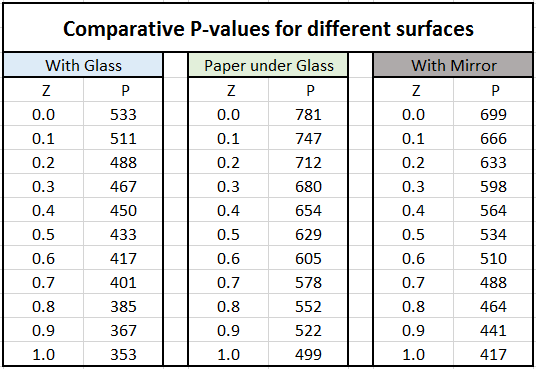

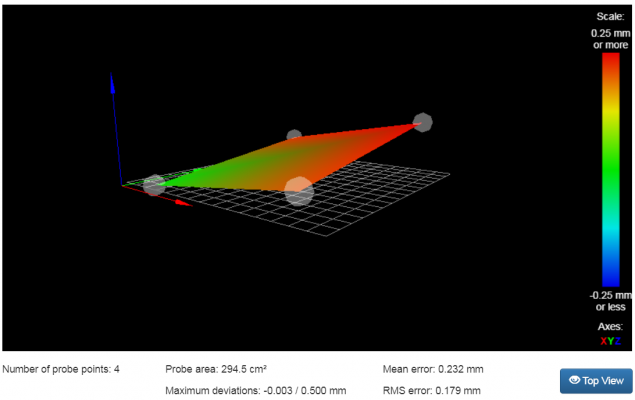

While my system is still functioning before I do the update of firmware I did a surface comparason in order to correlate P-values.

Here are the results

I will install a piece of blank paper under the glass bed.

Edited 1 time(s). Last edit at 11/22/2018 05:07AM by Karoo Klong.

Here are the results

I will install a piece of blank paper under the glass bed.

Edited 1 time(s). Last edit at 11/22/2018 05:07AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 05:43AM |

Registered: 9 years ago Posts: 383 |

If you want to do your own thing that's fine but we will be unlikely to help you out of difficulties.

If you want us to help out any further with the stock set up then I think you need to do the following including bits CheeseAndHam has already suggested:

If you still have a warping issue with the complete build run the first layer only and show us some close up pictures of that. If there are no areas where the bead is looking vastly different extrusion thicknesses (indicating a variation in the nozzle to bed height) then I'd wager your issue is not about a bent/distorted bed and more about standard ABS adhesion, thermal stress, and warping issues. In this case all is still not lost. You can try an enclosure and you can try other build surfaces. Some of these are also likely to improve the behaviour of the IR sensor.

DC42s sensor is a wise move as it is less susceptible to environmental issues like sunlight or filament bulbs etc. I've two here which I'm looking forward to trying, but currently I'm trying to address the more mechanical issues of the machine.

As a footnote to this I always manually set my nozzle offset after running the four point bed level test. I just don't trust the consistency of the sensor. I'm hoping this isn't needed with DC42s sensor unless I make a mechanical change to the hot end.

Edited 2 time(s). Last edit at 11/22/2018 05:48AM by WesBrooks.

If you want us to help out any further with the stock set up then I think you need to do the following including bits CheeseAndHam has already suggested:

- Update to the latest version of firmware and web control software.

- Find a way of securing four 25mm paper targets (or perhaps masking/painters tape?) onto the top of the surface running a test to ensure it stays put at your chosen bed temperature.

- Set up a mesh bed correction with just four points. (There is discussion about removing support for bed level correction using points specified in bed.g)

- Run the mesh bed and look at the image. If there appears to be a twist in the bed then try to correct the alignment of the y-axis rods. There are many threads on here discussing that and a few parts on thingverse that can help.

- Manually level the bed as best you can.

- Run your build that is giving you warping issues and see if it is still a problem.

If you still have a warping issue with the complete build run the first layer only and show us some close up pictures of that. If there are no areas where the bead is looking vastly different extrusion thicknesses (indicating a variation in the nozzle to bed height) then I'd wager your issue is not about a bent/distorted bed and more about standard ABS adhesion, thermal stress, and warping issues. In this case all is still not lost. You can try an enclosure and you can try other build surfaces. Some of these are also likely to improve the behaviour of the IR sensor.

DC42s sensor is a wise move as it is less susceptible to environmental issues like sunlight or filament bulbs etc. I've two here which I'm looking forward to trying, but currently I'm trying to address the more mechanical issues of the machine.

As a footnote to this I always manually set my nozzle offset after running the four point bed level test. I just don't trust the consistency of the sensor. I'm hoping this isn't needed with DC42s sensor unless I make a mechanical change to the hot end.

Edited 2 time(s). Last edit at 11/22/2018 05:48AM by WesBrooks.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 05:46AM |

Registered: 9 years ago Posts: 383 |

Quote

dc42

Detecting the surface is very easy for the differential IR sensor that I make. But as you say, the reflection from the back surface of the glass interferes with the reflection from the front surface, causing a change in trigger height. This is manageable under some conditions. My Ormerod uses 3mm float glass and the aluminium bed plate is painted matt black. I get acceptable results from the differential IR sensor. However, I only print PLA on it, which means I don't need to to use any kind of coating on the surface of the glass. Using a coating changes the balance of the reflections from top and bottom surfaces, and because the coating won't be uniform, this leads to inconsistent trigger height.

Using black glass might resolve this, however I've been unable to find black glass that isn't toughened (the toughening process usually causes warping) and doesn't have a textured surface.

Yes, sorry I should have been more careful with my wording. My comments were not about the generic IR sensing method and more specific to the stock sensor.

Do you need to check nozzle height after running a bed level (or four point mesh) check with your sensor or is it far more fire-and-forget? Regular baby-stepping needed at the start?

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 07:29AM |

Registered: 6 years ago Posts: 174 |

Thank you WesBrooks.

I I appreciate the help and I most certainly don't intend on following my own path into a dark chasm from which I will not return any results.

I just wanted to see how the IR sensor reacts to different materials before I take the step to completely recommission my machine.

I I appreciate the help and I most certainly don't intend on following my own path into a dark chasm from which I will not return any results.

I just wanted to see how the IR sensor reacts to different materials before I take the step to completely recommission my machine.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 07:35AM |

Registered: 9 years ago Posts: 383 |

That's fair enough. Don't get me wrong, the dark side is tempting! :-D Well worth a poke once you've got a steady base to work from. Trouble with these systems is that by their very nature there are so many things that come into play it can be very difficult to know what is causing problems until you've played around for a bit.

With regards your tests I would be more interested in the deviation in results from probing the same location a number of times rather than the results for different heights. On of the G code commands probes to the trigger point and reports the value rather than change it. Repeat this many times (30 would be ideal) to get an idea of the systems error.

With regards your tests I would be more interested in the deviation in results from probing the same location a number of times rather than the results for different heights. On of the G code commands probes to the trigger point and reports the value rather than change it. Repeat this many times (30 would be ideal) to get an idea of the systems error.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 07:49AM |

Registered: 8 years ago Posts: 123 |

Karoo,

You might like to know. I have dc42's sensor and while I like it, I've still got problems with mesh leveling with different print surfaces (printbite / lokbuild), so I'm running 4 point on the lokbuild

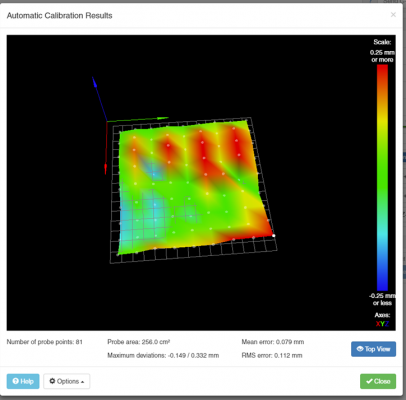

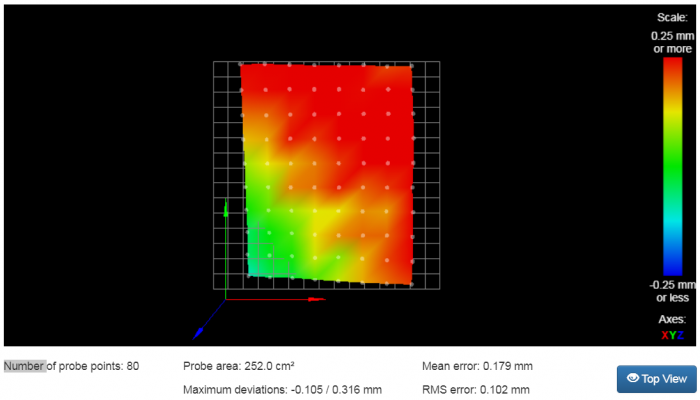

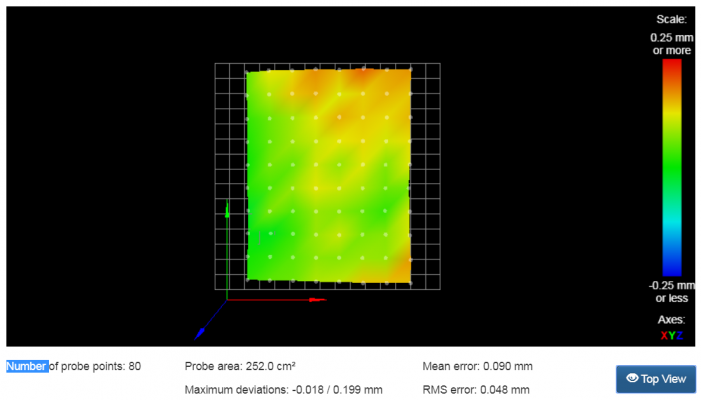

This is my last mesh with lokbuild stuck on my aluminium plate.

If you're wondering about the flatness of my aluminium plate, it is Aluminium ACP 5080 6mm, with a base tolerance is 0.1mm across a length of 3.3m x width 2.05m.

Then it was cut to 203mm x 203mm and ground flat to a tolerance of 0.4 microns.

It's pretty flat.

You might like to know. I have dc42's sensor and while I like it, I've still got problems with mesh leveling with different print surfaces (printbite / lokbuild), so I'm running 4 point on the lokbuild

This is my last mesh with lokbuild stuck on my aluminium plate.

If you're wondering about the flatness of my aluminium plate, it is Aluminium ACP 5080 6mm, with a base tolerance is 0.1mm across a length of 3.3m x width 2.05m.

Then it was cut to 203mm x 203mm and ground flat to a tolerance of 0.4 microns.

It's pretty flat.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 08:11AM |

Registered: 6 years ago Posts: 174 |

Wow Thats quite flat indeed. You went through alot of troube to make sure you get a decent flat surface.

Last major question for now guys...

Do I go for Firmware 1.21 with the •For Duet 06 or 085: RepRapFirmware.bin and iap.bin?

Or do I opt for the newer Firmware 1.22 where Duet 06 and 085 users should install RepRapFirmware.bin and DuetWebControl-1.22.3-dc42.zip.

AND should I use the latest DuetWebControl-1.22.5.zip form Release 2.02RC4 released this Nov 18, 2018 instead of DuetWebControl-1.22.3-dc42.zip

If I have consensus on this (Firmware 1.22 and DWC1.22.5 what it looks like to me?) then I will hit the MASTER RESET.

Edited 3 time(s). Last edit at 11/22/2018 08:43AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

Last major question for now guys...

Do I go for Firmware 1.21 with the •For Duet 06 or 085: RepRapFirmware.bin and iap.bin?

Or do I opt for the newer Firmware 1.22 where Duet 06 and 085 users should install RepRapFirmware.bin and DuetWebControl-1.22.3-dc42.zip.

AND should I use the latest DuetWebControl-1.22.5.zip form Release 2.02RC4 released this Nov 18, 2018 instead of DuetWebControl-1.22.3-dc42.zip

If I have consensus on this (Firmware 1.22 and DWC1.22.5 what it looks like to me?) then I will hit the MASTER RESET.

Edited 3 time(s). Last edit at 11/22/2018 08:43AM by Karoo Klong.

Ormerod 1 - Sructural parts evolving to mainly Aluminium and still upgrading.

Electronics: Duet 0.6

Firmware Name: RepRapFirmware for Duet

Firmware Version: 1.17e (2017-02-10)

Web Interface Version: HTML: 1.11, JS: 1.11

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 09:00AM |

Registered: 8 years ago Posts: 123 |

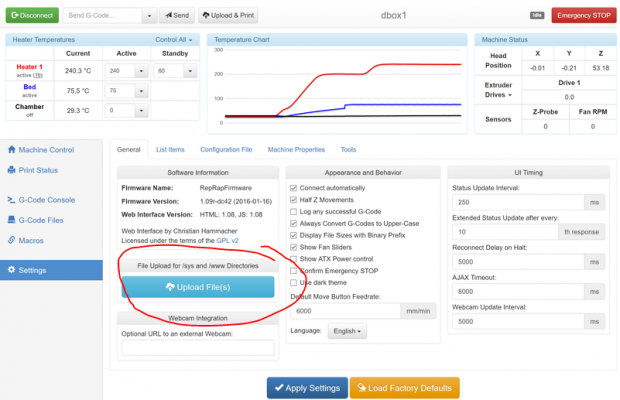

Read Installing and Updating Firmware on the Duet3D wiki

I'm not sure about DWC compatibility across firmwares. I personally would always keep the DWC that was released with the firmware, unless you find instructions from dc42 stating otherwise.

Upgrade the firmware first, then the Webcontrol

RepRapFirmware.bin

DuetWebControl-1.22.3.zip

You will probably also need the helper file

iap.bin

uploaded to the sys directory too.

If you are on 1.19, you shouldn't need to reset, but do a very easy upload of these files via the web interface as the "Usual Procedure". -

Edited 1 time(s). Last edit at 11/22/2018 09:01AM by cheeseandham.

I'm not sure about DWC compatibility across firmwares. I personally would always keep the DWC that was released with the firmware, unless you find instructions from dc42 stating otherwise.

Upgrade the firmware first, then the Webcontrol

RepRapFirmware.bin

DuetWebControl-1.22.3.zip

You will probably also need the helper file

iap.bin

uploaded to the sys directory too.

If you are on 1.19, you shouldn't need to reset, but do a very easy upload of these files via the web interface as the "Usual Procedure". -

Edited 1 time(s). Last edit at 11/22/2018 09:01AM by cheeseandham.

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 09:32AM |

Registered: 6 years ago Posts: 174 |

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 11:13AM |

Registered: 10 years ago Posts: 14,672 |

Quote

cheeseandham

Karoo,

You might like to know. I have dc42's sensor and while I like it, I've still got problems with mesh leveling with different print surfaces (printbite / lokbuild), so I'm running 4 point on the lokbuild

This is my last mesh with lokbuild stuck on my aluminium plate.

[attachment 108223 Capture.PNG]

That pattern indicates that there is a problem with your X axis. At low X values, the trigger height is depending on the direction in which the X axis last moved.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 22, 2018 01:03PM |

Registered: 9 years ago Posts: 383 |

Quote

dc42

That pattern indicates that there is a problem with your X axis. At low X values, the trigger height is depending on the direction in which the X axis last moved.

Assume you've got your Ormerod pretty tightly tuned in? Mind giving us a screen shot of a gold standard for our machines and your sensor?

|

Re: The Alumarod needs manual mesh bed leveling November 24, 2018 12:44PM |

Registered: 6 years ago Posts: 174 |

Great.

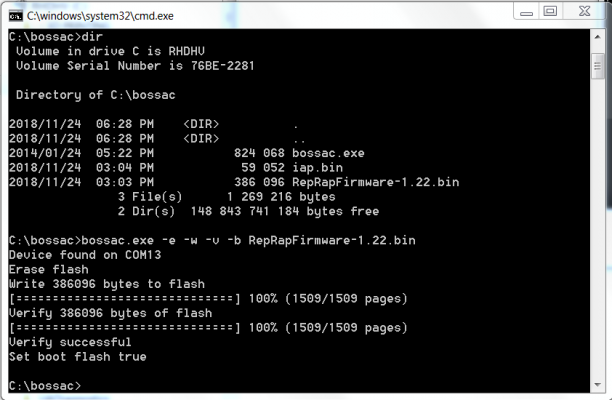

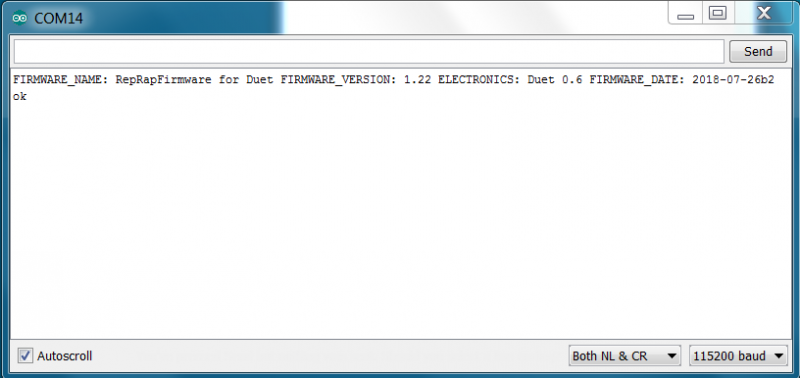

I managed to upload Firmware 1.22 by using bossac and confirmed via Arduino control.

I am not sure what to do with the iap.bin file. I uploaded it using the web interface but I did not note any changes.

Question, an anoying thing happened on the web interface while scroling down it keeps jumping to the top after a second or two. Is there something worng? I am using Chrome

I couldn't make any machine moves it kept complaining about no axis homed. It did home y-axis without trouble.

When I homed x it just ran into the end at the endstop but no homing happened. Gears keep slipping.

The IR sensor blue pin is plugged into pin #6.

The commisionong documentation does not correlate with what is available at the git hub.

There is no where where you can see any way to download the sys folder that supposedly comes with the new Firmware. (I did use the sys folder you compiled for me WesBrooks, but I realised it was for an earlier Firmware 1.17)

So I went to the RepRap configuration tool to set up new system files. I just chose Ormerod 1 for Duet 06 and kept on clicking next.

I downloaded the files and configuerd them in editor to customize for my printer.

I have movement again. I still need to do alot of amending to the .g files but hopefully I'll manage.

Thanks for all the help so far you guys, Especially WesBrooks and cheeseandham for your patience.

Edited 6 time(s). Last edit at 11/24/2018 02:06PM by Karoo Klong.

I managed to upload Firmware 1.22 by using bossac and confirmed via Arduino control.

I am not sure what to do with the iap.bin file. I uploaded it using the web interface but I did not note any changes.

Question, an anoying thing happened on the web interface while scroling down it keeps jumping to the top after a second or two. Is there something worng? I am using Chrome

I couldn't make any machine moves it kept complaining about no axis homed. It did home y-axis without trouble.

When I homed x it just ran into the end at the endstop but no homing happened. Gears keep slipping.

The IR sensor blue pin is plugged into pin #6.

The commisionong documentation does not correlate with what is available at the git hub.

There is no where where you can see any way to download the sys folder that supposedly comes with the new Firmware. (I did use the sys folder you compiled for me WesBrooks, but I realised it was for an earlier Firmware 1.17)

So I went to the RepRap configuration tool to set up new system files. I just chose Ormerod 1 for Duet 06 and kept on clicking next.

I downloaded the files and configuerd them in editor to customize for my printer.

I have movement again. I still need to do alot of amending to the .g files but hopefully I'll manage.

Thanks for all the help so far you guys, Especially WesBrooks and cheeseandham for your patience.

Edited 6 time(s). Last edit at 11/24/2018 02:06PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 24, 2018 02:49PM |

Registered: 8 years ago Posts: 123 |

|

Re: The Alumarod needs manual mesh bed leveling November 24, 2018 03:01PM |

Registered: 6 years ago Posts: 174 |

|

Re: The Alumarod needs manual mesh bed leveling November 24, 2018 06:47PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Karoo Klong

I am not sure what to do with the iap.bin file. I uploaded it using the web interface but I did not note any changes.

Having it on the system lets you update the firmware through the web interface in future.

Quote

Karoo Klong

Question, an anoying thing happened on the web interface while scroling down it keeps jumping to the top after a second or two. Is there something worng? I am using Chrome

I saw that reported in a post on the Duet3d forum recently. AFAIR the workaround was to un-check an option in the user interface settings. Something like "Always show headings".

Quote

Karoo Klong

I couldn't make any machine moves it kept complaining about no axis homed. It did home y-axis without trouble.

When I homed x it just ran into the end at the endstop but no homing happened. Gears keep slipping.

The IR sensor blue pin is plugged into pin #6.

Configuration file changes needed for the Ormerod when upgrading are covered in the firmware upgrade notes. Search the page for Ormerod or M574.

Edited 1 time(s). Last edit at 11/24/2018 06:48PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 28, 2018 06:07AM |

Registered: 6 years ago Posts: 174 |

Yesterday I got down and sorted as much out as possible.

I set up the bed probe positions and placed white stickers on the edges of the bed. I checked the height at P value 522 and it was 2.5

I had to change the config.g with limits to X-15 in order to get the offset right.

Changed the z probe to reflect the 2.5mm at P value 522

I changed the values in the bed.g file

adjusted the homez and home all files to correlate with my printers probing points.

I ran the home all on the Duet Web Control and it worked!

The new Web Control is down right AMAZING!!! The new Home All is also pretty cool with it homing x and y at the same time. AWESOME!!!

I then wanted to try meshbed leveing but that didn't work so well sice there are no white sickers elsewhere on the bed.

I then decided to take off the 3mm glass bed and replace it with the 2mm glass I have and place plain white paper underneath.

It works very well. It now returns a P value of 550 at height of 1.25mm. I figured that 550 would be the best to aim for since the sweetspot lies between 500 and 600. (Or should I rather aim for something like 520?)

I then ran the 4 corner level test. The two oposite corners of the bed shows to be higher than the origin X0Y0 and its oposing side. This happens because I use 5 leveling screws. one each corner as per noral close to the Z Axis side.. and on the open side of the printer the origional centre screw and then I aded another set of screws on the outside corners as well. I see now that this caused my problem with bed leveling.

Now I can finaly do mesh bed leveling with the probe being able to function all over the print surface.

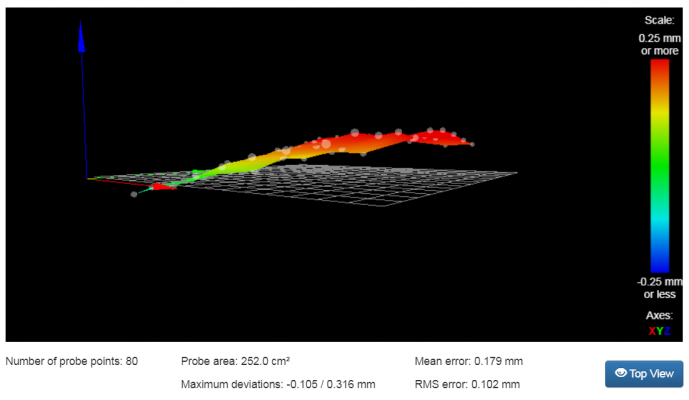

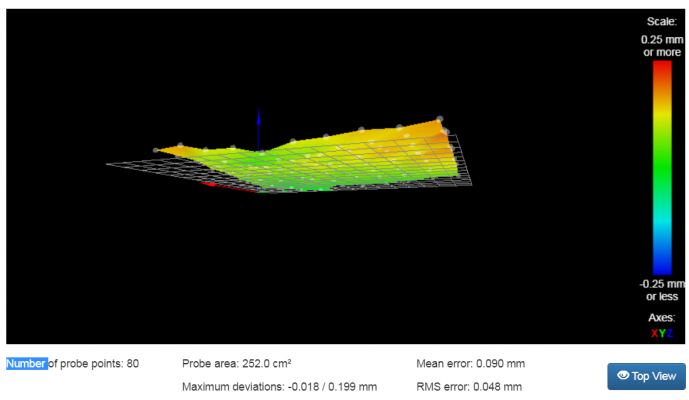

After running the mesh bed level you can see that the printbed looks like a Curled four sided Dorito chip.

I did the 4 corner probing again and started leveling out each corner after loosening the outside centre bed leveling screw.

I did this repeatedly untill I could get the bed as close as possible to flat.

I then set the centre level screw by doing the mesh bed leveling with large gaps from 20S to 60S

I use the centre set screw because I use it to support the x-arm. I place packaging foam around the printhead and support the x-arm when I travel in order to prevent it from bouncing. (Maybe I should remove the centre set screw. I think it might give problems when the bed is heated and expansion sets in.

Finaly the Alumerod has Mesh Bed Leveling!!!

I do notice however that I still get a 0.15mm variance between the centre of the bed and the Home-z position.

I suppose the best resolve for me would be to do manual mesh bed compensation.

I still need to try this.

Obtaining the Z0 is easy for me since I drop the print head and the moment it touches the glass bed, it makes a different buzzing noise. Then I know I hit Z0

Thank you all for helping me with achieving the ability to do Mesh Bed Leveling.

First Mesh taken

Last Mesh taken

Edited 5 time(s). Last edit at 11/28/2018 08:12AM by Karoo Klong.

I set up the bed probe positions and placed white stickers on the edges of the bed. I checked the height at P value 522 and it was 2.5

I had to change the config.g with limits to X-15 in order to get the offset right.

Changed the z probe to reflect the 2.5mm at P value 522

I changed the values in the bed.g file

adjusted the homez and home all files to correlate with my printers probing points.

I ran the home all on the Duet Web Control and it worked!

The new Web Control is down right AMAZING!!! The new Home All is also pretty cool with it homing x and y at the same time. AWESOME!!!

I then wanted to try meshbed leveing but that didn't work so well sice there are no white sickers elsewhere on the bed.

I then decided to take off the 3mm glass bed and replace it with the 2mm glass I have and place plain white paper underneath.

It works very well. It now returns a P value of 550 at height of 1.25mm. I figured that 550 would be the best to aim for since the sweetspot lies between 500 and 600. (Or should I rather aim for something like 520?)

I then ran the 4 corner level test. The two oposite corners of the bed shows to be higher than the origin X0Y0 and its oposing side. This happens because I use 5 leveling screws. one each corner as per noral close to the Z Axis side.. and on the open side of the printer the origional centre screw and then I aded another set of screws on the outside corners as well. I see now that this caused my problem with bed leveling.

Now I can finaly do mesh bed leveling with the probe being able to function all over the print surface.

After running the mesh bed level you can see that the printbed looks like a Curled four sided Dorito chip.

I did the 4 corner probing again and started leveling out each corner after loosening the outside centre bed leveling screw.

I did this repeatedly untill I could get the bed as close as possible to flat.

I then set the centre level screw by doing the mesh bed leveling with large gaps from 20S to 60S

I use the centre set screw because I use it to support the x-arm. I place packaging foam around the printhead and support the x-arm when I travel in order to prevent it from bouncing. (Maybe I should remove the centre set screw. I think it might give problems when the bed is heated and expansion sets in.

Finaly the Alumerod has Mesh Bed Leveling!!!

I do notice however that I still get a 0.15mm variance between the centre of the bed and the Home-z position.

I suppose the best resolve for me would be to do manual mesh bed compensation.

I still need to try this.

Obtaining the Z0 is easy for me since I drop the print head and the moment it touches the glass bed, it makes a different buzzing noise. Then I know I hit Z0

Thank you all for helping me with achieving the ability to do Mesh Bed Leveling.

First Mesh taken

Last Mesh taken

Edited 5 time(s). Last edit at 11/28/2018 08:12AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 28, 2018 02:08PM |

Registered: 10 years ago Posts: 14,672 |

It sounds like you've got it well-tuned. However, you might want to search this forum for posts about "Y axis twist" because it looks like your Ormerod may have a little.

Edited 1 time(s). Last edit at 11/28/2018 02:09PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/28/2018 02:09PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 28, 2018 02:48PM |

Registered: 6 years ago Posts: 174 |

Quote

WesBrooks

Ok, from what I can see in order to do probing completely manually then you need the following lines in your config file:

M558 P0 H5.0 F120 T3000

The critical parts of this are H which defines the height that the probe should be above it's trigger value before it displays the pop up to drop the nozzle to zero. F usually defines the speed that the head dives when it is auto-probing. I'm guessing that this may be the jog speed in your case but I'm not sure. Keep it low to start. Slow enough to hit the emergency stop if all goes weird!

G31 T0 X0.0 Y0.0 Z0.0

I'm not sure if this is needed but the above line says there is zero offset between the probe trigger value and the nozzle location. I'm not sure what would happen if you had 0.1mm in the Z parameter. In an ideal world the pop up would ask you to drop until the nozzle is 0.1mm above the bed and then automatically calculate the z=0 level from that for you. That might not make much sense unless you are dropping the nozzle onto a feeler gauge of a known thickness. The T0 sets the offsets to be applied to manual probing.

M557 X0.0:200.0 Y0.0:210.0 S100.0:105.0

This defines the grid that will be probed. Looking at the X0.0:200.0 section this defines the start of the grid at a x value of 0 and the grid ends at a grid value of 200. The S section defines the gap between the points in X and Y axis. In an ideal world we would just tell the Duet how many steps to break down the distance between min and max but we have to be explicit and tell it the step size. The example given says use a 100mm spacing in x and 105 in y. In a nut shell we've defined a 3 x 3 grid of 9 points that will be probed. The gotcha here is if you accidentally put 101 in the x spacing it would only probe at 2 x co-ordinates rather than 3 resulting in a grid of 6 points; 2 in x, 3 in y.

Once the above is in the config file and the duet has been restarted you should be able to run the probe just by sending the G29 command.

I have not checked through the above as my machines are running at the moment. I do need to convert my machines to run an automatic 4 point probe as the use of bed.g is potentially being removed from the the firmware judging by comments that dc42 has made on the Duet forums.

Take care with this and read through the links that I have provided. There are certain circumstances where the duet will happily drive beyond your axis limits set in the config file and I think this is one of them. Go slow and hit the emergency stop on DWC if the machine does something unexpected.

The specific x and y values you will need depend on the set up of your machine. For example I've set up my mendel to have 0,0 at the centre of the bed but my Ormerod is still 0,0 at the lower left of the build plate.

Since everything seemed to work 100% i now wanted to take the next xtepto go for manual mesh bed leveling.

I adjusted my config file as follows to incorporate what you mentioned above.

Quote

; Z-Probe

M574 X1 Z1 S2 ; Set endstops controlled by probe

;M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P550 X0 Y0 Z1.35 ; Set Z probe trigger value, offset and trigger height

M557 X40:195 Y0:190 S31:38 ; Define mesh grid that will be probed

M558 P0 H5.0 F120 T3000 ; in order to do probing completely manually

; H defines height that the probe should be above it's trigger value before it displays the pop up to drop the nozzle to zero.

; F usually defines the speed that the head dives when it is auto-probing

;G31 T0 X0.0 Y0.0 Z0.0 ;

However when I click on home all axis (because now you no longer are allowed to move the machine without homing all the axis at first) then the x carrridge just runs into the endstop and grinds the belt.

I cant seem to figure out how to keep the z probe active wile still wanting to do manual mesh bed leveling.

Edited 2 time(s). Last edit at 11/28/2018 02:53PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling November 28, 2018 02:52PM |

Registered: 6 years ago Posts: 174 |

Quote

dc42

It sounds like you've got it well-tuned. However, you might want to search this forum for posts about "Y axis twist" because it looks like your Ormerod may have a little.

Thank you dc42 I will definately place that on my next order of business list.

And may I again congratulate you on some really fine Firmware and an amazing web interface upgrade!

The fact that you can do editing on the systems files without having to shut down, take the sd card out, put in computer, code, and placing it back again...

WoW... Just WoW...

|

Re: The Alumarod needs manual mesh bed leveling November 29, 2018 04:24AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Karoo Klong

However when I click on home all axis (because now you no longer are allowed to move the machine without homing all the axis at first) then the x carrridge just runs into the endstop and grinds the belt.

I cant seem to figure out how to keep the z probe active wile still wanting to do manual mesh bed leveling.

Leave the Z probe type in config.g set as normal (P1 if using my differential IR sensor or the Ormerod 1 proximity sensor). Create a macro file that does M558 P0, then G29, then M558 P1 to reset the Z probe back to normal.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: The Alumarod needs manual mesh bed leveling November 29, 2018 07:20AM |

Registered: 6 years ago Posts: 174 |

Quote

dc42

Quote

Karoo Klong

However when I click on home all axis (because now you no longer are allowed to move the machine without homing all the axis at first) then the x carrridge just runs into the endstop and grinds the belt.

I cant seem to figure out how to keep the z probe active wile still wanting to do manual mesh bed leveling.

Leave the Z probe type in config.g set as normal (P1 if using my differential IR sensor or the Ormerod 1 proximity sensor). Create a macro file that does M558 P0, then G29, then M558 P1 to reset the Z probe back to normal.

Thank you dc42 I will try that tonight.

I am using the original Ormerod 1 Proximity sensor, I would love to upgrade to your differential IR Sensor.

Tom Sanladerer seemed quite impressed by its results in his sensor shootout video.

That and the panel Due would really round off the 3D Printing experience... I'll put it in my Santa Wishlist.

Edited 3 time(s). Last edit at 11/29/2018 07:25AM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 12:15PM |

Registered: 6 years ago Posts: 174 |

I finaly got down to add the macro file to my printer and...

Finaly it works!!!

I can now manually mesh bed level!!!

Thank you so much dc42, Wesbrooks and cheeseandham for all your help!

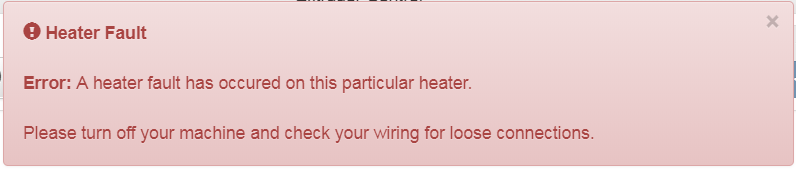

There is however a new problem wich I am almost certain is a setting in the system files that need to be changed.

Since I changed over to the new firmware my printer gives a heater error the moment it gets to 120'C

At 119 there is absolutely no problem and I simulated printing at 119 for an hour and had no problem but the moment I set it to 120'C it brings up the following error.

Could this just be a heater limit that is set?

Edited 2 time(s). Last edit at 12/03/2018 02:13PM by Karoo Klong.

Finaly it works!!!

I can now manually mesh bed level!!!

Thank you so much dc42, Wesbrooks and cheeseandham for all your help!

There is however a new problem wich I am almost certain is a setting in the system files that need to be changed.

Since I changed over to the new firmware my printer gives a heater error the moment it gets to 120'C

At 119 there is absolutely no problem and I simulated printing at 119 for an hour and had no problem but the moment I set it to 120'C it brings up the following error.

Could this just be a heater limit that is set?

Edited 2 time(s). Last edit at 12/03/2018 02:13PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 12:28PM |

Registered: 9 years ago Posts: 383 |

Good to hear it's running.

Check for M143 in the config file. Alternately run M143 H0 in the console to see what the limit is currently set to

[duet3d.dozuki.com]

Check for M143 in the config file. Alternately run M143 H0 in the console to see what the limit is currently set to

[duet3d.dozuki.com]

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 02:38PM |

Registered: 6 years ago Posts: 174 |

Quote

WesBrooks

Good to hear it's running.

Check for M143 in the config file. Alternately run M143 H0 in the console to see what the limit is currently set to

[duet3d.dozuki.com]

Ahhh I see...

; Heaters

M305 P0 T10000 B3988 C0 R1000 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 C0 R1000 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

What would you reccomend?

Edited 1 time(s). Last edit at 12/03/2018 02:38PM by Karoo Klong.

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 04:00PM |

Registered: 8 years ago Posts: 123 |

M303 H0 S100

Will give you a new C & D (and A & B ) values

Or you can use M500 to save the heater parameters in config-override.g and add tje command M501 near the end of config.g to invoke config-override.g.

You can also tune H1 also and do the same.

P.S. Is 120C the maximum? The problem is that when the heater has barely enough power to reach the desired temperature, the measurement of dead time during heater tuning becomes difficult. I suggest you tune it at about 100C. The same heater model should work at higher temperatures too. However you might want to tune to 120

Tuning the heaters

First time autotuning… Questions

Edited 1 time(s). Last edit at 12/03/2018 04:00PM by cheeseandham.

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 04:45PM |

Registered: 9 years ago Posts: 383 |

|

Re: The Alumarod needs manual mesh bed leveling December 03, 2018 05:02PM |

Registered: 6 years ago Posts: 174 |

Quote

WesBrooks

Looks like the maximum recomended temperature for the PCB het neds is aboit 120C. Realistically this means you can't raise that any further safely.

Ok thank you.

I set it to 122 and I am printing a large calibration file at 120'c without any problems.

I had some trouble with bed adheasion but some Jane Seymour Wonderset Hairspray Unscented makes the ABS stick like white on rice!

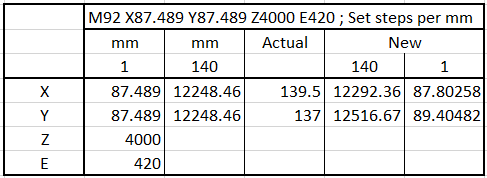

The extrusion steps were out of alignment so I adjusted it.

Next I have to optimise the print speeds and extrusion factors as well as temperatures.

I am geting anxsious to start printing PLA and PETG.

I am downloading the new Slic3r Prusa Edition. Would you reccomend any othet slicer?

And software?

Edited 1 time(s). Last edit at 12/03/2018 05:03PM by Karoo Klong.

Sorry, only registered users may post in this forum.