Smartrap Slanted Printing

Posted by botbuilder

|

Smartrap Slanted Printing March 17, 2014 09:46AM |

Registered: 10 years ago Posts: 18 |

After printing many calibration and test pieces, I felt that my machine was within reasonable tolerance of printing a spare set of smartrap parts.

However, after printing a plate of a bunch of parts, I noticed that the parts are slanting slightly in the x direction. Thought this was odd since I never saw a slant when I printed cubes and towers during the calibration.

So I then printed a single part and it was perfectly straight.

I am thinking that this related to line slip when the printer changes speed traveling from part to part? I tightened up the strings slightly, but think that I need to change something in firmware or slicer.

Here are my acceleration and jerk settings:

#define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000}

#define DEFAULT_ACCELERATION 3000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define EXTRUDER_OFFSET_X {0.0, 20.00}

#define EXTRUDER_OFFSET_Y {0.0, 5.00}

#define DEFAULT_XYJERK 20.0

#define DEFAULT_ZJERK 0.4

#define DEFAULT_EJERK 5.0

Slicer is set for travel speed of 60, perimeter = 30 and infill = 45.

Has anyone else ran into this issue?

Suggestions?

However, after printing a plate of a bunch of parts, I noticed that the parts are slanting slightly in the x direction. Thought this was odd since I never saw a slant when I printed cubes and towers during the calibration.

So I then printed a single part and it was perfectly straight.

I am thinking that this related to line slip when the printer changes speed traveling from part to part? I tightened up the strings slightly, but think that I need to change something in firmware or slicer.

Here are my acceleration and jerk settings:

#define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000}

#define DEFAULT_ACCELERATION 3000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define EXTRUDER_OFFSET_X {0.0, 20.00}

#define EXTRUDER_OFFSET_Y {0.0, 5.00}

#define DEFAULT_XYJERK 20.0

#define DEFAULT_ZJERK 0.4

#define DEFAULT_EJERK 5.0

Slicer is set for travel speed of 60, perimeter = 30 and infill = 45.

Has anyone else ran into this issue?

Suggestions?

|

Re: Smartrap Slanted Printing March 17, 2014 01:44PM |

Registered: 10 years ago Posts: 553 |

Can you post a picture?

You might need to re-tension your x-axis.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

You might need to re-tension your x-axis.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Smartrap Slanted Printing March 17, 2014 04:31PM |

Registered: 10 years ago Posts: 18 |

|

Re: Smartrap Slanted Printing March 18, 2014 03:36AM |

Registered: 11 years ago Posts: 72 |

Quote

botbuilder

After printing many calibration and test pieces, I felt that my machine was within reasonable tolerance of printing a spare set of smartrap parts.

However, after printing a plate of a bunch of parts, I noticed that the parts are slanting slightly in the x direction. Thought this was odd since I never saw a slant when I printed cubes and towers during the calibration.

So I then printed a single part and it was perfectly straight.

I am thinking that this related to line slip when the printer changes speed traveling from part to part? I tightened up the strings slightly, but think that I need to change something in firmware or slicer.

Here are my acceleration and jerk settings:

#define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000}

#define DEFAULT_ACCELERATION 3000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define EXTRUDER_OFFSET_X {0.0, 20.00}

#define EXTRUDER_OFFSET_Y {0.0, 5.00}

#define DEFAULT_XYJERK 20.0

#define DEFAULT_ZJERK 0.4

#define DEFAULT_EJERK 5.0

Slicer is set for travel speed of 60, perimeter = 30 and infill = 45.

Has anyone else ran into this issue?

Suggestions?

Try with these settings, a then work up from there if it works. I run DEFAULT_ACCELERATION 1500 on my Prusa i2 and 2000 on my Mendel90. They are both more stable printers.

Jesper

#define DEFAULT_MAX_ACCELERATION {3000,3000,100,10000}

#define DEFAULT_ACCELERATION 1000

#define DEFAULT_RETRACT_ACCELERATION 3000

#define EXTRUDER_OFFSET_X {0.0, 20.00}

#define EXTRUDER_OFFSET_Y {0.0, 5.00}

#define DEFAULT_XYJERK 10.0

#define DEFAULT_ZJERK 0.4

#define DEFAULT_EJERK 5.0

|

Re: Smartrap Slanted Printing April 10, 2014 11:33AM |

Registered: 10 years ago Posts: 349 |

Quote

botbuilder

The two on the left were printed together. Their slant matches each other (they were facing each other on the plate).

I printed the middle one again separately and it is on the right.

Hi Botbuilder,

The skew is more on one side if i see it right?

Did the scew occure on the side or in the center of the buildplate?

And was the scew more on the X or on the Y axis?

My first guess is that the winds of the fishingline are fighting against the tension when the printer reaches the outer ends. How many winds do you have on the motor axis? Is there less skew when you have less turns?

I'm also building a Smartrap soon, my order is still in production so i have to guess out loud for now.

PS this was my first post here on the forum

|

Re: Smartrap Slanted Printing April 10, 2014 11:35PM |

Registered: 10 years ago Posts: 814 |

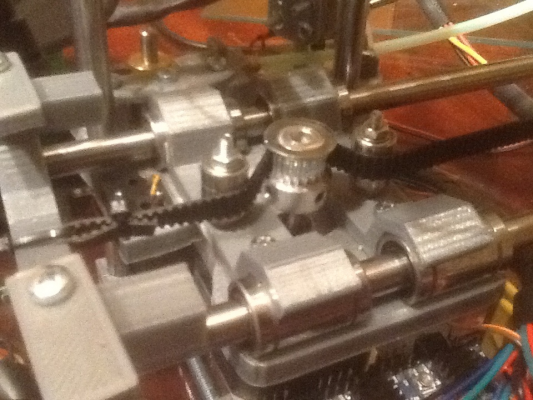

I switch to belts. It's a pretty easy upgrade. It made a big difference.

I kinda did a Mashup up the two different GT2 Belt upgrades out there. I used the 623zz bearings and 20T Pulley.

I use .9 degree steppers so My setting in Marlin was 160. If you use 1.8 degree steppers it would be 80.

I kinda did a Mashup up the two different GT2 Belt upgrades out there. I used the 623zz bearings and 20T Pulley.

I use .9 degree steppers so My setting in Marlin was 160. If you use 1.8 degree steppers it would be 80.

|

Re: Smartrap Slanted Printing April 11, 2014 09:32AM |

Registered: 10 years ago Posts: 12 |

|

Re: Smartrap Slanted Printing April 11, 2014 10:14AM |

Registered: 10 years ago Posts: 814 |

Mine is basically a mash up of these two.

Smartrap GT2 Upgrade

Smartrap Improvements

I used all 623zz bearing and M3x25 screws and M3 nuts and washers. I printed out the part that snaps into where the switch went from the GT2 Upgrade one and just screwed a couple 623zz bearings on top. I used a piece of scrap plastic to mount the limit switch under it, but you could also print the end piece that holds the switch too. All the other bearings were just drilled and mounted. Works great.

This is one of my prints since the belt upgrade.

Edited 1 time(s). Last edit at 04/11/2014 10:21AM by madmike8.

Smartrap GT2 Upgrade

Smartrap Improvements

I used all 623zz bearing and M3x25 screws and M3 nuts and washers. I printed out the part that snaps into where the switch went from the GT2 Upgrade one and just screwed a couple 623zz bearings on top. I used a piece of scrap plastic to mount the limit switch under it, but you could also print the end piece that holds the switch too. All the other bearings were just drilled and mounted. Works great.

This is one of my prints since the belt upgrade.

Edited 1 time(s). Last edit at 04/11/2014 10:21AM by madmike8.

|

Re: Smartrap Slanted Printing April 14, 2014 06:09AM |

Registered: 10 years ago Posts: 992 |

Hi,

first, sorry i couldn't come more often in this part of firm lately, i was too busy producing kits. I will come more often here. I see you do a wonderful job with this project.

I notice everyone says it works better with GT2 ? I really need to try and integrated in the man models.. at least the holes at the right place ( it will be for sure).

thx

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

first, sorry i couldn't come more often in this part of firm lately, i was too busy producing kits. I will come more often here. I see you do a wonderful job with this project.

I notice everyone says it works better with GT2 ? I really need to try and integrated in the man models.. at least the holes at the right place ( it will be for sure).

thx

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap Slanted Printing April 16, 2014 01:43PM |

Registered: 10 years ago Posts: 18 |

Still having occasional problems with slanted prints on my smartrap.

I have to constantly monitor the string tension on both axis. Have restrung both axis several times, keeping 7 turns of string on the motor. Have cranked down the speed and acceleration to the point its painfully slow to watch.

Going to go with the GT2 mashup approach like MadMike8. Will give me a chance to extend the x home switch too. I think this switch is a little too close for comfort with a Huxley hotend and reversed servo probe.

I have to constantly monitor the string tension on both axis. Have restrung both axis several times, keeping 7 turns of string on the motor. Have cranked down the speed and acceleration to the point its painfully slow to watch.

Going to go with the GT2 mashup approach like MadMike8. Will give me a chance to extend the x home switch too. I think this switch is a little too close for comfort with a Huxley hotend and reversed servo probe.

|

Re: Smartrap Slanted Printing April 16, 2014 03:49PM |

Registered: 10 years ago Posts: 992 |

you're not the only one to have this experience with fishing line.. maybe it depends of the line type ? or brand ? i can't tell.

I think i was lucky to find a cheap brand and working well ?

in all case, i'm working on adaptation for belts and rack&pinion solution too. we need the smartrap NO slipping !! lol

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I think i was lucky to find a cheap brand and working well ?

in all case, i'm working on adaptation for belts and rack&pinion solution too. we need the smartrap NO slipping !! lol

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap Slanted Printing April 17, 2014 01:21PM |

Registered: 10 years ago Posts: 349 |

Would be nice to see some pictures side by side of a filament drive that prints pefect and one with skew issues.

What thickness is the line?

How many turns on the motor axis?

Line tension?

What about a short youtube clip of the behavoir of the wire when printing?

What i like about the fishingline is that it results in a higher print resolution. the radius of the motor shaft or GT2 pulley devided by steps per rotation. (or am i wrong?)

Or is the difference small enough that it doesn't impact the resolution all that much?

GT2 does look great though and it might even make it more easy to assemble.

What thickness is the line?

How many turns on the motor axis?

Line tension?

What about a short youtube clip of the behavoir of the wire when printing?

What i like about the fishingline is that it results in a higher print resolution. the radius of the motor shaft or GT2 pulley devided by steps per rotation. (or am i wrong?)

Or is the difference small enough that it doesn't impact the resolution all that much?

GT2 does look great though and it might even make it more easy to assemble.

|

Re: Smartrap Slanted Printing April 17, 2014 03:24PM |

Registered: 10 years ago Posts: 992 |

That's the point to me : I think it's more easy to assemble

I have 4 smartraps in production for 4 weeks and they printed about 30 full smartrap kits now .

I use a cheap capelan 0.35mm 13kg line.

No line broke..but sometimes.. one slips. So i need to retention it . it's fast and it works again perfectly.

But, i think we will switch to belts..and rack and pinion in option for this reason : it's not so easy to setup if you're not used to.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I have 4 smartraps in production for 4 weeks and they printed about 30 full smartrap kits now .

I use a cheap capelan 0.35mm 13kg line.

No line broke..but sometimes.. one slips. So i need to retention it . it's fast and it works again perfectly.

But, i think we will switch to belts..and rack and pinion in option for this reason : it's not so easy to setup if you're not used to.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap Slanted Printing April 17, 2014 03:38PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap Slanted Printing April 22, 2014 02:56AM |

Registered: 11 years ago Posts: 791 |

Quote

smartfriendz

you're not the only one to have this experience with fishing line.. maybe it depends of the line type ? or brand ? i can't tell.

I think i was lucky to find a cheap brand and working well ?

in all case, i'm working on adaptation for belts and rack&pinion solution too. we need the smartrap NO slipping !! lol

I have built one using fishing line and am having no problems. (I was very surprised to say the least)

I have also built another one, not programmed it yet because I am using a Printrboard for that one.

and need to work out a few things in the programming.

The whole of the printer has been re-designed to use GT2 belts, servo-less leveling, geared type extruder (special design for SmartRap)

Will post some photos of both machines soon with close ups pf the parts.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap Slanted Printing April 22, 2014 09:06AM |

Registered: 10 years ago Posts: 148 |

The simpliest solution would probably be to get rid of belts and fishing lines.

A simple solution would be to use something like this but with piece of a belt attached instead of a printed groove.

Metal to plastic or plastic to plastic is to jangle.

[www.thingiverse.com]

I have some ideas for my cimbris remix as I also want to be able to attach a dremel to do some simple milling.

A simple solution would be to use something like this but with piece of a belt attached instead of a printed groove.

Metal to plastic or plastic to plastic is to jangle.

[www.thingiverse.com]

I have some ideas for my cimbris remix as I also want to be able to attach a dremel to do some simple milling.

|

Re: Smartrap Slanted Printing April 22, 2014 10:37AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap Slanted Printing April 22, 2014 10:54AM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

Regpye, I'm interested in seeing pics of your builds.

I will try and take some photos tomorrow and post them put.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap Slanted Printing April 22, 2014 12:52PM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

Regpye, I'm interested in seeing pics of your builds.

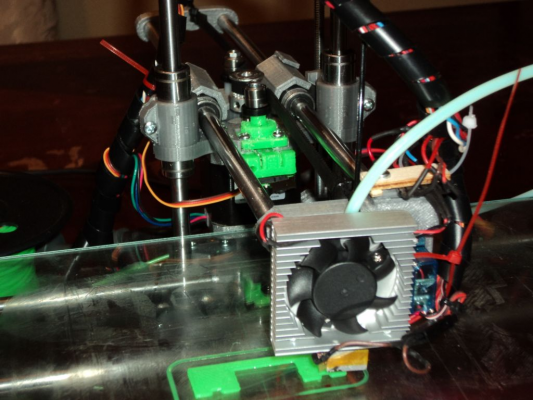

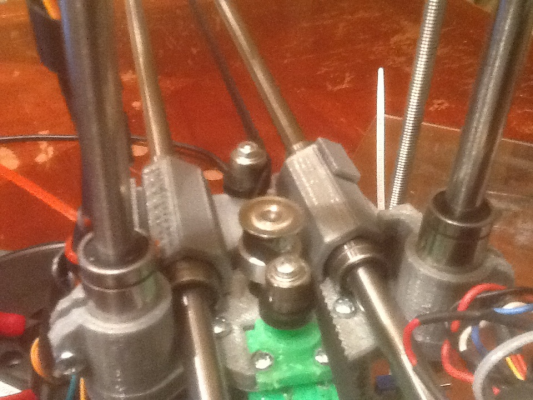

OK, it is nearly 2 am here in Australia, but I got my camera out and took some photos of one of the machines before the batteries went flat. Take some more of the other machine later in the day.

The photos are of the second machine. All parts that are printed in purple have been re-designed.

No servo for Z probing.

No fishing line, GT2 pulleys and belts now.

No direct drive extruder, designed a special geared extruder just for the SmartRap

Several other changes to the base plates.

All parts that needed GT2 belt attachments have also been re-designed.

Using a Printrboard electronics board instead of RAMPS (just because I have several of them not being used)

My own design of hotend, similar fitting as the J-head type, with finned aluminium heatsink, fan cooled (30mm)

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Complete machine without the glass plate attached.

A bit closer view.

GT2 pulleys added.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Geared extruder added (sorry about the poor focus, will take a better shot when batteries recharged)

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Z probing micro switch. (side view)

Z probing micro switch. (front view)

Limit switch attached here instead, makes so all wires can be loomed together.

Printrboard electronics and also view of the GT2 belt system.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

GT2 belt fitted into a toothed slot to retain the belt securely. Very easy to attach and get tight.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Another better view of the extruder.

Another shot of one of the GT2 belts connected.

Will take some more photos later when the batteries are charged and I have had some sleep (after 2am here now)

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap Slanted Printing April 22, 2014 01:15PM |

Registered: 10 years ago Posts: 148 |

Looks nice regpye

Intresting about your extruder

I haven't gone so far on my build but is the construction really that weak that you cant have a combined extruder hotend attached to the current original one?

I bought a Chinese mk8 extruder that after a lot of problems now is working great and I have plans on adding it somehow on to the smartrap also when I get there.

You should really add your own build thread also to show your dual build as I understand you have some years of reprapping behind you wath I could see on your page.

Intresting about your extruder

I haven't gone so far on my build but is the construction really that weak that you cant have a combined extruder hotend attached to the current original one?

I bought a Chinese mk8 extruder that after a lot of problems now is working great and I have plans on adding it somehow on to the smartrap also when I get there.

You should really add your own build thread also to show your dual build as I understand you have some years of reprapping behind you wath I could see on your page.

|

Re: Smartrap Slanted Printing April 22, 2014 02:28PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap Slanted Printing April 22, 2014 09:06PM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

Definately interesting Regpye. You should start a thread on your builds. I'm interested in the geared extruder too.

A few more shots of the first printer with fishing line and servo, and some close ups of the extruder parts.

Sorry for the rushed photos, I will take some time later and make some clearer ones. (time is always a problem, don't seem to have enough ha..ha..)

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

X end. One on right shows the Z probe micro switch.

X end. Showing the limit switch - moved from bearing plate to here.

X end. Showing the limit switch - moved from bearing plate to here.

X end - shows both switches, one limit the other Z probe.

Limit switch. Recessed zip tie, cable bracket for loom.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Sorry for the over exposure. Body of the SmartRap extruder.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Fishing line drive, works well.

Another view of fishing line drive.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Don't like the loose cables, fixed this on next build

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

My design of hotend - similar to J-head fitting. Has finned aluminium heatsink and 30mm fan.

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Image error

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

Connection to server failed (php_network_getaddresses: getaddrinfo failed: Name or service not known)

open image URL

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap Slanted Printing April 22, 2014 10:04PM |

Registered: 10 years ago Posts: 349 |

|

Re: Smartrap Slanted Printing April 23, 2014 12:57AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap Slanted Printing April 23, 2014 11:35AM |

Registered: 10 years ago Posts: 992 |

Impressive work regpye !

It's funny i'm working also on a geared extruder , as i'm not very happy with direct drive after all ! It's limiting speed just because of limited power on the filament . I hope you will share it ?

Congrats for those mods and builds.. it's really interesting !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

It's funny i'm working also on a geared extruder , as i'm not very happy with direct drive after all ! It's limiting speed just because of limited power on the filament . I hope you will share it ?

Congrats for those mods and builds.. it's really interesting !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap Slanted Printing April 23, 2014 06:32PM |

Registered: 11 years ago Posts: 791 |

Quote

smartfriendz

Impressive work regpye !

It's funny i'm working also on a geared extruder , as i'm not very happy with direct drive after all ! It's limiting speed just because of limited power on the filament . I hope you will share it ?

Congrats for those mods and builds.. it's really interesting !

Hi Serge,

I have full intentions of sharing it and will send to you so it can be added to your other files.

I have to go away in a few minutes and be back this evening. I will PM you when I get back and share the files with you.

I have been able to get 4Kg pull from this extruder, so it increases the power a lot for the Bowden tube delivery.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap Slanted Printing April 24, 2014 04:19AM |

Registered: 10 years ago Posts: 992 |

Hi Regpye,

Thank you

Take your time, i will build this version aside from the production for now . I think it will be good and could be integrated in the main model ?

With more power , we could go much faster with this printer. I'm working on alu tube and printed bushing to make the axis lighter .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

Thank you

Take your time, i will build this version aside from the production for now . I think it will be good and could be integrated in the main model ?

With more power , we could go much faster with this printer. I'm working on alu tube and printed bushing to make the axis lighter .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap Slanted Printing April 24, 2014 07:49AM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

Very Nice. Do you plan to share the geared extruder stl? I'd like to try it at some point.

The files will be available from Serge, I have sent him the files to add to his build files.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.