Madmike8's Smartrap Build

Posted by madmike8

|

Re: Madmike8's Smartrap Build April 27, 2014 09:21PM |

Registered: 10 years ago Posts: 814 |

Great, looked through my files and noticed I left out the Endstop inverting part. Edited my post above to reflect that. Oh and on mine I had the X direction inverted in the config.h Oops! I was too lazy to change the connector around...

I'm happy that I was able to help.

BTW, I used the Default Smartrap Marlin on my Ordbot because i had wired it the same and set up a servo for the autoleveling, and Y was inverted with it too. So I loaded up my Smartrap config on it and changed what needed to be changed and it worked perfectly...

I'm happy that I was able to help.

BTW, I used the Default Smartrap Marlin on my Ordbot because i had wired it the same and set up a servo for the autoleveling, and Y was inverted with it too. So I loaded up my Smartrap config on it and changed what needed to be changed and it worked perfectly...

|

Re: Madmike8's Smartrap Build April 28, 2014 03:56AM |

Registered: 10 years ago Posts: 992 |

Great job ! I'm happy you could resolve this . I've never had this mirror problem ? so i couldn't help about that .

It's true after building the Smartrap i thought i should have X and Y switched .I didn't think we would place the printer this way, so Y should be X..no doubt, but now it's a little too late

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

It's true after building the Smartrap i thought i should have X and Y switched .I didn't think we would place the printer this way, so Y should be X..no doubt, but now it's a little too late

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Madmike8's Smartrap Build April 28, 2014 08:24PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 03, 2014 03:38PM |

Registered: 10 years ago Posts: 29 |

Could you let me know the line number you have change in pin.h it's a little bit confused for me! Do you have change the endstop connector position on the ramps? My setting is similar excepted my endstop are NO !Quote

madmike8

I wanted to add this to my thread for future reference on my mirrored Y problem that was fixed.

I'm using Marlin

To Change the motor direction in Configuration.h change the

const bool Y_MIN_ENDSTOP_INVERTING to true

const bool Y_MAX_ENDSTOP_INVERTING to false

#define INVERT_Y_DIR from true to false

Then you need to Change your Homing Direction by changing

#define Y_HOME_DIR from -1 to 1

Now if you try it, it might not home, so you need to remark (add //) to the beginning of this line

#define DISABLE_MAX_ENDSTOPS

Then in pins.h under the Arduino Mega pin assignment

There are 2 places to set the Y Pins one is under #if MOTHERBOARD == 77

But we are using the RAMPS Motherboard, so we need to change the ones under the #else statement.

change

#define Y_MIN_PIN change the 14 to 15

And

#define Y_MAX_PIN change the 15 to 14

Hopefully this fixes your Y Mirrored issues...

|

Re: Madmike8's Smartrap Build May 03, 2014 09:38PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 04, 2014 01:20PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 04, 2014 01:29PM |

Registered: 9 years ago Posts: 116 |

Madmike8, sad to hear about messed up prints. I'm using aquarium air tube and it's working greate. I have tighened it with self-locking plastic band, and it's fine. Just be carefull with greasing the rod, watch that no grease gets inside the tube(I have this in last week) or it will start slipping and get messy.

Good to hear that you worked out this problem

Good to hear that you worked out this problem

|

Re: Madmike8's Smartrap Build May 04, 2014 05:50PM |

Registered: 10 years ago Posts: 29 |

Tks Madmike8, work number 1. Just had to reverse plug of X motor and I finaly changed my endstop NO,for the NC. Nothing wanted to work with configuartion in normally open !!!!Quote

madmike8

Line #s 450 and 451 in pins.h

You do not have to change the connector.

I'm not sure about the NO endstops, but my guess would be to change the Endstop Logic in configuration.h

const bool Y_ENDSTOPS_INVERTING = false; // set to true to invert the logic of the endstops.

|

Re: Madmike8's Smartrap Build May 04, 2014 06:50PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 11, 2014 11:11PM |

Registered: 10 years ago Posts: 814 |

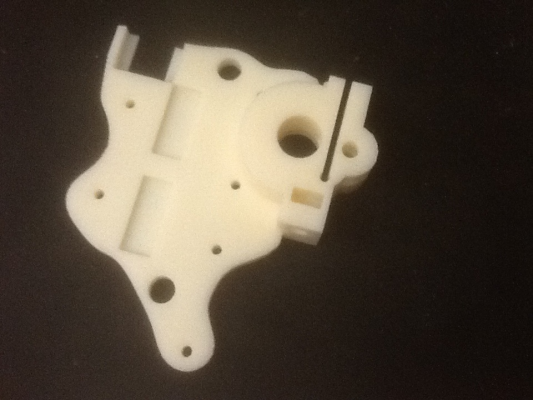

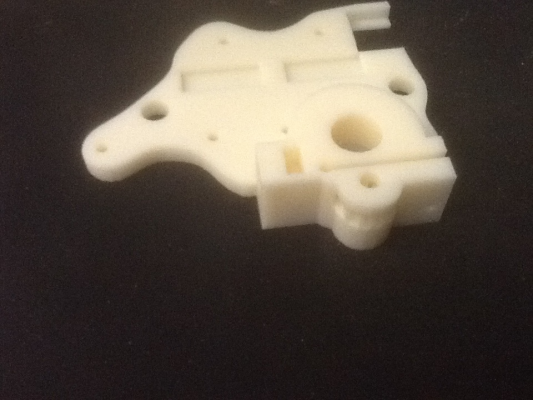

I printed this today to try out.mSimple Extruder for Smartrap

Seemed to be working ok till my Extruder Stepper Motor Died... Doh...

Now it just shutters back and forth..

Seemed to be working ok till my Extruder Stepper Motor Died... Doh...

Now it just shutters back and forth..

|

Re: Madmike8's Smartrap Build May 12, 2014 05:10AM |

Registered: 10 years ago Posts: 349 |

|

Re: Madmike8's Smartrap Build May 12, 2014 05:39AM |

Registered: 10 years ago Posts: 992 |

I tried this simple extruder too. It's a nice update to the smart rap's extruder in the way that it's adjustable ! I thought it would be ok with the simple one, but with the small differences between printers, it makes often a problem with slipping filament . We are in the 0.1 mm range to have a well working extruder or not working. It's too tight .

I will update certainly the main model to an adjustable one like this.

I'm also testing some geared extruder to have more power in reserve to go faster. Direct drive is more limited than i thought, even with a 1.75 filament. It's a pity to be limited by that .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I will update certainly the main model to an adjustable one like this.

I'm also testing some geared extruder to have more power in reserve to go faster. Direct drive is more limited than i thought, even with a 1.75 filament. It's a pity to be limited by that .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Madmike8's Smartrap Build May 14, 2014 06:25PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 15, 2014 04:00AM |

Registered: 10 years ago Posts: 349 |

Is there any improvement when i use a 48mm Motor instead of the 40mm one?

Would we get more power if we set the stepper driver to 8 micro steps and divide the feed rate by 2 in the firmware?

I'd like to try this myself though i first have to get some reliable config before i start making things more complicated.

This direct driven airtripper extruder seems to be fast and powerful enough. Though why is this one stronger?

http://www.youtube.com/watch?v=RlcrWq8CumM

I really like the simplicity of a direct drive. Though i can imagine that it is more convenient to go with lighter motors and a geared extruder

Would we get more power if we set the stepper driver to 8 micro steps and divide the feed rate by 2 in the firmware?

I'd like to try this myself though i first have to get some reliable config before i start making things more complicated.

This direct driven airtripper extruder seems to be fast and powerful enough. Though why is this one stronger?

http://www.youtube.com/watch?v=RlcrWq8CumM

I really like the simplicity of a direct drive. Though i can imagine that it is more convenient to go with lighter motors and a geared extruder

Quote

smartfriendz

I tried this simple extruder too. It's a nice update to the smart rap's extruder in the way that it's adjustable ! I thought it would be ok with the simple one, but with the small differences between printers, it makes often a problem with slipping filament . We are in the 0.1 mm range to have a well working extruder or not working. It's too tight .

I will update certainly the main model to an adjustable one like this.

I'm also testing some geared extruder to have more power in reserve to go faster. Direct drive is more limited than i thought, even with a 1.75 filament. It's a pity to be limited by that .

|

Re: Madmike8's Smartrap Build May 15, 2014 07:09AM |

Registered: 10 years ago Posts: 992 |

I will be honest backemf : I miss some tests with the extruder. I'm a little like you. I don't understand for now why the smartrap direct drive would be less powerful than the airstiper ( smartrap one is based on this one  .

.

From my guess, it can be the screw ( we are now with mk7 which is 11 mm diameter and we could have brass insert or mk8 : 7mm diameter.. that count i think ).

other point is the bowden cable and the path of it. Maybe we use too long and bad oriented bowden..that takes a lot of power i think.

Maybe someone has other idea ? I would love to keep with the direct drive too of course. so much simpler .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

.

. From my guess, it can be the screw ( we are now with mk7 which is 11 mm diameter and we could have brass insert or mk8 : 7mm diameter.. that count i think ).

other point is the bowden cable and the path of it. Maybe we use too long and bad oriented bowden..that takes a lot of power i think.

Maybe someone has other idea ? I would love to keep with the direct drive too of course. so much simpler .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Madmike8's Smartrap Build May 15, 2014 07:53AM |

Registered: 10 years ago Posts: 814 |

Honestly, I'm not sure. I'm new to this too. I read about steppers loosing torque with increased microsteping 1/16 is around 10% torque of a full step. So, I tried 1/8 step and 1/4 step. I didn't see any improvement but the stepper driver died just after that. I think the original Smartrap extruder works pretty good if you slow the printing down, but I think it has problems when the filament size is irregular. Hopefully with all of us working and sharing together we can find a workable setup.

Edited 1 time(s). Last edit at 05/15/2014 07:54AM by madmike8.

Edited 1 time(s). Last edit at 05/15/2014 07:54AM by madmike8.

|

Re: Madmike8's Smartrap Build May 16, 2014 04:48AM |

Registered: 10 years ago Posts: 349 |

I have a 2.5A Steppermotor (48mm) It has a gear on the shaft so i might be able to make a geared extruder out of it if i can find a bigger gear with the same tooth size.

The maths to find DEFAULT_AXIS_STEPS_PER_UNIT

(steps per revolution * (1/microstepping) * gear ratio) / (wheel_diameter * 3.14)

Please correct me if i'm wrong here...

Or does the filament diameter also have to be in this equation??

Holding Torque 4.8 kg/cm 47.1 N-cm for this motor, though I will not be able to drive it at 2.5A lets say that my driver can do 1.8A then i still should have reasonable torque from this motor?

Hmm, i'm affraid that is not much better then the 40mm 1.2A motor, though the gear might help just enough. I'm going to give it a try.

I'm all for the airtripper style extruder. I'm just in the dark why i can't get it working. It all seems to be mounted right. Sometimes the fillament seems to slip though the diameter of the fillament is constant. But i'm not able to adjust the distance of the bearing and i think that's the only issue.

I now have the no-servo firmware from regpie installed and the first layer issues seem to be fixed now, although the homing behavior seems a bit odd compared to how it acted before.

So once I have this extruder running then I should be on my way. :-)

The maths to find DEFAULT_AXIS_STEPS_PER_UNIT

(steps per revolution * (1/microstepping) * gear ratio) / (wheel_diameter * 3.14)

Please correct me if i'm wrong here...

Or does the filament diameter also have to be in this equation??

Holding Torque 4.8 kg/cm 47.1 N-cm for this motor, though I will not be able to drive it at 2.5A lets say that my driver can do 1.8A then i still should have reasonable torque from this motor?

Hmm, i'm affraid that is not much better then the 40mm 1.2A motor, though the gear might help just enough. I'm going to give it a try.

I'm all for the airtripper style extruder. I'm just in the dark why i can't get it working. It all seems to be mounted right. Sometimes the fillament seems to slip though the diameter of the fillament is constant. But i'm not able to adjust the distance of the bearing and i think that's the only issue.

I now have the no-servo firmware from regpie installed and the first layer issues seem to be fixed now, although the homing behavior seems a bit odd compared to how it acted before.

So once I have this extruder running then I should be on my way. :-)

|

Re: Madmike8's Smartrap Build May 16, 2014 10:01AM |

Registered: 10 years ago Posts: 814 |

That's the formula I used too. Yeah, I think an adjustable bearing would help with the current extruder.

BTW, update: I stuck a couple of strips of 3mm Styrofoam on under the bearing covers, and tightened them back down. It tightened everything up nicely. I've got to replace my extruder stepper motor sometime this week. Might replace my PTFE tube with a slightly longer one and rewire it a bit better too while I'm at it.

BTW, update: I stuck a couple of strips of 3mm Styrofoam on under the bearing covers, and tightened them back down. It tightened everything up nicely. I've got to replace my extruder stepper motor sometime this week. Might replace my PTFE tube with a slightly longer one and rewire it a bit better too while I'm at it.

|

Re: Madmike8's Smartrap Build May 16, 2014 11:29PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

I have a 2.5A Steppermotor (48mm) It has a gear on the shaft so i might be able to make a geared extruder out of it if i can find a bigger gear with the same tooth size.

The maths to find DEFAULT_AXIS_STEPS_PER_UNIT

(steps per revolution * (1/microstepping) * gear ratio) / (wheel_diameter * 3.14)

Please correct me if i'm wrong here...

Or does the filament diameter also have to be in this equation??

Holding Torque 4.8 kg/cm 47.1 N-cm for this motor, though I will not be able to drive it at 2.5A lets say that my driver can do 1.8A then i still should have reasonable torque from this motor?

Hmm, i'm affraid that is not much better then the 40mm 1.2A motor, though the gear might help just enough. I'm going to give it a try.

I'm all for the airtripper style extruder. I'm just in the dark why i can't get it working. It all seems to be mounted right. Sometimes the fillament seems to slip though the diameter of the fillament is constant. But i'm not able to adjust the distance of the bearing and i think that's the only issue.

I now have the no-servo firmware from regpie installed and the first layer issues seem to be fixed now, although the homing behavior seems a bit odd compared to how it acted before.

So once I have this extruder running then I should be on my way. :-)

It should probe in six places now and home the Z in the centre (Australian spelling) of the plate. Easy to send the nozzle to where you want it in your start code.

Try out the built-in tests and see how far your bed is actually out.

.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Madmike8's Smartrap Build May 17, 2014 04:06PM |

Registered: 10 years ago Posts: 349 |

I finally found the cause of my extruder problems, the pulley has a production flaw, on a small area there are no 'teeth' so thats the zone where the fillament slipped. I'll make a picture of it and send it later.

The improvised geared extruder is now up and running, i'm still tuning the feedrate.

Regpye, your marlin is running like a dream.

I had to set #define min_software_endstops false to make it home correctly, so that it doesn't keep the endstop triggerd at home.

The 2.5A motor runs fine on the geared extruder (5:1 ratio) the driver is set to about 1.2A now and everything seems to be ok. I'm now able to print without manually adding pressure.

The improvised geared extruder is now up and running, i'm still tuning the feedrate.

Regpye, your marlin is running like a dream.

I had to set #define min_software_endstops false to make it home correctly, so that it doesn't keep the endstop triggerd at home.

The 2.5A motor runs fine on the geared extruder (5:1 ratio) the driver is set to about 1.2A now and everything seems to be ok. I'm now able to print without manually adding pressure.

|

Re: Madmike8's Smartrap Build May 17, 2014 04:26PM |

Registered: 10 years ago Posts: 814 |

|

Re: Madmike8's Smartrap Build May 17, 2014 06:34PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

I finally found the cause of my extruder problems, the pulley has a production flaw, on a small area there are no 'teeth' so thats the zone where the fillament slipped. I'll make a picture of it and send it later.

The improvised geared extruder is now up and running, i'm still tuning the feedrate.

Regpye, your marlin is running like a dream.

I had to set #define min_software_endstops false to make it home correctly, so that it doesn't keep the endstop triggerd at home.

The 2.5A motor runs fine on the geared extruder (5:1 ratio) the driver is set to about 1.2A now and everything seems to be ok. I'm now able to print without manually adding pressure.

Are you using my extruder or an different one? I can show you how to make a good hobbed bolt that gives no trouble like stripping filament or clogging between the teeth.

You will however need access to a lathe to do it.

That is interesting about changing the min_software_endstops, I am running my machines the same way that I left it in the configuration

Are you returning to zero position on one of the axis? If so reduce that to 5 and the problem will go away because it wont re-trigger the end stop..

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Madmike8's Smartrap Build May 18, 2014 10:01AM |

Registered: 10 years ago Posts: 349 |

Quote

madmike8

Congrats BackEMF! What geared extruder are you using?

I've hacked one together with scavanged gears (that where already on a plate) form an old printer and a piece of wood that presses the filament against the gear. not ideal but for now i'm able to print and i'm stunned buy the results. Now printing at layer heightst of 0.2 though i also have a produced a few reasonable 0.1 layer prints. I'm going to stay at 0.2 from now on, 0.1 layers take to much time. (my print speed is 15 mm/sec and experimenting at 20mm/sec now)

It looks a bit like this http://www.thingiverse.com/thing:167265 but then geared and without the bearing.

Actually i'm going to print this minimalistic extruder and see how that performs.

|

Re: Madmike8's Smartrap Build May 18, 2014 10:30AM |

Registered: 10 years ago Posts: 349 |

Quote

regpye

Are you using my extruder or an different one? I can show you how to make a good hobbed bolt that gives no trouble like stripping filament or clogging between the teeth.

You will however need access to a lathe to do it.

That is interesting about changing the min_software_endstops, I am running my machines the same way that I left it in the configuration

Are you returning to zero position on one of the axis? If so reduce that to 5 and the problem will go away because it wont re-trigger the end stop..

Cool, i dont have a lathe though i sure like to see how you make the hobbed bolt, my hacked extruder might soon give the ghost so i'm interested in everything that can take me to the next level. Where can I download your .stl files?

what i'm starting to like about smartrap is how all the different approaches can be mixed. Serge's X-plate, Regpye's Gears, different hotends. Fishingline, GT2, T5, R&P etc. etc.

Whatever you have available, you can build a smartrap from it. :-D

min_software_endstops false works great for me.

When I do homing it goes to X 'klik-klak' then Y 'klik-klak' and then Z... then it moves X1 Y1 and it goes to auto-probe. etc.

min_software_endstops true however it homes X 'klik' Y 'klik' and it stays on top of the endstops. Nothing bad as long as you leave it powered on. But when the power has been off and i do a fresh start, then it starts homing FROM that position deeper INTO the X and Y so that could in the long run do damage to the fishingline and couplers (or GT2 belt).

Maybe it works different in your config since you have one or two motors reversed compared to my config?

So if it' aint broke, don't fix it hehehe..

I'll post my new config in my build thread.

|

Re: Madmike8's Smartrap Build May 18, 2014 11:20AM |

Registered: 10 years ago Posts: 814 |

Quote

BackEMF

what i'm starting to like about smartrap is how all the different approaches can be mixed. Serge's X-plate, Regpye's Gears, different hotends. Fishingline, GT2, T5, R&P etc. etc.

Whatever you have available, you can build a smartrap from it. :-D

Very True! Wood, Metal, Plastic. Different ways of thinking still come come together with this thing...

|

Re: Madmike8's Smartrap Build May 18, 2014 12:39PM |

Registered: 10 years ago Posts: 992 |

It's the true goal of the smartrap project in fact.

I'm actually designing a new version, more simple, less plastic and all options integrated ( fishing line, rack, belt, direct drive, geared ) and..more LEGO like => simple lm8 holders everywhere with some special small parts .. I think those parts will be more simple to make in aluminium too ... soon to be updated.

it srtarts to be interesting let's see what happen

let's see what happen

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I'm actually designing a new version, more simple, less plastic and all options integrated ( fishing line, rack, belt, direct drive, geared ) and..more LEGO like => simple lm8 holders everywhere with some special small parts .. I think those parts will be more simple to make in aluminium too ... soon to be updated.

it srtarts to be interesting

let's see what happen

let's see what happenthe Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Madmike8's Smartrap Build May 18, 2014 07:42PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Quote

regpye

Are you using my extruder or an different one? I can show you how to make a good hobbed bolt that gives no trouble like stripping filament or clogging between the teeth.

You will however need access to a lathe to do it.

That is interesting about changing the min_software_endstops, I am running my machines the same way that I left it in the configuration

Are you returning to zero position on one of the axis? If so reduce that to 5 and the problem will go away because it wont re-trigger the end stop..

Cool, i dont have a lathe though i sure like to see how you make the hobbed bolt, my hacked extruder might soon give the ghost so i'm interested in everything that can take me to the next level. Where can I download your .stl files?

what i'm starting to like about smartrap is how all the different approaches can be mixed. Serge's X-plate, Regpye's Gears, different hotends. Fishingline, GT2, T5, R&P etc. etc.

Whatever you have available, you can build a smartrap from it. :-D

min_software_endstops false works great for me.

When I do homing it goes to X 'klik-klak' then Y 'klik-klak' and then Z... then it moves X1 Y1 and it goes to auto-probe. etc.

min_software_endstops true however it homes X 'klik' Y 'klik' and it stays on top of the endstops. Nothing bad as long as you leave it powered on. But when the power has been off and i do a fresh start, then it starts homing FROM that position deeper INTO the X and Y so that could in the long run do damage to the fishingline and couplers (or GT2 belt).

Maybe it works different in your config since you have one or two motors reversed compared to my config?

So if it' aint broke, don't fix it hehehe..

Could have just turned the plug around on one of the motors?

I'll post my new config in my build thread.

I will either make a video or take some photos of the process of making the hobbed bolts.

Here are all my files for the last build that I have made. I am working on two others at present, one of them totally different.

[regpye.com.au] Extruder and Guidler

The extruder needs to have the filament outlet hole tapped with a M5 tap so that a pneumatic fitting can be screwed in for the Bowden hose.

[regpye.com.au] Gear Set

[regpye.com.au] X and Y ends

[regpye.com.au] X and Y plates

If the plates are too big to print in one go on your machine, use Cura to split the parts up and print out in smaller number of parts.

The latest built (above) works great, is more stable, not so much flex, takes a bit longer to print and uses a bit more PLA (but worth it)

The hotend that it uses will be available in about a month when they come back from the CNC shop.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Madmike8's Smartrap Build May 21, 2014 11:19PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Quote

regpye

Are you using my extruder or an different one? I can show you how to make a good hobbed bolt that gives no trouble like stripping filament or clogging between the teeth.

You will however need access to a lathe to do it.

That is interesting about changing the min_software_endstops, I am running my machines the same way that I left it in the configuration

Are you returning to zero position on one of the axis? If so reduce that to 5 and the problem will go away because it wont re-trigger the end stop..

Cool, i dont have a lathe though i sure like to see how you make the hobbed bolt, my hacked extruder might soon give the ghost so i'm interested in everything that can take me to the next level. Where can I download your .stl files?

what i'm starting to like about smartrap is how all the different approaches can be mixed. Serge's X-plate, Regpye's Gears, different hotends. Fishingline, GT2, T5, R&P etc. etc.

Whatever you have available, you can build a smartrap from it. :-D

min_software_endstops false works great for me.

When I do homing it goes to X 'klik-klak' then Y 'klik-klak' and then Z... then it moves X1 Y1 and it goes to auto-probe. etc.

min_software_endstops true however it homes X 'klik' Y 'klik' and it stays on top of the endstops. Nothing bad as long as you leave it powered on. But when the power has been off and i do a fresh start, then it starts homing FROM that position deeper INTO the X and Y so that could in the long run do damage to the fishingline and couplers (or GT2 belt).

Maybe it works different in your config since you have one or two motors reversed compared to my config?

So if it' aint broke, don't fix it hehehe..

I'll post my new config in my build thread.

Photos of how to make a good hobbed bolt.

First stay away from small teeth, they cause most of the problems, cut into the filament and get clogged easily. You need the biggest teeth you can make.

I am using a large tap mounted in the chuck of my lathe.

I made a make-shift bracket from wood (later I made an aluminium one, but I am showing you the easiest way)

Put a socket on the bolt head so you can give the bolt a turn to get it started,. Once the tap starts cutting it will turn by itself.

Don't go in too deep, you may have to do a trial one or two to get the right depth, and notice how far you move the carriage into the tap so you can repeat for the next one.

The photos should show you enough to be able to do it.

Advantage of a big tap is that you get big teeth that don't clog. Also the teeth are flatter than using a small tap, this makes alignment in the extruder less critical.

A big tap doesn't break as easily as a small tap.

You can make direct drive gear wheels the same way, just modify the bracket so that you can slip a bolt in place with the brass blank on it and use some washers to take up the slack.

Edited 1 time(s). Last edit at 05/21/2014 11:26PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Madmike8's Smartrap Build May 22, 2014 11:42AM |

Registered: 10 years ago Posts: 349 |

|

Re: Madmike8's Smartrap Build June 06, 2014 05:45PM |

Registered: 10 years ago Posts: 814 |

Sorry, only registered users may post in this forum.