Smartrap - Cimbria - Wood frame project.

Posted by Cliff Mellangård

|

Re: Smartrap - Cimbria - Wood frame project. May 03, 2014 08:18AM |

Registered: 10 years ago Posts: 148 |

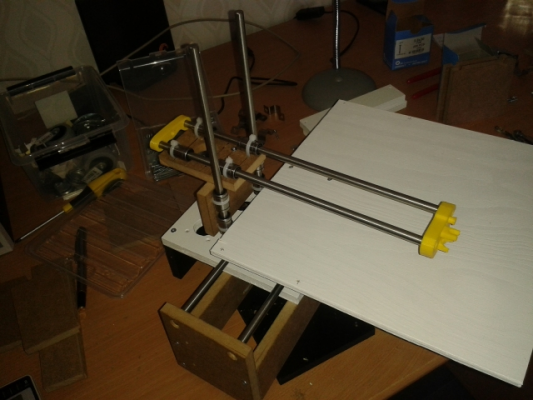

I think this is a design to go on with a woodrap version ?

Very little parts and easy to assemble and use only rectangle and squared parts that is easy to cut your self.

But there is a whole lot of holes to drill

The motor will be used as a support on the x carriage when mounted to make it even more solid that I will show as soon as I get my motors.

Edited 2 time(s). Last edit at 05/03/2014 08:21AM by Cliff Mellangård.

Very little parts and easy to assemble and use only rectangle and squared parts that is easy to cut your self.

But there is a whole lot of holes to drill

The motor will be used as a support on the x carriage when mounted to make it even more solid that I will show as soon as I get my motors.

Edited 2 time(s). Last edit at 05/03/2014 08:21AM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. May 09, 2014 12:13AM |

Registered: 11 years ago Posts: 791 |

Quote

Cliff Mellangård

I think this is a design to go on with a woodrap version ?

Very little parts and easy to assemble and use only rectangle and squared parts that is easy to cut your self.

But there is a whole lot of holes to drill

The motor will be used as a support on the x carriage when mounted to make it even more solid that I will show as soon as I get my motors.

You should be able to hide all the electronics and maybe power supply in the base.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap - Cimbria - Wood frame project. May 09, 2014 03:13AM |

Registered: 10 years ago Posts: 148 |

First of all sorry for the lack of updates

But as iam unemployed so did the unemployement office send me to work at a hot dog factory with very long hours so iam pretty tired when iam back at home.

Iam going to have this work until august with week by week notice on how many hours I get?

But hopefully will It give me some money for my love of electronics

Not much have happened so far but I have my motors and this extruder.

[www.ebay.co.uk]

After I solved all my problems with my Chinese mk8 so do I sort of love these small extruders as they are very compact and work at good speed with a 0.4-0.5 nozzle.

The zip ties will be replaced by small printed parts when I see wath parts of the design that work good.

So far have I measured the print size to 220x210 on the xy axis with 300 mm long rods.

Iam going to see how much I manage todo this weekend as iam also free on Monday next week.

Regpy.

You think like I do

I have this power supplie at home but I think I could find a smaller one that fits better to the design?

[www.ebay.co.uk]

This supplie do I use on my prus ai3.

[forums.reprap.org]

Be patient everyone with my slow progress during this time as iam extremely tired after the work days on this temporary work place.

Ps..........

Regpy I noticed that you are from Australia

My mother used to dig for opals down there before she meet my father .

But that whas many years ago as iam 39 years old now

Edited 1 time(s). Last edit at 05/09/2014 03:16AM by Cliff Mellangård.

But as iam unemployed so did the unemployement office send me to work at a hot dog factory with very long hours so iam pretty tired when iam back at home.

Iam going to have this work until august with week by week notice on how many hours I get?

But hopefully will It give me some money for my love of electronics

Not much have happened so far but I have my motors and this extruder.

[www.ebay.co.uk]

After I solved all my problems with my Chinese mk8 so do I sort of love these small extruders as they are very compact and work at good speed with a 0.4-0.5 nozzle.

The zip ties will be replaced by small printed parts when I see wath parts of the design that work good.

So far have I measured the print size to 220x210 on the xy axis with 300 mm long rods.

Iam going to see how much I manage todo this weekend as iam also free on Monday next week.

Regpy.

You think like I do

I have this power supplie at home but I think I could find a smaller one that fits better to the design?

[www.ebay.co.uk]

This supplie do I use on my prus ai3.

[forums.reprap.org]

Be patient everyone with my slow progress during this time as iam extremely tired after the work days on this temporary work place.

Ps..........

Regpy I noticed that you are from Australia

My mother used to dig for opals down there before she meet my father .

But that whas many years ago as iam 39 years old now

Edited 1 time(s). Last edit at 05/09/2014 03:16AM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. May 09, 2014 03:22AM |

Registered: 11 years ago Posts: 791 |

Quote

Cliff Mellangård

First of all sorry for the lack of updates

But as iam unemployed so did the unemployement office send me to work at a hot dog factory with very long hours so iam pretty tired when iam back at home.

Iam going to have this work until august with week by week notice on how many hours I get?

But hopefully will It give me some money for my love of electronics

Not much have happened so far but I have my motors and this extruder.

[www.ebay.co.uk]

After I solved all my problems with my Chinese mk8 so do I sort of love these small extruders as they are very compact and work at good speed with a 0.4-0.5 nozzle.

The zip ties will be replaced by small printed parts when I see wath parts of the design that work good.

So far have I measured the print size to 220x210 on the xy axis with 300 mm long rods.

Iam going to see how much I manage todo this weekend as iam also free on Monday next week.

Regpy.

You think like I do

I have this power supplie at home but I think I could find a smaller one that fits better to the design?

[www.ebay.co.uk]

This supplie do I use on my prus ai3.

[forums.reprap.org]

Be patient everyone with my slow progress during this time as iam extremely tired after the work days on this temporary work place.

Ps..........

Regpy I noticed that you are from Australia

My mother used to dig for opals down there before she meet my father .

But that whas many years ago as iam 39 years old now

I am older than you ha..ha.. nearly double.

I originally came from Manchester, but have been in Australia for 65 years.

Have a look at these power supplies, I am using them on my SmartRaps and they work very well.

[www.ebay.co.uk]

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap - Cimbria - Wood frame project. May 09, 2014 05:10PM |

Registered: 10 years ago Posts: 349 |

Cliff, if you dont use a hotbed then a 12V 5A (60Watt) PSU would be more then enough.

[www.ebay.com]

something like that.

With a hotbed then you might want to double that. A hotbed is usually around 50Watt.

If you use RAMPS then it might be an idea to use two 5A PSU's (RAMPS has 2 inlets, one for the hotbed)

[www.ebay.com]

something like that.

With a hotbed then you might want to double that. A hotbed is usually around 50Watt.

If you use RAMPS then it might be an idea to use two 5A PSU's (RAMPS has 2 inlets, one for the hotbed)

|

Re: Smartrap - Cimbria - Wood frame project. May 10, 2014 04:01AM |

Registered: 10 years ago Posts: 148 |

Thanks regpy and backemf.

I don't have a heatbed as priority as a lot of people seam to state that its not neaded for pla when done the right way,and to keep everything as cheap as possible.

My thoughts for this build is to do a super cheap reprap version to get more people intrested in joining our revolution and to be able to afford it. (smartrap is only the beginning )

)

That's why I also wanted the large construction parts to be in cheap wood.

Iam going to order that small cheap power supply and test it

If it don't work so will I test the one recommended by regpy and work my way up

Iam looking at serges new stuff with no belt or fishing line also.

Iam currently making new wood parts with my drill after all my experiment parts as I have a foundation on how it should look now.

I I might do a small vdeo to show it later.

edited.................

Ok I ordered this one as its small and still make a small punch

12v 8.5a 102w

[www.ebay.co.uk]

Edited 1 time(s). Last edit at 05/10/2014 04:17AM by Cliff Mellangård.

I don't have a heatbed as priority as a lot of people seam to state that its not neaded for pla when done the right way,and to keep everything as cheap as possible.

My thoughts for this build is to do a super cheap reprap version to get more people intrested in joining our revolution and to be able to afford it. (smartrap is only the beginning

)

)That's why I also wanted the large construction parts to be in cheap wood.

Iam going to order that small cheap power supply and test it

If it don't work so will I test the one recommended by regpy and work my way up

Iam looking at serges new stuff with no belt or fishing line also.

Iam currently making new wood parts with my drill after all my experiment parts as I have a foundation on how it should look now.

I I might do a small vdeo to show it later.

edited.................

Ok I ordered this one as its small and still make a small punch

12v 8.5a 102w

[www.ebay.co.uk]

Edited 1 time(s). Last edit at 05/10/2014 04:17AM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. May 11, 2014 07:16PM |

Registered: 10 years ago Posts: 349 |

Hi Cliff,

I'm thinking about alternatives for the LM8UU, and since your design is mostly build around hardware store items I'im wondering if you have considered drawer slides instead of LM8UU

This guy has figured out how to line up the slides to remove any play in the ball bearings.

https://woodgears.ca/pantorouter/glides.html

The average hardware store doesn't have much choice when it comes to linear sliding, they don't have LM8UU either.

On the 8MM rods i'm much more in favour of bronze bushings then the LM8UU but on the other hand printed bushings make even more sense, even if i need to change them every 2 months or so...

I'm thinking about alternatives for the LM8UU, and since your design is mostly build around hardware store items I'im wondering if you have considered drawer slides instead of LM8UU

This guy has figured out how to line up the slides to remove any play in the ball bearings.

https://woodgears.ca/pantorouter/glides.html

The average hardware store doesn't have much choice when it comes to linear sliding, they don't have LM8UU either.

On the 8MM rods i'm much more in favour of bronze bushings then the LM8UU but on the other hand printed bushings make even more sense, even if i need to change them every 2 months or so...

|

Re: Smartrap - Cimbria - Wood frame project. May 11, 2014 07:35PM |

Registered: 10 years ago Posts: 148 |

Yes I have looked at it but I don't have any good store with them in stock and I nead to feel them before I buy

Iam currently caught up with some work on my game and also the work in the hotdog factory. (I start to work 6 a clock in the morning there wich means I have to get up as early as 5 a clock in the morning)

But I will soon post the latest progress where I actually use small amount of printed parts

Makes a lot simpler with some things in the build.

Iam currently caught up with some work on my game and also the work in the hotdog factory. (I start to work 6 a clock in the morning there wich means I have to get up as early as 5 a clock in the morning)

But I will soon post the latest progress where I actually use small amount of printed parts

Makes a lot simpler with some things in the build.

|

Re: Smartrap - Cimbria - Wood frame project. May 18, 2014 07:26AM |

Registered: 10 years ago Posts: 148 |

Here is a small video of the current state and I will try to do it like a video blog.

[www.youtube.com]

[www.youtube.com]

|

Re: Smartrap - Cimbria - Wood frame project. May 18, 2014 11:42AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap - Cimbria - Wood frame project. May 18, 2014 03:08PM |

Registered: 10 years ago Posts: 148 |

Thanks mike and I hope I can show that soon

I have a shortage in funds for some small pieces but it should be up and running soon.

And its probably stupid to have so many large projects at once like I do

Please check my game project also and give feedback about that on wath you would see in that project also if you guys have the time?

While I build this printer do I also rewrite almost the entire game engine I do with a friend in England.

Ps............

do you guys think its stupid to do a build with also m5 threaded rods for the x carriage?

Iam not sure how hot they get when doing a lot of small movements during long periods?

I noticed on my prusa with m5 threaded rods that they can get hot on the z axis if you move long distances in one go and make it stutter?

And haven't tested it on any other axis?

Reprap is a nation without borders where everyone belonges to the nation of tinkerheads

Its great to so so many people from many nations join in tinkering in the reprap forums.

Edited 3 time(s). Last edit at 05/18/2014 03:15PM by Cliff Mellangård.

I have a shortage in funds for some small pieces but it should be up and running soon.

And its probably stupid to have so many large projects at once like I do

Please check my game project also and give feedback about that on wath you would see in that project also if you guys have the time?

While I build this printer do I also rewrite almost the entire game engine I do with a friend in England.

Ps............

do you guys think its stupid to do a build with also m5 threaded rods for the x carriage?

Iam not sure how hot they get when doing a lot of small movements during long periods?

I noticed on my prusa with m5 threaded rods that they can get hot on the z axis if you move long distances in one go and make it stutter?

And haven't tested it on any other axis?

Reprap is a nation without borders where everyone belonges to the nation of tinkerheads

Its great to so so many people from many nations join in tinkering in the reprap forums.

Edited 3 time(s). Last edit at 05/18/2014 03:15PM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. May 19, 2014 10:33AM |

Registered: 10 years ago Posts: 349 |

Quote

Cliff Mellangård

Ps............

do you guys think its stupid to do a build with also m5 threaded rods for the x carriage?

Iam not sure how hot they get when doing a lot of small movements during long periods?

I noticed on my prusa with m5 threaded rods that they can get hot on the z axis if you move long distances in one go and make it stutter?

And haven't tested it on any other axis?

I guess the speed will never be high, though the precision might be great. So it's not stupid, it's just different.

If the rod is of a hard steel (INOX) and the nut of a softer material (bronze) then you might have less friction thus less heat. But i don't know if that really makes a big difference.

If you need power (for milling for instance) then a rod will be a good choice.

|

Re: Smartrap - Cimbria - Wood frame project. May 22, 2014 07:24PM |

Registered: 10 years ago Posts: 349 |

Hi Cliff,

Today i rediscovered this in my digital notebook:

make wooden linear slides

It might be an option to make the Y axis like this?

And to Serge, Markstephen and RegPye Would it be feasible to make printed version of this kind of slide?

Wooden baseplate, and glass sheet as main parts and then these kind of slides attached to the wood and glass.

Minimising the actual part count on the Y axis... and making the whole Y axis printable. One side also a R&P tooth and the Y motor is mounted in a hole in the baseplate (like Cliff's Smartrap has) Maybe also fit mountingholes for a Heated bed? (do heatedbed's have some kind of standard mount hole pattern?)

Unfortunately a heated bed expands a bit when it heats up so the bed itself can not be used as a structural part, or would the auto bedleveling be enough to account for this? Hmmm...

Yea many questions, in a way i'd like to do the experimental stuff myself though why not just throw it in the group and see what happens... :-)

Edited 2 time(s). Last edit at 05/22/2014 07:42PM by BackEMF.

Today i rediscovered this in my digital notebook:

make wooden linear slides

It might be an option to make the Y axis like this?

And to Serge, Markstephen and RegPye Would it be feasible to make printed version of this kind of slide?

Wooden baseplate, and glass sheet as main parts and then these kind of slides attached to the wood and glass.

Minimising the actual part count on the Y axis... and making the whole Y axis printable. One side also a R&P tooth and the Y motor is mounted in a hole in the baseplate (like Cliff's Smartrap has) Maybe also fit mountingholes for a Heated bed? (do heatedbed's have some kind of standard mount hole pattern?)

Unfortunately a heated bed expands a bit when it heats up so the bed itself can not be used as a structural part, or would the auto bedleveling be enough to account for this? Hmmm...

Yea many questions, in a way i'd like to do the experimental stuff myself though why not just throw it in the group and see what happens... :-)

Edited 2 time(s). Last edit at 05/22/2014 07:42PM by BackEMF.

|

Re: Smartrap - Cimbria - Wood frame project. May 24, 2014 04:12AM |

Registered: 10 years ago Posts: 148 |

|

Re: Smartrap - Cimbria - Wood frame project. May 25, 2014 06:36AM |

Registered: 10 years ago Posts: 148 |

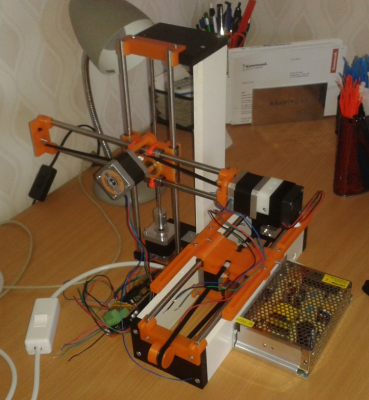

Here is the latest video that shows more how it could end up with the printer.

Iam using printed parts now to test that the construction is good and solid and if works so will I replace most of the printed parts with hardware replacements.

Iam going to wire it up next to see how much the axis wooble or other distortion before I start with that.

I know its a slow build but I don't have much time now to spend on the build.

[youtu.be]

Iam going to replace many parts with these ones later on when the construction is solid.

[www.ebay.co.uk]

[www.ebay.co.uk]

Edited 1 time(s). Last edit at 05/25/2014 06:38AM by Cliff Mellangård.

Iam using printed parts now to test that the construction is good and solid and if works so will I replace most of the printed parts with hardware replacements.

Iam going to wire it up next to see how much the axis wooble or other distortion before I start with that.

I know its a slow build but I don't have much time now to spend on the build.

[youtu.be]

Iam going to replace many parts with these ones later on when the construction is solid.

[www.ebay.co.uk]

[www.ebay.co.uk]

Edited 1 time(s). Last edit at 05/25/2014 06:38AM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. May 25, 2014 09:46AM |

Registered: 10 years ago Posts: 148 |

|

Re: Smartrap - Cimbria - Wood frame project. May 25, 2014 10:32AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap - Cimbria - Wood frame project. May 25, 2014 09:22PM |

Registered: 10 years ago Posts: 349 |

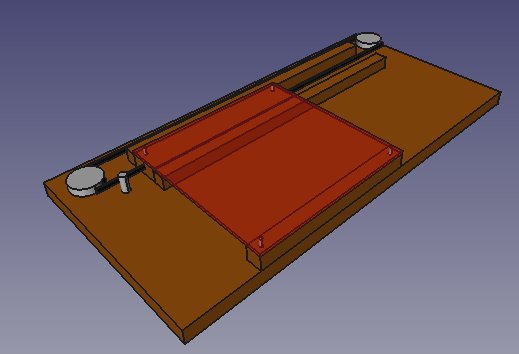

I've spend a few hours in FreeCAD and tried to do a rough drawing of what i would try for the X-axis

This will probably not run very smooth though i share it anyway, to show off what a rookie can draw after 2 hours of FreeCAD. :-)

The bed is meant to be a heated bed or a thin sheet of MFD where the glass can be clamped on.

the black stripes are a belt

the 'motor shaft cylinder' is not in the right position though i think this gives a good idea of an approximate location for the motor

Don't take this drawing to serious... i was more occupied with getting FreeCAD memorized

Actually I like the rod driven axis in the video. I think you could eventually try M10 threaded rods to double the speed?

This will probably not run very smooth though i share it anyway, to show off what a rookie can draw after 2 hours of FreeCAD. :-)

The bed is meant to be a heated bed or a thin sheet of MFD where the glass can be clamped on.

the black stripes are a belt

the 'motor shaft cylinder' is not in the right position though i think this gives a good idea of an approximate location for the motor

Don't take this drawing to serious... i was more occupied with getting FreeCAD memorized

Actually I like the rod driven axis in the video. I think you could eventually try M10 threaded rods to double the speed?

|

Re: Smartrap - Cimbria - Wood frame project. May 25, 2014 11:34PM |

Registered: 10 years ago Posts: 229 |

Hey, not to bad for a rookie.

If you want to stick with a rod, and the axis is moving free enough, you could always try a ThreadlessBallscrew. You can get those going real fast if you need to. Plane threaded rod just moves to slow for the X and Y IMO. You can't get the speed out of the steppers.

Mark

Edit - also search for " threadless nut ", it will turn up a few more examples.

Edited 2 time(s). Last edit at 05/25/2014 11:41PM by markstephen.

If you want to stick with a rod, and the axis is moving free enough, you could always try a ThreadlessBallscrew. You can get those going real fast if you need to. Plane threaded rod just moves to slow for the X and Y IMO. You can't get the speed out of the steppers.

Mark

Edit - also search for " threadless nut ", it will turn up a few more examples.

Edited 2 time(s). Last edit at 05/25/2014 11:41PM by markstephen.

|

Re: Smartrap - Cimbria - Wood frame project. May 26, 2014 09:03AM |

Registered: 10 years ago Posts: 349 |

Thanks!Quote

markstephen

Hey, not to bad for a rookie.

Quote

markstephen

If you want to stick with a rod, and the axis is moving free enough, you could always try a ThreadlessBallscrew.

Yes i've seen those ballscrews, though Cliff is trying to make a 'wooden+hardwarestore sourced' smartrap. It's about time every city has a little Shanghai shop next to the hardware store.

I wonder if it's possible to make all wooden slides (XY and Z) Although that probably will then no longer fit in the smartrap philosophy (or does it?). And I'm also thinking about using the smooth glass as a slide itself, but then it's more difficult to attach a heated bed.

Ideally Serges idea to make an all printed smartrap that can print all of itself is exelent. Though in my case i found out that the other challenge, to build a printer without having access to a printer is still a bit of a pain. (but very educational)

And ... now I wonder if there are Japanese wood specialists here on the forum.

|

Re: Smartrap - Cimbria - Wood frame project. May 26, 2014 09:49AM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Thanks!Quote

markstephen

Hey, not to bad for a rookie.

Quote

markstephen

If you want to stick with a rod, and the axis is moving free enough, you could always try a ThreadlessBallscrew.

Yes i've seen those ballscrews, though Cliff is trying to make a 'wooden+hardwarestore sourced' smartrap. It's about time every city has a little Shanghai shop next to the hardware store.

I wonder if it's possible to make all wooden slides (XY and Z) Although that probably will then no longer fit in the smartrap philosophy (or does it?). And I'm also thinking about using the smooth glass as a slide itself, but then it's more difficult to attach a heated bed.

Ideally Serges idea to make an all printed smartrap that can print all of itself is exelent. Though in my case i found out that the other challenge, to build a printer without having access to a printer is still a bit of a pain. (but very educational)

And ... now I wonder if there are Japanese wood specialists here on the forum.

How about if you added a second piece of glass for the slide are that is very narrow. That way you could still have the glass for the bed, a heater pad (or whatever) and the second thin strip of glass as the slide area (maybe glue it in place with silicone adhesive?? or even clip it in place (food for thought??))

And for the driving mechanism, how about the threadless ball screw idea that can be printed? [www.thingiverse.com]

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap - Cimbria - Wood frame project. May 26, 2014 12:22PM |

Registered: 10 years ago Posts: 148 |

Thanks guys for all the input

I actually started to tear down my prototype to see where I got it wrong with the simple assembly?

It looked simple for me but a person that are a completely new to 3d printers remarked that it looked complicated to assemble.

I have a better design now that is even simplier but how it looks in the end is another question ?

Yes to if I have seen all cool new stuff that are printable in the smartrap sections

Iam only hanging around the smartrap section due to time shortage now days.

I have got employement for 3 months and start very early nowdays.

I will post a image soon or even a video.

I actually started to tear down my prototype to see where I got it wrong with the simple assembly?

It looked simple for me but a person that are a completely new to 3d printers remarked that it looked complicated to assemble.

I have a better design now that is even simplier but how it looks in the end is another question ?

Yes to if I have seen all cool new stuff that are printable in the smartrap sections

Iam only hanging around the smartrap section due to time shortage now days.

I have got employement for 3 months and start very early nowdays.

I will post a image soon or even a video.

|

Re: Smartrap - Cimbria - Wood frame project. June 12, 2014 01:36PM |

Registered: 10 years ago Posts: 148 |

Long time no updates

Here is the latest design and will be final if nothing critical is found with the design?

I nead to power it and do some stress tests.

[www.youtube.com]

Edited 1 time(s). Last edit at 06/12/2014 01:36PM by Cliff Mellangård.

Here is the latest design and will be final if nothing critical is found with the design?

I nead to power it and do some stress tests.

[www.youtube.com]

Edited 1 time(s). Last edit at 06/12/2014 01:36PM by Cliff Mellangård.

|

Re: Smartrap - Cimbria - Wood frame project. June 12, 2014 07:17PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap - Cimbria - Wood frame project. June 12, 2014 07:27PM |

Registered: 11 years ago Posts: 791 |

Quote

Cliff Mellangård

Long time no updates

Here is the latest design and will be final if nothing critical is found with the design?

I nead to power it and do some stress tests.

[www.youtube.com]

YES! That looks solid.

I see that you did the same as I did and turned the rods over 90 degrees.

I like the way you have done the X belting too - clever.

Y looks good too, moving carriage instead of moving rods.

Well done.

EDIT:

I just noticed that you are using a direct drive extruder, similar to the QU-BD model.

I was using that before going to the Wades style and made some modifications to that one. I printed them out of PLA and they worked fine, no issues with heat.

If anyone wants the STL file for that I can find it and post it.

It uses a grub screw for the adjustment, the end of the grub screw needs to be polished.

Only drawback I found with this extruder was that you need to ne a bit patient to get the pressure right, once right it works fine.

.

Edited 1 time(s). Last edit at 06/12/2014 08:17PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap - Cimbria - Wood frame project. June 12, 2014 08:11PM |

Registered: 10 years ago Posts: 349 |

That looks great Cliff,

I personally would not like to have all that weight of the extruder on those X axis LM8UU bearings, though printrbot also does this so it should not be an issue.

The Y axis looks nice and light. the GT2 belts are they horizontal? Looks like they are a bit on an angle. (can be an optical illusion)

I personally would not like to have all that weight of the extruder on those X axis LM8UU bearings, though printrbot also does this so it should not be an issue.

The Y axis looks nice and light. the GT2 belts are they horizontal? Looks like they are a bit on an angle. (can be an optical illusion)

|

Re: Smartrap - Cimbria - Wood frame project. June 13, 2014 04:21AM |

Registered: 9 years ago Posts: 9 |

|

Re: Smartrap - Cimbria - Wood frame project. June 13, 2014 05:04AM |

Registered: 11 years ago Posts: 1,865 |

hi,

really great work.

you may try this geared extruder [www.thingiverse.com]

Enrico

[www.dapa3dservice.it] [www.studiodapa.it]

repstrap dApA, Ramps 1.4, MarlinKimbra / scanner 3D Cubify Sense / Formlabs Form 2

really great work.

you may try this geared extruder [www.thingiverse.com]

Enrico

[www.dapa3dservice.it] [www.studiodapa.it]

repstrap dApA, Ramps 1.4, MarlinKimbra / scanner 3D Cubify Sense / Formlabs Form 2

|

Re: Smartrap - Cimbria - Wood frame project. June 13, 2014 12:38PM |

Registered: 10 years ago Posts: 148 |

Thanks everyone

wich one of the gt2 belts ?

I have a angle issue to fix on the x carriage! that sweet peas pointed out when I saved his day with giving new stepsticks to him for the ones he fried in his smartrap kit

Hope they are working ok for you pontus

regpy I always look on all modifications and grabb the best parts for my build

And I actually think the company I bought the extruder from are using your version when you mention the grubb screw and all ?

But please find your stl files and let me have a look

wich one of the gt2 belts ?

I have a angle issue to fix on the x carriage! that sweet peas pointed out when I saved his day with giving new stepsticks to him for the ones he fried in his smartrap kit

Hope they are working ok for you pontus

regpy I always look on all modifications and grabb the best parts for my build

And I actually think the company I bought the extruder from are using your version when you mention the grubb screw and all ?

But please find your stl files and let me have a look

|

Re: Smartrap - Cimbria - Wood frame project. June 13, 2014 07:45PM |

Registered: 11 years ago Posts: 791 |

Quote

Cliff Mellangård

regpy I always look on all modifications and grabb the best parts for my build

And I actually think the company I bought the extruder from are using your version when you mention the grubb screw and all ?

But please find your stl files and let me have a look

The full SAT file,that is the extruder, hotend and stepper motor can be downloaded from my website. It is pretty big about 6M

full extruder

Edit;

Here it is as a zip

Edited 3 time(s). Last edit at 06/13/2014 08:07PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.