Bowden connection

Posted by milt

|

Bowden connection April 28, 2014 12:19PM |

Registered: 10 years ago Posts: 18 |

Hi everyone. I'm ordering the last few bits for my Smartrap build but I am having trouble understanding how the Bowden tube connects to the base plate and hot-end. I seem to recall that some sort of brass coupling was used to connect to the base plate / extruder along with the "tongue" piece... Can someone provide a link to that part for me? Also, I am using a J-head lite V2 with markstephan's servo-less mount. I have both the push-fit and bowden support x-arms printed but unsure as to how the bowden support version works. Do I just thread a M4 nut onto the PFTE?

I'll post a build log as I near completion... getting close!!

Thanks!

I'll post a build log as I near completion... getting close!!

Thanks!

|

Re: Bowden connection April 28, 2014 12:38PM |

Registered: 10 years ago Posts: 229 |

The default is yes, just a 4 mm nut threaded in to the tube holds it very well. When I threaded my nuts on, (J-head uses one on the other end too), I had to use a drill bit to ream out the ends of the tube as the nut compressed the ID a bit. No drill motor, just a couple of turns with my fingers spinning the bit. The plastic is rather soft and it doesn't take much. There are mods out there for the push connects and the like, but the nuts work just fine.

Looking forward to seeing your build.

Mark

Edited 1 time(s). Last edit at 04/28/2014 12:38PM by markstephen.

Looking forward to seeing your build.

Mark

Edited 1 time(s). Last edit at 04/28/2014 12:38PM by markstephen.

|

Re: Bowden connection April 28, 2014 05:11PM |

Registered: 10 years ago Posts: 814 |

|

Re: Bowden connection April 28, 2014 05:52PM |

Registered: 10 years ago Posts: 229 |

|

Re: Bowden connection April 28, 2014 06:07PM |

Registered: 10 years ago Posts: 18 |

|

Re: Bowden connection May 02, 2014 01:28AM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

Yup - Here ya go.

Mark

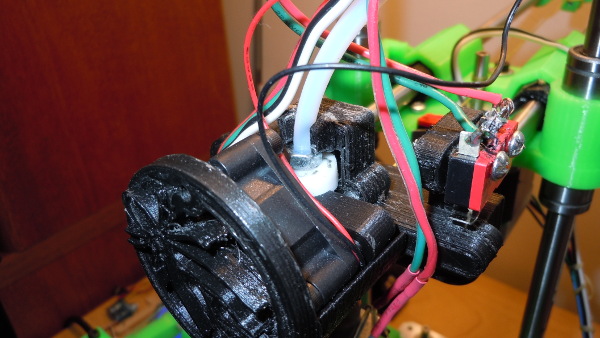

[attachment 31767 ColdEnd_Nut.JPG]

[attachment 31768 HotEnd_Nut.JPG]

I found it much easier to put the nut on the outside of the extruder and also use the clamping hook on the bolt that is closest to the nut.

I stopped using that type of drive drive extruder and designed my own geared type. Will posy some photos later.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Bowden connection May 02, 2014 10:00AM |

Registered: 10 years ago Posts: 18 |

Quote

regpye

I found it much easier to put the nut on the outside of the extruder and also use the clamping hook on the bolt that is closest to the nut.

I stopped using that type of drive drive extruder and designed my own geared type. Will posy some photos later.

Wish I had seen this post last night! I struggled for a good while trying to get that nut deep enough into the well to have a clear shot at threading the PFTE. Ended up removing some material from the well with a drill to make it work. Your strategy would have been a lot easier. I also couldn't get the M4 nut threaded on the hot-end side of the bowden tube... there wasn't enough room between the top of the hotend (J-head Lite V2) and the tube guide on markstephan's J-head Lite mount (a previous version) to fit the nut. I'll go to the hardware store today and see if I can find a thinner nut... otherwise I'll swap parts for a push-fit.

Sorry, only registered users may post in this forum.