How precise can your Smartrap print? - Alignment issues

Posted by cristian

|

How precise can your Smartrap print? - Alignment issues July 14, 2014 07:11PM |

Registered: 9 years ago Posts: 344 |

Hi all,

I am in the process of assembling my smartrap. The mechanical part is more or less done, so that even if I cannot print yet, I am starting already to see some of the well known the problems it will give (perpendicularity, Z wobble, etc.).

As soon as I am able to print I would like to try to improve the current design in many respects, but before I start I would like to know if you found this kind of issues too, if you already started addressing them and how.

Here are a couple of remarks to start the discussion:

What is your experience?

You are also invited to share here all your tips about alignment issues, so that they are all collected in one forum thread for quick reference later on.

Cristian

I am in the process of assembling my smartrap. The mechanical part is more or less done, so that even if I cannot print yet, I am starting already to see some of the well known the problems it will give (perpendicularity, Z wobble, etc.).

As soon as I am able to print I would like to try to improve the current design in many respects, but before I start I would like to know if you found this kind of issues too, if you already started addressing them and how.

Here are a couple of remarks to start the discussion:

- the design is not entirely symmetric: the threaded rod is on one side, the belts (I have one of the last kits with GT2 belts) are often attached to the corners, which causes a deformation of the X and Y carriages to make them look as trapezoids instead of rectangles (and probably they slide less smoothly);

- globally, the structure seems a bit weak and prone to oscillations and vibrations (I noticed that some of you already modified the original design to improve this issue in particular);

- there is no obvious way to tune the alignment of the printer: most of the possible tuning must be done during the initial assembly, if something goes wrong one has probably to restart from scratch and if some plastic pieces came slightly deformed one is doomed.

What is your experience?

You are also invited to share here all your tips about alignment issues, so that they are all collected in one forum thread for quick reference later on.

Cristian

|

Re: How precise can your Smartrap print? - Alignment issues July 14, 2014 07:25PM |

Registered: 10 years ago Posts: 37 |

My solution to the X-Y skew problem was to add a skew matrix to the three-point auto-leveling matrix:

I printed a 100x100x1mm square frame, put it on some graph paper to measure the skew, and calculated the skew angle to offset the printer's x-y skew. For example, the square on the positive side of my x axis was shifted 0.9 mm to the right along the y axis. arctan(0.9mm/100mm) = 0.515 degrees. I set my Y_SKEW_ANGLE_DEG to -0.52 (degrees) to compensate. Now I have no skew!

--- Configuration.h ---

#define SKEW_AXES // Can add a scew to the x, y or both axes to compensate for

#ifdef SKEW_AXES

// Adds an X and/or Y axis scew to the auto level matrix. Can compensate for non-rectangular cartesian problems

#define X_SKEW_ANGLE_DEG 0.00 // Shift the x axis up as the head moves in positive y

#define Y_SKEW_ANGLE_DEG -0.52 // Shift the y axis up as the head moves in positive x

#endif

--- Marlin_main.cpp ---

static void set_bed_level_equation_3pts(float z_at_pt_1, float z_at_pt_2, float z_at_pt_3) {

plan_bed_level_matrix.set_to_identity();

// smartrap modif: we add some delta on 3rd point because of smartrap's special design : x is porte a faux and there's a diff between probe and print

z_at_pt_3 += Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_X;

vector_3 pt1 = vector_3(ABL_PROBE_PT_1_X, ABL_PROBE_PT_1_Y, z_at_pt_1);

vector_3 pt2 = vector_3(ABL_PROBE_PT_2_X, ABL_PROBE_PT_2_Y, z_at_pt_2);

vector_3 pt3 = vector_3(ABL_PROBE_PT_3_X, ABL_PROBE_PT_3_Y, z_at_pt_3);

vector_3 from_2_to_1 = (pt1 - pt2).get_normal();

vector_3 from_2_to_3 = (pt3 - pt2).get_normal();

vector_3 planeNormal = vector_3::cross(from_2_to_1, from_2_to_3).get_normal();

planeNormal = vector_3(planeNormal.x, planeNormal.y, abs(planeNormal.z));

plan_bed_level_matrix = matrix_3x3::create_look_at(planeNormal);

#ifdef SKEW_AXES

plan_bed_level_matrix.debug("bed level before axis skew");

float tanx=tan(M_PI*X_SKEW_ANGLE_DEG/180.0);

float tany=tan(M_PI*Y_SKEW_ANGLE_DEG/180.0);

float* mmatrix = plan_bed_level_matrix.matrix;

#define m(r,c) mmatrix[3*r+c]

vector_3 row1 = vector_3( m(0,0)+tany*m(1,0), m(0,1)+tany*m(1,1), m(0,2)+tany*m(1,2) );

vector_3 row2 = vector_3( m(1,0)+tanx*m(0,0), m(1,1)+tanx*m(0,1), m(1,2)+tanx*m(0,2) );

vector_3 row3 = vector_3( m(2,0), m(2,1), m(2,2) );

plan_bed_level_matrix = matrix_3x3::create_from_rows(row1, row2, row3);

plan_bed_level_matrix.debug("bed level after axis skew");

#endif

vector_3 corrected_position = plan_get_position();

current_position[X_AXIS] = corrected_position.x;

current_position[Y_AXIS] = corrected_position.y;

current_position[Z_AXIS] = corrected_position.z;

// put the bed at 0 so we don't go below it.

current_position[Z_AXIS] = zprobe_zoffset + Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_Z;

plan_set_position(current_position[X_AXIS], current_position[Y_AXIS], current_position[Z_AXIS], current_position[E_AXIS]);

}

--- END ---

I printed a 100x100x1mm square frame, put it on some graph paper to measure the skew, and calculated the skew angle to offset the printer's x-y skew. For example, the square on the positive side of my x axis was shifted 0.9 mm to the right along the y axis. arctan(0.9mm/100mm) = 0.515 degrees. I set my Y_SKEW_ANGLE_DEG to -0.52 (degrees) to compensate. Now I have no skew!

|

Re: How precise can your Smartrap print? - Alignment issues July 14, 2014 11:33PM |

Registered: 9 years ago Posts: 80 |

Thanks for sharing this, CellJeffe!

So, even the skew can be compensated. I t think even the most poorly aligned printer will be capable of great prints!

I'm not an expert programmer but I really want to understand how it does it. If you don't mind, would you be able to explain it? Or you could just point me to some references maybe?

Thanks again!

So, even the skew can be compensated. I t think even the most poorly aligned printer will be capable of great prints!

I'm not an expert programmer but I really want to understand how it does it. If you don't mind, would you be able to explain it? Or you could just point me to some references maybe?

Thanks again!

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 12:53AM |

Registered: 10 years ago Posts: 37 |

Short answer: The autoleveling code already calculates a rotation matrix so that Z is always perpendicular to the actual XY plane. I added an XY skew transformation matrix to the bed-leveling matrix through a simple matrix multiplication.

Long Answer: Linear Algebra Time!

The existing bed leveling algorithm calculates a 3x3 rotation matrix that can turn any 3D coordinate (x,y,z) into another 3D coordinate rotated about some point.

The existing auto-leveling algorithm finds a matrix that rotates all coordinates so that the Z is perpendicular to the X-Y plane. It finds two line parallel to the bed and takes the cross product to determine the surface normal perpendicular to the plane. This surface normal is the direction the new Z should point. Once you have a surface normal, it is moderately easy to generate a rotation matrix that will make all Z coordinate point along this new surface normal (the "create_look_at" part of the code).

Since there was already a 3x3 matrix coverting g-code 3D coordinates into rotated coordinates, I used that matrix as a "hook" to add a skew matrix. A 3x3 matrix is general enough that it can do a little more than rotate. (It cannot translate. For that one needs a 4x4 matrix, but that's another story).

You can chain multiple transformation operation together with matrix multiplications to get several transformations for the price of one. Say you want to rotate in direction 1 then in direction 2, then in direction 3. You have matrices M1, M2, and M3 that do these rotation separately. To get the new point, you multiply the old point by these matrices in reverse order.

This means rotate in direction 1 followed by direction 2 followed by direction 3.

But you can combine those three matrices into a single matrix to save time. M123 = M3 x M2 x M1. Once you compute M123, you can use it instead of each individual matrix.

A skew matrix is similar to a rotation matrix in that it is also a 3x3 transformation matrix. In this case, we only care about shearing along the XY plane. Formally, this skew (aka shear) matrix for the XY plane in three dimensions is

You might ask, "But CellJeffe, what about Z skewing?" Good question! The bed leveling rotation matrix already took care of that. The new Z direction was calculated to be always perpendicular to the measured XY plane!

Relevant XKCD -- 2D Rotation Matrix

Long Answer: Linear Algebra Time!

The existing bed leveling algorithm calculates a 3x3 rotation matrix that can turn any 3D coordinate (x,y,z) into another 3D coordinate rotated about some point.

New_point = Matrix x Old_point | xnew | | a b c | | xold | | ynew | = | d e f | x | yold | | znew | | g h i | | zold | (read the equations right-to-left)

The existing auto-leveling algorithm finds a matrix that rotates all coordinates so that the Z is perpendicular to the X-Y plane. It finds two line parallel to the bed and takes the cross product to determine the surface normal perpendicular to the plane. This surface normal is the direction the new Z should point. Once you have a surface normal, it is moderately easy to generate a rotation matrix that will make all Z coordinate point along this new surface normal (the "create_look_at" part of the code).

Since there was already a 3x3 matrix coverting g-code 3D coordinates into rotated coordinates, I used that matrix as a "hook" to add a skew matrix. A 3x3 matrix is general enough that it can do a little more than rotate. (It cannot translate. For that one needs a 4x4 matrix, but that's another story).

You can chain multiple transformation operation together with matrix multiplications to get several transformations for the price of one. Say you want to rotate in direction 1 then in direction 2, then in direction 3. You have matrices M1, M2, and M3 that do these rotation separately. To get the new point, you multiply the old point by these matrices in reverse order.

new_point = M3 x M2 x M1 x old_point (read right to left)

This means rotate in direction 1 followed by direction 2 followed by direction 3.

But you can combine those three matrices into a single matrix to save time. M123 = M3 x M2 x M1. Once you compute M123, you can use it instead of each individual matrix.

A skew matrix is similar to a rotation matrix in that it is also a 3x3 transformation matrix. In this case, we only care about shearing along the XY plane. Formally, this skew (aka shear) matrix for the XY plane in three dimensions is

| 1 tan(Ay) 0 |

Mskew = | tan(Ax) 1 0 |

| 0 0 1 |

Where Ay is the shear angle about the Y axis and Ax is the shear angle about the X axis. The code containing m(0,0), etc is the simplified matrix multiplication of the original bed leveling matrix by this skew matrix, Mskewlevel = Mskew x Mlevel. Once that new matrix is calculated, the code just replaces the existing auto-leveling matrix with this new one.You might ask, "But CellJeffe, what about Z skewing?" Good question! The bed leveling rotation matrix already took care of that. The new Z direction was calculated to be always perpendicular to the measured XY plane!

Relevant XKCD -- 2D Rotation Matrix

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 04:19AM |

Registered: 10 years ago Posts: 992 |

Thank you for starting this thread Christian. This design, with ts evolutions, is at a point we need to re-work some parts to have a better and more clean structure.

You pointed the right problems in my view. Expecially the new tensions on X and Y axis coming from the belt system. Note it it doesn't happen with the rack&pinion or with fishing line , as they are symmetric or using an M5 thread to block the all axis in place. GT2 was a later implementation

For now, i didn't notice any difference between rack&pinion Smartrap and GT2 one on the printed parts, strangely! it should have dif because GT2 brings some deformations of the structure. I think i didn't see dif because the all quality is not top notch. That wasn't the first goal of this design. The goal is to have a simple, less possible plastic , printed structure, simple to assemble and with options to adapt to anyone need.

If you want to work on the design, it's wonderful. thank you.One reason of printed structure is that it let the community design and update the model because it's easy to share and test for everyone ( not like laser cut parts). Note that on the last version, we have some M3x10 blocking the smooth rods on the Y axis ends. It's better and we will have it on X axis too.

CellJeff ! I'm just amazed by what you just did I was looking for a solution like this for long time now . I even think it would be great for the all repraps. I've posted something on marlin github, but had no good answers. I was looking for more complicated things that what you did, which is absolutely perfect

I was looking for a solution like this for long time now . I even think it would be great for the all repraps. I've posted something on marlin github, but had no good answers. I was looking for more complicated things that what you did, which is absolutely perfect

I will integrate it in my marlin . I would like to implement the M556 gcode like reprappro did with the omerod and like it is written in reprap.org ( [reprappro.com]) .

Thank you so far you just unblocked a level of the game and thank you for the little course about 3d matrix ..it's a good reminder

and thank you for the little course about 3d matrix ..it's a good reminder

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

You pointed the right problems in my view. Expecially the new tensions on X and Y axis coming from the belt system. Note it it doesn't happen with the rack&pinion or with fishing line , as they are symmetric or using an M5 thread to block the all axis in place. GT2 was a later implementation

For now, i didn't notice any difference between rack&pinion Smartrap and GT2 one on the printed parts, strangely! it should have dif because GT2 brings some deformations of the structure. I think i didn't see dif because the all quality is not top notch. That wasn't the first goal of this design. The goal is to have a simple, less possible plastic , printed structure, simple to assemble and with options to adapt to anyone need.

If you want to work on the design, it's wonderful. thank you.One reason of printed structure is that it let the community design and update the model because it's easy to share and test for everyone ( not like laser cut parts). Note that on the last version, we have some M3x10 blocking the smooth rods on the Y axis ends. It's better and we will have it on X axis too.

CellJeff ! I'm just amazed by what you just did

I was looking for a solution like this for long time now . I even think it would be great for the all repraps. I've posted something on marlin github, but had no good answers. I was looking for more complicated things that what you did, which is absolutely perfect

I was looking for a solution like this for long time now . I even think it would be great for the all repraps. I've posted something on marlin github, but had no good answers. I was looking for more complicated things that what you did, which is absolutely perfect

I will integrate it in my marlin . I would like to implement the M556 gcode like reprappro did with the omerod and like it is written in reprap.org ( [reprappro.com]) .

Thank you so far you just unblocked a level of the game

and thank you for the little course about 3d matrix ..it's a good reminder

and thank you for the little course about 3d matrix ..it's a good reminder

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 07:36AM |

Registered: 9 years ago Posts: 344 |

Quote

CellJeffe

My solution to the X-Y skew problem was to add a skew matrix to the three-point auto-leveling matrix:

Thanks CellJeffe! Have you measured skew for Z axis too?

Quote

smartfriendz

Expecially the new tensions on X and Y axis coming from the belt system. Note it it doesn't happen with the rack&pinion or with fishing line , as they are symmetric or using an M5 thread to block the all axis in place. GT2 was a later implementation

Indeed in my mind belts are not the optimal solution, although every system has its own pros and cons. It seems to me that the fishing line is the most elegant, but I read many posts about tightening problems. Serge, may you list here all the problems you were told about rack&pinion and fishing line?

Quote

smartfriendz

Note that on the last version, we have some M3x10 blocking the smooth rods on the Y axis ends. It's better and we will have it on X axis too.

This is important I think. In the version I have, they are only on one side of the Y axis (so only in one rod): I think it would be important to have them for each rod of X and Y as they may help to reduce the skew if properly used. Moreover, I noticed that plastic undergoes strong deformation near these screws, so it may be probably better to increase the infill for those pieces or to make their design more solid around these screws holes.

About the Z axis: have you thought about adding a bridge on the top of the Z rods? It would be also important to reinforce the Z axis which in my opinion suffers from two problems:

- the Z wobble caused by the threaded rod which is not straight: it can be mitigated by adding lubricant to the small piece bound to the threaded rod which supports the Z carriage, but the wobble does not disappear completely;

- the skew coming from the unbalanced weight of the X axis: the Z axis fluctuates a little depending on the position of the X carriage: the only way I see to reduce this effect is to have some additional vertical structure behind the two Z smooth rods with a cap that binds their tops, so that the Z axis does not rely only on two support points but at least on a triangle.

What do you think?

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 09:34AM |

Registered: 10 years ago Posts: 992 |

Hi Christian,

Thank you for those feedback. I can only agree with all that

About the Z , I think that making a triangle would be the best too, with maybe two threaded rods going on the back , behind the steppers and attached on the top. That would make a solid triangle reducing the flexibility of those two smooth rods. It is that or using M12 smooth rods like in the ptrintrbot simple. I would choose triangle structure personally. i started a design about that . i will maybe put it here to think about

About the wobble, with the last system , i had very good result ? The support need to be maybe adjusted under the Plate_x to be free ( with a little grease under ). My M5 threaded rod is shaking like crazy now , but all the wobble goes into this support, not on the plate.

About the GT2, it just works well and i choose to use them for assembly easiness for the commercial kits. Especially the aluminiums pinions . Maybe it could change in the future . I had indeed very good result with fishing line, but it needs to be very straight , and we need to fin the good one. Too small an it brakes..too big and it's not so accurate anymore .

.

I love the rack&pinions too, i have one machine in production with it and it works like a charm. I add some vaseline on it and it's very smooth. The problem here is to adjust very precise because if too large, you will have backslash , and too tight, it will make waves on the printed parts. I would easy go back to r&p with a better design, more adjustable. And maybe without the long threaded rods inside. I think it's possible to have just racks printed and attached to both ends.

For the Y, we are maybe going to switch to aluminium plate because of a new auto level system using proximity sensors inductive ( so , metal needed). In that case, we could rework the Y ends and racks so we can fix it directly on the aluminium plate.. maybe.. it's just ideas

I would love to have an all printed structure one day . Not because it's better than other solutions, but because it's just sooo reproductive without human intervention ( click : print ! ) and because it's the only way i know to have community interactive design ( everyone model and test on its own printer in almost real time ). Canot be practically done with other technologies actually.

But let's work on the Z reinforcement for now ? I'm working on it in spare time lately ( with the auto level too, as it's very important to have one without touching the bed..with the Smartrap's design).

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

Thank you for those feedback. I can only agree with all that

About the Z , I think that making a triangle would be the best too, with maybe two threaded rods going on the back , behind the steppers and attached on the top. That would make a solid triangle reducing the flexibility of those two smooth rods. It is that or using M12 smooth rods like in the ptrintrbot simple. I would choose triangle structure personally. i started a design about that . i will maybe put it here to think about

About the wobble, with the last system , i had very good result ? The support need to be maybe adjusted under the Plate_x to be free ( with a little grease under ). My M5 threaded rod is shaking like crazy now , but all the wobble goes into this support, not on the plate.

About the GT2, it just works well and i choose to use them for assembly easiness for the commercial kits. Especially the aluminiums pinions . Maybe it could change in the future . I had indeed very good result with fishing line, but it needs to be very straight , and we need to fin the good one. Too small an it brakes..too big and it's not so accurate anymore

.

. I love the rack&pinions too, i have one machine in production with it and it works like a charm. I add some vaseline on it and it's very smooth. The problem here is to adjust very precise because if too large, you will have backslash , and too tight, it will make waves on the printed parts. I would easy go back to r&p with a better design, more adjustable. And maybe without the long threaded rods inside. I think it's possible to have just racks printed and attached to both ends.

For the Y, we are maybe going to switch to aluminium plate because of a new auto level system using proximity sensors inductive ( so , metal needed). In that case, we could rework the Y ends and racks so we can fix it directly on the aluminium plate.. maybe.. it's just ideas

I would love to have an all printed structure one day . Not because it's better than other solutions, but because it's just sooo reproductive without human intervention ( click : print ! ) and because it's the only way i know to have community interactive design ( everyone model and test on its own printer in almost real time ). Canot be practically done with other technologies actually.

But let's work on the Z reinforcement for now ? I'm working on it in spare time lately ( with the auto level too, as it's very important to have one without touching the bed..with the Smartrap's design).

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 10:04AM |

Registered: 10 years ago Posts: 814 |

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 10:58AM |

Registered: 10 years ago Posts: 37 |

Quote

cristian

Thanks CellJeffe! Have you measured skew for Z axis too?

Yes. Theoretically, the existing autolevel matrix corrects for Z-axis skew. Theoretically. It would be nice to see other smartrap users verify that theory

.

.Here are my calibration files and the openscad programs that generate them.

XY Skew calibration

- Print out the XYCalibration-100x1.stl calibration object (or generate from XYCalibration.scad).

- Mark the positive x- and y-axis directions before pulling it off of the printer.

- Put it on a sheet of graph paper with one side aligned.

- Measure how far off the opposite side is from the perpendicular (yskew in mm) ie the amount of skew.

- Divide that measurement by the 100mm length and take the arctan(yskew/100) to determine the skew angle.

- Convert from radians to degrees if necessary (180*arctan(yskew/100)/PI) and take the negative of that number as the skew compensation.

- Update your configuration.h file in marlin with that deskew angle, either X_SKEW_ANGLE_DEG or Y_SKEW_ANGLE_DEG depending on which axis you measured.

- If you aligned the X axis to the graph paper and measured the shift in the Y direction, update Y_SKEW_ANGLE_DEG.

- If you aligned the Y axis to the graph paper, update X_SKEW_ANGLE_DEG.

- Upload the new firmware and print the calibration again.

Z Skew calibration

- Print out the XYZCalibration-50x6x2.stl calibration object (or generate from XYZCalibration.scad). This is similar to the XYCalibration object but with two towers on one side.

- Mark positive x- y- and z-axis directions before pulling it off.

- Check alignment against graph paper as before.

NOTE: The skew compensation only takes effect after the 3-point autocalibration.

Attachments

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 02:33PM |

Registered: 9 years ago Posts: 344 |

Quote

smartfriendz

But let's work on the Z reinforcement for now ? I'm working on it in spare time lately ( with the auto level too, as it's very important to have one without touching the bed..with the Smartrap's design).

Absolutely! As soon as I get my printer working.

Quote

CellJeffe

Theoretically, the existing autolevel matrix corrects for Z-axis skew.

It seems to me that the autolevel matrix cannot detect everything. It will detect correctly the Y-Z skew I think, however for the X-Z skew the autolevel will only correct the difference of skew between the bed and the X/Z rods. Of course the X/Z rods skew should be negligible unless the plate_x is faulty. Nevertheless I would like to measure it to be sure.

Moreover, it should be (theoretically

) possible to get rid of most of the bed skew manually once for all, by adding some shim on the right/left and/or front/back supports of the glass plate. So the bed skew should be really the most gentle of the problems here, while for X/Y and X/Z rods skew one absolutely needs software calibration as you did.

) possible to get rid of most of the bed skew manually once for all, by adding some shim on the right/left and/or front/back supports of the glass plate. So the bed skew should be really the most gentle of the problems here, while for X/Y and X/Z rods skew one absolutely needs software calibration as you did.It is very important indeed to have this software calibration to allow a correct evolution of the "Smartrap species": otherwise, after every generation of Smartraps the precision of the printed parts would quickly degrade and the new born Smartraps would not be able to procreate

Edited 1 time(s). Last edit at 07/15/2014 02:39PM by cristian.

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 03:38PM |

Registered: 9 years ago Posts: 3 |

And what if in the bed center depth is 1 mm? The detail top too will be with a hole? Or gradual alignment? Or back? ! ! ! NO! ! ! the hole will be! ! ! It is better to level a bed hands of 1 times in 1 month.

forgive for my English

Edited 1 time(s). Last edit at 07/15/2014 03:39PM by Lukashuk.

forgive for my English

Edited 1 time(s). Last edit at 07/15/2014 03:39PM by Lukashuk.

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 05:05PM |

Registered: 10 years ago Posts: 37 |

Quote

cristian

It seems to me that the autolevel matrix cannot detect everything. It will detect correctly the Y-Z skew I think, however for the X-Z skew the autolevel will only correct the difference of skew between the bed and the X/Z rods. Of course the X/Z rods skew should be negligible unless the plate_x is faulty. Nevertheless I would like to measure it to be sure.

If there is Z skew, it shouldn't be too hard to come up with a correction matrix to adjust it! There are just several possible skew matrices - depending on the skew plane. We could probably get away with an XZ skew or YZ skew matrix in addition to the XY skew matrix if it comes to that. I should probably update the vector3x3 code to formally do matrix multiplication, but then I would be very tempted to convert it to a 4x4 affine transformation matrix. I have been avoiding merging my marlin codebase with the smartrap github. I'm slowly learning git since I have worked primarily with subverion in the past. Hmm.. Maybe I should ask smartfriendz nicely for push request permission on the marlin autolevel folder...

Quote

cristian

It is very important indeed to have this software calibration to allow a correct evolution of the "Smartrap species": otherwise, after every generation of Smartraps the precision of the printed parts would quickly degrade and the new born Smartraps would not be able to procreate

Yes. That was why I went in with the skew correction. I printed upgraded plastic for my smartrap, then went to upgrade again only to find that my original upgraded parts introduced a skew into everything

. There was no way to go backwards to a rigid system since I had cracked a couple of the original parts. I also had to go back from rack-and-pinion to string because of the warping. I had too much GT2 belt slippage over the tension bearing to go back to the belt drive. But, I discovered that GT2 pulleys work well enough with string. The string kept slipping off of my bare, short motor shafts.

. There was no way to go backwards to a rigid system since I had cracked a couple of the original parts. I also had to go back from rack-and-pinion to string because of the warping. I had too much GT2 belt slippage over the tension bearing to go back to the belt drive. But, I discovered that GT2 pulleys work well enough with string. The string kept slipping off of my bare, short motor shafts. My smartrap has been busy printing test pieces for some other ideas, but eventually I will switch back to de-skewed 0.4.9 parts and a reprinted rack-and-pinion.

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 10:09PM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

My z stepper/threaded rod connector had broke, so I tried the fish aquarium air hose mod that someone suggested. It worked great, but also had the benefit of cleaning up the z wobble.

The wobble of the threaded rod doesn't matter a hoot.

If the top end of the threaded rod is left to wobble it will reduce or even eliminate the Z wobble at the print because the rod is able to move instead of transferring the movement to the printhead.

I know it looks bad if the Z thread is wobbling, but actually it is a good thing.

If you can straighten the rod and remove the wobble that way it is better, but leave the top end of the threaded rod free to wobble if it must.

Biggest mistake of all is to add a bearing at the top of the Z thread, all that does is transfer all the load from any wobble to the printhead via the X axis

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 10:13PM |

Registered: 11 years ago Posts: 791 |

Quote

Lukashuk

And what if in the bed center depth is 1 mm? The detail top too will be with a hole? Or gradual alignment? Or back? ! ! ! NO! ! ! the hole will be! ! ! It is better to level a bed hands of 1 times in 1 month.

forgive for my English

If you can manually level the bed as best you can do it will remove a lot of the additional movement made from the auto bed leveling adjustment. This will reduce wear and tear on the machine and also reduce additional actions by the machine which is what we all should be aiming for.

Auto bed leveling was originally designed to remove the hand leveling operation which is a bit of a pain, but now maybe it is good to do it at least once when doing the initial build to make the machine as accurate as possible.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 10:20PM |

Registered: 11 years ago Posts: 791 |

Quote

Lukashuk

And what if in the bed center depth is 1 mm? The detail top too will be with a hole? Or gradual alignment? Or back? ! ! ! NO! ! ! the hole will be! ! ! It is better to level a bed hands of 1 times in 1 month.

forgive for my English

If I understand what you are meaning, that the centre (Australian spelling) of the bed has a hollow that is 1mm lower than the outside edges, then yes you will start with a low point in the middle that would make it very hard to do a print at all. The print may not attach to the bed properly in that case. If however the first layer does attach, the following layers would soon level out and after maybe three layers the print would now continue as normal. The bottom of the pint however would have a bulge that would be very slight, depending on the size of the print base.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 15, 2014 11:22PM |

Registered: 10 years ago Posts: 349 |

|

Re: How precise can your Smartrap print? - Alignment issues July 17, 2014 06:40AM |

Registered: 9 years ago Posts: 344 |

Quote

cristian

It will detect correctly the Y-Z skew I think

Actually this is false. If the plate is perfectly parallel to the Y rods, the auto-leveling procedure will not detect any skew, even if there might be some.

Quote

CellJeffe

If there is Z skew, it shouldn't be too hard to come up with a correction matrix to adjust it! There are just several possible skew matrices - depending on the skew plane. We could probably get away with an XZ skew or YZ skew matrix in addition to the XY skew matrix if it comes to that. I should probably update the vector3x3 code to formally do matrix multiplication, but then I would be very tempted to convert it to a 4x4 affine transformation matrix.

Yes I think we will need some general approach which can handle any skew on XY, ZY and ZX. The affine transform may be even too general, unless one wants to put there all the transformations including the auto-leveling and length adjustments, which in the end may even be a very good idea, much cleaner than it is now...

Are you going to add it to smartrap marlin firmware, CellJeffe? To tell the truth I do not undestand why the authors did not put already something like that in the original marlin.

|

Re: How precise can your Smartrap print? - Alignment issues July 17, 2014 07:49AM |

Registered: 10 years ago Posts: 992 |

I would like to integrate it in smartfriendz marlin . I would like to implement the M556 gcode like reprappro did with the omerod and like it is written in reprap.org ( [reprappro.com]) .

I can't tell why it's not in marlin, I've asked there on github but people just laughed at me ?!?! . I've been said that " A hardware problem shouldn't be recovered by software .. you must do a better design ! period. Your smartrap is not that smart "

"

Then i asked why all the reprap developers where running after auto level, which IS a software recover from bad hardware design ? ..no answer .

.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I can't tell why it's not in marlin, I've asked there on github but people just laughed at me ?!?! . I've been said that " A hardware problem shouldn't be recovered by software .. you must do a better design ! period. Your smartrap is not that smart

"

" Then i asked why all the reprap developers where running after auto level, which IS a software recover from bad hardware design ? ..no answer

.

.the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: How precise can your Smartrap print? - Alignment issues July 17, 2014 08:32AM |

Registered: 11 years ago Posts: 791 |

Quote

smartfriendz

Hi Christian,

Thank you for those feedback. I can only agree with all that

About the Z , I think that making a triangle would be the best too, with maybe two threaded rods going on the back , behind the steppers and attached on the top. That would make a solid triangle reducing the flexibility of those two smooth rods. It is that or using M12 smooth rods like in the ptrintrbot simple. I would choose triangle structure personally. i started a design about that . i will maybe put it here to think about

About the wobble, with the last system , i had very good result ? The support need to be maybe adjusted under the Plate_x to be free ( with a little grease under ). My M5 threaded rod is shaking like crazy now , but all the wobble goes into this support, not on the plate.

About the GT2, it just works well and i choose to use them for assembly easiness for the commercial kits. Especially the aluminiums pinions . Maybe it could change in the future . I had indeed very good result with fishing line, but it needs to be very straight , and we need to fin the good one. Too small an it brakes..too big and it's not so accurate anymore.

I love the rack&pinions too, i have one machine in production with it and it works like a charm. I add some vaseline on it and it's very smooth. The problem here is to adjust very precise because if too large, you will have backslash , and too tight, it will make waves on the printed parts. I would easy go back to r&p with a better design, more adjustable. And maybe without the long threaded rods inside. I think it's possible to have just racks printed and attached to both ends.

For the Y, we are maybe going to switch to aluminium plate because of a new auto level system using proximity sensors inductive ( so , metal needed). In that case, we could rework the Y ends and racks so we can fix it directly on the aluminium plate.. maybe.. it's just ideas

I would love to have an all printed structure one day . Not because it's better than other solutions, but because it's just sooo reproductive without human intervention ( click : print ! ) and because it's the only way i know to have community interactive design ( everyone model and test on its own printer in almost real time ). Canot be practically done with other technologies actually.

But let's work on the Z reinforcement for now ? I'm working on it in spare time lately ( with the auto level too, as it's very important to have one without touching the bed..with the Smartrap's design).

Still working on this model, not had time to wire it up yet and test.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 17, 2014 08:46AM |

Registered: 9 years ago Posts: 344 |

Quote

smartfriendz

I can't tell why it's not in marlin, I've asked there on github but people just laughed at me ?!?! . I've been said that " A hardware problem shouldn't be recovered by software .. you must do a better design ! period. Your smartrap is not that smart"

Then i asked why all the reprap developers where running after auto level, which IS a software recover from bad hardware design ? ..no answer.

Indeed such an answer is totally illogical and contradictory, as you pointed out. It is only justified by some laziness or narrow-mindedness. There is no reason why software should not recover something, as long as it is an optional procedure that one may or may not apply. Moreover, nowhere is written that all the printers must have orthogonal axes by design...

Quote

regpye

Still working on this model, not had time to wire it up yet and test.

Looking forward to watching it moving!

Edited 1 time(s). Last edit at 07/17/2014 08:48AM by cristian.

|

Re: How precise can your Smartrap print? - Alignment issues July 17, 2014 08:50AM |

Registered: 10 years ago Posts: 992 |

ha yes .. why didn't you wire it up ? i know you do nothing all day long

seriously, i'm very curious about it .. but i'm sure it will run very good. It's nice design , no doubt

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

seriously, i'm very curious about it .. but i'm sure it will run very good. It's nice design , no doubt

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: How precise can your Smartrap print? - Alignment issues July 18, 2014 04:32AM |

Registered: 10 years ago Posts: 170 |

I had no problem with printer configuration or aligment. It prints very well at good speeds and belt arrangement doesn't create any problem. You can check the printer that I have and quality of prints here: http://forums.reprap.org/read.php?344,383743. I dropped auto bed leveling since it wasn't perfect for me. I added manual bed leveling and Z homing with hot end tip probing and I had very reliable prints since then.

Edited 1 time(s). Last edit at 07/18/2014 04:41AM by ldanut.

[www.build3dparts.com]

[www.3dhubs.com]

Edited 1 time(s). Last edit at 07/18/2014 04:41AM by ldanut.

[www.build3dparts.com]

[www.3dhubs.com]

|

Re: How precise can your Smartrap print? - Alignment issues July 18, 2014 09:19AM |

Registered: 10 years ago Posts: 349 |

I do understand why some people would bounce it on 'bad hardware design' though i also see the advantages of having clever software solutions.

And since autolevel already exists and the addition of this skew correction looks like it is only a small extra addition i don't see why it shouldn't be included.

Actually it would be great if this somehow could be included IN the autolevel procedure.

Pitty that the guys at marlins github don't see the advantage in this yet. I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

And since autolevel already exists and the addition of this skew correction looks like it is only a small extra addition i don't see why it shouldn't be included.

Actually it would be great if this somehow could be included IN the autolevel procedure.

Pitty that the guys at marlins github don't see the advantage in this yet. I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

|

Re: How precise can your Smartrap print? - Alignment issues July 18, 2014 05:02PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

I do understand why some people would bounce it on 'bad hardware design' though i also see the advantages of having clever software solutions.

And since autolevel already exists and the addition of this skew correction looks like it is only a small extra addition i don't see why it shouldn't be included.

Actually it would be great if this somehow could be included IN the autolevel procedure.

Pitty that the guys at marlins github don't see the advantage in this yet. I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

I agree, we can't have enough options available, more the better.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 19, 2014 03:23AM |

Registered: 9 years ago Posts: 344 |

Quote

BackEMF

I do understand why some people would bounce it on 'bad hardware design'

The "bad hardware design" (I would rather say that Smartrap is young and on its way to evolve) is true, still I do not see how it justifies that "hardware problems shouldn't be recovered by software".

Actually I would like to have both a better hardware design where skewness (and other minor problems) can be at 95% (or up to "eye" and "hand" precision) removed by manual tuning, and the remaining part corrected by software if one needs super-high precision.

Quote

BackEMF

I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

That woudl be great, but even after thinking about it for some time I cannot find ways to detect automatically skew. It may probably be detected without printing a calibration object by using some fanciful measurement method, but all the ways I can think about require at some point a measurement done by a human.

And let's not forget that the "simple" autoleveling procedure is not so neat for the smartrap, yet.

|

Re: How precise can your Smartrap print? - Alignment issues July 19, 2014 06:10PM |

Registered: 10 years ago Posts: 37 |

Quote

cristian

That woudl be great, but even after thinking about it for some time I cannot find ways to detect automatically skew. It may probably be detected without printing a calibration object by using some fanciful measurement method, but all the ways I can think about require at some point a measurement done by a human.Quote

BackEMF

I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

And let's not forget that the "simple" autoleveling procedure is not so neat for the smartrap, yet.

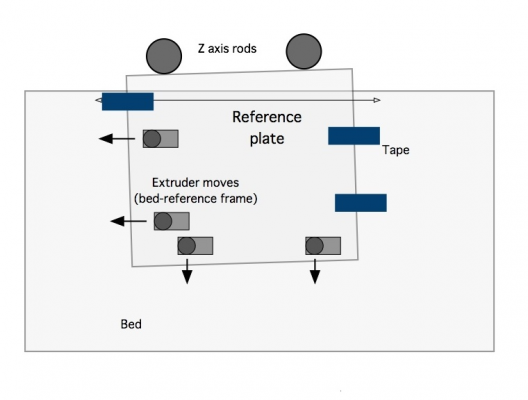

Hmm... How about semi-automated method using a reference object. Put a short plate with a good 90 degree angle on top of your existing bed plate, slide it up against the Z axis rods and tape it down. Lower the extruder until the Z endstop engages. Then slide off in one direction and make a note of where the extruder falls off the edge and the endstop disengages. Do this at four points to get the relative edges of the glass test plate. That gives you two vectors that are at right angles to each other. The difference between that and where the extruder thinks it slid off can be used to calculate the existing skew.

I would think about doing it, but I'm going to be away from my printer for a couple of weeks. And, I find the marlin code to be a bit... cobbled together.

|

Re: How precise can your Smartrap print? - Alignment issues July 19, 2014 06:40PM |

Registered: 11 years ago Posts: 791 |

Quote

CellJeffe

Quote

cristian

That woudl be great, but even after thinking about it for some time I cannot find ways to detect automatically skew. It may probably be detected without printing a calibration object by using some fanciful measurement method, but all the ways I can think about require at some point a measurement done by a human.Quote

BackEMF

I think it would be great to be able to slap together 3 axis and hit the print button, let the machine figure out the wonkeyness and spit out a perfect print.

And let's not forget that the "simple" autoleveling procedure is not so neat for the smartrap, yet.

Hmm... How about semi-automated method using a reference object. Put a short plate with a good 90 degree angle on top of your existing bed plate, slide it up against the Z axis rods and tape it down. Lower the extruder until the Z endstop engages. Then slide off in one direction and make a note of where the extruder falls off the edge and the endstop disengages. Do this at four points to get the relative edges of the glass test plate. That gives you two vectors that are at right angles to each other. The difference between that and where the extruder thinks it slid off can be used to calculate the existing skew.

I would think about doing it, but I'm going to be away from my printer for a couple of weeks. And, I find the marlin code to be a bit... cobbled together.

[attachment 36882 AutoDeskew.jpg]

If the Z axis and the Y axis are separated, like my last version, then it wouldn't be too hard to make the Z axis adjustable with reference to the Y axis.(or make the Y axis adjustable to the Z axis, same difference)

It would be possible to have a mounting bolt that the Z axis can swing on and then using a good square, line up the Y axis and put in the second or third (or more if needed) mounting bolts for the Z axis.

That way you will have the machine mechanically square in those two axis. I actually had to do that when I assembled my machine. I mounted the Z axis first and then eye-balled the Y axis to put in the first mounting screw, and then used a square to line up the Z rods to the Y rods and put in the other three screws. The separated Y axis makes this quite easy to do.

Maybe something could also be worked out for setting the Y and X axis in a similar way? I will have to think about that one.

The closer we can get the machines squared up, the easier it will be for auto bed leveling too, and better prints as well.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 20, 2014 10:16PM |

Registered: 10 years ago Posts: 349 |

@ CellJeffe

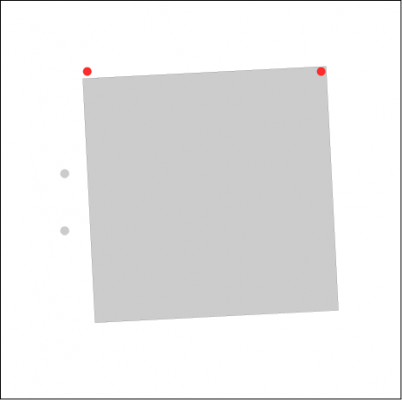

Serge was working on the inductive sensor., Now i'm not sure if my next idea will work but maybe if the inductive sensor is moved to the edge of the buildplate that it is possible to sense if the edge is "more" or "less" under the sensor. Or better detect all 4 edges off the plate.

grey square = Alu plate

grey dots = Z axis

red dots = inductive sensor (attached to X axis)

After auto bedlevel we know where to expect induction, so when then moving over the edge then there will be no induction so thats the end of the bed. Since the alu plate is square then we know how skewed it is.

The only essential thing is then that the alu plate has to be 100 linear to the guiding rods, but that shouldn't be an issue.

Serge was working on the inductive sensor., Now i'm not sure if my next idea will work but maybe if the inductive sensor is moved to the edge of the buildplate that it is possible to sense if the edge is "more" or "less" under the sensor. Or better detect all 4 edges off the plate.

grey square = Alu plate

grey dots = Z axis

red dots = inductive sensor (attached to X axis)

After auto bedlevel we know where to expect induction, so when then moving over the edge then there will be no induction so thats the end of the bed. Since the alu plate is square then we know how skewed it is.

The only essential thing is then that the alu plate has to be 100 linear to the guiding rods, but that shouldn't be an issue.

|

Re: How precise can your Smartrap print? - Alignment issues July 20, 2014 10:29PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

@ CellJeffe

Serge was working on the inductive sensor., Now i'm not sure if my next idea will work but maybe if the inductive sensor is moved to the edge of the buildplate that it is possible to sense if the edge is "more" or "less" under the sensor. Or better detect all 4 edges off the plate.

[attachment 36929 sensor.png]

grey square = Alu plate

grey dots = Z axis

red dots = inductive sensor (attached to X axis)

After auto bedlevel we know where to expect induction, so when then moving over the edge then there will be no induction so thats the end of the bed. Since the alu plate is square then we know how skewed it is.

The only essential thing is then that the alu plate has to be 100 linear to the guiding rods, but that shouldn't be an issue.

The issue described can be easily fixed by using my separate Y axis and mechanically set it up square. The problem that needs to be overcome that I haven't worked out yet is to take your example and turn it around 90 degrees so that it shows the Z axis in relation to the X axis, at is the Z axis is vertical and the X axis running square to the Z axis. Y can easily be set, but the X is a little harder. Maybe this is where the software needs to come in?

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: How precise can your Smartrap print? - Alignment issues July 21, 2014 09:33PM |

Registered: 10 years ago Posts: 349 |

Yes i know, though the idea was to be able to make the machine figure it out. (and include it in auto bedlevel)

I prefer to build a machine that is perfect by default. Though even perfect machines can get wonkey when dragging them around. (in the back of a car, backpack etc.)

And i think it would be a great if you can just slap the thing on a table, hit print and just get a good print. Building a perfect printer is expensive, though this way even a low cost machine thats strapped together can just print.

Wait, i'm reading your reply several times and i'm feeling like i'm not 100% on the same page. (could be the heat...)

What i'm trying to say is: If the inductive sensor is next to the hotend then you can use it to detect the height as in auto bed level, but you can also scan over the alu bed and detect where the alu bed ends then you know edges of the alu plate and thus also the mis-alignment.

Now there are a few obstacles... for instance screws, iron has a different inductance then aluminium, so that can cause errors in the sensing values.

I prefer to build a machine that is perfect by default. Though even perfect machines can get wonkey when dragging them around. (in the back of a car, backpack etc.)

And i think it would be a great if you can just slap the thing on a table, hit print and just get a good print. Building a perfect printer is expensive, though this way even a low cost machine thats strapped together can just print.

Wait, i'm reading your reply several times and i'm feeling like i'm not 100% on the same page. (could be the heat...)

What i'm trying to say is: If the inductive sensor is next to the hotend then you can use it to detect the height as in auto bed level, but you can also scan over the alu bed and detect where the alu bed ends then you know edges of the alu plate and thus also the mis-alignment.

Now there are a few obstacles... for instance screws, iron has a different inductance then aluminium, so that can cause errors in the sensing values.

Sorry, only registered users may post in this forum.