Problems with the leveling

Posted by SweetPeas

|

Problems with the leveling August 13, 2014 03:46AM |

Registered: 9 years ago Posts: 9 |

Hi guys,

I built my SmartRap a few months back and have been really pleased with it so far. Got some help from my friend Cliff to get everything up and running and it has been working fine until I started to try and print larger objects. The problem I have is that close to the frame the print gets smeared onto the glass and on the far end of the glass it barely sticks to the glass.

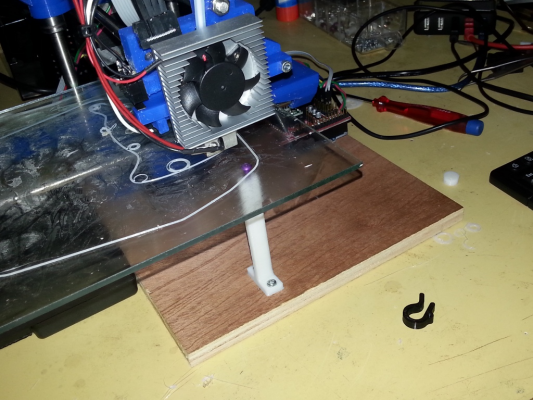

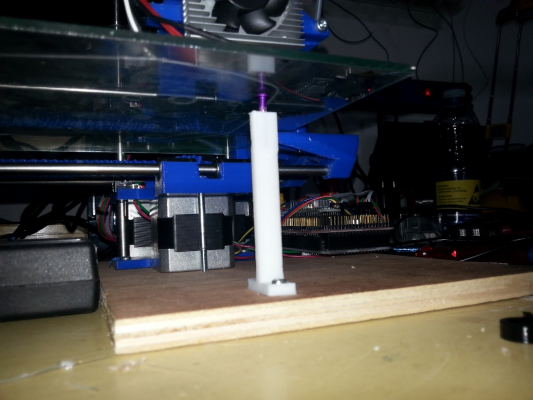

I noticed early that the glass was flexing when performing autoleveling and printed a support for the glass. I use a ballhead hex screw to be able to adjust the height easy as can be seen in the pictures.

I have executed the autoleveling according to Serge's instruction several time and although I think it works properly it does not make the printer print evenly.

Any tips anyone ?

/Pontus

I built my SmartRap a few months back and have been really pleased with it so far. Got some help from my friend Cliff to get everything up and running and it has been working fine until I started to try and print larger objects. The problem I have is that close to the frame the print gets smeared onto the glass and on the far end of the glass it barely sticks to the glass.

I noticed early that the glass was flexing when performing autoleveling and printed a support for the glass. I use a ballhead hex screw to be able to adjust the height easy as can be seen in the pictures.

I have executed the autoleveling according to Serge's instruction several time and although I think it works properly it does not make the printer print evenly.

Any tips anyone ?

/Pontus

|

Re: Problems with the leveling August 13, 2014 07:43AM |

Registered: 9 years ago Posts: 156 |

|

Re: Problems with the leveling August 14, 2014 06:50AM |

Registered: 9 years ago Posts: 9 |

|

Re: Problems with the leveling August 19, 2014 07:11AM |

Registered: 9 years ago Posts: 9 |

|

Re: Problems with the leveling August 24, 2014 03:10PM |

Registered: 10 years ago Posts: 125 |

|

Re: Problems with the leveling August 24, 2014 05:18PM |

Registered: 9 years ago Posts: 156 |

|

Re: Problems with the leveling September 04, 2014 04:20AM |

Registered: 9 years ago Posts: 9 |

|

Re: Problems with the leveling September 04, 2014 06:03AM |

Registered: 10 years ago Posts: 992 |

It is not as easy as it should be for now.

BUT... I just finished testing with inductive sensor and small aluminium foil under the glass ..and it works perfectly. I will integrate this solution right away ( even on the actual shipping kits). I found this really good and we don't need Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_X anymore because we never touch the bed anymore .

the sensor is : [www.aliexpress.com] ans it is used in place of the Z endstop.

However I'm interested by your solution with screws sweet peas ? I've never found a good one and i find good to have this option with the Smartrap.

thank you

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

BUT... I just finished testing with inductive sensor and small aluminium foil under the glass ..and it works perfectly. I will integrate this solution right away ( even on the actual shipping kits). I found this really good and we don't need Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_X anymore because we never touch the bed anymore .

the sensor is : [www.aliexpress.com] ans it is used in place of the Z endstop.

However I'm interested by your solution with screws sweet peas ? I've never found a good one and i find good to have this option with the Smartrap.

thank you

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Problems with the leveling September 06, 2014 10:51PM |

Registered: 11 years ago Posts: 791 |

Using this method is so easy and very accurate too.

Just one variable to change in the firmware and then the rest is done automatically.

1. Home the Z.

2. Lower nozzle to bed position. Use paper to get the correct bed space.

3. Send M114 from Pronterface to read the position.

4. The reading shown on the screen will be the exact value to put in the firmware for the offset.

5. Program the board as usual.

Takes just a couple of minutes beginning to end and can be checked at anytime and changed if anything moves out of kilter So Easy.

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

#define min_software_endstops false // If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Just one variable to change in the firmware and then the rest is done automatically.

1. Home the Z.

2. Lower nozzle to bed position. Use paper to get the correct bed space.

3. Send M114 from Pronterface to read the position.

4. The reading shown on the screen will be the exact value to put in the firmware for the offset.

5. Program the board as usual.

Takes just a couple of minutes beginning to end and can be checked at anytime and changed if anything moves out of kilter So Easy.

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

#define min_software_endstops false // If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Problems with the leveling September 13, 2014 09:14AM |

Registered: 10 years ago Posts: 125 |

Serge, you stated that

"I just finished testing with inductive sensor and small aluminium foil under the glass ..and it works perfectly."

If it sees the foil under the glass, will blue tape, PVA glue or kapton tape confuse the proximity sensor?

I mean if the probe probes the bed in 3 places, then those 3 points would have to be absolutely clear from tape, plastic or PVA right?

Another thought, maybe the machine could put down the first layer at a layer as measured by the sensor in real time. Without probing at all. So the machine constantly measures the gap and compensates for the height while working.

Regards

Mike

Edited 1 time(s). Last edit at 09/13/2014 09:36AM by mikefiatx19.

"I just finished testing with inductive sensor and small aluminium foil under the glass ..and it works perfectly."

If it sees the foil under the glass, will blue tape, PVA glue or kapton tape confuse the proximity sensor?

I mean if the probe probes the bed in 3 places, then those 3 points would have to be absolutely clear from tape, plastic or PVA right?

Another thought, maybe the machine could put down the first layer at a layer as measured by the sensor in real time. Without probing at all. So the machine constantly measures the gap and compensates for the height while working.

Regards

Mike

Edited 1 time(s). Last edit at 09/13/2014 09:36AM by mikefiatx19.

|

Re: Problems with the leveling September 13, 2014 03:32PM |

Registered: 10 years ago Posts: 992 |

that would be great indeed. You need a full metal bed and the right height of the sensor so you don't need any offset ( when it triggers, the head would be at the right height) . That's possible as the sensor has a screw to adjust height.

maybe i will try that ? . Can be nice with not so plane metal beds

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

maybe i will try that ? . Can be nice with not so plane metal beds

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Problems with the leveling September 13, 2014 04:15PM |

Registered: 10 years ago Posts: 116 |

Hello all, Im back on the forum again

Metal beds seems to be a nice tought. If it would work, then why not to try use it as the heated bed in the same time. Only the mounting should be somehow heat resistant, and the bed shrinking from the changed temp. can be a bit problematic.

Annyway, Mikefiatx19 idea with measuring the gap in real time while printing sounds grate!

Edited 2 time(s). Last edit at 09/13/2014 04:16PM by verteez.

Metal beds seems to be a nice tought. If it would work, then why not to try use it as the heated bed in the same time. Only the mounting should be somehow heat resistant, and the bed shrinking from the changed temp. can be a bit problematic.

Annyway, Mikefiatx19 idea with measuring the gap in real time while printing sounds grate!

Edited 2 time(s). Last edit at 09/13/2014 04:16PM by verteez.

|

Re: Problems with the leveling September 15, 2014 02:52AM |

Registered: 10 years ago Posts: 992 |

Thank you verteeez ,

I'm testing aluminium heated bed for production , as people say that PLA can stick well on an alu bed at 60 and stop sticking at lower temp. I've never tried it before .

About the sensor mike, I use a 18mm ith 8mm detection, so it works with anything on the bed, tape, glue, whatever, it will work the same.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I'm testing aluminium heated bed for production , as people say that PLA can stick well on an alu bed at 60 and stop sticking at lower temp. I've never tried it before .

About the sensor mike, I use a 18mm ith 8mm detection, so it works with anything on the bed, tape, glue, whatever, it will work the same.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Problems with the leveling September 15, 2014 05:34PM |

Registered: 9 years ago Posts: 20 |

Hi Guys,

just wanted to pass a comment on Mr Reg Pye's last post in this chain....because I too have had a sore head trying to understand how to calculate off-set, possibly due to zero experience at printing.

Many thanks to the detailed response by Reg this is clear for a single point setting on the bed – but what I am having a tough time trying to understand is how to take into consideration if the glass is at an angle or not perfectly flat (unlikely). .

So I was looking at the GCodes and I would have thought we need to use a G32 with M557 using a 4 point reference points to ensure against any twists.

Am I over thinking all of this?

just wanted to pass a comment on Mr Reg Pye's last post in this chain....because I too have had a sore head trying to understand how to calculate off-set, possibly due to zero experience at printing.

Many thanks to the detailed response by Reg this is clear for a single point setting on the bed – but what I am having a tough time trying to understand is how to take into consideration if the glass is at an angle or not perfectly flat (unlikely). .

So I was looking at the GCodes and I would have thought we need to use a G32 with M557 using a 4 point reference points to ensure against any twists.

Am I over thinking all of this?

|

Re: Problems with the leveling September 15, 2014 07:45PM |

Registered: 10 years ago Posts: 125 |

The G29 in the slicer code takes care of any angle in the plane of the glass. The 3 point level reads the height of the bed at 3 points and records the angle to use as a reference for the gcode commands. If you watch a print after the 3 point level has happened you should see the Z screw constantly turning to compensate for the uneven bed.

The only time I can think of when this would not work correctly is if the glass was somehow bent and like you said i think thats unlikely to happen.

Edited 1 time(s). Last edit at 09/15/2014 07:47PM by mikefiatx19.

The only time I can think of when this would not work correctly is if the glass was somehow bent and like you said i think thats unlikely to happen.

Edited 1 time(s). Last edit at 09/15/2014 07:47PM by mikefiatx19.

|

Re: Problems with the leveling September 15, 2014 10:33PM |

Registered: 11 years ago Posts: 791 |

Quote

mikefiatx19

The G29 in the slicer code takes care of any angle in the plane of the glass. The 3 point level reads the height of the bed at 3 points and records the angle to use as a reference for the gcode commands. If you watch a print after the 3 point level has happened you should see the Z screw constantly turning to compensate for the uneven bed.

The only time I can think of when this would not work correctly is if the glass was somehow bent and like you said i think thats unlikely to happen.

One thing I will pass on to you guys about this particular subject.

Glass is slightly flexible and will bend.

If the bed that the glass sits on is bent and you use four spring clamps or paper clips, it will bend the glass to the shape of the bed underneath.

In this case it is best to use only two clamps so that the glass plate is held in the centre (Australian spelling) of the front and back edges only. That way the glass will not bend and will stay flat.

If using wooden rails as some of us are doing, the four glass clips can be used because there is nothing in the centre to make the glass bend.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Problems with the leveling September 16, 2014 03:00AM |

Registered: 9 years ago Posts: 20 |

|

Re: Problems with the leveling October 11, 2014 10:55AM |

Registered: 9 years ago Posts: 17 |

|

Re: Problems with the leveling October 11, 2014 06:10PM |

Registered: 10 years ago Posts: 125 |

I don't really think I get that much flexing during the probes. How far away from the home position are you probing?

I suppose the further from X0 you go to take the probe point the more flex you will have in the X axis. Try probing closer to the start position. So, if you are currently probing X180, Y0 try changing it to X100, Y0 and see if it still flexes.

I suppose the further from X0 you go to take the probe point the more flex you will have in the X axis. Try probing closer to the start position. So, if you are currently probing X180, Y0 try changing it to X100, Y0 and see if it still flexes.

|

Re: Problems with the leveling October 12, 2014 02:24AM |

Registered: 10 years ago Posts: 992 |

hi shootquinn,

for the flex, i've setup a hack in marlin on our github. It's in configuration.h at line 412 :

#define Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_X 0

you can enter a value here , like 0.2 to ..whatever you feel is good

this will add an offset to the last Z probe to recover from the extra Z coming from the flexing . It gave very good result until now ( logically ) .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

for the flex, i've setup a hack in marlin on our github. It's in configuration.h at line 412 :

#define Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_X 0

you can enter a value here , like 0.2 to ..whatever you feel is good

this will add an offset to the last Z probe to recover from the extra Z coming from the flexing . It gave very good result until now ( logically ) .

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Problems with the leveling October 19, 2014 06:07AM |

Registered: 9 years ago Posts: 9 |

I did the same thing but for the Y axis since my printer was crooked somewhere and now it prints like a dream.....

#define Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_Y 0.4 // smartrap: This is my own addition to tweak my slightly crooked printer.

and added the following to the set_bed_level_equation_3pts function

// My own mod:

z_at_pt_2 += Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_Y;

#define Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_Y 0.4 // smartrap: This is my own addition to tweak my slightly crooked printer.

and added the following to the set_bed_level_equation_3pts function

// My own mod:

z_at_pt_2 += Z_PROBE_OFFSET_FROM_EXTRUDER_DELTA_Y;

|

Re: Problems with the leveling October 19, 2014 08:38AM |

Registered: 10 years ago Posts: 992 |

haha. cool

the funny thing is : i did the same at home but didn't put it online .. i had one bad printer i couldn't manage to know why it wasn't straight on Y .

and it works, right ?

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

the funny thing is : i did the same at home but didn't put it online .. i had one bad printer i couldn't manage to know why it wasn't straight on Y .

and it works, right ?

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

Sorry, only registered users may post in this forum.