Smartrap can print flexible filaments!

Posted by cristian

Smartrap can print flexible filaments! August 31, 2014 05:07PM |

Registered: 9 years ago Posts: 344 |

Hi smartrappers,

this is probably old news, but in any case let me share my enthusiasm after discovering that it is possible to print with flexible filaments on a smartrap.

So far I tested soft PLA and PVA, and it works great (although I disabled retraction for now).

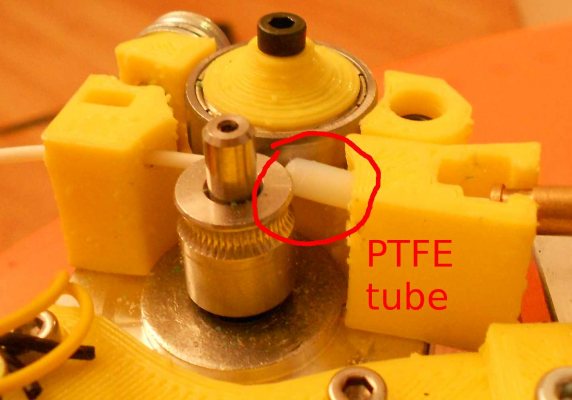

However the cold end of the standard extruder needed a little hack to work properly, because the hobbed bolt is too far from the hole in the plastic support (see picture attached), which caused the filaments to bend before entering the bowden. Maybe a small detail to take into account for the future versions!

this is probably old news, but in any case let me share my enthusiasm after discovering that it is possible to print with flexible filaments on a smartrap.

So far I tested soft PLA and PVA, and it works great (although I disabled retraction for now).

However the cold end of the standard extruder needed a little hack to work properly, because the hobbed bolt is too far from the hole in the plastic support (see picture attached), which caused the filaments to bend before entering the bowden. Maybe a small detail to take into account for the future versions!

Re: Smartrap can print flexible filaments! September 01, 2014 10:34AM |

Registered: 9 years ago Posts: 7 |

Re: Smartrap can print flexible filaments! September 01, 2014 11:37AM |

Registered: 10 years ago Posts: 229 |

Quote

Basher

Is that idler bearing on a concentric hub so you can adjust tension?

Tension is adjustable - [www.thingiverse.com]

From FreeCAD To The Real World- Demo video using FreeCAD and featuring the Smartrap 3D Printer

Re: Smartrap can print flexible filaments! September 01, 2014 12:03PM |

Registered: 9 years ago Posts: 7 |

Re: Smartrap can print flexible filaments! October 10, 2014 10:14AM |

Registered: 9 years ago Posts: 15 |

Re: Smartrap can print flexible filaments! October 10, 2014 03:36PM |

Registered: 10 years ago Posts: 229 |

Quote

mrmillsy

Off-topic (sorry) but what purpose does the "washer" on top of the bearing serve for the build?

It keeps the bearing from "walking" up and off the axle. Not a good thing to have happen in the middle of a print.

Mark

From FreeCAD To The Real World- Demo video using FreeCAD and featuring the Smartrap 3D Printer

Re: Smartrap can print flexible filaments! October 10, 2014 08:52PM |

Registered: 9 years ago Posts: 15 |

Re: Smartrap can print flexible filaments! October 10, 2014 09:16PM |

Registered: 10 years ago Posts: 229 |

Quote

mrmillsy

Ahh I see, thank you, that makes sense. I take it it should be attached loosely then?

No, tighten it down. It holds the center hub and does not contact the outer hub.

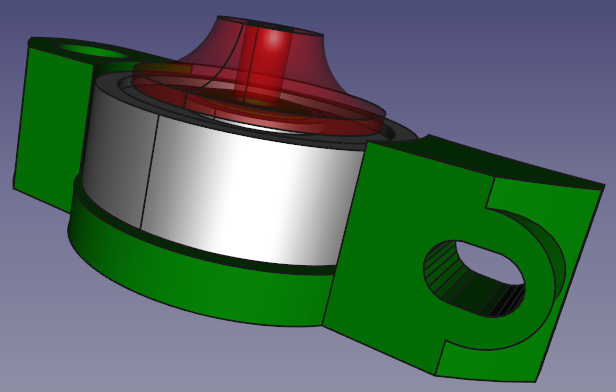

Here is a CAD assembly of the Idler, Bearing and Cap. Hope this helps.

Mark

From FreeCAD To The Real World- Demo video using FreeCAD and featuring the Smartrap 3D Printer

Re: Smartrap can print flexible filaments! March 05, 2015 08:01PM |

Registered: 9 years ago Posts: 344 |

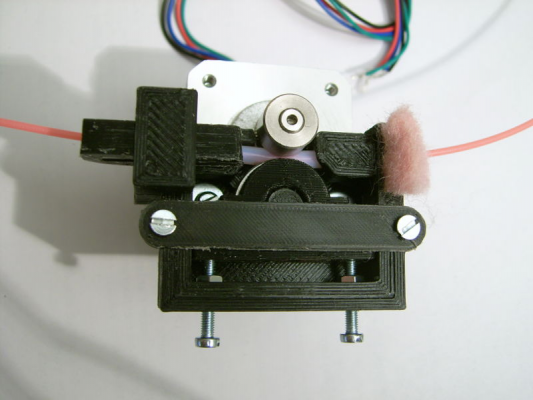

After several months and some weeks of testing, I can finally confirm that it is possible to print with soft filaments on a Smartrap (that is on any printer with a Bowden tube of about 40cm) at reasonable speeds.

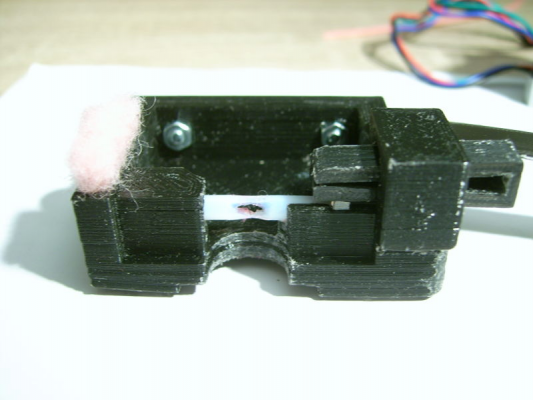

I designed another extruder from scratch, whose basic idea is to hold a PTFE liner that is finely cut around the point of contact of the hobbed and the bearing, so that the filament has no freedom of movement. Since I had some problems with the original Smartrap extruder (it broke easily if not well printed) I made this one rock solid, therefore quite big and somehow wasteful of filament. But, you know, it works for me, it may not work for you...

Here is how it looks like:

It has a slot where you can put some tissue (a pink fluffy piece of felt in the pictures) through which the filament passes, so that the dust around the filament is held back (and believe me, one of my ESUN spools came with quite some of it).

The Bowden tube is held down with a sort of horseshoe-shaped spring, very easy to remove.

With this extruder I can print with this soft filament at least at (0.25mm layer height) * (0.5mm layer width) * (30mm/s printing speed) with a 0.3mm nozzle diameter, which makes about 4mm3/s of filament flux. Surely not fast, but reasonable (and by the way, this was done with Reg's Genie hotend, I will also update the post about all its tests with exotic filaments). A 0.5mm nozzle diameter would likely increase the printing speed further.

If somebody is interested, I will post more detailed info on the extruder.

Edited 1 time(s). Last edit at 03/05/2015 08:34PM by cristian.

I designed another extruder from scratch, whose basic idea is to hold a PTFE liner that is finely cut around the point of contact of the hobbed and the bearing, so that the filament has no freedom of movement. Since I had some problems with the original Smartrap extruder (it broke easily if not well printed) I made this one rock solid, therefore quite big and somehow wasteful of filament. But, you know, it works for me, it may not work for you...

Here is how it looks like:

It has a slot where you can put some tissue (a pink fluffy piece of felt in the pictures) through which the filament passes, so that the dust around the filament is held back (and believe me, one of my ESUN spools came with quite some of it).

The Bowden tube is held down with a sort of horseshoe-shaped spring, very easy to remove.

With this extruder I can print with this soft filament at least at (0.25mm layer height) * (0.5mm layer width) * (30mm/s printing speed) with a 0.3mm nozzle diameter, which makes about 4mm3/s of filament flux. Surely not fast, but reasonable (and by the way, this was done with Reg's Genie hotend, I will also update the post about all its tests with exotic filaments). A 0.5mm nozzle diameter would likely increase the printing speed further.

If somebody is interested, I will post more detailed info on the extruder.

Edited 1 time(s). Last edit at 03/05/2015 08:34PM by cristian.

Re: Smartrap can print flexible filaments! March 05, 2015 08:51PM |

Registered: 9 years ago Posts: 178 |

Nice work, I made a similar mod on my wades to have the bowden all the way up at the hobbed bolt as well, works soo much better on all types of filaments. Just modified my brand new hotend(well the push fitting) to allow the bowden to extend into the metal body, there was about a 2-3mm air gap from the fitting to the smaller hole inside. I might just take it all the way and bore the heatsink to allow the ptfe to run all the way to the heat break just like the E3D's

Re: Smartrap can print flexible filaments! March 06, 2015 02:13PM |

Registered: 9 years ago Posts: 180 |

Re: Smartrap can print flexible filaments! June 28, 2015 11:59AM |

Registered: 9 years ago Posts: 58 |

Re: Smartrap can print flexible filaments! June 30, 2015 03:49PM |

Registered: 9 years ago Posts: 344 |

Quote

lyscanthrope

I really like the design of this extruder!

Would you share the files?

Sure. If you plan to use it I must also write you some tips. If you want the STL no problem, if you want openscad source, beware it is a total mess.

I will share the files asap.

Quote

lyscanthrope

I was wondering if the bearing is mandatory can't you just push the filament against the ptfe? (with a support for the ptfe)

I haven't tried, but I think that it would be less efficient and the filament would dig a groove in the ptfe quite quickly, given the quite high pressure.

Re: Smartrap can print flexible filaments! June 30, 2015 05:05PM |

Registered: 9 years ago Posts: 58 |

Thank you very much for your kind answer !

I will try to build one with something pushing on the PTFE tube (so no need of a roller bearing). I think there will be too much friction ...but well ...i'll check

I have already done a sketch on freecad... just have to print .... and dismantle my extruder xD

I will try to build one with something pushing on the PTFE tube (so no need of a roller bearing). I think there will be too much friction ...but well ...i'll check

I have already done a sketch on freecad... just have to print .... and dismantle my extruder xD

Re: Smartrap can print flexible filaments! July 16, 2015 06:58PM |

Registered: 9 years ago Posts: 344 |

I am very sorry for the delay, I wanted to do some final improvements to the model (not to its readability, though!) before releasing it, and the last days were busy...

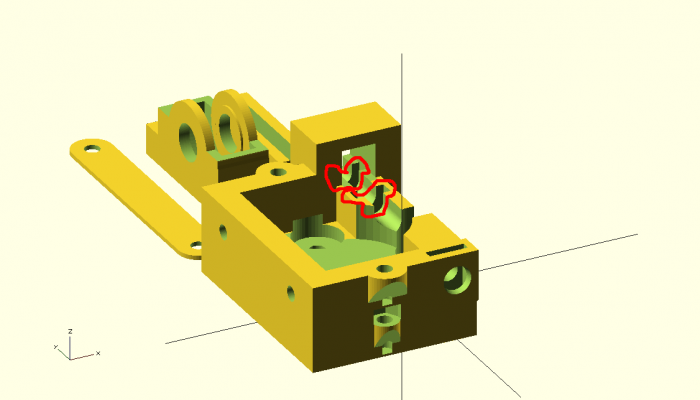

Anyway, the openscad model is finally attached.

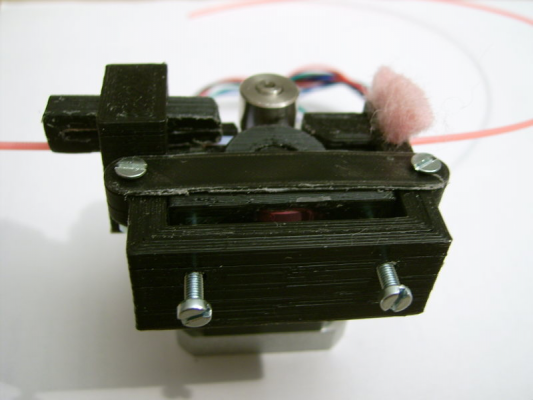

While you are of course free to modify it the way you prefer, the current model is thought to be used in a precise way. The PTFE liner that is used to guide the filament through the hobbed gear and the 608zz bearing is a short piece of tube of the length of few centimeters. It is kept in place at one end by a hole in the plastic that surrounds it completely, at the other end by a M4 nut. The Bowden tube is also kept in place by a M4 nut, reason why there are two grooves in the extruder, one for each M4 nut:

The Bowden and the short liner should be fixed so that their close ends are perfectly aligned and touch each other. The short liner should be finely cut at the center with a scalpel to create the grooves for the hobbed gear and the bearing without cutting the liner completely: I use a small ink tampon on the hobbed gear and on the bearing to mark the points where the liner needs to be sliced. With the scalpel you may also countersink the end where the filament is inserted to ease its insertion. You may also countersink the end of the Bowden if you want, although it should not be necessary. As you can see from the previous pictures, there is also a little hole for a sponge or piece of fabric to clean the filament before reaching the hotend (I find it very effective).

If you need to clean the main piece of the extruder once it is printed, you may use a 4mm drill for most of the liner guide, but for its very beginning where the filament is inserted you should use a 3.5mm drill. All the other holes are for 3M screws, so you may use a 3mm drill.

There are also some bridges that you will need to remove by hand.

Everything is parametric of course, although I think it will not be easy to spot the right parameters given that the code is really awfully written. You may need in particular to adapt the diameter for the hobbed gear. The current parameters are for this kind of hobbed gear, whose diameter should be 6mm.

Edit: I recently discovered that if you put one spring around one of the screws that push the bearing against the hobbed gear (or even one around each of them), extrusion may become smoother with some problematic filaments, such as woodfill.

Edited 1 time(s). Last edit at 07/16/2015 07:08PM by cristian.

Anyway, the openscad model is finally attached.

While you are of course free to modify it the way you prefer, the current model is thought to be used in a precise way. The PTFE liner that is used to guide the filament through the hobbed gear and the 608zz bearing is a short piece of tube of the length of few centimeters. It is kept in place at one end by a hole in the plastic that surrounds it completely, at the other end by a M4 nut. The Bowden tube is also kept in place by a M4 nut, reason why there are two grooves in the extruder, one for each M4 nut:

The Bowden and the short liner should be fixed so that their close ends are perfectly aligned and touch each other. The short liner should be finely cut at the center with a scalpel to create the grooves for the hobbed gear and the bearing without cutting the liner completely: I use a small ink tampon on the hobbed gear and on the bearing to mark the points where the liner needs to be sliced. With the scalpel you may also countersink the end where the filament is inserted to ease its insertion. You may also countersink the end of the Bowden if you want, although it should not be necessary. As you can see from the previous pictures, there is also a little hole for a sponge or piece of fabric to clean the filament before reaching the hotend (I find it very effective).

If you need to clean the main piece of the extruder once it is printed, you may use a 4mm drill for most of the liner guide, but for its very beginning where the filament is inserted you should use a 3.5mm drill. All the other holes are for 3M screws, so you may use a 3mm drill.

There are also some bridges that you will need to remove by hand.

Everything is parametric of course, although I think it will not be easy to spot the right parameters given that the code is really awfully written. You may need in particular to adapt the diameter for the hobbed gear. The current parameters are for this kind of hobbed gear, whose diameter should be 6mm.

Edit: I recently discovered that if you put one spring around one of the screws that push the bearing against the hobbed gear (or even one around each of them), extrusion may become smoother with some problematic filaments, such as woodfill.

Edited 1 time(s). Last edit at 07/16/2015 07:08PM by cristian.

Sorry, only registered users may post in this forum.