Smartcore build log and pre-build questions

Posted by smerrett79

|

Re: Smartcore build log and pre-build questions September 17, 2015 06:05PM |

Registered: 9 years ago Posts: 107 |

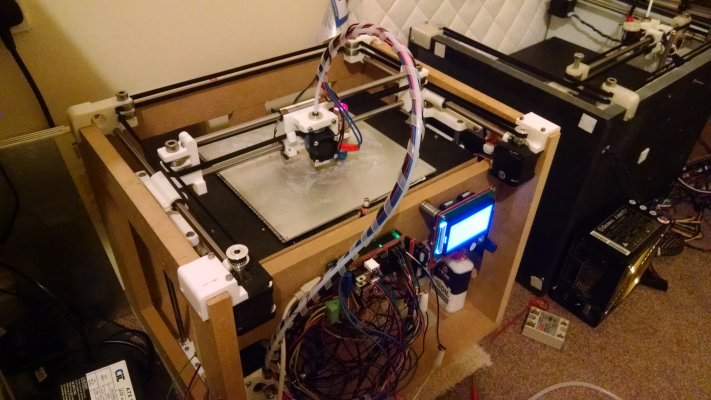

Here are some photos of my V1.2 build in progress

One side of the double z axis, mounted underneath the y rod:

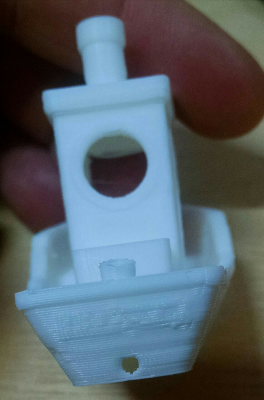

The other side Z screw - smooth rods not yet added so you can see the oilless bushings sitting very nicely:

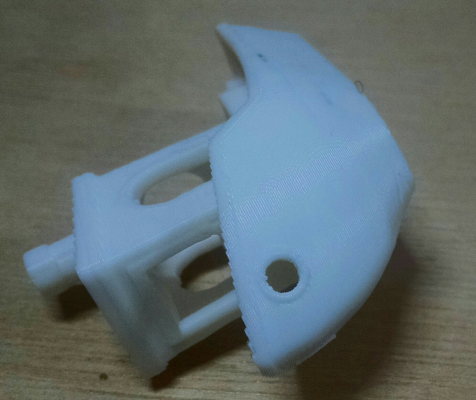

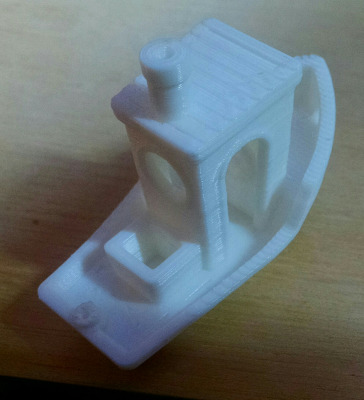

The printer head mount/block. I have noticed that when you change the LM bearing outer diameter (to 10.2mm in the case of these bushings) it also adjusts the total depth (as opposed to height) of the print head block so that the ends of the GT2 belt on each side are closer than the diameter of the 608 bearings. This leads to more belt tension and noticeable drag when the block slides to the ends of the x rods, as opposed to the central region. I'm going to see what needs changing in the code and reprint this part at some point.

Hope you can see these photos by clicking on the links, even if they won't render in this post. I'll try and do an update when more parts arrive. I added some of the electronics tonight and found stepper driver pins were connected electrically thanks to a rogue blob of solder. Turned the x and y stepper VRefs down to 0.3V on the A4988s and have noticed some noise improvement but am really pinning my hopes on the DRV8825s.

I also think I might get brave enough to put the (as yet unused) E3D Volcano on this one if it can do high speed without ripples (the improved rigidity of the print head over V1.01 is already apparent).

Happy to share code if anyone wants to make a bushing version.

One side of the double z axis, mounted underneath the y rod:

The other side Z screw - smooth rods not yet added so you can see the oilless bushings sitting very nicely:

The printer head mount/block. I have noticed that when you change the LM bearing outer diameter (to 10.2mm in the case of these bushings) it also adjusts the total depth (as opposed to height) of the print head block so that the ends of the GT2 belt on each side are closer than the diameter of the 608 bearings. This leads to more belt tension and noticeable drag when the block slides to the ends of the x rods, as opposed to the central region. I'm going to see what needs changing in the code and reprint this part at some point.

Hope you can see these photos by clicking on the links, even if they won't render in this post. I'll try and do an update when more parts arrive. I added some of the electronics tonight and found stepper driver pins were connected electrically thanks to a rogue blob of solder. Turned the x and y stepper VRefs down to 0.3V on the A4988s and have noticed some noise improvement but am really pinning my hopes on the DRV8825s.

I also think I might get brave enough to put the (as yet unused) E3D Volcano on this one if it can do high speed without ripples (the improved rigidity of the print head over V1.01 is already apparent).

Happy to share code if anyone wants to make a bushing version.

|

Re: Smartcore build log and pre-build questions September 17, 2015 09:23PM |

Registered: 8 years ago Posts: 13 |

|

Re: Smartcore build log and pre-build questions September 17, 2015 09:51PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartcore build log and pre-build questions September 18, 2015 03:23AM |

Registered: 9 years ago Posts: 107 |

@jjazzyj Thanks - they all look clean before you put the cables in! I have now started reading about people finding DRV8825s noisier, after originally hearing that they are quieter than A4988s. Oh well, they aren't expensive and it will be nice to find out for myself. The noise of the 3d printer is one thing for the person in the room operating it but my wife is a very light sleeper so printing at night is forbidden at our house - The vibrations have been travelling through walls. I've been following a guy who owned the same Q3D Two-Up as me originally who designed his own CoreXY: Eclips3D, and he was going for quietness . He's using the Azteeg X5/3 which uses the DRV8825s BUT also uses a more powerful processor so I don't know which has most impact on the noise. He's also using bushings BUT has an aluminium profile frame, so again hard to tell what the noise improvements are caused by. The final difference as far as I can see is that he's running Repetier Firmware.

@madmike8 Thanks!

@madmike8 Thanks!

|

Re: Smartcore build log and pre-build questions September 18, 2015 09:24AM |

Registered: 8 years ago Posts: 24 |

|

Re: Smartcore build log and pre-build questions September 18, 2015 10:02AM |

Registered: 9 years ago Posts: 95 |

|

Re: Smartcore build log and pre-build questions September 18, 2015 05:30PM |

Registered: 9 years ago Posts: 107 |

Update: Initial look (or listen) with DRV8825s

The DRV8825s arrived today and I installed them on my X and Y motors on the RAMPS 1.4. After adjusting the trim pot VRefs down to about 0.4V (from 1.6V - thanks for the warning!) and doubling the steps per mm in configuration.h (+uploading it) I tested the movement out. I haven't got the hotend wires connected yet so couldn't run a test print (as far as I know the dry run feature only works on Repetier FW). I used X and Y axis movement in manual commands and recorded sound levels with a free android app (I only care about relative values, so shouldn't be to big a compromise). I kept all three driver jumpers in place to set 1/32 microstepping.

I heard the high pitch whining that many have reported with the DRV8825s and reducing the VRef to 0.3-0.25V helped with this. Overall I found the slower manual command moves to be significantly noisier than the faster axis-homing moves and the DRV8825s to be noisier than the A4988s. I couldn't say for sure but would estimate from the sound power meter app readings that 3-5dB was the difference between the same move with the two different stepper driver types. I have to remember that the sound I am worried about is the lower frequency vibration that travels through the house, rather than the readings in the app which will probably have the frequencies weighted to the human ear's sensitivity.

I'm going to persevere with the DRV8825s as the reports by others on the internet, including the reprap wiki page at the "warning" link above, make me think that they have potential that my very basic test can't realise. Bear in mind that I haven't asked it to change direction suddenly (like infill) or go around curves (usually a melodic event in my printing). There's always the potential that I'm just getting resonances in my particular motors and that changing to a different decay mode or dropping to 1/16 microstepping may somehow help (although I doubt the latter).

@CeledaBcn which bits are you most interested in? I can share my thoughts on those bits first. Here's the latest version of openjscad code that I use. Yet to check all the parts. Here are the .stl files for the Z axis parts - they're public files on onshape too, search for "Smartcore Threaded Z Parts". I had to cut about 50mm off my 300mm threaded rod but my 300mm smooth Z rods fit perfectly without cutting required as the stepper motor height doesn't contribute to their height off the floor of the box. I have spaced the smooth rods out too - now 120mm between centres rather than original 60mm.

The DRV8825s arrived today and I installed them on my X and Y motors on the RAMPS 1.4. After adjusting the trim pot VRefs down to about 0.4V (from 1.6V - thanks for the warning!) and doubling the steps per mm in configuration.h (+uploading it) I tested the movement out. I haven't got the hotend wires connected yet so couldn't run a test print (as far as I know the dry run feature only works on Repetier FW). I used X and Y axis movement in manual commands and recorded sound levels with a free android app (I only care about relative values, so shouldn't be to big a compromise). I kept all three driver jumpers in place to set 1/32 microstepping.

I heard the high pitch whining that many have reported with the DRV8825s and reducing the VRef to 0.3-0.25V helped with this. Overall I found the slower manual command moves to be significantly noisier than the faster axis-homing moves and the DRV8825s to be noisier than the A4988s. I couldn't say for sure but would estimate from the sound power meter app readings that 3-5dB was the difference between the same move with the two different stepper driver types. I have to remember that the sound I am worried about is the lower frequency vibration that travels through the house, rather than the readings in the app which will probably have the frequencies weighted to the human ear's sensitivity.

I'm going to persevere with the DRV8825s as the reports by others on the internet, including the reprap wiki page at the "warning" link above, make me think that they have potential that my very basic test can't realise. Bear in mind that I haven't asked it to change direction suddenly (like infill) or go around curves (usually a melodic event in my printing). There's always the potential that I'm just getting resonances in my particular motors and that changing to a different decay mode or dropping to 1/16 microstepping may somehow help (although I doubt the latter).

@CeledaBcn which bits are you most interested in? I can share my thoughts on those bits first. Here's the latest version of openjscad code that I use. Yet to check all the parts. Here are the .stl files for the Z axis parts - they're public files on onshape too, search for "Smartcore Threaded Z Parts". I had to cut about 50mm off my 300mm threaded rod but my 300mm smooth Z rods fit perfectly without cutting required as the stepper motor height doesn't contribute to their height off the floor of the box. I have spaced the smooth rods out too - now 120mm between centres rather than original 60mm.

|

Re: Smartcore build log and pre-build questions September 21, 2015 09:18PM |

Registered: 9 years ago Posts: 107 |

Update: Basic comparisons - DRV8825s vs A4988s & Repetier FW vs Marlin

So here's the first experiment: run three layers of a print (without filament or even a hotend attached to the print head of my new Smartcore) excluding the first layer (slow compared to normal layers). Use a sound meter app on phone placed on print bed to record a noise dB level. Of course this is poor technique and instrumentation but ok for a rough comparison. The background noise level was recorded at 21dB. Both stepper drivers were set to ~1.25A Imax (VRef = 0.5 for A4988, 0.62 for DRV8825).

Stepper Driver: A4988 ---DRV8825

Firmware:

Repetier -----------43dB -----46dB

Marlin ------------- 42dB -----42dB

However, the Repetier FW was, in my subjective opinion, much quieter and produced much less motor/frame resonances than the Marlin. Of course, these frequencies are relatively low in the human hearing range, so probably under-weighted by the meter in my opinion.

DRV8825s still not great but they may yield as yet unseen benefits in print quality. I may look into the decay mode stuff.

So here's the first experiment: run three layers of a print (without filament or even a hotend attached to the print head of my new Smartcore) excluding the first layer (slow compared to normal layers). Use a sound meter app on phone placed on print bed to record a noise dB level. Of course this is poor technique and instrumentation but ok for a rough comparison. The background noise level was recorded at 21dB. Both stepper drivers were set to ~1.25A Imax (VRef = 0.5 for A4988, 0.62 for DRV8825).

Stepper Driver: A4988 ---DRV8825

Firmware:

Repetier -----------43dB -----46dB

Marlin ------------- 42dB -----42dB

However, the Repetier FW was, in my subjective opinion, much quieter and produced much less motor/frame resonances than the Marlin. Of course, these frequencies are relatively low in the human hearing range, so probably under-weighted by the meter in my opinion.

DRV8825s still not great but they may yield as yet unseen benefits in print quality. I may look into the decay mode stuff.

|

Re: Smartcore build log and pre-build questions September 24, 2015 08:12AM |

Registered: 8 years ago Posts: 24 |

@smerrett79 I want to use oil less bushings to, and not in openjsad to modify and correct the pieces for fit it, i was planning to use a printed adaptor for use it. And interested on the sizing, i want to buy a 300m thread rod Lead screw, but don't want to cut it  more Z space for print. Then, if i understood, if i add 50mm to the print height... i will can mount the 300mm thread rod without cutting? I will cut my own smoth rods, i did it before for my prusa i3 box frame, and is no problem to have a "rare" size

more Z space for print. Then, if i understood, if i add 50mm to the print height... i will can mount the 300mm thread rod without cutting? I will cut my own smoth rods, i did it before for my prusa i3 box frame, and is no problem to have a "rare" size

I like the design of the Z axis you do, you have to share it on thingiverse and youmagine ;-) Locks more clean and stable, i fall in love with it

And another thing... is posible to have a bom? Don't know if is one some where...

more Z space for print. Then, if i understood, if i add 50mm to the print height... i will can mount the 300mm thread rod without cutting? I will cut my own smoth rods, i did it before for my prusa i3 box frame, and is no problem to have a "rare" size

more Z space for print. Then, if i understood, if i add 50mm to the print height... i will can mount the 300mm thread rod without cutting? I will cut my own smoth rods, i did it before for my prusa i3 box frame, and is no problem to have a "rare" size

I like the design of the Z axis you do, you have to share it on thingiverse and youmagine ;-) Locks more clean and stable, i fall in love with it

And another thing... is posible to have a bom? Don't know if is one some where...

|

Re: Smartcore build log and pre-build questions September 25, 2015 05:37PM |

Registered: 9 years ago Posts: 107 |

@CeledaBcn I shared the Z parts in a previous post - are they working for you?

If you cut your z axis smooth rods longer and make your box/frame taller you could definitely keep your threaded rod at 300mm. My box was sized using the openjscad 1.0 code for 300mm rods in every axis (XYZ) which you need to check by changing the print volume and seeing if you end up with 300mm rods. Once you do, take the wood dimensions and add some height in the z axis to make sure you don't need to cut your 300mm lead screw. If I find the offcuts I'll measure with the calipers and tell you how much I cut so you have an idea of how much to add.

BOM is possible but I'd wait until the build has been proven to work! I mainly rely on eBay for cheap metric stainless allen bolts which are not expensive in UK. If you go back in this thread you can see the main parts I use but I agree BOM is very useful when preparing for a build. I was quite frustrated when I found the BOM for Smartcore on Youmagine specified M8 bolts which were too short!

If you cut your z axis smooth rods longer and make your box/frame taller you could definitely keep your threaded rod at 300mm. My box was sized using the openjscad 1.0 code for 300mm rods in every axis (XYZ) which you need to check by changing the print volume and seeing if you end up with 300mm rods. Once you do, take the wood dimensions and add some height in the z axis to make sure you don't need to cut your 300mm lead screw. If I find the offcuts I'll measure with the calipers and tell you how much I cut so you have an idea of how much to add.

BOM is possible but I'd wait until the build has been proven to work! I mainly rely on eBay for cheap metric stainless allen bolts which are not expensive in UK. If you go back in this thread you can see the main parts I use but I agree BOM is very useful when preparing for a build. I was quite frustrated when I found the BOM for Smartcore on Youmagine specified M8 bolts which were too short!

|

Re: Smartcore build log and pre-build questions September 29, 2015 04:05AM |

Registered: 9 years ago Posts: 107 |

Coming along nicely with the E3D Volcano and 0.6mm nozzle fitted. The print bed is really solid laterally and I'm hopeful that will turn into really clean geometry prints when I start to ramp the speed up.

Just a note for the wider nozzle - don't try and slice a calibration shape with wall thickness less than the nozzle hole diameter - it confuses both cura and slic3r!

Edited 2 time(s). Last edit at 09/29/2015 08:22AM by smerrett79.

Just a note for the wider nozzle - don't try and slice a calibration shape with wall thickness less than the nozzle hole diameter - it confuses both cura and slic3r!

Edited 2 time(s). Last edit at 09/29/2015 08:22AM by smerrett79.

|

Re: Smartcore build log and pre-build questions September 29, 2015 07:53AM |

Registered: 9 years ago Posts: 95 |

|

Re: Smartcore build log and pre-build questions September 29, 2015 11:47AM |

Registered: 8 years ago Posts: 24 |

|

Re: Smartcore build log and pre-build questions September 29, 2015 07:34PM |

Registered: 9 years ago Posts: 107 |

|

Re: Smartcore build log and pre-build questions October 19, 2015 10:18AM |

Registered: 9 years ago Posts: 107 |

Just a quick update - been having problems with the (too low) filament flow rate for the Volcano and I have finally given up and reluctantly switched back to the Lite6. It's probably a slicer issue.

However, the first couple of Lite6 prints look good, even without part cooling. Still working out how best to mount a part cooling fan.

Will show a picture of Benchy when I can remember to take one. Looking forward to ramping up the speed and also trying some PETG. Then I'll get on to E3D and see if I can fix the problem with the Volcano.

When I swapped the hotends around, I noticed that the Lite6 is significantly heavier thanks to its stainless steel heat sink. I think the V6 and Volcano's relatively low masses would make a significant contribution to reducing the shadow/ripples caused by rapid direction changes.

Edited 1 time(s). Last edit at 10/19/2015 10:23AM by smerrett79.

However, the first couple of Lite6 prints look good, even without part cooling. Still working out how best to mount a part cooling fan.

Will show a picture of Benchy when I can remember to take one. Looking forward to ramping up the speed and also trying some PETG. Then I'll get on to E3D and see if I can fix the problem with the Volcano.

When I swapped the hotends around, I noticed that the Lite6 is significantly heavier thanks to its stainless steel heat sink. I think the V6 and Volcano's relatively low masses would make a significant contribution to reducing the shadow/ripples caused by rapid direction changes.

Edited 1 time(s). Last edit at 10/19/2015 10:23AM by smerrett79.

|

Re: Smartcore build log and pre-build questions October 19, 2015 09:01PM |

Registered: 9 years ago Posts: 107 |

@CeledaBCN: 58mm. Sorry that took so long. I had to go digging around the rubbish bag.

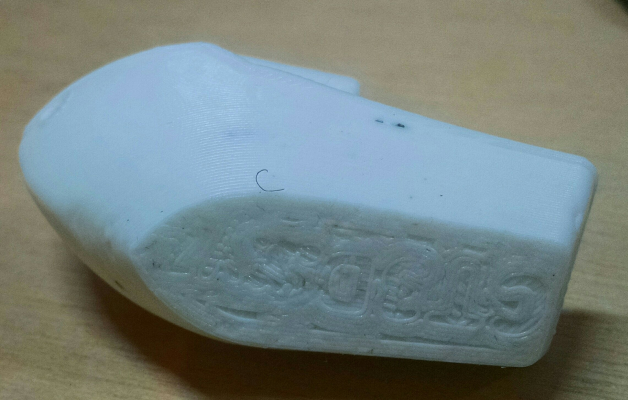

Some Benchy pics. Remember this is without fan (except frantic blowing by me for bridging the cabin roof!) and with periodic +/-3*C hotend changes. Not perfect but very happy for early results. The black bits are black ABS which is still coming out of the hotend.

Edited 2 time(s). Last edit at 10/19/2015 09:04PM by smerrett79.

Some Benchy pics. Remember this is without fan (except frantic blowing by me for bridging the cabin roof!) and with periodic +/-3*C hotend changes. Not perfect but very happy for early results. The black bits are black ABS which is still coming out of the hotend.

Edited 2 time(s). Last edit at 10/19/2015 09:04PM by smerrett79.

|

Re: Smartcore build log and pre-build questions October 19, 2015 11:07PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartcore build log and pre-build questions February 05, 2016 01:58PM |

Registered: 8 years ago Posts: 24 |

Hey... today i downloaded your files from thingiverse to take a lock, and i see that the diameter for the bushings is about 10mm? (i used netfabb basic to mesure it)

The bushings i'm gonna to use are 12mm... you made the files parameterizable?

Thx

|

Re: Smartcore build log and pre-build questions February 05, 2016 02:25PM |

Registered: 9 years ago Posts: 107 |

Stls aren't parametric but you can go to Onshape and search as per my post dated 18 Sep 15. Then you can copy and edit yourself with an onshape account (free and easy to get used to). You could also import stl into sketchup and edit there but I left sketchup for onshape and haven't been back once!

|

Re: Smartcore build log and pre-build questions February 06, 2016 03:07AM |

Registered: 8 years ago Posts: 24 |

|

Re: Smartcore build log and pre-build questions February 06, 2016 03:27AM |

Registered: 9 years ago Posts: 107 |

Sorry, only registered users may post in this forum.