V1.2x issues

Posted by smerrett79

|

Re: V1.2x issues August 04, 2015 01:33AM |

Registered: 9 years ago Posts: 44 |

|

Re: V1.2x issues August 05, 2015 09:29AM |

Registered: 8 years ago Posts: 95 |

Quote

3DFreezeMe

I have read somewhere that people who tried that, had issues with the two split parts where the rods are fastened.

I believe that is why smerrett79 did ask that question.

the part is structurally more sound printed on its side.. the split where the rods go when printed on its side has break away material for support it is easily popped or pushed out ,, it is intentionally there ...I have printed it.. it works great...

Edited 1 time(s). Last edit at 08/05/2015 11:53AM by mike3.

|

Re: V1.2x issues August 05, 2015 12:36PM |

Registered: 9 years ago Posts: 44 |

You are correct mike3, I am aware of the better part strength when printed on their side.

But the slide_y parts itself do not have any break away support? You must have used support which was generated by your slicer.

My attempt printing them on their side, I have used support type 'lines' in Cura. But when the top parts of the splitted rod part started printing they became loose before the bridge (above the rod holes) was closed.

Maybe I should have used the 'grid' style support, with some denser fill amount.

Which slicer have you used for these parts?

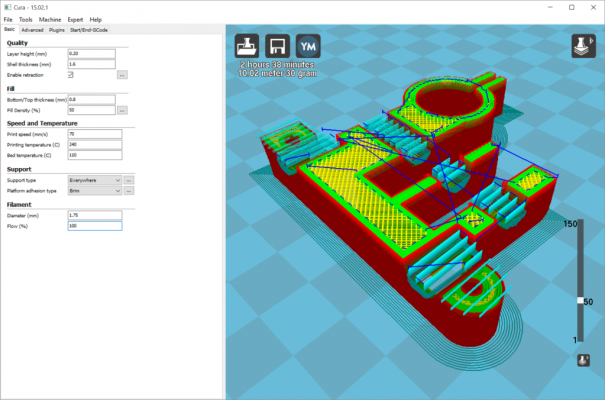

Slicer and support settings:

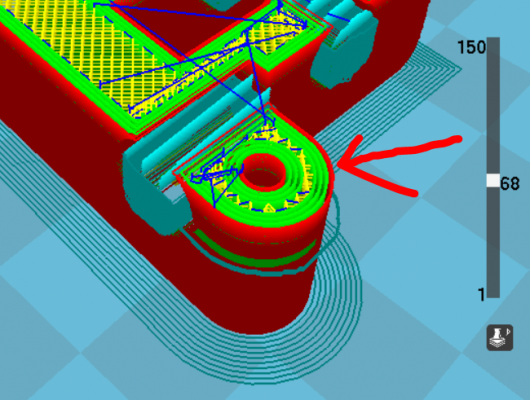

About here the floating part broke loose (on both sides):

But the slide_y parts itself do not have any break away support? You must have used support which was generated by your slicer.

My attempt printing them on their side, I have used support type 'lines' in Cura. But when the top parts of the splitted rod part started printing they became loose before the bridge (above the rod holes) was closed.

Maybe I should have used the 'grid' style support, with some denser fill amount.

Which slicer have you used for these parts?

Slicer and support settings:

About here the floating part broke loose (on both sides):

|

Re: V1.2x issues August 05, 2015 03:55PM |

Registered: 9 years ago Posts: 107 |

I think I'd have to agree that the orientation is best how you have it pictured. I'm stuck in a hotel with only my phone at the moment but given that these two parts are not going to change with box wall thickness or print volume (there will be 6mm and 8mm x axis rod versions), would someone be able to add support to the actual design, so that you don't need to rely on the foibles of your particular slicer? I'm thinking along the lines described here http://support.3dverkstan.se/article/30-getting-better-prints#custom-supports.

Ps it seems like the rest of the web page has some other good tips too.

Ps it seems like the rest of the web page has some other good tips too.

|

Re: V1.2x issues August 05, 2015 03:58PM |

Registered: 8 years ago Posts: 95 |

|

Re: V1.2x issues August 05, 2015 04:02PM |

Registered: 9 years ago Posts: 107 |

|

Re: V1.2x issues August 08, 2015 04:20PM |

Registered: 9 years ago Posts: 44 |

@smerrett79

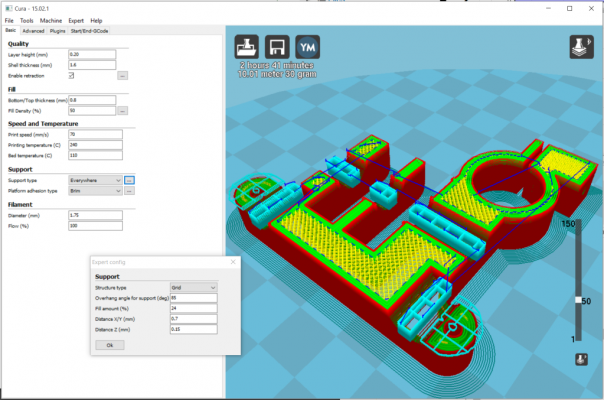

I have made a second attempt on printing this piece sideways and succeeded. I now have used the grid type support (which is default btw), i.s.o. the line type and the floating parts above the split stayed put.

See my settings in the screenshot. I bumped up the overhang from default 60% to 85% so there is the least amount of support in the circles, where it does not need it really.

I have made a second attempt on printing this piece sideways and succeeded. I now have used the grid type support (which is default btw), i.s.o. the line type and the floating parts above the split stayed put.

See my settings in the screenshot. I bumped up the overhang from default 60% to 85% so there is the least amount of support in the circles, where it does not need it really.

|

Re: V1.2x issues August 08, 2015 04:38PM |

Registered: 9 years ago Posts: 107 |

|

Re: V1.2x issues August 08, 2015 05:01PM |

Registered: 9 years ago Posts: 44 |

I currently print on a Delta type KosselXL printer with around 250mm diameter bed size (300mm z-height).

The borosilicate glass bed is covered with a PEI sheet on which I print the ABS directly, without any extra adhesives like PVA stick or hairspray.

For this SmartrapCore build, I have choosen for ABS because I want to make an enclosed printer with a heated chamber. So I need the ABS with its high temperature tolerance.

This is not the easiest filament but when you control the environment in which you print, you can have very nice results.

The borosilicate glass bed is covered with a PEI sheet on which I print the ABS directly, without any extra adhesives like PVA stick or hairspray.

For this SmartrapCore build, I have choosen for ABS because I want to make an enclosed printer with a heated chamber. So I need the ABS with its high temperature tolerance.

This is not the easiest filament but when you control the environment in which you print, you can have very nice results.

|

Re: V1.2x issues August 08, 2015 05:32PM |

Registered: 9 years ago Posts: 107 |

I'm using the smartcore V1 with an E3D Lite6 and my first parts for the smartcore were from my (pretty poor) Q3D 2up in clear PLA. For the recent foray into ABS printing I made a makeshift shroud/hood from 2-3mm packing foam you get on a roll. I have been fortunate enough to avoid warping and splitting even with bed down at 60C and extruding at 240C. Obviously the form makes a difference so I can't say whether those settings would work for smartcore parts until I try. Anyway, the PLA hasn't stretched noticeably with the insulation hood in place. Just thought you might be interested.

The main issues I have with the smartcore is ripples along the side faces of even medium speed prints which resemble the previous feature in the tool path. My hypothesis is that this is in part due to the spacing of the x rods and the lack of rigidity in the 3 piece x/extruder carriage. That's why I'm keen to try V1.2. The other part I'm looking at is the lateral play in the bed - either a second screw (just switched from M8 to stainless steel 8mm lead screw) or at least another smooth rod and bearing to the side to prevent sideways vibration (if such a phenomenon is actually happening).

Edited 1 time(s). Last edit at 08/08/2015 05:32PM by smerrett79.

The main issues I have with the smartcore is ripples along the side faces of even medium speed prints which resemble the previous feature in the tool path. My hypothesis is that this is in part due to the spacing of the x rods and the lack of rigidity in the 3 piece x/extruder carriage. That's why I'm keen to try V1.2. The other part I'm looking at is the lateral play in the bed - either a second screw (just switched from M8 to stainless steel 8mm lead screw) or at least another smooth rod and bearing to the side to prevent sideways vibration (if such a phenomenon is actually happening).

Edited 1 time(s). Last edit at 08/08/2015 05:32PM by smerrett79.

|

Re: V1.2x issues August 10, 2015 03:40AM |

Registered: 9 years ago Posts: 44 |

I use cheap waste-bin clear plastic bags as shroud/hood to keep the warmth inside and the draught outside.

Let's hope the newer v1.2 will fix your issues!

To get back on topic, I found the fix for the issues on the openjscad.org website on the Youmagine SmartFriendz SmartrapCore discussion page. The fix was posted by tseglevskiy:

User mnm.mihir posted a fixed v1.2.3 jscad file as text in the comment above, but you loose the comprehensive formatting when copied and pasted as text.

I included a fixed v1.2.4 jscad file with all formatting kept in this reply, which you can use on the openjscad,org site. All views are working now.

Let's hope the newer v1.2 will fix your issues!

To get back on topic, I found the fix for the issues on the openjscad.org website on the Youmagine SmartFriendz SmartrapCore discussion page. The fix was posted by tseglevskiy:

If you have error like this

return this.color.join("/");

TypeError: undefined is not a function

you can find in the source (smartcore-v1.2.jscad) the string

.setColor("grey")

and change it, for example, to

.setColor(0.8,0.8,0.8)

OpenJSCAD currently doesn't support setColor by name:

[github.com]

User mnm.mihir posted a fixed v1.2.3 jscad file as text in the comment above, but you loose the comprehensive formatting when copied and pasted as text.

I included a fixed v1.2.4 jscad file with all formatting kept in this reply, which you can use on the openjscad,org site. All views are working now.

|

Re: V1.2x issues August 11, 2015 08:33AM |

Registered: 8 years ago Posts: 95 |

Quote

3DFreezeMe

I use cheap waste-bin clear plastic bags as shroud/hood to keep the warmth inside and the draught outside.

Let's hope the newer v1.2 will fix your issues!

To get back on topic, I found the fix for the issues on the openjscad.org website on the Youmagine SmartFriendz SmartrapCore discussion page. The fix was posted by tseglevskiy:

If you have error like this return this.color.join("/"); TypeError: undefined is not a function you can find in the source (smartcore-v1.2.jscad) the string .setColor("grey") and change it, for example, to .setColor(0.8,0.8,0.8) OpenJSCAD currently doesn't support setColor by name: [github.com]

User mnm.mihir posted a fixed v1.2.3 jscad file as text in the comment above, but you loose the comprehensive formatting when copied and pasted as text.

I included a fixed v1.2.4 jscad file with all formatting kept in this reply, which you can use on the openjscad,org site. All views are working now.

downloaded this and printed out the two front corner stepper brackets.. and the screw holes are off too close together and needs lots of drilling out to get them to fit stepper....

|

Re: V1.2x issues September 02, 2015 11:49PM |

Registered: 8 years ago Posts: 13 |

I made individual .stl files of all the parts in the correct orientation required for successful printing. They are for 5/16 or 8mm rod and sized for 19mm which fits either 3/4" Alu tube or 5/8 (16mm) MDF with a cork/foam spacer to help with vibration.

Would you like me to post a zip with them? I know they work as successfully built my Smartcore with them. One note is that you may still have to clean up the screw holes with a drill after wards. I did. Almost all the M3 holes had to be cleaned out with a 1/8 or 3mm drill.

Edited 1 time(s). Last edit at 09/02/2015 11:50PM by jjazzyj.

Would you like me to post a zip with them? I know they work as successfully built my Smartcore with them. One note is that you may still have to clean up the screw holes with a drill after wards. I did. Almost all the M3 holes had to be cleaned out with a 1/8 or 3mm drill.

Edited 1 time(s). Last edit at 09/02/2015 11:50PM by jjazzyj.

Sorry, only registered users may post in this forum.