Custom Smartrapcore ALU

Posted by s0me

|

Custom Smartrapcore ALU December 30, 2015 12:19PM |

Registered: 9 years ago Posts: 26 |

Hi,

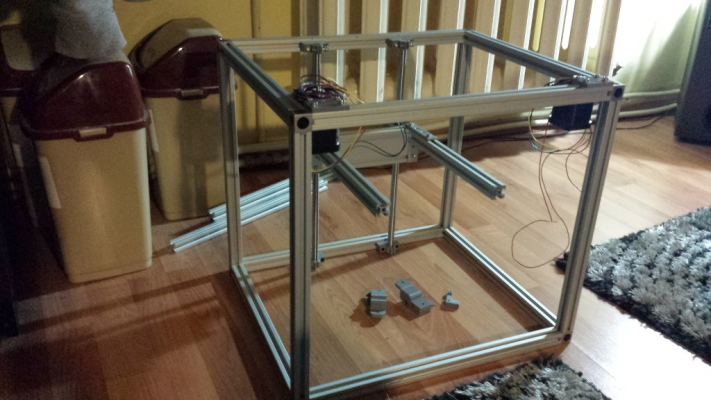

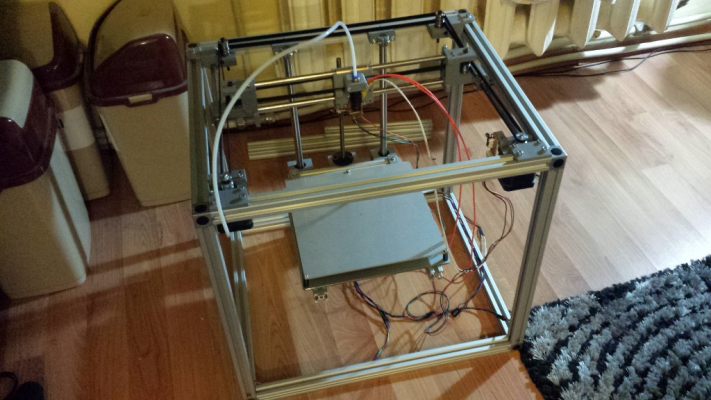

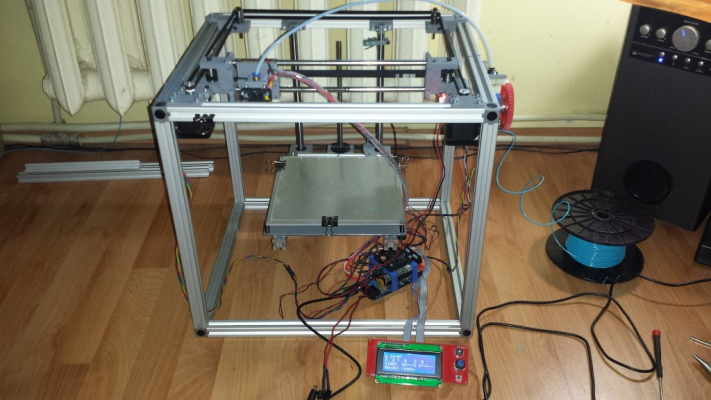

This is my version of the Smartrapcore Alu

Parts used for this build:

- TR8x8 leadscrew with anti backlash nut

- flexible coupling

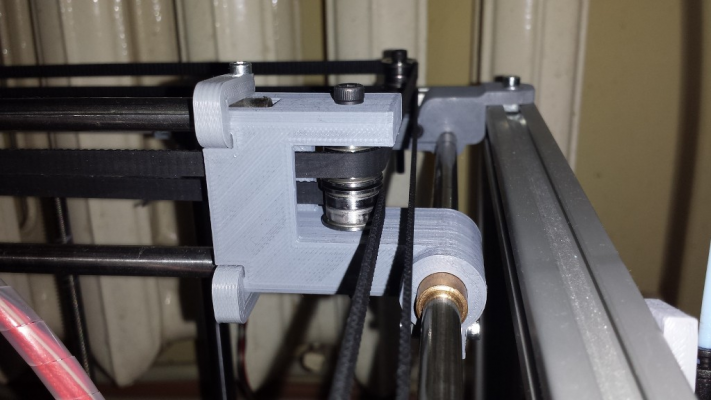

- F624ZZ bearings (instead of 608ZZ)

- 16 tooth GT2 pulleys

- 0.9 step angle / 400 steps Nema 17 motors for XY

- 1.8 step angle / 200 steps Nema 17 motors for Z / E

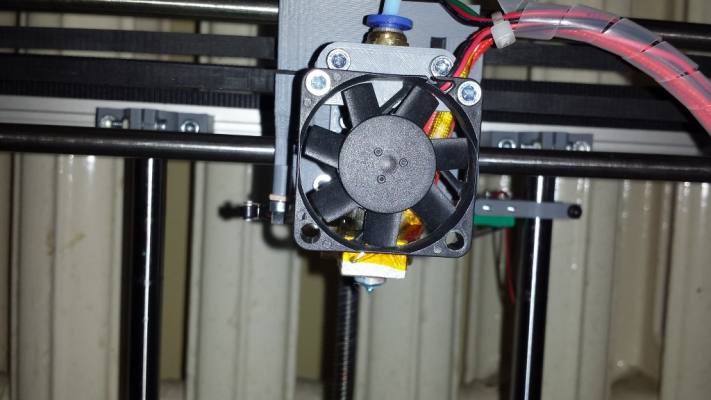

- J-head clone 0.5mm nozzle / 1.75mm filament

- Ramps 1.4 + LCD

- Mk3 aluminium heatbed + borosilicate glass plate + SSR

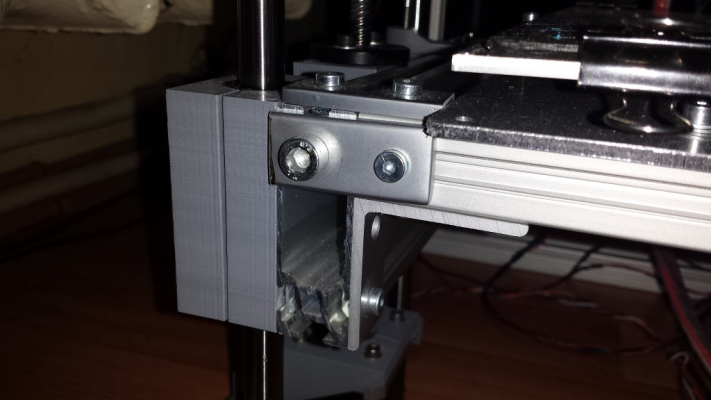

- 8mm linear rods + selflubricating bronze bushings

-12mm linear rods + bearings for Z axis

- Wade extruder (bowden)

- laptop style 12v 10A PSU

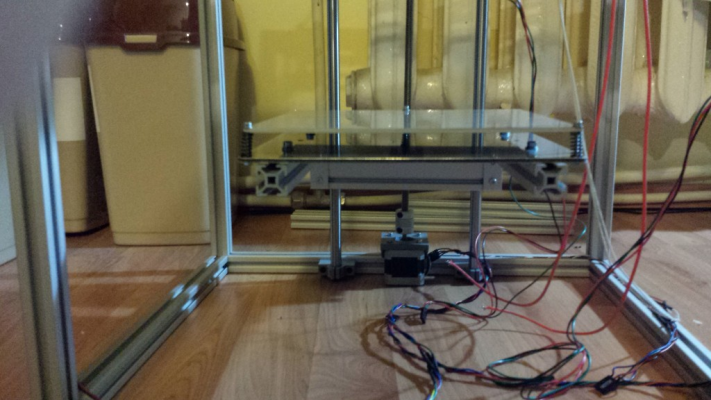

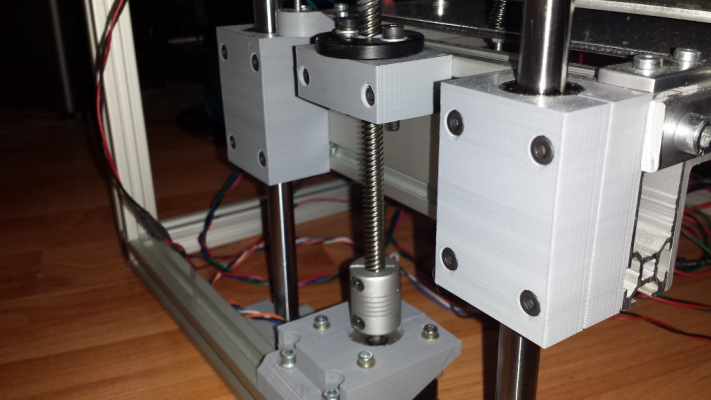

The Z axis design is "borrowed" from the G&C printer but it uses more printed parts, different aluminium extrusion lenghts and the motor is mounted at the bottom. Because of this I used 360mm vertical extrusions.

The MK3 heatbed sits on top of a 3mm Dibond plate.

The plan is to use a IR probe (from dc42) for auto bed leveling but for the moment the build plate will be manually leveled because I use it on another printer.

Currently the plastic parts are printed in PLA but will be reprinted in ABS after I wire the heatbed and make some minor.

The only plastic parts that are not modified are the motor mounts with their rod holders.

It will be upgraded with the following parts: 24v power supply, 24v Arduino Mega / Duet (which is intended for a Rostock mini but...), E3D V6 hotend, 24v fans

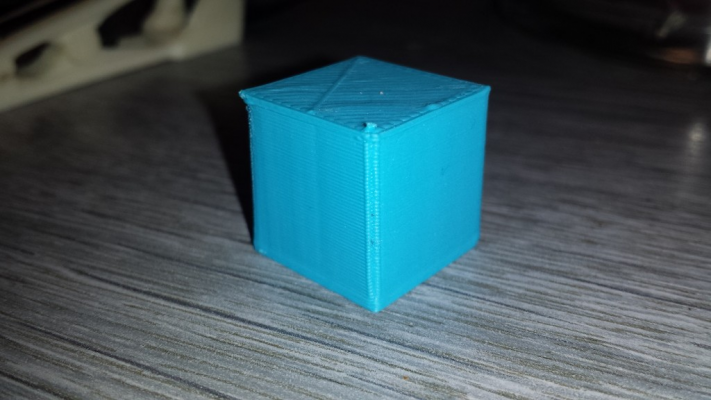

Cable management is a mess at the moment, I just wanted to see how it works. I will post pictures of the print quality after I fine tune the extruder.

Any suggestions?

Edited 2 time(s). Last edit at 12/30/2015 02:22PM by s0me.

This is my version of the Smartrapcore Alu

Parts used for this build:

- TR8x8 leadscrew with anti backlash nut

- flexible coupling

- F624ZZ bearings (instead of 608ZZ)

- 16 tooth GT2 pulleys

- 0.9 step angle / 400 steps Nema 17 motors for XY

- 1.8 step angle / 200 steps Nema 17 motors for Z / E

- J-head clone 0.5mm nozzle / 1.75mm filament

- Ramps 1.4 + LCD

- Mk3 aluminium heatbed + borosilicate glass plate + SSR

- 8mm linear rods + selflubricating bronze bushings

-12mm linear rods + bearings for Z axis

- Wade extruder (bowden)

- laptop style 12v 10A PSU

The Z axis design is "borrowed" from the G&C printer but it uses more printed parts, different aluminium extrusion lenghts and the motor is mounted at the bottom. Because of this I used 360mm vertical extrusions.

The MK3 heatbed sits on top of a 3mm Dibond plate.

The plan is to use a IR probe (from dc42) for auto bed leveling but for the moment the build plate will be manually leveled because I use it on another printer.

Currently the plastic parts are printed in PLA but will be reprinted in ABS after I wire the heatbed and make some minor.

The only plastic parts that are not modified are the motor mounts with their rod holders.

It will be upgraded with the following parts: 24v power supply, 24v Arduino Mega / Duet (which is intended for a Rostock mini but...), E3D V6 hotend, 24v fans

Cable management is a mess at the moment, I just wanted to see how it works. I will post pictures of the print quality after I fine tune the extruder.

Any suggestions?

Edited 2 time(s). Last edit at 12/30/2015 02:22PM by s0me.

|

Re: Custom Smartrapcore ALU January 10, 2016 05:49AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Custom Smartrapcore ALU January 16, 2016 07:54AM |

Registered: 9 years ago Posts: 26 |

I didnt test it yet so its still a work in progress.

The vertical aluminium extrusions of the frame are 360mm long (original SMC Alu 300mm).

Extrusions:

2060 x 192mm

2020 x 250mm x 2

Screws&nuts

M4x25mm x 16 + 16 t-nuts

M4x20mm x 2 + 2 nuts

Here is the onshape link: Z axis corexy

STL files and a dxf file attached.

The vertical aluminium extrusions of the frame are 360mm long (original SMC Alu 300mm).

Extrusions:

2060 x 192mm

2020 x 250mm x 2

Screws&nuts

M4x25mm x 16 + 16 t-nuts

M4x20mm x 2 + 2 nuts

Here is the onshape link: Z axis corexy

STL files and a dxf file attached.

|

Re: Custom Smartrapcore ALU February 12, 2016 01:55PM |

Registered: 8 years ago Posts: 52 |

|

Re: Custom Smartrapcore ALU February 13, 2016 05:56AM |

Registered: 9 years ago Posts: 26 |

|

Re: Custom Smartrapcore ALU March 09, 2016 08:51AM |

Registered: 9 years ago Posts: 101 |

Thanks for sharing your build! I'm looking at upgrading (and silencing) my ALU. It looks like you modified your idler and x carriage to account for the flanged bearings would you happen to have those files? If not what did you use for source files, the OnShape machine files?

Machine looks great!

Machine looks great!

|

Re: Custom Smartrapcore ALU March 09, 2016 10:23AM |

Registered: 9 years ago Posts: 26 |

Yes I modified the onshape files. Here is the link but the assembly and the edited parts are a mess: SCALU Custom

The parts need adjustments because the belts are really close to the XY parts and may rub at the home and the end of the x axis. Another thing that I dont like is the smoothrod fixing method for the X axis.

I ordered some T-slot wheels to convert it and use the extra space to mount 2 cooling fans on the sides of the hotend + direct drive extruder. I'll post pictures in the COREXY subforum next week I hope.

The parts need adjustments because the belts are really close to the XY parts and may rub at the home and the end of the x axis. Another thing that I dont like is the smoothrod fixing method for the X axis.

I ordered some T-slot wheels to convert it and use the extra space to mount 2 cooling fans on the sides of the hotend + direct drive extruder. I'll post pictures in the COREXY subforum next week I hope.

|

Re: Custom Smartrapcore ALU March 12, 2016 11:24AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Custom Smartrapcore ALU March 12, 2016 11:31AM |

Registered: 9 years ago Posts: 26 |

|

Re: Custom Smartrapcore ALU April 27, 2016 07:50AM |

Registered: 9 years ago Posts: 26 |

Converting the Smartrapcore Alu to Biguide wheels on T-slot

|

Re: Custom Smartrapcore ALU April 27, 2016 10:27AM |

Registered: 8 years ago Posts: 3,525 |

Quote

s0me

No, flanged bearings F624ZZ. You could replace yours with F608ZZ + a big washer and get rid of those printed sleeves.

Have you done this on your smartrapcore? I tried it and the f608zz bearings were not wide enough for the belts to ride nicely on even with washers, and the belts rubbed on the x carriage.

I'd say you want a larger bearing both in terms of outside diameter and width.

Edited 1 time(s). Last edit at 04/27/2016 10:28AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Custom Smartrapcore ALU April 27, 2016 12:14PM |

Registered: 9 years ago Posts: 26 |

|

Re: Custom Smartrapcore ALU April 30, 2016 03:36PM |

Registered: 8 years ago Posts: 54 |

Did you do the upgrade ? I'm interested !

Did you gain some build volume ? You could put the motors outside the frame, the bearings on top of the carriage , maybe even arriving at 300x250 or something ... this could mean the birth of smartrapcore alu 2.0

Also how is your z-axis working ?

Edited 3 time(s). Last edit at 04/30/2016 03:43PM by Gibbon91.

Did you gain some build volume ? You could put the motors outside the frame, the bearings on top of the carriage , maybe even arriving at 300x250 or something ... this could mean the birth of smartrapcore alu 2.0

Also how is your z-axis working ?

Edited 3 time(s). Last edit at 04/30/2016 03:43PM by Gibbon91.

|

Re: Custom Smartrapcore ALU May 01, 2016 06:45AM |

Registered: 9 years ago Posts: 26 |

I have to desgn the x carriage, hotend mount, cooling fan mount, endstop holder for Y axis.

I'm not looking to gain print volume with this printer.

The Z axis seems to work fine, no visible Z wobble effect / banding.

I'm not looking to gain print volume with this printer.

The Z axis seems to work fine, no visible Z wobble effect / banding.

|

Re: Custom Smartrapcore ALU May 01, 2016 08:46AM |

Registered: 8 years ago Posts: 54 |

|

Re: Custom Smartrapcore ALU May 01, 2016 09:04AM |

Registered: 9 years ago Posts: 26 |

|

Re: Custom Smartrapcore ALU May 02, 2016 04:33AM |

Registered: 8 years ago Posts: 54 |

yeah, i meant x axis, well it doesn't seem difficult your upgrade, maybe i'll do it too, but changing the 2 axis with v-slot aluminum extruded (profile ? beam? how do you call this things in english), that would mean spending like 20 €, but i think it might be worth it ...

Edited 1 time(s). Last edit at 05/02/2016 04:34AM by Gibbon91.

Edited 1 time(s). Last edit at 05/02/2016 04:34AM by Gibbon91.

|

Re: Custom Smartrapcore ALU May 02, 2016 04:48AM |

Registered: 9 years ago Posts: 26 |

You can use aluminium gantry plates with V-slot, no need for plastic parts besides the hotend mount (maybe X carriage too?).

I can't use V-slot with my corners because the T-slot has a 6mm center hole.

Need to redesign the belt clamps or the whole X carriage.

Belt tensioning is done via the idlers.

I can't use V-slot with my corners because the T-slot has a 6mm center hole.

Need to redesign the belt clamps or the whole X carriage.

Belt tensioning is done via the idlers.

|

Re: Custom Smartrapcore ALU May 02, 2016 04:58AM |

Registered: 8 years ago Posts: 54 |

|

Re: Custom Smartrapcore ALU May 18, 2016 08:02AM |

Registered: 8 years ago Posts: 52 |

|

Re: Custom Smartrapcore ALU May 29, 2016 02:36PM |

Registered: 8 years ago Posts: 52 |

|

Re: Custom Smartrapcore ALU May 29, 2016 04:05PM |

Registered: 8 years ago Posts: 3,525 |

Looks cool but the standard hot end mount will take a v6, when I tried one I had to take the endstop off the bottom of the x carriage and relocate it to the y slide on

the left, but it fits into the groove mount.

Edited 1 time(s). Last edit at 05/29/2016 04:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

the left, but it fits into the groove mount.

Edited 1 time(s). Last edit at 05/29/2016 04:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Custom Smartrapcore ALU May 30, 2016 10:21PM |

Registered: 7 years ago Posts: 558 |

This was what I ended up changing for an E3D V6 hotend. It was just taking the same part in Onshape and sliding the offset down and adding a few extra cutouts for screw clearances. This brought my hotend down below the microswitch about 8-10mm which gave me the comfortable feeling I wouldn't cook the microswitch on the hotbed.

|

Re: Custom Smartrapcore ALU June 01, 2016 03:29AM |

Registered: 9 years ago Posts: 26 |

Quote

Yoko

ok i made a hotend holder for e3d hotend

kindly review it and send me your feedback (i am a total noob in 3d modeling)

Already told you in a private message that I don't own an E3D hotend for this printer.

I don't even own a "Smartrapcore" anymore. My design is not compatible with the Smartrapcore anyway.

Sorry, only registered users may post in this forum.