Why the bearings pulley-sleeves?

Posted by realthor

|

Why the bearings pulley-sleeves? February 17, 2016 07:21PM |

Registered: 9 years ago Posts: 1,035 |

I wonder why not leave the belt roll on the bearings race and go for the trouble of printing sleeves in the new version.

I could guess that the belt didn't stay in line but that must be because of not enough tension in the line.

I am building a corexy that has exposed bearings with no retaining mechanism for the belts and I believe the tension in the belt will prevent it to deviate from the straight path (deviating from the straight line would tension it further as it mathematically means increasing its length, which it would't naturally do)

So why then? :-/

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I could guess that the belt didn't stay in line but that must be because of not enough tension in the line.

I am building a corexy that has exposed bearings with no retaining mechanism for the belts and I believe the tension in the belt will prevent it to deviate from the straight path (deviating from the straight line would tension it further as it mathematically means increasing its length, which it would't naturally do)

So why then? :-/

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? February 19, 2016 10:58AM |

Registered: 10 years ago Posts: 992 |

Hi realthor,

It was more about design concept. We had the belt right on the bearings before and the sleeves where assumed by the Yslide parts, but they where fixed , so in lot of cases , the belt where touching them and after some time , the belt went broken ( we found a lot of black stuff around).

I found that it would be better to have the sleeves running with the bearings and since I find it better.

The best of course would be to have aluminium sleeves right on the bearings, but i find them too expensive for our budget.

I'm sure we will find a way . For now, the feeling with those printed sleeves is not great because they turn a little funny sometimes, but it works really well

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

It was more about design concept. We had the belt right on the bearings before and the sleeves where assumed by the Yslide parts, but they where fixed , so in lot of cases , the belt where touching them and after some time , the belt went broken ( we found a lot of black stuff around).

I found that it would be better to have the sleeves running with the bearings and since I find it better.

The best of course would be to have aluminium sleeves right on the bearings, but i find them too expensive for our budget.

I'm sure we will find a way . For now, the feeling with those printed sleeves is not great because they turn a little funny sometimes, but it works really well

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Why the bearings pulley-sleeves? February 19, 2016 11:20AM |

Registered: 9 years ago Posts: 1,035 |

You actually had the belts snap off due to rubbing damage at the washer-thing that was part of the Y-carriage? Or it was only some black rubber that had broken away from the belts?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? March 15, 2016 08:58AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Why the bearings pulley-sleeves? March 15, 2016 01:29PM |

Registered: 9 years ago Posts: 1,035 |

If properly tensioned the belts should not walk off on the bearings because the straight belt is at its shortest length. Any walking would mean the belt increases length and that shouldn't be a natural thing to happen imho.

I am interested in this too as I have a design with no flanges whatsoever ...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am interested in this too as I have a design with no flanges whatsoever ...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? March 15, 2016 02:35PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Why the bearings pulley-sleeves? March 15, 2016 03:00PM |

Registered: 9 years ago Posts: 1,035 |

Oh, forgot about the crossed-belts corexy printers. Mine is a dual layer one just like Smartrapcore.

I wonder how it is going to work out for me with no flanges but I am going to try it and if the belts tend to walk then there are other places where one can have some sort of roll to keep the belts from going too far. But for me that walking would mean something bad about the construction.

You could place the flaged bearings facing each other and a big washer in between. That would be the easiest solution.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I wonder how it is going to work out for me with no flanges but I am going to try it and if the belts tend to walk then there are other places where one can have some sort of roll to keep the belts from going too far. But for me that walking would mean something bad about the construction.

You could place the flaged bearings facing each other and a big washer in between. That would be the easiest solution.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? March 18, 2016 11:40AM |

Registered: 9 years ago Posts: 1,035 |

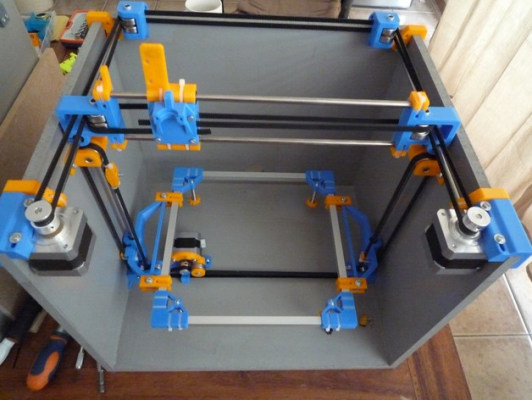

Here's an image for a corexy without crossing of the belts that is apparently using no sleeves and no "plastic washer thing":

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? March 25, 2016 08:24AM |

Registered: 8 years ago Posts: 3,525 |

I've had a try at replacing the bearings in my Scalu printer with f608zz with large washers. There are a number of problems. The two x carriage ends which form the y slides are too wide for 608 bearings so the belts rub the carriages. Not a tricky fix I know...

The 6mm belts don't run that nicely on f608zz bearings as they aren't wide enough with the flange, only 60-70% if the belt sits on the bearing.

Perhaps a larger diameter, wider bearing might work but I've gone back to the sleeved 608's my belts run much better on them.

The 6mm belts don't run that nicely on f608zz bearings as they aren't wide enough with the flange, only 60-70% if the belt sits on the bearing.

Perhaps a larger diameter, wider bearing might work but I've gone back to the sleeved 608's my belts run much better on them.

|

Re: Why the bearings pulley-sleeves? March 25, 2016 09:29AM |

Registered: 9 years ago Posts: 1,035 |

How thin can such a sleeve be to be effective? As I understand the sleeve's grip on the bearing is not that effective and it basically slides on the bearing, actually a combination of the sleeve freely rotating around the bearing and the bearing rotating around its spindle.

My problem is that everything is calculated with 22mm 608 bearings in mind (motor position, Y_carriage, belt_redirect, belts' insert on the X_Carriage) so whatever I do I have to stick to this diameter for the Y-carriage pulleys. So if I am to keep the 608s i have to make a sleeve that is very thin so I don't deviate mush from the straight lines.

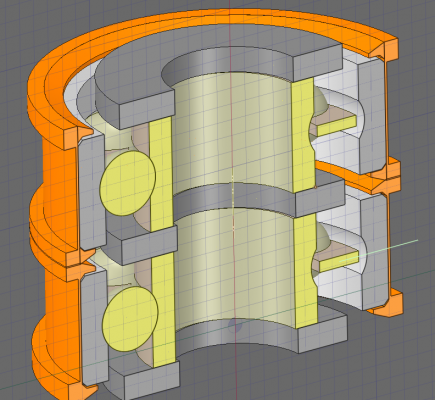

I am wondering if we can make such a sleeve but very thin, something like 2 or 3 layers thick around the bearing and some thicker flanges. Would that work or would such a thin thing wear up too fast? Something like this:

I have the bearings surrounded by washers so I have room to design the sleeve slightly taller than the 7mm of the bearing itself so I can have at least 6.5mm between the flanges.

My other option is to create the same but with the belt profile so I have some thicker parts around the bearing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

My problem is that everything is calculated with 22mm 608 bearings in mind (motor position, Y_carriage, belt_redirect, belts' insert on the X_Carriage) so whatever I do I have to stick to this diameter for the Y-carriage pulleys. So if I am to keep the 608s i have to make a sleeve that is very thin so I don't deviate mush from the straight lines.

I am wondering if we can make such a sleeve but very thin, something like 2 or 3 layers thick around the bearing and some thicker flanges. Would that work or would such a thin thing wear up too fast? Something like this:

I have the bearings surrounded by washers so I have room to design the sleeve slightly taller than the 7mm of the bearing itself so I can have at least 6.5mm between the flanges.

My other option is to create the same but with the belt profile so I have some thicker parts around the bearing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? March 26, 2016 03:33AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Why the bearings pulley-sleeves? May 14, 2016 05:31AM |

Registered: 8 years ago Posts: 3,525 |

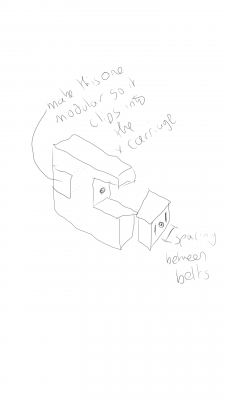

So I'm now using just the f608zz bearings and some large washers. Its working better than before its just getting the belt runs to the x carriage at 90 deg to the y carriage. @realthor I'm wondering if with your design skills you can make your x carriage with adjustable width between the belt clips? Might be too complex to fit in.

Or how about making the fixed belt clip on the carriage modular so you can offer a range of belt spacings? This should be fairly straight forward yes?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Or how about making the fixed belt clip on the carriage modular so you can offer a range of belt spacings? This should be fairly straight forward yes?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Why the bearings pulley-sleeves? May 14, 2016 05:34AM |

Registered: 9 years ago Posts: 1,035 |

If you can spare some time to make a napkin sketch I might try. Didn't quite get what you're asking.

Post a picture of the current setup/ video ... and adnotate it or something

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Post a picture of the current setup/ video ... and adnotate it or something

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? May 14, 2016 05:52AM |

Registered: 8 years ago Posts: 3,525 |

I will try to be more accurate. So the belt clips on your x carriage, the one which is the tensioner can be swapped for another with a different width between the belts to accommodate different pulley widths and keep the belts parallel from the y slides to the x carriage. What I am talking about is making the belt clip on the other side of the x carriage which is currently fixed, modular so you could download and print the one which matches your pulleys and fix it into the x carriage. You would ne d to make 3 in different widths, you have made 2 already it's just the one which matches 608 bearings that's needed and a way of attaching it so that it fixes to the carriage. Of course you could make 3 different carriages but a modular belt clip would be a much more exciting design.

Just an idea.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Just an idea.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Why the bearings pulley-sleeves? May 14, 2016 06:46AM |

Registered: 9 years ago Posts: 1,035 |

That's easy enough. My original (http://www.thingiverse.com/thing:1369402) has the 608 spacing between belts.

They are actually the same thing in my design, just that the fixed one I export in the STL and it gets glued by the repairing service

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

They are actually the same thing in my design, just that the fixed one I export in the STL and it gets glued by the repairing service

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? May 14, 2016 06:51AM |

Registered: 8 years ago Posts: 3,525 |

That's good, the black one I printed that I posted as a make on thingiverse, the belts can be directly fixed rather than going around the clips so that works. I've designed a flex3drive mount to fit onto this carriage I'll post it if it works. Also I move the top hole for the extruder mount downwards (see the one I made) as where you have it now does not allow any adjustment of the extruder bracket height.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Why the bearings pulley-sleeves? May 14, 2016 07:10AM |

Registered: 9 years ago Posts: 1,035 |

I have adjustability through the hotends mount itself and my newest design (not yet posted, i think), can even take it on/off easily by just unscrewing a couple threads on the bolts. But I have so many things to design/redesign constantly it's overwhelming

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Why the bearings pulley-sleeves? May 15, 2016 12:36PM |

Registered: 9 years ago Posts: 1,035 |

Quote

DjDemonD

That's good, the black one I printed that I posted as a make on thingiverse, the belts can be directly fixed rather than going around the clips so that works. I've designed a flex3drive mount to fit onto this carriage I'll post it if it works. Also I move the top hole for the extruder mount downwards (see the one I made) as where you have it now does not allow any adjustment of the extruder bracket height.

Let's continue discussing this matter at the other thread, which is actually about the SCOUTcorexy X carriage... (http://forums.reprap.org/read.php?344,654822)

This way I have them all in one thread.

Thanks.

Edited 1 time(s). Last edit at 05/15/2016 12:36PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.