Bit of speed testing

Posted by DjDemonD

|

Bit of speed testing June 01, 2016 07:04AM |

Registered: 8 years ago Posts: 3,525 |

So a lot of people ask how fast these printers are. I've haven't really tried to see how fast until now but here are is a video of a bit of a test.

[onedrive.live.com]

At the beginning the speed starts at 130% on the LCD, and goes up in 20-30% increments to 300%, which I estimate is around 150-175mm/s

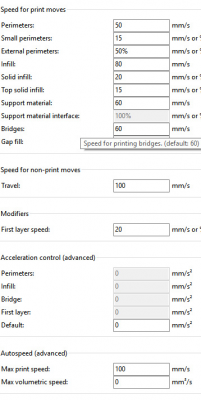

Its a smartrapcore alu enlarged to 300x200, flex3drive extruder, 1.75mm PLA at 200 deg C bed at 65 deg C, e3d v5 hotend. I am using slic3r speed settings are:

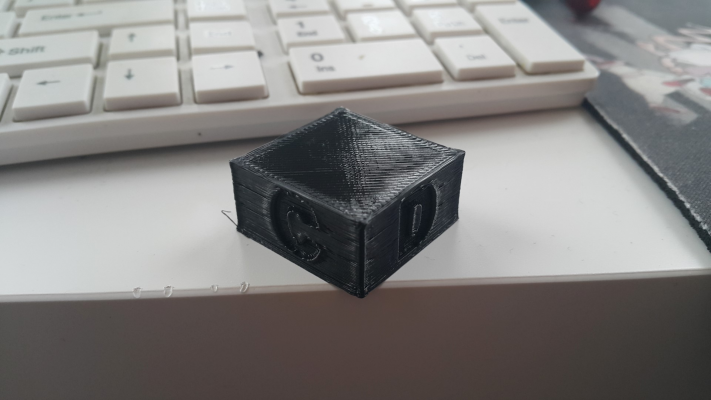

The resulting cube certainly isnt perfect, but I had no idea this machine would quite happily print at this speed. The only thing slowing it down is the retraction which is a bit slower with the flex3drive, but on the converse its the super light print head that facilitates the high speed. I suspect a bowden setup would be no quicker to retract but have much less precise filament placement.

Edited 2 time(s). Last edit at 06/01/2016 07:37AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

[onedrive.live.com]

At the beginning the speed starts at 130% on the LCD, and goes up in 20-30% increments to 300%, which I estimate is around 150-175mm/s

Its a smartrapcore alu enlarged to 300x200, flex3drive extruder, 1.75mm PLA at 200 deg C bed at 65 deg C, e3d v5 hotend. I am using slic3r speed settings are:

The resulting cube certainly isnt perfect, but I had no idea this machine would quite happily print at this speed. The only thing slowing it down is the retraction which is a bit slower with the flex3drive, but on the converse its the super light print head that facilitates the high speed. I suspect a bowden setup would be no quicker to retract but have much less precise filament placement.

Edited 2 time(s). Last edit at 06/01/2016 07:37AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 01, 2016 04:07PM |

Registered: 7 years ago Posts: 558 |

Mine is still the standard 200x200, but attach your STL file for the cube and I'll give it a try. Mine has the E3d V6 hotend and the stock motors at the current moment and I'd be interested to see what it looked like with your slic3r setup. When mine goes "chunk" on a travel move, I think its trying to achieve 130mm/s which was what default slic3r configuration is, but noticing your 100mm/s might be doable without the chunk.

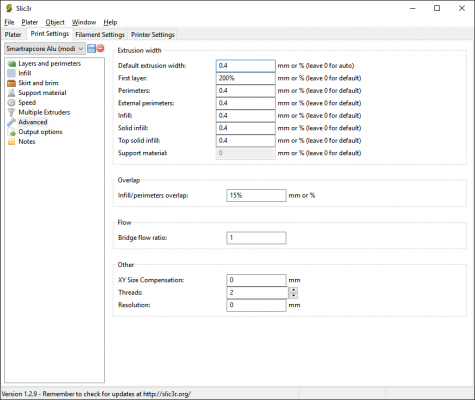

One other question though, in your slic3r config, did you do anything with the advanced tabs with regards to extrusion width? When I run a few test plates that are supposed to have 3mm, 4mm, and 5mm holes they don't quite measure up but come in around 2.8mm, 3.8, and 4.6mm roughly. Ofcourse, I'm still wondering if the sizes are correct in the test plates as when I draw the 20x20 empty box with 0.5mm wall thickness, it comes out exactly 20x20 with a 0.5 wall thickness, of which cura won't even slice.

One other question though, in your slic3r config, did you do anything with the advanced tabs with regards to extrusion width? When I run a few test plates that are supposed to have 3mm, 4mm, and 5mm holes they don't quite measure up but come in around 2.8mm, 3.8, and 4.6mm roughly. Ofcourse, I'm still wondering if the sizes are correct in the test plates as when I draw the 20x20 empty box with 0.5mm wall thickness, it comes out exactly 20x20 with a 0.5 wall thickness, of which cura won't even slice.

|

Re: Bit of speed testing June 01, 2016 05:25PM |

Registered: 8 years ago Posts: 3,525 |

I'll try the box for sure. The cube I did above - if you print it 45 deg rotated around z it can be used to check belt tension by measuring sides a versus b. I printed it sacled up by 150% so its 30mm x 30mm x 15mm.

The only one I adjust is the first layer and set it to 100% otherwise I get a very piled-up first layer which actually sticks less well rather than better.

Edited 1 time(s). Last edit at 06/01/2016 05:41PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The only one I adjust is the first layer and set it to 100% otherwise I get a very piled-up first layer which actually sticks less well rather than better.

Edited 1 time(s). Last edit at 06/01/2016 05:41PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 01, 2016 06:28PM |

Registered: 8 years ago Posts: 3,525 |

Well that cube prints 20.00 x 20.06 mm with 0.66mm wall thickness. I am using a 0.4 nozzle.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 01, 2016 08:47PM |

Registered: 7 years ago Posts: 558 |

I too am using a 0.4 nozzle. Just out of curiosity, if you go into your slicer config and on the print settings tab under advanced, set all your extrusion widths to 0.4 and see if its any different when it prints. Nice part with the 20x20 empty box, its very little plastic and very quick to print.

I've heard there are some other issues with a corexy that's not square, which might produce slightly skewed parts which could also explain the 20.06mm and 0.6mm dimensions.

Edited 1 time(s). Last edit at 06/01/2016 10:27PM by PDBeal.

I've heard there are some other issues with a corexy that's not square, which might produce slightly skewed parts which could also explain the 20.06mm and 0.6mm dimensions.

Edited 1 time(s). Last edit at 06/01/2016 10:27PM by PDBeal.

|

Re: Bit of speed testing June 02, 2016 06:10AM |

Registered: 8 years ago Posts: 3,525 |

Well to be fair I'd take 20.06 as good enough, but I'd like to experiment with that extrusion width to see if I can get it to come out closer to the actual size of the part.

To be honest I am partially through switching to simplfy3d, it is a much better slicer than slic3r or cura but I am very comfortable in slic3r and still finding my feet with simplify.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

To be honest I am partially through switching to simplfy3d, it is a much better slicer than slic3r or cura but I am very comfortable in slic3r and still finding my feet with simplify.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 02, 2016 10:41AM |

Registered: 7 years ago Posts: 558 |

I've wondered about Simplify3d, but not ready to jump in the $149 game for something I can't try out first especially while I'm still dialing in my machine setup. You think it is worth it?

It talks about dual extrusion support, but any chance it also supports the kraken? My ultimate goal would be to build a printer that can print 450 x 450 x 700 and use the kraken with 3 colors and 1 dissoluble support material. The dissoluble support material I think is well worth it with a dedicated nozzle for a 3d printer. We have a Stratasys uPrint SE Plus at my place of work that uses a dissoluble support material, and although this machine has very expensive material costs, its an idiot proof 3D printer and can print the impossible with the support material setup within it's given build size.

It talks about dual extrusion support, but any chance it also supports the kraken? My ultimate goal would be to build a printer that can print 450 x 450 x 700 and use the kraken with 3 colors and 1 dissoluble support material. The dissoluble support material I think is well worth it with a dedicated nozzle for a 3d printer. We have a Stratasys uPrint SE Plus at my place of work that uses a dissoluble support material, and although this machine has very expensive material costs, its an idiot proof 3D printer and can print the impossible with the support material setup within it's given build size.

|

Re: Bit of speed testing June 02, 2016 05:21PM |

Registered: 8 years ago Posts: 3,525 |

I'd say S3D is much more capable than Slic3r or Cura, and its faster, much faster. The name is quite ironic as its anything but simple. However I've only just started to use it so am nowhere near as familiar as I am with slic3r.

Don't know anything about dual extrusion, never tried it. I love the ideal of soluble support material but the levelling and controlling of two nozzles let alone 4 sounds like a headache in the making. I would be tempted with a dual filament-single nozzle approach for multicoloured prints possibly.

One odd thing with S3D though is that you set it up for a certain machine and this controls the display of the virtual build area you see on screen, but nowhere does it seem to cater for those with several different printers. I suppose I could have 2 logins on windows and install it on each with different printer settings. I suspect anyone reading this who does know how to use it will quickly tell me how to do it more easily (fingers crossed).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Don't know anything about dual extrusion, never tried it. I love the ideal of soluble support material but the levelling and controlling of two nozzles let alone 4 sounds like a headache in the making. I would be tempted with a dual filament-single nozzle approach for multicoloured prints possibly.

One odd thing with S3D though is that you set it up for a certain machine and this controls the display of the virtual build area you see on screen, but nowhere does it seem to cater for those with several different printers. I suppose I could have 2 logins on windows and install it on each with different printer settings. I suspect anyone reading this who does know how to use it will quickly tell me how to do it more easily (fingers crossed).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 03, 2016 06:22PM |

Registered: 8 years ago Posts: 3,525 |

Tried your cube again, 20.01 x 20.03 so fairly happy with that. Wall thickness came out 0.48mm with slic3r set up as you showed above with extrusion width set to 0.4 for everything. This fits with my understanding that for a 0.4mm nozzle the default extrusion width is often 0.48 (this is what S3D uses as its default extrusion width for this nozzle size). Interestingly S3D wouldn't slice it at all, but this might be that I haven't quite got it setup right yet.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Bit of speed testing June 06, 2016 09:19AM |

Registered: 7 years ago Posts: 558 |

One thing to note, I upgraded the Arduino Mega / Ramps / 4x20 LCD boards to a Duet with PanelDue 7". With the base motors, the Duet is able to achieve higher travel speeds with ease, no grinding, no missed steps, no chunking. I'm not sure I'd go faster while extruding, but it is interesting even travel moves are speed limited by the 8-bot processing of the Arduino Mega.

And the PanelDue is miles beyond the 4x20 LCD on the Mega.

Although this being said, I'm not sure I'd buy another Duet as I really don't like the integrated stepper drivers in the board and then the lack of heat sinks supplied or attached to the board is a small let down especially based on the price, but it is promising with the expansion board.

And the PanelDue is miles beyond the 4x20 LCD on the Mega.

Although this being said, I'm not sure I'd buy another Duet as I really don't like the integrated stepper drivers in the board and then the lack of heat sinks supplied or attached to the board is a small let down especially based on the price, but it is promising with the expansion board.

|

Re: Bit of speed testing June 11, 2016 08:04AM |

Registered: 8 years ago Posts: 3,525 |

This video is another high speed print, this time the HODOR door stop (lol) - [www.thingiverse.com].

VIDEO - [onedrive.live.com]

This is printing in ABS, at 100 mm/s perimeters, 50 mm/s external perimeters, and 160mm/s infill, shown here laying down 3d honeycomb.

This is the final object:

Which has large steps on the surface, this is not an artefact.

Which took 50 minutes to print and is 100x25x18mm.

And all running off the much maligned but still quite capable Ramps 1.4 controller board.

Edited 1 time(s). Last edit at 06/11/2016 02:21PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

VIDEO - [onedrive.live.com]

This is printing in ABS, at 100 mm/s perimeters, 50 mm/s external perimeters, and 160mm/s infill, shown here laying down 3d honeycomb.

This is the final object:

Which has large steps on the surface, this is not an artefact.

Which took 50 minutes to print and is 100x25x18mm.

And all running off the much maligned but still quite capable Ramps 1.4 controller board.

Edited 1 time(s). Last edit at 06/11/2016 02:21PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.