Home

>

Safety & Best Practices

>

Topic

Effectiveness of cardboard fume hood?

Posted by qrp-gaijin

|

Effectiveness of cardboard fume hood? July 03, 2021 12:29AM |

Registered: 3 years ago Posts: 93 |

I print in PLA and was thinking of building a simple fume hood from a large corrugated cardboard box. It would look similar to this:

[www.stlfinder.com]

The box would sealed on all sides (except the bottom) with duct tape. The bottom of the box would be open. The box would then be lowered down from above to cover the printer. A hole in the top of the box would accommodate the fan, which would draw air out of the box and into a duct that would be vented to a window. The bottom of the box would not be sealed, but would simply be resting on the table supporting the printer. This would leave some small gaps between the table surface and the bottom edge of the box. The fan should be powerful enough to create negative pressure inside the box so that air only flows in through the gaps, and never out.

I would also plan to cut a viewing window into in one side of the box, and use duct tape to affix plexiglass or similar to allow viewing the interior contents during printing.

My main question is: Would a cardboard fume hood be effective at preventing fumes from escaping into the room? Or does a more "airtight" material need to be used?

[www.stlfinder.com]

The box would sealed on all sides (except the bottom) with duct tape. The bottom of the box would be open. The box would then be lowered down from above to cover the printer. A hole in the top of the box would accommodate the fan, which would draw air out of the box and into a duct that would be vented to a window. The bottom of the box would not be sealed, but would simply be resting on the table supporting the printer. This would leave some small gaps between the table surface and the bottom edge of the box. The fan should be powerful enough to create negative pressure inside the box so that air only flows in through the gaps, and never out.

I would also plan to cut a viewing window into in one side of the box, and use duct tape to affix plexiglass or similar to allow viewing the interior contents during printing.

My main question is: Would a cardboard fume hood be effective at preventing fumes from escaping into the room? Or does a more "airtight" material need to be used?

|

Re: Effectiveness of cardboard fume hood? July 03, 2021 02:27AM |

Registered: 10 years ago Posts: 14,672 |

If you would be satisfied with extracting 95% of fumes then I expect that design can be made to work. If you want to extract 99.99% of fumes then you will need something better.

Most people don't worry about fumes generated while printing PLA. ABS is worse.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Most people don't worry about fumes generated while printing PLA. ABS is worse.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Effectiveness of cardboard fume hood? July 03, 2021 02:47AM |

Registered: 3 years ago Posts: 93 |

Quote

dc42

If you would be satisfied with extracting 95% of fumes then I expect that design can be made to work. If you want to extract 99.99% of fumes then you will need something better.

Thanks for the reply... I'm heading out to the hardware store now to scope out what materials are available. What do you see as the weaknesses (that account for the approximately 4.99% difference in fume extraction) of my proposed design vs. something better?

Is it the porosity of the cardboard that allows the fumes to escape? If so, then a simple improvement would be to use a non-porous material -- for example, using 5 pieces of plexiglass, duct-taped together to make a cube with an open bottom.

Or, is it the gaps at the bottom of the enclosure that allow the fumes to escape? If so, then would it work to temporarily use duct-tape to "completely" seal the box when printing (e.g. applying tape along the entire length of the bottom perimeter of the box, to form a seal between the box's lower edge and the work table)? Then, the box would be "almost completely" sealed, and the fan would theoretically create a rather large negative pressure inside the box, further minimizing the chances of fumes leaking out.

Quote

dc42

Most people don't worry about fumes generated while printing PLA. ABS is worse.

True, and I plan to stay with PLA. But I'd prefer to do something rather than nothing about the fumes.

Thanks again for your advice.

|

Re: Effectiveness of cardboard fume hood? July 03, 2021 04:42AM |

Admin Registered: 16 years ago Posts: 13,886 |

... the "effectiveness" is mostly due the venting system - the ventilator in your image isn't really capable of high volumes ... in my laser-fume-absorber is a jet-turbine with much more power - so maybe better look for a stronger ventilator ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Effectiveness of cardboard fume hood? August 05, 2021 08:21PM |

Registered: 3 years ago Posts: 93 |

It seems this soft/collapsible enclosure (reportedly made of "vinyl"), with a zipper-sealed flap for the access door, can sufficiently seal the enclosure, such that a fan can then generate enough negative pressure to prevent interior fumes from being detectable outside the enclosure.

[www.amazon.com]

A review for that enclosure states:

For myself, my plan now is to use a taped-up cardboard box with the front face cut out. Then, I will tape a transparent vinyl sheet on the open front face of the cardboard box, cut seam in the vinyl creating a flap for the door, and use hot melt glue to attach a zipper to the seam, allowing closing of the flap and the creation of negative pressure when the fan is activated. My main concern at this point is whether the generated negative pressure will be so much as to collapse the cardboard box, in which case additional structural bracing will be needed.

[www.amazon.com]

A review for that enclosure states:

Quote

This couldn't have gone better. I needed an enclosure for my CR-10V2 to print some nylon. Ended up using the tube out the back and a printed tube to fit a 30x10mm fan for venting....out a flexible dryer tube and a drier window vent. Worked beautifully. Just enough negative pressure to slowly concave the vinyl sides but not move enough air to cool the part. Over a dozen 20hour prints of nylon and polycarbonate inside the house and we never smelled a thing.

For myself, my plan now is to use a taped-up cardboard box with the front face cut out. Then, I will tape a transparent vinyl sheet on the open front face of the cardboard box, cut seam in the vinyl creating a flap for the door, and use hot melt glue to attach a zipper to the seam, allowing closing of the flap and the creation of negative pressure when the fan is activated. My main concern at this point is whether the generated negative pressure will be so much as to collapse the cardboard box, in which case additional structural bracing will be needed.

|

Re: Effectiveness of cardboard fume hood? August 07, 2021 12:09PM |

Registered: 3 years ago Posts: 93 |

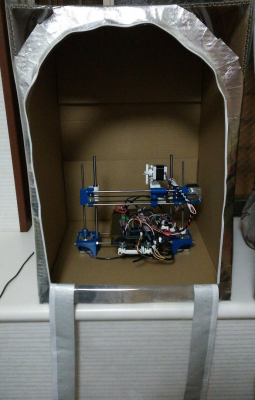

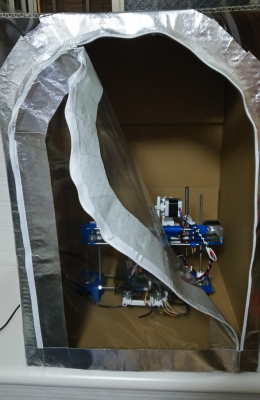

Here's how my work-in-progress cardboard box enclosure looks now. I am using a plastic sheet, with a cut-out flap door, as the front face of the open cardboard box. The plastic sheet is a 0.2 mm-thick plastic table covering, with a long zipper taped to it along a curve. It was a bit of a pain to route the zipper along the curve, since it doesn't want to bend along such a flat curve while being forced to lie in the plane of the plastic sheet. The zipper is held in place just with duct tape, which may be prone to loosening over time.

Next steps are figuring out the details of ventilation (air intake, air outlet, ducting, and duct fan).

Next steps are figuring out the details of ventilation (air intake, air outlet, ducting, and duct fan).

|

Re: Effectiveness of cardboard fume hood? August 07, 2021 12:41PM |

Admin Registered: 16 years ago Posts: 13,886 |

... not too bad!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Effectiveness of cardboard fume hood? September 12, 2021 04:09AM |

Registered: 3 years ago Posts: 93 |

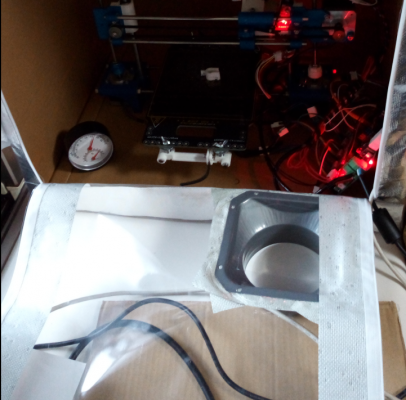

It's finished! It's not an exactly example of superb engineering, but it hopefully can serve as a reference on how this kind of vented enclosure can be built easily and at low cost with cardboard, duct tape, plastic sheet, and other simple materials. Here's how it looks.

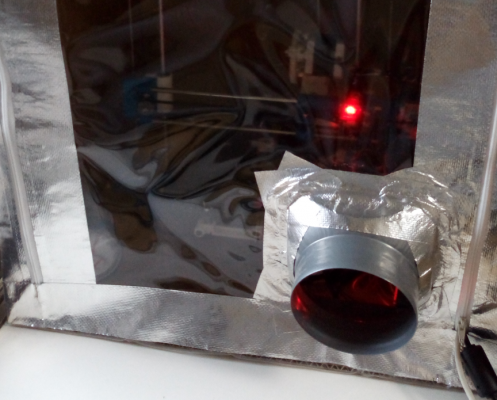

The transparent plastic sheet and the zippered door were already described above. Next, I cut a small hole in the plastic door, and used duct-tape to affix a metal duct connector on top of the hole. The duct tape I am using is somewhat flexible to allow stretching around oddly-shaped curves, and was specifically recommended for duct work.

When the duct hose is not attached, the enclosure's door can still be opened with the zipper as normal, allowing easy access to the interior for removing prints, loading filament, or removing the printer entirely from the enclosure for maintenance. The unconnected duct connector simply lies flat on the table.

When the door is zipped shut, the duct connector is held in a vertical position by the plastic sheet, which has now been drawn taut by closing the zipper. In this condition, the duct hose can then be slipped onto the duct connector. I am simply using a friction fit, without a hose clamp, to allow for easy connecting and disconnecting of the duct hose. During my first trial run, the friction fit seemed tight enough to avoid any smell of PLA leaking out into the room during a print.

Two cables -- the power cable and the USB control cable -- exit from the interior of the enclosure. These are routed out of the enclosure at the location where the zipper closes, and the zipper is zipped tight against the exiting cables to form a tight seal.

The other end of the duct is permanently duct-taped to a small inline duct fan, which in turn is permanently duct-taped to another duct connector, which in turn is permanently duct-taped to a long cardboard shim, against which the window, venting to the outside, is closed. The edges cardboard shim are lined with adhesive-backed weatherproofing foam in an attempt to increase the air-tightness of the fit against the window. The exterior side of the cardboard shim is covered with plastic tape to protect somewhat against light rainfall.

When not in use, the entire shim assembly (cardboard shim + duct connector + duct fan + duct hose) can be dismounted from the window in seconds for storage.

There is a small issue that with the window being closed against the shim, and with the window hence not in its fully-closed condition, there is an air gap between the sliding and the stationary part of the window, from which outside air can again enter the room. This can be solved with some kind of foam or other insulation.

Filament is fed into the box from the top, through a tiny hole in the cardboard. This hole should be small enough to prevent loss of negative pressure, hence maintaining the desired flow of air only out through the duct hose, and not out through the filament hole. It might be a good idea to attach a piece of foam on top of the filament hole for two reasons: (1) to further reduce airflow through the hole and (2) to clean the filament of dust as it is pulled into the box by the printer.

The "spool holder" is an improvised affair made from a rolled-up piece of cardboard serving as the spindle, which rests on two wedge-shaped supports. Each wedge-shaped support is made from a wide piece of cardboard (wide for stability) bent into a triangular prism, with V-shaped notches cut into the apex of the prism on which the spindle can rest.

It's not perfect, but it seems good enough to remove the smell of PLA.

The transparent plastic sheet and the zippered door were already described above. Next, I cut a small hole in the plastic door, and used duct-tape to affix a metal duct connector on top of the hole. The duct tape I am using is somewhat flexible to allow stretching around oddly-shaped curves, and was specifically recommended for duct work.

When the duct hose is not attached, the enclosure's door can still be opened with the zipper as normal, allowing easy access to the interior for removing prints, loading filament, or removing the printer entirely from the enclosure for maintenance. The unconnected duct connector simply lies flat on the table.

When the door is zipped shut, the duct connector is held in a vertical position by the plastic sheet, which has now been drawn taut by closing the zipper. In this condition, the duct hose can then be slipped onto the duct connector. I am simply using a friction fit, without a hose clamp, to allow for easy connecting and disconnecting of the duct hose. During my first trial run, the friction fit seemed tight enough to avoid any smell of PLA leaking out into the room during a print.

Two cables -- the power cable and the USB control cable -- exit from the interior of the enclosure. These are routed out of the enclosure at the location where the zipper closes, and the zipper is zipped tight against the exiting cables to form a tight seal.

The other end of the duct is permanently duct-taped to a small inline duct fan, which in turn is permanently duct-taped to another duct connector, which in turn is permanently duct-taped to a long cardboard shim, against which the window, venting to the outside, is closed. The edges cardboard shim are lined with adhesive-backed weatherproofing foam in an attempt to increase the air-tightness of the fit against the window. The exterior side of the cardboard shim is covered with plastic tape to protect somewhat against light rainfall.

When not in use, the entire shim assembly (cardboard shim + duct connector + duct fan + duct hose) can be dismounted from the window in seconds for storage.

There is a small issue that with the window being closed against the shim, and with the window hence not in its fully-closed condition, there is an air gap between the sliding and the stationary part of the window, from which outside air can again enter the room. This can be solved with some kind of foam or other insulation.

Filament is fed into the box from the top, through a tiny hole in the cardboard. This hole should be small enough to prevent loss of negative pressure, hence maintaining the desired flow of air only out through the duct hose, and not out through the filament hole. It might be a good idea to attach a piece of foam on top of the filament hole for two reasons: (1) to further reduce airflow through the hole and (2) to clean the filament of dust as it is pulled into the box by the printer.

The "spool holder" is an improvised affair made from a rolled-up piece of cardboard serving as the spindle, which rests on two wedge-shaped supports. Each wedge-shaped support is made from a wide piece of cardboard (wide for stability) bent into a triangular prism, with V-shaped notches cut into the apex of the prism on which the spindle can rest.

It's not perfect, but it seems good enough to remove the smell of PLA.

|

Re: Effectiveness of cardboard fume hood? September 17, 2021 09:07AM |

Registered: 3 years ago Posts: 93 |

One problem I noticed is that after a print, opening the box gives a strong smell of PLA. I am pretty sure what is happening is that the poor suction of the duct fan is only pulling air out of the bottom of the box (where the vent hole is located), but fumes from the top of the box rise and stay stagnant at the top without being sucked down to the bottom vent hole due to insufficient suction.

The easy solution I think is to add another small fan in the top corner of the interior of the box, to circulate the air inside the box so that no stagnant areas form and so that all air in the box will eventually be vented out of the vent hole, through the duct, and out the window.

The easy solution I think is to add another small fan in the top corner of the interior of the box, to circulate the air inside the box so that no stagnant areas form and so that all air in the box will eventually be vented out of the vent hole, through the duct, and out the window.

|

Re: Effectiveness of cardboard fume hood? October 03, 2021 11:07AM |

Registered: 3 years ago Posts: 93 |

Another problem I'm noticing with the ventilated enclosure is an increased tendency for corner lifting on my PLA prints, with a heated bed at 42 degrees C. My understanding is that if upper layers cool too quickly, they contract, thus pulling the corners up.

So two approaches to remove the temperature differences between the layers would be: (1) stop using the heated bed, so that the entire print cools down to ambient temperature at the same rate, or (2) continue using the heated bed, but stop or reduce the ventilation fan's usage at the beginning of the print to prevent heat from escaping and prevent the first few layers from cooling too quickly.

Any comments on if my understanding and approaches have merit?

So two approaches to remove the temperature differences between the layers would be: (1) stop using the heated bed, so that the entire print cools down to ambient temperature at the same rate, or (2) continue using the heated bed, but stop or reduce the ventilation fan's usage at the beginning of the print to prevent heat from escaping and prevent the first few layers from cooling too quickly.

Any comments on if my understanding and approaches have merit?

|

Re: Effectiveness of cardboard fume hood? October 27, 2021 11:27AM |

Registered: 3 years ago Posts: 92 |

I'd recommend keeping the fan off during printing. In my early days of printing I had all sorts of trouble with cooling shrinkage due to convection with the room air, especially with the printer sitting on the floor where cold air sinks to. Much better in an enclosure with stagnant air.

Try 60C bed temperature for PLA. Prints should stick to the bare glass, and pop off like magic when cool. Keep the glass clean. Wash with soap and water now and then. Print with a 2-3mm brim so sharp corners don't peel up. Often there will be a small divot in the underside of the print where the corner itself did curl, but the brim is thin enough to flex and remain stuck down so the curling doesn't progress. There are certain situations where a corner can be stressed enough that a spot of glue stick is necessary to hold it down. Best not to glue stick the whole print or you may never get it off the glass.

Try 60C bed temperature for PLA. Prints should stick to the bare glass, and pop off like magic when cool. Keep the glass clean. Wash with soap and water now and then. Print with a 2-3mm brim so sharp corners don't peel up. Often there will be a small divot in the underside of the print where the corner itself did curl, but the brim is thin enough to flex and remain stuck down so the curling doesn't progress. There are certain situations where a corner can be stressed enough that a spot of glue stick is necessary to hold it down. Best not to glue stick the whole print or you may never get it off the glass.

Sorry, only registered users may post in this forum.