Belt configuration

Posted by jtoombs

|

Belt configuration December 15, 2014 11:16AM |

Registered: 10 years ago Posts: 102 |

Hello. I have been designing a Core XY machine but have come to a problem. I can't decide on what type of permanent idler pulley setup to use. By this I mean I have seen some pulleys mounted on the same axis of rotation like this

or on close to the same plane like this.

The pulleys on the same axis of rotation seems simpler than on different axes but it also seems like a point of high stress when the belts are properly tensioned. The belt having that much more of a lever arm seems like it would tend to bent the shaft or break the part the pulleys were mounted to. I am just wondering what is the more commonly used option? Also, is there a way to do it so that the belts and pulleys can be on the same plane? I am just looking for advice from a builder who has experience with Core XY setups.

Thanks

JTT

or on close to the same plane like this.

The pulleys on the same axis of rotation seems simpler than on different axes but it also seems like a point of high stress when the belts are properly tensioned. The belt having that much more of a lever arm seems like it would tend to bent the shaft or break the part the pulleys were mounted to. I am just wondering what is the more commonly used option? Also, is there a way to do it so that the belts and pulleys can be on the same plane? I am just looking for advice from a builder who has experience with Core XY setups.

Thanks

JTT

|

Re: Belt configuration December 15, 2014 12:55PM |

Registered: 10 years ago Posts: 105 |

I designed mine such that they were in the same X-Y alignment, but turned one motor upside down. That way it was symmetrical and each pulley takes on the same amount of lever force.

Edited 1 time(s). Last edit at 12/15/2014 12:58PM by runninfarmer.

Edited 1 time(s). Last edit at 12/15/2014 12:58PM by runninfarmer.

|

Re: Belt configuration December 15, 2014 03:42PM |

Registered: 14 years ago Posts: 128 |

On my Openbeam COREXY, I attached my bearings/pulleys using the block arrangement as per attached picture. Used model helicopter bearings; 10mm (outside dia) x 5mm (inside dia) x 4mm (width), sourced via Ebay.

Block arrangement gives solid non-twisting but also you can slide them about for fine alignment adjustments. You just have to make sure the bearings are position right before doing up the holding screws.

I used 6 mm steel shafts and turned down the ends to 5mm on my mini lathe. Blocks are 30mm long x 15mm high. I machined my blocks from some 10mm think polycarbonate sheet that I had.

Like your work.......

Block arrangement gives solid non-twisting but also you can slide them about for fine alignment adjustments. You just have to make sure the bearings are position right before doing up the holding screws.

I used 6 mm steel shafts and turned down the ends to 5mm on my mini lathe. Blocks are 30mm long x 15mm high. I machined my blocks from some 10mm think polycarbonate sheet that I had.

Like your work.......

|

Re: Belt configuration December 16, 2014 10:23AM |

Registered: 10 years ago Posts: 344 |

Or like this, belts are not crossing anywere.

|

Re: Belt configuration December 17, 2014 01:55PM |

Registered: 10 years ago Posts: 102 |

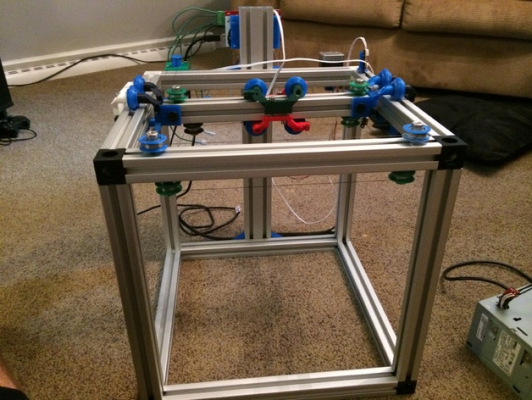

I think after browsing around for long enough I have decided to support the pulleys from top and bottom similar to this machine I found on thingiverse:

My design (I guess I can't really call it my design since it's just a compilation of a bunch of designs I found on thingiverse and elsewhere) is pretty much the same as this except I will be using NEMA 23's for everything but the extruder.

Attached is a render of the top of my machine. I can't really draw the belt path very easily but it's the same as the picture from thingiverse.

JTT

My design (I guess I can't really call it my design since it's just a compilation of a bunch of designs I found on thingiverse and elsewhere) is pretty much the same as this except I will be using NEMA 23's for everything but the extruder.

Attached is a render of the top of my machine. I can't really draw the belt path very easily but it's the same as the picture from thingiverse.

JTT

|

Re: Belt configuration December 24, 2014 06:33PM |

Registered: 9 years ago Posts: 11 |

|

Re: Belt configuration December 26, 2014 10:05AM |

Registered: 10 years ago Posts: 344 |

|

Re: Belt configuration December 29, 2014 01:40PM |

Registered: 9 years ago Posts: 11 |

Quote

gforce1

Thanks. I am still building, waiting for bearings.Quote

Rectangled

@gforce1 I really like that belt configuration and I was contemplating using it. Does it actually work?

I can move everything by hand and it works sofar.

Sweet, any pictures? Or updated CAD? How did you execute the stacked idlers?

|

Re: Belt configuration December 30, 2014 05:18PM |

Registered: 10 years ago Posts: 344 |

It is based on this one: [forums.reprap.org]

I just changed some parts for a " nicer" belt configuration.

I have printed some testbearings to see if it works. And it does.

I don't have any pictures yet.

I just changed some parts for a " nicer" belt configuration.

I have printed some testbearings to see if it works. And it does.

I don't have any pictures yet.

|

Re: Belt configuration January 01, 2015 09:46AM |

Registered: 10 years ago Posts: 344 |

Idler is stacked like this: there are two pairs of f695 bearings seperated by M5 washers.

It is fixed in the aluminum extrusion by a M5 socket-head screw.

It is fixed in the aluminum extrusion by a M5 socket-head screw.

|

Re: Belt configuration January 13, 2015 04:12AM |

Registered: 9 years ago Posts: 56 |

@gforce1 : did you go further in your build ? That belt setup is very nice !

About pulleys, i plan to use RC helicopter belt tensioner pulleys (mainly because they are rock-solid, they are cheap (well, as cheap as a bearing-pulley can be).

About pulleys, i plan to use RC helicopter belt tensioner pulleys (mainly because they are rock-solid, they are cheap (well, as cheap as a bearing-pulley can be).

|

Re: Belt configuration January 14, 2015 04:40PM |

Registered: 10 years ago Posts: 344 |

|

Re: Belt configuration January 17, 2015 09:32AM |

Registered: 10 years ago Posts: 344 |

Here some pics. Printer is not finished yet. I have to do some cable management etc.

Sorry, only registered users may post in this forum.