Layer displacement problem

Posted by PropellerHat

|

Layer displacement problem September 08, 2015 09:55AM |

Registered: 9 years ago Posts: 65 |

Hello

I have a quite large CoreXY-printer and I noticed there is weird behaviour when I print on the full scale of the machine. I tried to print a text consisting only the outlines of the letters. So I had several objects to build at the same time. In the center of the build area there is huge misalignment with the layers printed on opposite directions - Cura sliced the file so that every other layer is printed clock wise and every other counter clockwise. in the center of the build platform every other layer is appr 3mm different place than the others. The difference is in 45° direction so I assume it is due too long belts or something - When printing letters clockwise from left to right the belt streches "from the other side of the motors" and when coming back from right to the left and when printing CCW the belt streches the other way. I have a 9mm GT2 belt SUPER TIGHT but the problem still remains. I hope it is something else than too long belt since I have no solution for that. alltogether there is 7.5 meters of belt to move the XY. CoreXY effectively makes two loops out of the belt so basically the lenght of each loop is a bit less than 4 meters.

Could it be worth trying to reinforce the belts, like gluing another belt on the backside?

Does anybody have any other reasons that might cause the 3mm 45° offset on the layers?

Here is a pic of the first two layers to explain the problem:

[imgur.com]

Thanks for any advice!

Edited 4 time(s). Last edit at 09/08/2015 02:26PM by PropellerHat.

I have a quite large CoreXY-printer and I noticed there is weird behaviour when I print on the full scale of the machine. I tried to print a text consisting only the outlines of the letters. So I had several objects to build at the same time. In the center of the build area there is huge misalignment with the layers printed on opposite directions - Cura sliced the file so that every other layer is printed clock wise and every other counter clockwise. in the center of the build platform every other layer is appr 3mm different place than the others. The difference is in 45° direction so I assume it is due too long belts or something - When printing letters clockwise from left to right the belt streches "from the other side of the motors" and when coming back from right to the left and when printing CCW the belt streches the other way. I have a 9mm GT2 belt SUPER TIGHT but the problem still remains. I hope it is something else than too long belt since I have no solution for that. alltogether there is 7.5 meters of belt to move the XY. CoreXY effectively makes two loops out of the belt so basically the lenght of each loop is a bit less than 4 meters.

Could it be worth trying to reinforce the belts, like gluing another belt on the backside?

Does anybody have any other reasons that might cause the 3mm 45° offset on the layers?

Here is a pic of the first two layers to explain the problem:

[imgur.com]

Thanks for any advice!

Edited 4 time(s). Last edit at 09/08/2015 02:26PM by PropellerHat.

|

Re: Layer displacement problem September 08, 2015 03:21PM |

Registered: 9 years ago Posts: 346 |

Hello,

Before you spend too much time on trouble-shooting you have to clear out the basics;

1) Is your stepper drivers too hot and overheating? If the electronics gets too hot they have a thermal shutdown. A couple of missed stepped on one driver will give you what you see. Be sure to put a fan to blow fresh air on those things (especially if using RAMPS). This type of error is NOT audible.

2) Do you have enough current on your motors? Maybe your motors are skipping a step because they don't have enough power? That type of error is CLEARLY audible.

3) Is it a power problem? Try to print from SD card without the PC connected. This means the electronics will only be powered from your main power source. If it has any problems the electronics will shut down clearly showing you that you have a problem. Such an electronic problem is NOT audible.

4) Is your belt pulleys firm on the motor shaft? Imagine if your pulleys can rotate a little on the motor shaft then it does not matter how tight your belt is - It will lose steps - This will NOT be audible.

5) Is your two motors the same type? Any chance that the steps pr mm is giving you problems? Try to ask it to move 100 mm in X and Y direction and verify that it moves just that.

6) How does your printer feel? Try to feel around it all. Any crazy chance that your glass bed might be moving around? Do you have any bare wires that might occasionally touch?

Once you have covered those grounds don't hesitate to report back. Even if you solve the problem be sure to come back here and post the solution so future "googlers" may have the benefit of knowing what worked for you.

Before you spend too much time on trouble-shooting you have to clear out the basics;

1) Is your stepper drivers too hot and overheating? If the electronics gets too hot they have a thermal shutdown. A couple of missed stepped on one driver will give you what you see. Be sure to put a fan to blow fresh air on those things (especially if using RAMPS). This type of error is NOT audible.

2) Do you have enough current on your motors? Maybe your motors are skipping a step because they don't have enough power? That type of error is CLEARLY audible.

3) Is it a power problem? Try to print from SD card without the PC connected. This means the electronics will only be powered from your main power source. If it has any problems the electronics will shut down clearly showing you that you have a problem. Such an electronic problem is NOT audible.

4) Is your belt pulleys firm on the motor shaft? Imagine if your pulleys can rotate a little on the motor shaft then it does not matter how tight your belt is - It will lose steps - This will NOT be audible.

5) Is your two motors the same type? Any chance that the steps pr mm is giving you problems? Try to ask it to move 100 mm in X and Y direction and verify that it moves just that.

6) How does your printer feel? Try to feel around it all. Any crazy chance that your glass bed might be moving around? Do you have any bare wires that might occasionally touch?

Once you have covered those grounds don't hesitate to report back. Even if you solve the problem be sure to come back here and post the solution so future "googlers" may have the benefit of knowing what worked for you.

|

Re: Layer displacement problem September 09, 2015 02:07AM |

Registered: 9 years ago Posts: 65 |

Thanks for the reply.

1: No

2: Yes

3: No

4: I will tighten them up today but probably they are fine

5: Yes

6: It feels tight and nice No play in the idler pulley attachements, for example. I was hoping to find something like this that could be solved with a screw driver.

No play in the idler pulley attachements, for example. I was hoping to find something like this that could be solved with a screw driver.

The electronics stay cool all the way. I have external DM806A drivers and big Nema 23s for XYZ and the Ramps with only E-driver on it is suprisingly cool too, max 40°C when pushing hard.

The thing that counts all of those possibilities out is that the error disappears almost completely when getting back to one end of the build platform - it appears in the middle of the print area. If it would be skipped steps or loose pulley the error would not go away again, right? Instead it would continue into the very boundaries of the print, probably. I was suspecting diagonal forces on the frame due to a bit over built system but I could not measure any changes in the corner to corner distances while printing. Also the error occurs at all speeds equally, though VERY slow is yet to be tested.

Some days ago I was trying how much a 9mm GT2 actually streches when pulled by hand on the other end and the other tightened into a vice. A 4 meter strip does have noticeable stretch in the scale of a couple of millimeters with quite a little force applied onto it which is not a surprise. I am talking about that kind of forces that the belt is under in normal conditions in a printer, not too loose but not violently tight neither. In the "sensible" area of tightness it does stretch like 1-2mm per meter.

Is there belts with less strech? Like some steel wire reinforced ones or what ever Kevlar that would really stretch less than fibre glass reinforced ones? I bought my belt as a Gates belt but there is no markings of the manufacturer on the back so I suspect it to be a chinese copy. Maybe a genuine one would strech less..?

Last night I got a idea that maybe there is slight resistance in the gantry system around the middle area - maybe things move with less friction on the edges. This I have to check today but most likely the problem will remain.

If there is no solution for making the CoreXY work on this scale I have to modify the printer into the boring most traditional build where X-motor(s) are carried in the Y-gantry

1: No

2: Yes

3: No

4: I will tighten them up today but probably they are fine

5: Yes

6: It feels tight and nice

No play in the idler pulley attachements, for example. I was hoping to find something like this that could be solved with a screw driver.

No play in the idler pulley attachements, for example. I was hoping to find something like this that could be solved with a screw driver.The electronics stay cool all the way. I have external DM806A drivers and big Nema 23s for XYZ and the Ramps with only E-driver on it is suprisingly cool too, max 40°C when pushing hard.

The thing that counts all of those possibilities out is that the error disappears almost completely when getting back to one end of the build platform - it appears in the middle of the print area. If it would be skipped steps or loose pulley the error would not go away again, right? Instead it would continue into the very boundaries of the print, probably. I was suspecting diagonal forces on the frame due to a bit over built system but I could not measure any changes in the corner to corner distances while printing. Also the error occurs at all speeds equally, though VERY slow is yet to be tested.

Some days ago I was trying how much a 9mm GT2 actually streches when pulled by hand on the other end and the other tightened into a vice. A 4 meter strip does have noticeable stretch in the scale of a couple of millimeters with quite a little force applied onto it which is not a surprise. I am talking about that kind of forces that the belt is under in normal conditions in a printer, not too loose but not violently tight neither. In the "sensible" area of tightness it does stretch like 1-2mm per meter.

Is there belts with less strech? Like some steel wire reinforced ones or what ever Kevlar that would really stretch less than fibre glass reinforced ones? I bought my belt as a Gates belt but there is no markings of the manufacturer on the back so I suspect it to be a chinese copy. Maybe a genuine one would strech less..?

Last night I got a idea that maybe there is slight resistance in the gantry system around the middle area - maybe things move with less friction on the edges. This I have to check today but most likely the problem will remain.

If there is no solution for making the CoreXY work on this scale I have to modify the printer into the boring most traditional build where X-motor(s) are carried in the Y-gantry

|

Re: Layer displacement problem September 09, 2015 04:26AM |

Registered: 9 years ago Posts: 65 |

Well, now I got to tighten things in the printer and the problem DID get better indeed! One motor pulley was not completely tightened and now about half of the misalignment is gone. Maybe all the littlest play in the parts produces the rest of the problem and it just needs endless fine tuning and perfecting...

|

Re: Layer displacement problem September 09, 2015 09:21AM |

Registered: 9 years ago Posts: 4,977 |

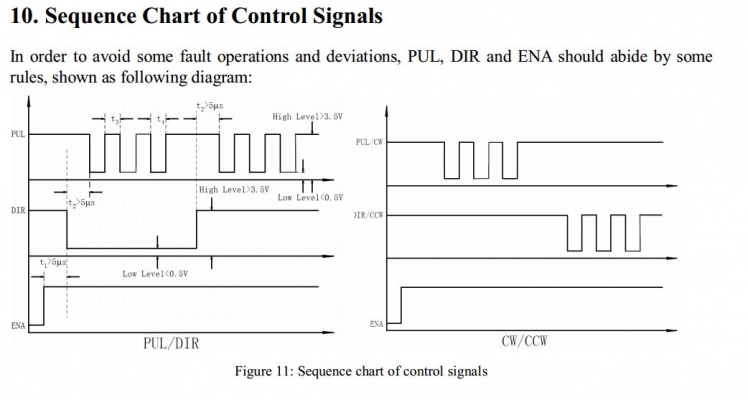

The M860A drivers need at least 5µs delay between a DIR and a STEP-signal (doesn't find any other datasheet). Which firmware do you use?

Edited 1 time(s). Last edit at 09/09/2015 09:24AM by Wurstnase.

Edited 1 time(s). Last edit at 09/09/2015 09:24AM by Wurstnase.

| Triffid Hunter's Calibration Guide | --> X <-- Drill for new Monitor | Most important Gcode. |

|

Re: Layer displacement problem September 09, 2015 01:52PM |

Registered: 9 years ago Posts: 346 |

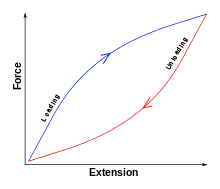

I am sorry to heat that it did not solve the entire problem. Hysteresis errors are common for belts, it is even one of the example used at the wiki page to show the concept:

For those who are a little unsure what it means - It is that a system shows one behavior while moving towards a point and a different one while returning but at the same time it returns to the 0. For elastic belts this is because the spring effect is not ideal.

That said, and as a comment to this:

I don't see the belts stretching that much. The experiment you conducted - Did you pre tension the belts first? The extra pull that your motors adds to static tension should not be enough to give anything in the mm scale pr m. I don't like putting a number to it but I feel that it will be in the 0.0x range. If you have problems with uneven walls then - yes - I would agree that it could be belt slack. But as much as in your photo or even half that - No. I don't think so.

I think good things to investigate now would be;

1) Can you manually with you hand and relatively easily move the carriage around to all points? If you have to grip your print firmly to not have it fall off the table when moving the carriage around, then something is wrong.

2) Can you try to actually SLACK one of the belts. You say you have it super tense now - Try to relax it and see what happens. If it is belt slack then this should make the displacement much worse. My guess is that it is the same.

Other then that I don't have any good inputs. I just say that looking at your picture, I just don't see it being "normal" slack in the printer / belts. Your printer is doing something that is working against you and if it sure returns perfectly to the 0 point all the time, then it is something in the setup. Firmware and slicer options is where I would look now.

For those who are a little unsure what it means - It is that a system shows one behavior while moving towards a point and a different one while returning but at the same time it returns to the 0. For elastic belts this is because the spring effect is not ideal.

That said, and as a comment to this:

Quote

PropellerHat

Some days ago I was trying how much a 9mm GT2 actually streches when pulled by hand on the other end and the other tightened into a vice. A 4 meter strip does have noticeable stretch in the scale of a couple of millimeters with quite a little force applied onto it which is not a surprise. I am talking about that kind of forces that the belt is under in normal conditions in a printer, not too loose but not violently tight neither. In the "sensible" area of tightness it does stretch like 1-2mm per meter.

I don't see the belts stretching that much. The experiment you conducted - Did you pre tension the belts first? The extra pull that your motors adds to static tension should not be enough to give anything in the mm scale pr m. I don't like putting a number to it but I feel that it will be in the 0.0x range. If you have problems with uneven walls then - yes - I would agree that it could be belt slack. But as much as in your photo or even half that - No. I don't think so.

I think good things to investigate now would be;

1) Can you manually with you hand and relatively easily move the carriage around to all points? If you have to grip your print firmly to not have it fall off the table when moving the carriage around, then something is wrong.

2) Can you try to actually SLACK one of the belts. You say you have it super tense now - Try to relax it and see what happens. If it is belt slack then this should make the displacement much worse. My guess is that it is the same.

Other then that I don't have any good inputs. I just say that looking at your picture, I just don't see it being "normal" slack in the printer / belts. Your printer is doing something that is working against you and if it sure returns perfectly to the 0 point all the time, then it is something in the setup. Firmware and slicer options is where I would look now.

|

Re: Layer displacement problem September 09, 2015 02:06PM |

Registered: 10 years ago Posts: 14,672 |

I suggest one more test. With the motors energised so that they hold position, how far can you move the carriage by hand in the X or Y direction, or diagonally, without forcing one of the motors to jump a step?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Layer displacement problem September 09, 2015 05:51PM |

Registered: 9 years ago Posts: 233 |

The error you are seeing I can re-create VERY easily by forgetting to tighten the connections that hold the x axis slide perpendicular to the 2 y axis slides... IE, a very slight bend from perpendicular in one way when the printer is moving one way, and the other way if it is moving in the opposite direction.

Core XY movement tends to hold the slides very perpendicular (or keeps the same degree lack of perpendicular that you built in...) even when the connections are not tight (it is the nature of the core XY pulley system that it keeps everything balanced with belt forces...) BUT there will be 1mm or a bit more toward the ends of the X slides if the connection is lose on my machine. This looseness becomes most apparent in print quality when Cura does its thing printing from one direction on one layer, then the other on the next layer.

The fact that there is flex from perpendicular is not readily apparent from watching it print, but you can see it if you do the flex test that dc42 recommends....especially if you "twist" the x axis by pushing one end of the x slide and pulling the other end, and then alternating the push pull... if you have some "twist" visible, you need to tighten up the connections. Having the belts tighter also reduces this as the belt force holds perpendicular (or your particular lack thereof) better the tighter the belts are.

Edited 4 time(s). Last edit at 09/09/2015 06:16PM by patrickrio.

Core XY movement tends to hold the slides very perpendicular (or keeps the same degree lack of perpendicular that you built in...) even when the connections are not tight (it is the nature of the core XY pulley system that it keeps everything balanced with belt forces...) BUT there will be 1mm or a bit more toward the ends of the X slides if the connection is lose on my machine. This looseness becomes most apparent in print quality when Cura does its thing printing from one direction on one layer, then the other on the next layer.

The fact that there is flex from perpendicular is not readily apparent from watching it print, but you can see it if you do the flex test that dc42 recommends....especially if you "twist" the x axis by pushing one end of the x slide and pulling the other end, and then alternating the push pull... if you have some "twist" visible, you need to tighten up the connections. Having the belts tighter also reduces this as the belt force holds perpendicular (or your particular lack thereof) better the tighter the belts are.

Edited 4 time(s). Last edit at 09/09/2015 06:16PM by patrickrio.

Sorry, only registered users may post in this forum.