Laser cutted CoreXY printer platform

Posted by JeanClaudeMerlot

|

Laser cutted CoreXY printer platform February 06, 2016 07:22PM |

Registered: 10 years ago Posts: 26 |

Hello Makers,

We started to develop a modular 3D-Printer platform that we want to share with you. After several years of printer usage in fablabs, we found that:

- All electronic parts have to be easily accessible

- All electronic parts have to be totally enclosed / no loose wires

- The extruder+hotend should be swappable in under 2 minutes

- should have a solid frame

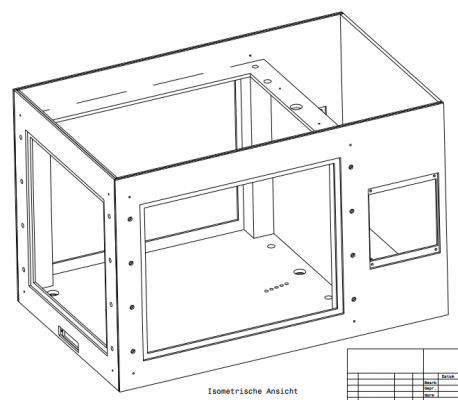

We designed a modular system that consist of:

- the frame with Z-Axis

• Laser-cutted wooden panels screwed onto 4x 272mm Bosch Rexroth 30x30mm

• slot for graphic panel

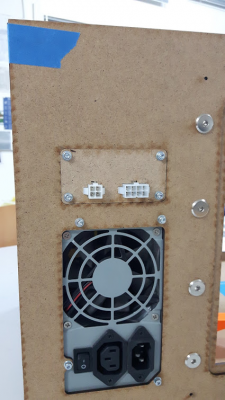

• short wiring in a closed electronic compartment with

• enclosed ATX-power supply

• easy to swap extruder with molex connector (Panel on the left)

• window ready for enclosed print-area

• Z-Axis with:

o 1220mm closed-loop GT2

o 3x either M8 or TR10x2 screws guided by

o 625 ball bearings

o 2x 10mm guides

- The xy-Kinematic-module that holds either an h-bot or a core-xy kinematic

Currently in the design phase

It will be clamped to the plate on top of the print area a connected with 3 plugs. The two steppers are less then 15cm away from the board.

Next week we will build the first frame and continue with the integration of the z-axis.

We would love to hear your ideas and inputs on the design. Maybe someone wants to join our next design-session via google hangout?

We are going to meet 11th of February at around 7pm UTC+1

Cheers

Jan

We started to develop a modular 3D-Printer platform that we want to share with you. After several years of printer usage in fablabs, we found that:

- All electronic parts have to be easily accessible

- All electronic parts have to be totally enclosed / no loose wires

- The extruder+hotend should be swappable in under 2 minutes

- should have a solid frame

We designed a modular system that consist of:

- the frame with Z-Axis

• Laser-cutted wooden panels screwed onto 4x 272mm Bosch Rexroth 30x30mm

• slot for graphic panel

• short wiring in a closed electronic compartment with

• enclosed ATX-power supply

• easy to swap extruder with molex connector (Panel on the left)

• window ready for enclosed print-area

• Z-Axis with:

o 1220mm closed-loop GT2

o 3x either M8 or TR10x2 screws guided by

o 625 ball bearings

o 2x 10mm guides

- The xy-Kinematic-module that holds either an h-bot or a core-xy kinematic

Currently in the design phase

It will be clamped to the plate on top of the print area a connected with 3 plugs. The two steppers are less then 15cm away from the board.

Next week we will build the first frame and continue with the integration of the z-axis.

We would love to hear your ideas and inputs on the design. Maybe someone wants to join our next design-session via google hangout?

We are going to meet 11th of February at around 7pm UTC+1

Cheers

Jan

|

Re: Laser cutted CoreXY printer platform February 06, 2016 08:53PM |

Registered: 11 years ago Posts: 5,780 |

The hobbyist 3D printer market used to be full of machines that had laser cut plywood frames and they have all but disappeared. Do you know why? Because plywood is a crappy material for a 3D printer frame. It will warp and delaminate over time and exposure to heat from print beds. It isn't very rigid to start and unless you retighten the screws that hold it all together every couple weeks, it just keeps getting worse over time. We have a Makerbot (of the type shown below) at the makerspace that started warping within a year.

If you want maximum versatility, enclose the build chamber and insulate to allow printing of ABS and to control fumes/smell, make sure the electronics will be outside the build chamber, use a 32 bit controller board with an easily accessible LCD control panel and SD card slot. This will put you ahead of about 90% of the printers out there.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you want maximum versatility, enclose the build chamber and insulate to allow printing of ABS and to control fumes/smell, make sure the electronics will be outside the build chamber, use a 32 bit controller board with an easily accessible LCD control panel and SD card slot. This will put you ahead of about 90% of the printers out there.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Laser cutted CoreXY printer platform February 07, 2016 04:10AM |

Registered: 10 years ago Posts: 179 |

|

Re: Laser cutted CoreXY printer platform February 07, 2016 05:57AM |

Registered: 10 years ago Posts: 26 |

Hey dentist, I know these printers. In my opinion the problem with the makerbot and ultimakers frames is, that they use tiny M3 screws and bolds, that cut into the plywood. This is why we use 4x 30x30 Bosch extrusions in the corners, to hold it all together. This gives us 32x M6 screws,secured with loctite, with a solid aluminium base. Thanks fo your input! We know there are a lot of printers out there allready and that it is hard to come up with something better. It is going to have a 32bit RADDs board. The panel is going to be on the right side.

@Edvardas: Little changes are neededds. After we verfied the design with plywood, we want to build one with 3mm waterjetted aluminium plates (inner) + 3mm pmma (outer)

@Edvardas: Little changes are neededds. After we verfied the design with plywood, we want to build one with 3mm waterjetted aluminium plates (inner) + 3mm pmma (outer)

|

Re: Laser cutted CoreXY printer platform February 10, 2016 07:06AM |

Registered: 11 years ago Posts: 1,807 |

Hi Jean Claude,

Aluminium Laser cutting in good Quality and not so expensive you can test it by:

cutworks.de

Here the Materials:

[cutworks.de]

Mein Club: [hackerspace-ffm.de]

RADDS-Shield -> Commercial [max3dshop.org]

Aluminium Laser cutting in good Quality and not so expensive you can test it by:

cutworks.de

Here the Materials:

[cutworks.de]

Mein Club: [hackerspace-ffm.de]

RADDS-Shield -> Commercial [max3dshop.org]

|

Re: Laser cutted CoreXY printer platform February 16, 2016 04:23PM |

Registered: 10 years ago Posts: 26 |

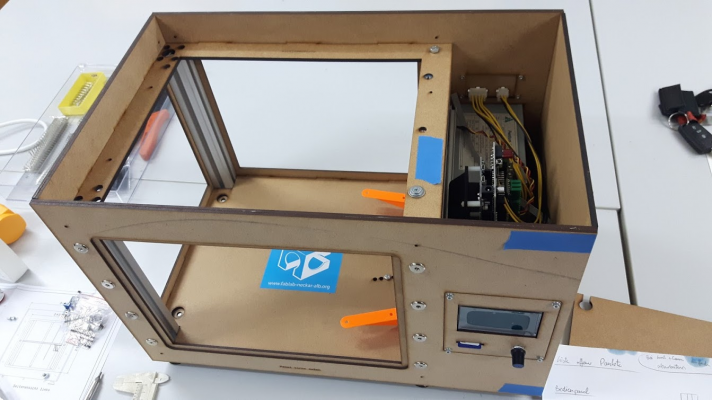

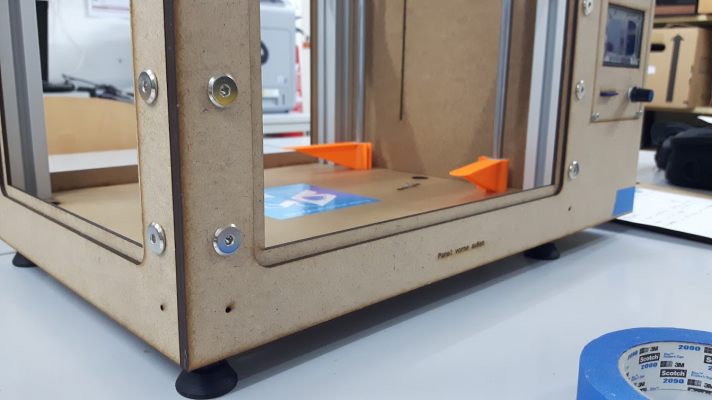

Hi Makers,

we have finished the first prototype of the frame.

The XY module sits on top and closes the frame. It holds the two steppers end stops

Arduino Due on a DIN rail with RADDS board on top.

(http://www.thingiverse.com/thing:240547)

The breakout for an easy extruder and hotend change is made with molex connectors. In this case we used ATX extension cords. They fit perfectly into a 3mm plate and cost only 2 / 2,50€ per cable.

@angelo: Danke für den Tipp! - Grüße nach Frankfurt

Cheers

Jan

Edited 1 time(s). Last edit at 02/16/2016 04:26PM by JeanClaudeMerlot.

we have finished the first prototype of the frame.

The XY module sits on top and closes the frame. It holds the two steppers end stops

Arduino Due on a DIN rail with RADDS board on top.

(http://www.thingiverse.com/thing:240547)

The breakout for an easy extruder and hotend change is made with molex connectors. In this case we used ATX extension cords. They fit perfectly into a 3mm plate and cost only 2 / 2,50€ per cable.

@angelo: Danke für den Tipp! - Grüße nach Frankfurt

Cheers

Jan

Edited 1 time(s). Last edit at 02/16/2016 04:26PM by JeanClaudeMerlot.

|

Re: Laser cutted CoreXY printer platform March 07, 2016 09:23AM |

Registered: 8 years ago Posts: 346 |

Sorry, only registered users may post in this forum.