Centering collars (3-point-steady) for smooth rods alignment?

Posted by realthor

|

Centering collars (3-point-steady) for smooth rods alignment? March 31, 2016 02:42PM |

Registered: 9 years ago Posts: 1,035 |

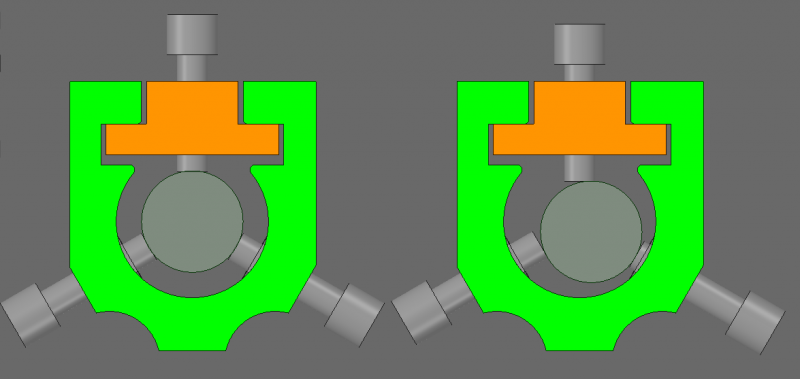

Hi I am exploring an idea of having the smooth rods ends mount designed with a larger hole than the diameter of the rod itself and then have a 3-point centering system similar to how lathes' do the centering of the part on the chuck.

I can see that I would be introducing complexity in the system and that alignment calibration would be hell albeit having the possibility to do it to perfection and, depending on how much larger the receiving hole is, can take a quite out-of-square frame and still get a square printing system.

What do you think.. is this worth any further thought? How would one go about squaring the whole thing? It's hard enough to do it with fixed ends so I am not that confident in the idea myself but before discarding it I wanted to ask around.

Edit: I've just learned that this is called a "3-point-steady" in lathe machining lingo.

Edited 8 time(s). Last edit at 03/31/2016 05:18PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I can see that I would be introducing complexity in the system and that alignment calibration would be hell albeit having the possibility to do it to perfection and, depending on how much larger the receiving hole is, can take a quite out-of-square frame and still get a square printing system.

What do you think.. is this worth any further thought? How would one go about squaring the whole thing? It's hard enough to do it with fixed ends so I am not that confident in the idea myself but before discarding it I wanted to ask around.

Edit: I've just learned that this is called a "3-point-steady" in lathe machining lingo.

Edited 8 time(s). Last edit at 03/31/2016 05:18PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? March 31, 2016 09:21PM |

Registered: 11 years ago Posts: 5,780 |

Are those parts going to be plastic or metal? If they flex when you tighten the screws you may have trouble getting the rails aligned. Whatever you make them out of, I'd bulk them up quite a lot.

I think that at one end, both rails should fit into a single piece with two holes and no adjustments. At the other end, a single piece with two holes and one of them with this 3 point adjustment would be good to allow the one rail to be brought into alignment with the other. That should work for the x and y axes, but the Z axis (in i3 type configurations) and y axis in coreXY presents a special problem.

In my printer, I made the frame as square as possible and aligned the Z axis screw assemblies to the frame. I also used a digital protractor to measure some of the angles and bring them as close together as the resolution of the instrument (0.2 degrees) would allow. Then I ran the x axis up and down the Z axis to check for smooth motion without binding (the screw assemblies have fully supported rails that are very unforgiving of misalignment because they won't flex) and made some test prints to check alignment. This worked for me because the frame is very solid. In machines with more flexible frames it may not guarantee proper alignment of the Z axis rails and screws. This is one place where a little flex may help because it makes the machine more tolerant of misalignment.

In a coreXY machine the rail alignment problem in the x axis can be eliminated completely by using a single linear guide. In the y axis the problem can be minimized the same way.

Edited 1 time(s). Last edit at 03/31/2016 09:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I think that at one end, both rails should fit into a single piece with two holes and no adjustments. At the other end, a single piece with two holes and one of them with this 3 point adjustment would be good to allow the one rail to be brought into alignment with the other. That should work for the x and y axes, but the Z axis (in i3 type configurations) and y axis in coreXY presents a special problem.

In my printer, I made the frame as square as possible and aligned the Z axis screw assemblies to the frame. I also used a digital protractor to measure some of the angles and bring them as close together as the resolution of the instrument (0.2 degrees) would allow. Then I ran the x axis up and down the Z axis to check for smooth motion without binding (the screw assemblies have fully supported rails that are very unforgiving of misalignment because they won't flex) and made some test prints to check alignment. This worked for me because the frame is very solid. In machines with more flexible frames it may not guarantee proper alignment of the Z axis rails and screws. This is one place where a little flex may help because it makes the machine more tolerant of misalignment.

In a coreXY machine the rail alignment problem in the x axis can be eliminated completely by using a single linear guide. In the y axis the problem can be minimized the same way.

Edited 1 time(s). Last edit at 03/31/2016 09:26PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? March 31, 2016 10:02PM |

Registered: 9 years ago Posts: 1,035 |

Thanks @the_digital_dentist for chiming in.

These collars are going to be plastic, but they are embedded into another piece that is larger so I don't think they will have flex. I can beef them up a bit but I don't expect the need to tighten them too hard.

I am assuming you are talking here about X in a CoreXY arrangement. I have only considered this for Y and Z in my corexy build. But it's something I will consider now that I realize only one alignment collar is needed.

Can you please explain what is the challenge on Y in a corexy?

Your above advise for X - to have two rods' ends with no adjustment bolts, I like it, at least partially. Again, I am talking for Y here, where, because the clamps for the rods' ends are at the four corners of a possible unsquare frame, they can be displaced on Z as well as on XY. So I am thinking that one of the 4 will be fixed so I can align the remaining 3 ends in relation to it to achieve the squareness of the rods in a plane parallel to the bed. I am also thinking to have the X move from one end to the other with no binding but also it has to move in a plane perfectly parallel with the bed, hence the one fixed rod's end to establish a fixed Z and all others to align to this Z.

Edited 1 time(s). Last edit at 03/31/2016 10:05PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Quote

the_digital_dentist

Are those parts going to be plastic or metal? If they flex when you tighten the screws you may have trouble getting the rails aligned. Whatever you make them out of, I'd bulk them up quite a lot.

These collars are going to be plastic, but they are embedded into another piece that is larger so I don't think they will have flex. I can beef them up a bit but I don't expect the need to tighten them too hard.

Quote

the_digital_dentist

I think that at one end, both rails should fit into a single piece with two holes and no adjustments. At the other end, a single piece with two holes and one of them with this 3 point adjustment would be good to allow the one rail to be brought into alignment with the other.

I am assuming you are talking here about X in a CoreXY arrangement. I have only considered this for Y and Z in my corexy build. But it's something I will consider now that I realize only one alignment collar is needed.

Quote

the_digital_dentist

That should work for the x and y axes, but the Z axis (in i3 type configurations) and y axis in coreXY presents a special problem.

Can you please explain what is the challenge on Y in a corexy?

Your above advise for X - to have two rods' ends with no adjustment bolts, I like it, at least partially. Again, I am talking for Y here, where, because the clamps for the rods' ends are at the four corners of a possible unsquare frame, they can be displaced on Z as well as on XY. So I am thinking that one of the 4 will be fixed so I can align the remaining 3 ends in relation to it to achieve the squareness of the rods in a plane parallel to the bed. I am also thinking to have the X move from one end to the other with no binding but also it has to move in a plane perfectly parallel with the bed, hence the one fixed rod's end to establish a fixed Z and all others to align to this Z.

Edited 1 time(s). Last edit at 03/31/2016 10:05PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 01, 2016 08:31AM |

Registered: 11 years ago Posts: 5,780 |

You don't adjust the guide rails to be in a plane parallel to the bed. You set the guide rails orthogonal to each other, then you adjust the bed to be parallel to the xy plane as defined by the guide rails. The guide rails are the reference.

My point about the Y axis rail alignment being more difficult in a coreXY machine is similar to the Z axis rail alignment in an i3 type machine. The distance between the rails makes aligning them parallel to each other a little harder than the x axis because you can't anchor one end of the pair in a single mount. If the coreXY machine has the xy mechanism built up on a flat plate, alignment of the y axis rails gets a little easier, assuming you can keep the plate reasonably flat.

Since the Z or y axes are typically harder to align, I'd align them parallel to each other first, then worry about getting the other axes orthogonal to them.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My point about the Y axis rail alignment being more difficult in a coreXY machine is similar to the Z axis rail alignment in an i3 type machine. The distance between the rails makes aligning them parallel to each other a little harder than the x axis because you can't anchor one end of the pair in a single mount. If the coreXY machine has the xy mechanism built up on a flat plate, alignment of the y axis rails gets a little easier, assuming you can keep the plate reasonably flat.

Since the Z or y axes are typically harder to align, I'd align them parallel to each other first, then worry about getting the other axes orthogonal to them.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 01, 2016 02:57PM |

Registered: 9 years ago Posts: 1,035 |

I don't have a flat to build the XY stage off-frame and then attach it. In this particular build I must install each Y corner clamp on its own, then make sure everything is square rods-wise. That's why I devised this 3-point-collar thing to allow me to square the rods to each other however skewed the frame would be (within the limits of the 3-point-collar I designed).

If I manage to create a way to square the xyz movement independent of the squareness of the frame I believe this would improve many printers out there. And this 3-point-steady or whatever its name is can achieve that because it basically places the rods' ends in midair and they can be directed to their square position using the bolts.

A digital protractor (angle finder) would definitely help but I don't have one and they are pretty expensive as far as I remember.

Edited 2 time(s). Last edit at 04/01/2016 03:01PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

If I manage to create a way to square the xyz movement independent of the squareness of the frame I believe this would improve many printers out there. And this 3-point-steady or whatever its name is can achieve that because it basically places the rods' ends in midair and they can be directed to their square position using the bolts.

A digital protractor (angle finder) would definitely help but I don't have one and they are pretty expensive as far as I remember.

Edited 2 time(s). Last edit at 04/01/2016 03:01PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 01, 2016 11:04PM |

Registered: 11 years ago Posts: 5,780 |

It is harder to align the Y axis rails when the XY mechanism isn't built on a flat plate. For the Y axis in your machine it might indeed be a good idea to use one of the three point adjusters on each rail.

Digital protractors can be found on eBay for $30-60. $60 gets one with a built in accelerometer that can measure rotation angles in addition to the usual tilting. I have one of those and find the rotation measurement not especially useful for the stuff I do. Otherwise, these devices are useful and a lot more accurate than any bubble level they might replace. They are primarily sold to woodworkers for adjusting saw blade angles.

[m.ebay.com]

[m.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Digital protractors can be found on eBay for $30-60. $60 gets one with a built in accelerometer that can measure rotation angles in addition to the usual tilting. I have one of those and find the rotation measurement not especially useful for the stuff I do. Otherwise, these devices are useful and a lot more accurate than any bubble level they might replace. They are primarily sold to woodworkers for adjusting saw blade angles.

[m.ebay.com]

[m.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 02, 2016 07:58AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

It is harder to align the Y axis rails when the XY mechanism isn't built on a flat plate. For the Y axis in your machine it might indeed be a good idea to use one of the three point adjusters on each rail.

Just as I thought. Although I can leave one fixed, as I said before your suggestion might me applicable for this case.

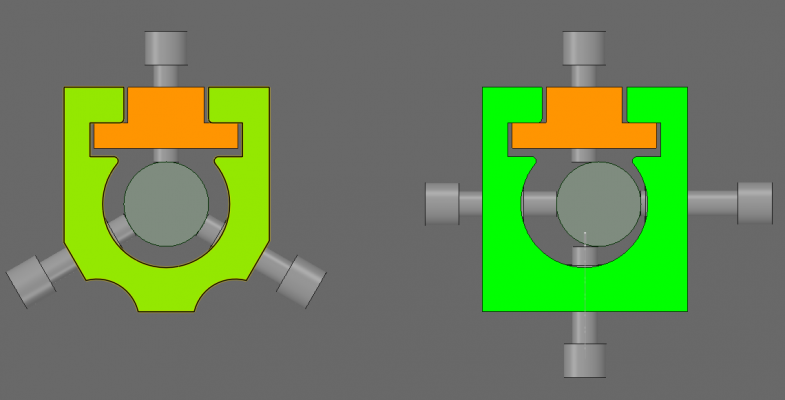

I'm trying to devise a method to use these spacial adjusters so that one ends up with a perfectly square Y even if the frame leaves some to be desired in terms of squareness. The X rail/rods can be used to square the Y as it slides on it you can notice where there is more friction or where is less and adjust the screws on the collars accordingly. But here's the gotcha: adjusting 3 screws at 120 degrees is very unintuitive because as you retract one you can affect Z also in the way I have designed them. So I am really thinking of changing the arrangement into a more manageable 0-90-180 adjusting system like the sketch below:

In this way, after you get Z right for 3 corners (one will be the reference), you can play left-right to get Y rods/rails parallel. The top is just the clamping system.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 02, 2016 08:11PM |

Registered: 11 years ago Posts: 5,780 |

3 screws will move it anywhere in space that it needs to go. To me it seems like it's overconstrained if you use four screws. I think you could position the three screws to make the alignment easier. The other thing you could do is position the rail horizontally by mounting the rail holder on a slot in the frame for side to side motion, and then shim it for vertical. You should only have to set it up once and never touch it again, so while screws to turn are nice, they aren't completely necessary.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 02, 2016 10:49PM |

Registered: 11 years ago Posts: 1,049 |

I am confused.

What is Orange piece for? ease in removing rod?

Quick rod replacement every day?

Is this, two guide rods that will define an axis?

By match drilling two plates -- the distance between guide rods would be set.

Mounting the plates parallel to each other would assure rods are not twisted,

and define / set plane.

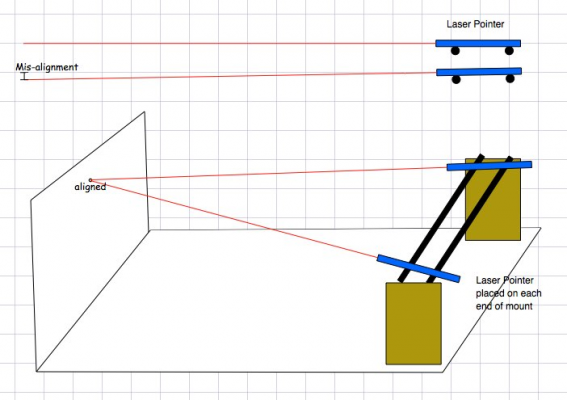

A simple way to align plates

--- place laser pointer on one plate or across rods

and shoot it across a room , -- mark spot

move laser to other plate

align to mark on wall

A little mis-align would show up as vertical inches in laser spot difference

(depending how far wall is away from rods being aligned)

The mark on wall could be reference for all other alignments.

A level line all around your work room could be used to align all axes?

BWDIK?

What is Orange piece for? ease in removing rod?

Quick rod replacement every day?

Is this, two guide rods that will define an axis?

By match drilling two plates -- the distance between guide rods would be set.

Mounting the plates parallel to each other would assure rods are not twisted,

and define / set plane.

A simple way to align plates

--- place laser pointer on one plate or across rods

and shoot it across a room , -- mark spot

move laser to other plate

align to mark on wall

A little mis-align would show up as vertical inches in laser spot difference

(depending how far wall is away from rods being aligned)

The mark on wall could be reference for all other alignments.

A level line all around your work room could be used to align all axes?

BWDIK?

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 03, 2016 04:37AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

3 screws will move it anywhere in space that it needs to go. To me it seems like it's overconstrained if you use four screws. I think you could position the three screws to make the alignment easier. The other thing you could do is position the rail horizontally by mounting the rail holder on a slot in the frame for side to side motion, and then shim it for vertical. You should only have to set it up once and never touch it again, so while screws to turn are nice, they aren't completely necessary.

Yes I know d_d but it is very unintuitive. 4 screws seem a lot and unnecessary just like 4-screws bed plane adjusting but it's not the same. With 4 screws you first define Z by dialing in first the lower screw and then just fasten it by turning the upper vertical screw. That's it for Z, you now have it dialed in, all you have to be concerned about is left-right micro-adjustment so that the rods are square to each other, which is again very simple.

With 3 screws at 120 deg it is simply too difficult to adjust for a certain alignment. It's easy on the lathe where you only have to adjust one 3-point-steady but here you just have too many of them and it's hell when you turn one screw you have to un-turn another and you modify with this the position in all 3 axes... then you have to realign all others in consequence. It reminds me of calibrating Delta, where you dial in for one tower, then re-do all towers to match, then check again, etc

BTW: did you ever had a Christmas tree base that has this 3-point-steady system to make it vertical? It's incredibly difficult to dial in the right amount of turns per each screw to obtain the vertical.

Quote

cozmicray

I am confused.

What is Orange piece for? ease in removing rod?

Quick rod replacement every day?

Yes the initial intention was to first install the plastic holders then add the rods. It's not necessary at this point, when I can take the plastic holder off without disassembling the frame.

However, plastic gives and the amount of disassembling I've been doing/witnessing being done on Solidoodle just makes a way to easily take out the Y rods so you can replace parts on Y or on X a welcomed option.

Quote

cozmicray

A simple way to align plates

--- place laser pointer on one plate or across rods

and shoot it across a room , -- mark spot

move laser to other plate

align to mark on wall

A little mis-align would show up as vertical inches in laser spot difference

(depending how far wall is away from rods being aligned)

The mark on wall could be reference for all other alignments.

A level line all around your work room could be used to align all axes?

This is intriguing and I am interested in this method even if I don't have a laser level. Can you make a quick napkin sketch as I can imagine what you wanted to say but am not sure i got it right.

Edited 2 time(s). Last edit at 04/03/2016 04:47AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 03, 2016 04:13PM |

Registered: 11 years ago Posts: 1,049 |

Keep it simple?

You really only need a $3 laser pointer with a nice straight round / square barrel

that gives nice small spot

Length of measurement points here exaggerates the mis-alignment

Example:

My mill is in middle of room

lay laser pointer on bed pointing to right wall mark on wall

swing laser around and point toward left wall mark on wall

Put laser on mill head which is 40cm above bed

mark on L R walls 40cm above other mark

adjust mill head so laser spot is on mark

check it on other wall

Mill head is aligned with some good precision to bed

Assume Mill shaft orthogonal to head (well spec sez it's 90+-0.0001 degree)

mill cutter should be orthogonal to bed ( good enough for government work)

============

(Water level) Hey piece of clear tubing filled with water can show you level

even if tubing is 100 feet long

A weight on a string will show you plumb

Example: Laser level on eBay (nice flat bottom) $5.50

[www.ebay.com]

You really only need a $3 laser pointer with a nice straight round / square barrel

that gives nice small spot

Length of measurement points here exaggerates the mis-alignment

Example:

My mill is in middle of room

lay laser pointer on bed pointing to right wall mark on wall

swing laser around and point toward left wall mark on wall

Put laser on mill head which is 40cm above bed

mark on L R walls 40cm above other mark

adjust mill head so laser spot is on mark

check it on other wall

Mill head is aligned with some good precision to bed

Assume Mill shaft orthogonal to head (well spec sez it's 90+-0.0001 degree)

mill cutter should be orthogonal to bed ( good enough for government work)

============

(Water level) Hey piece of clear tubing filled with water can show you level

even if tubing is 100 feet long

A weight on a string will show you plumb

Example: Laser level on eBay (nice flat bottom) $5.50

[www.ebay.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 04, 2016 04:00AM |

Registered: 9 years ago Posts: 1,035 |

Thanks, I'll have to try the laser method. I was thinking of those lasers that shoot a line across on the wall.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 04, 2016 07:07AM |

Registered: 11 years ago Posts: 5,780 |

Very good- just make sure the same surface on the laser rests on the surface being tested (don't trust the laser diode to be cenetered or aligned within its own tube) at every place you're testing. You could print a plastic holder with a flat surface to use as the reference surface on the laser pointer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 04, 2016 04:30PM |

Registered: 11 years ago Posts: 1,049 |

Yes your right about laser being parallel to case.

If round --- roll it around and see if spot stays centered.

It's a relative thing and good procedure

results in good alignment.

Some good measurement and some Trigonometry

you may set angles, do alignment

even measure the diameter of the earth.

I have a inexpensive laser with flat magnetic bottom

and a lens can be a line rotated any way

or if lens is removed a nice bright spot.

Beware even low power lasers can do eye damage!

If round --- roll it around and see if spot stays centered.

It's a relative thing and good procedure

results in good alignment.

Some good measurement and some Trigonometry

you may set angles, do alignment

even measure the diameter of the earth.

I have a inexpensive laser with flat magnetic bottom

and a lens can be a line rotated any way

or if lens is removed a nice bright spot.

Beware even low power lasers can do eye damage!

|

Anonymous User

Re: Centering collars (3-point-steady) for smooth rods alignment? April 07, 2016 11:37AM |

Quote

the_digital_dentist

It is harder to align the Y axis rails when the XY mechanism isn't built on a flat plate. For the Y axis in your machine it might indeed be a good idea to use one of the three point adjusters on each rail.

Digital protractors can be found on eBay for $30-60. $60 gets one with a built in accelerometer that can measure rotation angles in addition to the usual tilting. I have one of those and find the rotation measurement not especially useful for the stuff I do. Otherwise, these devices are useful and a lot more accurate than any bubble level they might replace. They are primarily sold to woodworkers for adjusting saw blade angles.

[m.ebay.com]

[m.ebay.com]

I used a similar but older model (6 ears) but it broke down !

I was ready to buy this new one. Do your have it ? Is it up to its claim (0.01°) and is it really metal and well made ?

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 07, 2016 10:35PM |

Registered: 11 years ago Posts: 5,780 |

I have both of the linked units. The housings are plastic but seem well-enough made. They have magnets in the corners so the unit will stick to steel in any position. Battery life on a charge is very good. While the second unit will read out in 0.01 degree steps, there's always a little instability, so the last digit bounces up and down a couple 1/100 ths of a degree. I don't think I'd trust it to be better than 0.1 degree accurate. The readings do seem to be repeatable within +/-0.03 degrees or so.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 07, 2016 10:57PM |

Registered: 11 years ago Posts: 5,780 |

At first glance it seemed like a good way to test rail alignment, but after thinking about it, I realized it isn't.

Let's say the rails are parallel but one end of the pair is higher than the other. When you mark the spots on the wall they will not match. Then you have to decide if the rails are not parallel vertically or if the rails are parallel but not level. If the ends are at the same level and the rails are not parallel in the horizontal plane the marks on the wall will line up as if the rails are parallel. So the laser pointer trick doesn't distinguish between vertically nonparallel rails and vertically parallel but not level rails, and it can't tell you anything about whether the rails are parallel in the horizontal plane.

The technique requires further development to be useful.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Let's say the rails are parallel but one end of the pair is higher than the other. When you mark the spots on the wall they will not match. Then you have to decide if the rails are not parallel vertically or if the rails are parallel but not level. If the ends are at the same level and the rails are not parallel in the horizontal plane the marks on the wall will line up as if the rails are parallel. So the laser pointer trick doesn't distinguish between vertically nonparallel rails and vertically parallel but not level rails, and it can't tell you anything about whether the rails are parallel in the horizontal plane.

The technique requires further development to be useful.

Quote

cozmicray

Keep it simple?

You really only need a $3 laser pointer with a nice straight round / square barrel

that gives nice small spot

[attachment 75869 Laser_align.jpg]

Length of measurement points here exaggerates the mis-alignment

Example:

My mill is in middle of room

lay laser pointer on bed pointing to right wall mark on wall

swing laser around and point toward left wall mark on wall

Put laser on mill head which is 40cm above bed

mark on L R walls 40cm above other mark

adjust mill head so laser spot is on mark

check it on other wall

Mill head is aligned with some good precision to bed

Assume Mill shaft orthogonal to head (well spec sez it's 90+-0.0001 degree)

mill cutter should be orthogonal to bed ( good enough for government work)

============

(Water level) Hey piece of clear tubing filled with water can show you level

even if tubing is 100 feet long

A weight on a string will show you plumb

Example: Laser level on eBay (nice flat bottom) $5.50

[www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 08, 2016 12:51PM |

Registered: 9 years ago Posts: 1,035 |

Ummm... I see your point.

I am still trying to figure out what is the best way to achieve a leveled and square assembly.

Was thinking to have one of the four corners a fixed hole (by design), and the other three corners having free-floating rods' ends to adjust. First I would have the two rods leveled so they are on a perfectly horizontal plane. Start with the free end of the constrained rod raised/lowered so that it is perfectly horizontal, then continue with making horizontal one end of the first rod with one of the free ends of the second rod.In this matter the digital protractor/angle finder/bubble should do the trick.

Then I need to go about squareness. A moving X carriage can help here as you can feel binding while traveling from end to end. But there's about where my ideas end. Also a laser would do the trick now that the rods are on a perfectly horizontal plane.

Edited 1 time(s). Last edit at 04/08/2016 12:52PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am still trying to figure out what is the best way to achieve a leveled and square assembly.

Was thinking to have one of the four corners a fixed hole (by design), and the other three corners having free-floating rods' ends to adjust. First I would have the two rods leveled so they are on a perfectly horizontal plane. Start with the free end of the constrained rod raised/lowered so that it is perfectly horizontal, then continue with making horizontal one end of the first rod with one of the free ends of the second rod.In this matter the digital protractor/angle finder/bubble should do the trick.

Then I need to go about squareness. A moving X carriage can help here as you can feel binding while traveling from end to end. But there's about where my ideas end. Also a laser would do the trick now that the rods are on a perfectly horizontal plane.

Edited 1 time(s). Last edit at 04/08/2016 12:52PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Centering collars (3-point-steady) for smooth rods alignment? April 08, 2016 05:19PM |

Registered: 11 years ago Posts: 1,049 |

Level --- meaningless?

?? a horizontal position or condition

?? an imaginary line or surface everywhere at right angles to the plumb line.

?? the horizontal line or plane in which anything is situated, with regard to its elevation.

Parallel lines or parallel planes better

X axis --- to --- build plate parallel

By your own measurements with digital dial gauge

The rails are parallel because the mounting plates are matched drilled

The laser is facilitating making the two separated mounting plates parallel

so no twist in rail system

Then make the rail system parallel to reference ( build platform )

or whatever is the chosen "reference" plane

Shooting both sides of the surface of your granite build block

could provide a level line, or parallel line on the wall?

or

by procedure you align your printer reference to the line on the wall

every time you do any alignments

The wall somewhat far away from unit being aligned

provides a lot of displacement for angular mis-alignment

Maybe that wall orthogonal can be put into play

or

breakout the optical bench and 16 precision mirrors / prisms

and the smoke and glasses to see lines

hummmm

new house plans, needs

--- granite block in basement floor, precision aligned walls, alignment cubes

?? a horizontal position or condition

?? an imaginary line or surface everywhere at right angles to the plumb line.

?? the horizontal line or plane in which anything is situated, with regard to its elevation.

Parallel lines or parallel planes better

X axis --- to --- build plate parallel

By your own measurements with digital dial gauge

The rails are parallel because the mounting plates are matched drilled

The laser is facilitating making the two separated mounting plates parallel

so no twist in rail system

Then make the rail system parallel to reference ( build platform )

or whatever is the chosen "reference" plane

Shooting both sides of the surface of your granite build block

could provide a level line, or parallel line on the wall?

or

by procedure you align your printer reference to the line on the wall

every time you do any alignments

The wall somewhat far away from unit being aligned

provides a lot of displacement for angular mis-alignment

Maybe that wall orthogonal can be put into play

or

breakout the optical bench and 16 precision mirrors / prisms

and the smoke and glasses to see lines

hummmm

new house plans, needs

--- granite block in basement floor, precision aligned walls, alignment cubes

Quote

the_digital_dentist

At first glance it seemed like a good way to test rail alignment, but after thinking about it, I realized it isn't.

Let's say the rails are parallel but one end of the pair is higher than the other. When you mark the spots on the wall they will not match. Then you have to decide if the rails are not parallel vertically or if the rails are parallel but not level. If the ends are at the same level and the rails are not parallel in the horizontal plane the marks on the wall will line up as if the rails are parallel. So the laser pointer trick doesn't distinguish between vertically nonparallel rails and vertically parallel but not level rails, and it can't tell you anything about whether the rails are parallel in the horizontal plane.

The technique requires further development to be useful.

Sorry, only registered users may post in this forum.