Do CoreXY belts need to be of equal tension?

Posted by realthor

|

Do CoreXY belts need to be of equal tension? April 21, 2016 02:53AM |

Registered: 9 years ago Posts: 1,035 |

Hi guysI have a bit of a dilemma here: in a corexy setup, do I have to make sure belts have the same tension on both sides?

As far as I can tell, having them adjusted differently can help squaring the top -which is notoriously difficult to square as one can't install cross bracing in there- and also (maybe) can be used for other artifacts in prints (oval circles,etc).

Please let me know your experience with proper tension in the belts.

Note: I have a design that does simultaneous tensioning of both belts but it has been brought to my attention that it might not be the best solution.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

As far as I can tell, having them adjusted differently can help squaring the top -which is notoriously difficult to square as one can't install cross bracing in there- and also (maybe) can be used for other artifacts in prints (oval circles,etc).

Please let me know your experience with proper tension in the belts.

Note: I have a design that does simultaneous tensioning of both belts but it has been brought to my attention that it might not be the best solution.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 07:57AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Hi guysI have a bit of a dilemma here: in a corexy setup, do I have to make sure belts have the same tension on both sides?

ohhhh yes. most definitely. if the belts are tensioned differently they will have different characteristics and different effects, which will cause minor odd variations resulting in odd and unpredictable patterns, head movement... yeah. definitely.

Quote

As far as I can tell, having them adjusted differently can help squaring the top -which is notoriously difficult to square as one can't install cross bracing in there- and also (maybe) can be used for other artifacts in prints (oval circles,etc).

the coffeetable guy [forums.reprap.org] has come up with a great way to do stiff bars without needing corner-bracing: offset bars with bolts going through. the cheap-and-cheerful brackets i found on ebay do an extremely impressive job, [www.ebay.co.uk] because they're actually quite hard to find with a keyword search.

it can be done... and it is absolutely essential that you find a way, if you want decent prints.

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 08:56AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

If the belts are tensioned differently they will have different characteristics and different effects, which will cause minor odd variations resulting in odd and unpredictable patterns, head movement... yeah. definitely.

So far I haven't seen any method to equally adjust the two belts hence my design (linked above). But it was just a feeling. Actually I don't quite believe that a difference in tension can result in artifacts as long as the motors can pull the right amount of (micro)steps to achieve the desired movement. And because the belts are positioned symmetrically in the middle of the two X rods in quite a narrow carriage, the twisting could be negligible. Actually carriage twisting is the only thing I would be worried if different tensions would be setup in the belts.

Quote

lkcl

the coffeetable guy [forums.reprap.org] has come up with a great way to do stiff bars without needing corner-bracing: offset bars with bolts going through

it can be done... and it is absolutely essential that you find a way, if you want decent prints.

That one is this very guy

... but even so another means of ensuring squareness wouldn't hurt.

... but even so another means of ensuring squareness wouldn't hurt.Edited 2 time(s). Last edit at 04/21/2016 08:56AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 11:17AM |

Registered: 10 years ago Posts: 553 |

You can use a single length of belt (assuming you are not using the 2 plane method), connect the ends to the x carriage, tension the belt with the motors (or really anywhere), and secure the belt to the carriage again to effectively form 2 individual belts. That should give you the same tension in each section of belt.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 11:22AM |

Registered: 9 years ago Posts: 1,035 |

Quote

gmh39

You can use a single length of belt (assuming you are not using the 2 plane method), connect the ends to the x carriage, tension the belt with the motors (or really anywhere), and secure the belt to the carriage again to effectively form 2 individual belts. That should give you the same tension in each section of belt.

I am using the 2 planes so I can't apply this method, have to find another one

. Thanks for chiming in.

. Thanks for chiming in.BTW: here's my Thingiverse 3D Printer Design: [www.thingiverse.com]

and here's a better 3D viewer @ Sketchfab: [sketchfab.com]

...Also the X Carriage I linked above, in a Sketchfab viewer: [sketchfab.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 11:27AM |

Registered: 10 years ago Posts: 553 |

Quote

realthor

Quote

gmh39

You can use a single length of belt (assuming you are not using the 2 plane method), connect the ends to the x carriage, tension the belt with the motors (or really anywhere), and secure the belt to the carriage again to effectively form 2 individual belts. That should give you the same tension in each section of belt.

I am using the 2 planes so I can't apply this method, have to find another one. Thanks for chiming in.

BTW: here's my Thingiverse 3D Printer Design: [www.thingiverse.com]

and here's a better 3D viewer @ Sketchfab: [sketchfab.com]

...Also the X Carriage I linked above, in a Sketchfab viewer: [sketchfab.com]

Actually now that I think about it, technically you could, but it would move the cross over to inside the X carriage. Probably more trouble than it's worth though...

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 12:56PM |

Registered: 10 years ago Posts: 651 |

For a while I've been thinking of ways for me to easily tension my belts, and have a way to look over and just know. Here's what I've been thinking about, envision this.

Start with your standard CoreXY setup, without the belts installed yet.

Motor mounts slide and are adjustable with a thumb screw, thumb screw pulls motor mount away from opposite idler, thus tensioning the belt if were installed

Currently open so the motor is at 3/4 it's full range of motion, 3/4 the distance the mount will allow it to move towards the opposite idler as it will allow.

Sliding portion of motor mount will allow attachment of a spring scale (like), the other end attached to the frame.

When placing the belt, install it so it barely touches the motor pulley.

Zero out the scale

Then crank the thumbscrew to the proper tension for the belt.

Maybe even have an adjustable screw on the opposite side to tighten up against the motor mount so it doesn't move.

Complicated to explain, but I don't think to implement.

Edit: Or some implementation thereof, I thought about putting it on the carriage but decided it'd be unnecessary moving mass.

Edited 4 time(s). Last edit at 04/21/2016 02:00PM by FA-MAS.

Start with your standard CoreXY setup, without the belts installed yet.

Motor mounts slide and are adjustable with a thumb screw, thumb screw pulls motor mount away from opposite idler, thus tensioning the belt if were installed

Currently open so the motor is at 3/4 it's full range of motion, 3/4 the distance the mount will allow it to move towards the opposite idler as it will allow.

Sliding portion of motor mount will allow attachment of a spring scale (like), the other end attached to the frame.

When placing the belt, install it so it barely touches the motor pulley.

Zero out the scale

Then crank the thumbscrew to the proper tension for the belt.

Maybe even have an adjustable screw on the opposite side to tighten up against the motor mount so it doesn't move.

Complicated to explain, but I don't think to implement.

Edit: Or some implementation thereof, I thought about putting it on the carriage but decided it'd be unnecessary moving mass.

Edited 4 time(s). Last edit at 04/21/2016 02:00PM by FA-MAS.

|

Re: Do CoreXY belts need to be of equal tension? April 21, 2016 03:13PM |

Registered: 9 years ago Posts: 1,035 |

I find it very difficult to add a tensioning system elsewhere in the corexy path. I don't have pockets/slots in the motor mounts that would allow adjusting tension. I have designed slots for lateral adjustment so I ensure square belts for the corexy setup. Adding perpendicular slots to those is close to impossible.

So I have finally decided to add it straight to the X carriage. One bolt+nut is not such a weight penalty. And you have the advantage that with that single bolt+belt-gripper-slide you adjust both belts' tension.

But I got the advice on google groups that I should be able to adjust both belts independently which is for me quite surprising. The fact that one can square the top plane of a corexy printer using belt tension is a happy surprise but if that brings artifacts in the print due to different tensions in the belts than it's not such a sweet deal.

Hence my thread here...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

So I have finally decided to add it straight to the X carriage. One bolt+nut is not such a weight penalty. And you have the advantage that with that single bolt+belt-gripper-slide you adjust both belts' tension.

But I got the advice on google groups that I should be able to adjust both belts independently which is for me quite surprising. The fact that one can square the top plane of a corexy printer using belt tension is a happy surprise but if that brings artifacts in the print due to different tensions in the belts than it's not such a sweet deal.

Hence my thread here...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 22, 2016 09:00AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

I find it very difficult to add a tensioning system elsewhere in the corexy path. I don't have pockets/slots in the motor mounts that would allow adjusting tension. I have designed slots for lateral adjustment so I ensure square belts for the corexy setup. Adding perpendicular slots to those is close to impossible.

[attachment 76848 ScoutCoreXY-XYSteppers_MountsAreAdjustable2.png][attachment 76849 ScoutCoreXY-XYSteppers_MountsAreAdjustable3.png]

So I have finally decided to add it straight to the X carriage. One bolt+nut is not such a weight penalty. And you have the advantage that with that single bolt+belt-gripper-slide you adjust both belts' tension.

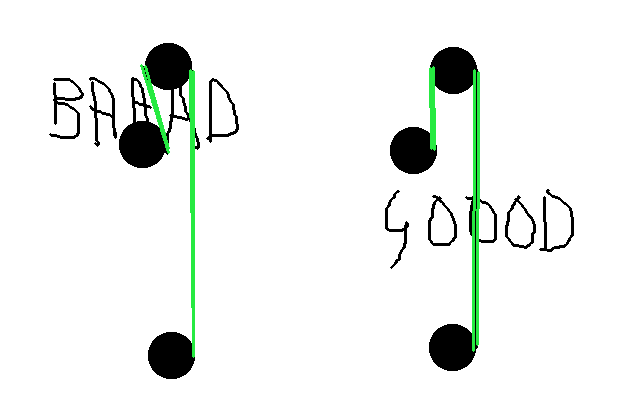

that would work. bit of a pain to set up, but it would work. err.. you've got the slots the wrong way round. you can't tension the belt with those! oh, btw for goodness sake make sure that the belt lines up:

if you get that alignment wrong, you're f*****d. what happens is that the x-carriage belt *changes length* - which will change the tension (causing damage to parts) as well as creating inaccurate prints. GET IT RIGHT basically

been there, designed idlers that were in the wrong place *sigh*....

been there, designed idlers that were in the wrong place *sigh*....Quote

But I got the advice on google groups that I should be able to adjust both belts independently which is for me quite surprising.

you _need_ to be able to adjust both belts independently, so that on the outer equal-length parts of the 2 belts you get the same "pungggg" note out of them. make sure you design the idlers so that the distance between turn-points *is* equal, so that you can do exactly that.

Quote

The fact that one can square the top plane of a corexy printer using belt tension is a happy surprise but if that brings artifacts in the print due to different tensions in the belts than it's not such a sweet deal.

absolutely correct it would be bad. it's a bit like the reprap demo my friend went to, years ago, he asked how to get the bed level, and the guy doing the demo came over, and stuck his thumb on the corner of the bed - whilst it was printing - and went, "there! sorted!". from then on he was shocked to have been made aware that there were complete idiots in the reprap community, whom people were quite happily following without a single ounce of actual thought going on in their own heads.

in this case, changing the tension on the belts to "correct" non-square (rhomboid) planes risks just moving one rhombus of badly-engineered construction to another part of the build. and also ending up with artefacts due to different elasticity properties of the two belts.

baaad

the point is: design and construct the corexy top so that it *is* square, and the rods *are* absolutely perpendicular and parallel to something.

no, you shouldn't even be attempting to put the belts *on* the corexy top until you're absolutely absolutely dead-certain that the damn top of the frame - xrods and yrods - are dead square. in the Fusebox design what Alex_F did was he made the yrod holders "movable". they're bolted in to the rails, there are slots in the extrusion, so setup is a pain but it's doable. basically you put the x-carriage at one end, tighten up (not completely) the y-rod bolts there, then move the x-carriage to the other end, tighten up (not completely) the bolts there, then move back again, and lock the y-rod bolts down solid, move back again, lock the other end y-rod bolts down. but you *HAVE* to have a square corexy frame even before you start that.

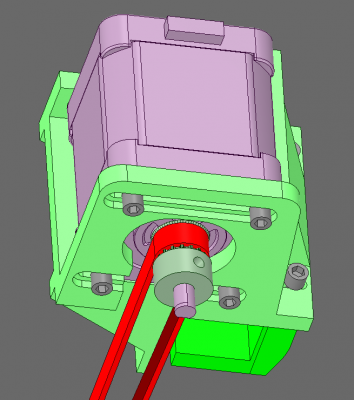

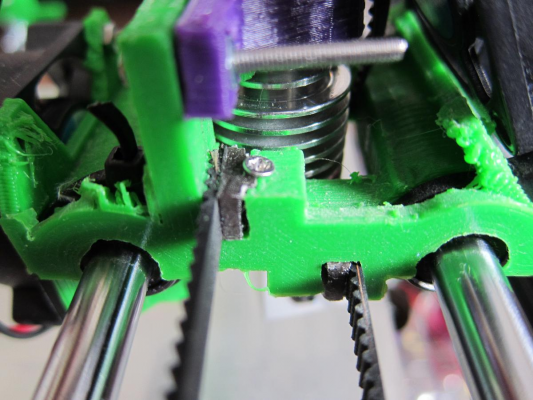

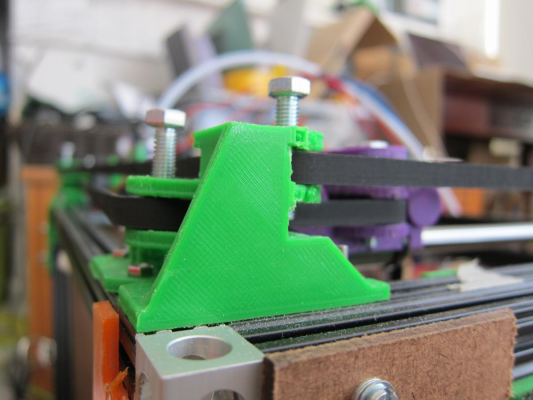

this is how nophead did the belt tensioners on the mendel90:

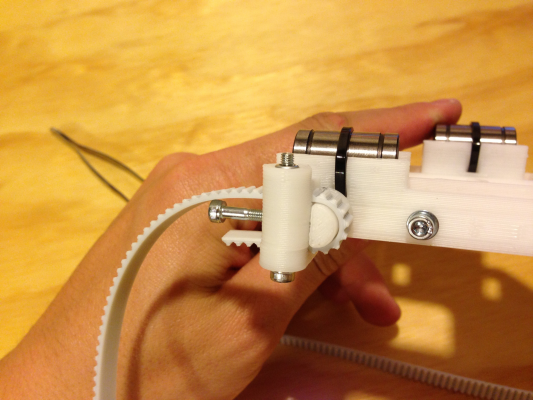

you can see there's a bolt which moves that D-shape, that's how you get to adjust the tension, ta-daaa.

for equalising tensioning, the Fusebox design is quite cute, there are some teeth on the carriage, you just slot the belt in and ta-daaa, belt's in. wrong tension? take it out, move the belt up one notch, drop it in... ta-daaaa, correct tension. i didn't like the "fixed width" that he had, i wasted about 6m of PLA trying to print 2 carriages, then wasted 4 HOURS drilling them out with a screwdriver.... discussion's here.... [forums.reprap.org]

that's worked out very well - the M2 nut and bolt tend to drop out if you're not careful, but... yeah, just... be careful and patient

anyway here's a close-up photo of the sandwich200v1 carriage:

|

Re: Do CoreXY belts need to be of equal tension? April 22, 2016 10:43AM |

Registered: 9 years ago Posts: 1,035 |

1) My setup is just like Smartrapcore regarding the belts lines. Only the side of the motor belt that goes to the Y Carriage and the side of the belt that goes from the idler to the Ycarriage need to be dead straight. The other side, the outer long belt doesn't need to be parallel with anything. It only needs to not catch on itself when the Y carriage approaches the idler. I am pretty sure I have that ok, if not else at least because Smartrapcore works.

2) If both lengths of belt are equal and the frame is square then adjusting them independently would only make room for error (ex: different tensions in each of them due to human error, like thinking you hear the same tone when "striking the chord"

3) I have a lot of adjusting elements, from the clamps themselves that can "slide" on the square tubing to the Y Rod hole which is larger than the diameter of the rod and fine adjustment can be done by turning the screws in the 3(or 4)-point-adjusting mechanism.

The design challenge I have now is designing a jig (3d printed + metal bushings) to drill the tubes at precise positions and at straight angles so that when fastening the frame everything comes up square.

The other challenge is developing a "procedure" to make everything straight and square.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

2) If both lengths of belt are equal and the frame is square then adjusting them independently would only make room for error (ex: different tensions in each of them due to human error, like thinking you hear the same tone when "striking the chord"

3) I have a lot of adjusting elements, from the clamps themselves that can "slide" on the square tubing to the Y Rod hole which is larger than the diameter of the rod and fine adjustment can be done by turning the screws in the 3(or 4)-point-adjusting mechanism.

The design challenge I have now is designing a jig (3d printed + metal bushings) to drill the tubes at precise positions and at straight angles so that when fastening the frame everything comes up square.

The other challenge is developing a "procedure" to make everything straight and square.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 11:09AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

1) My setup is just like Smartrapcore regarding the belts lines. Only the side of the motor belt that goes to the Y Carriage and the side of the belt that goes from the idler to the Ycarriage need to be dead straight. The other side, the outer long belt doesn't need to be parallel with anything. It only needs to not catch on itself when the Y carriage approaches the idler. I am pretty sure I have that ok, if not else at least because Smartrapcore works.

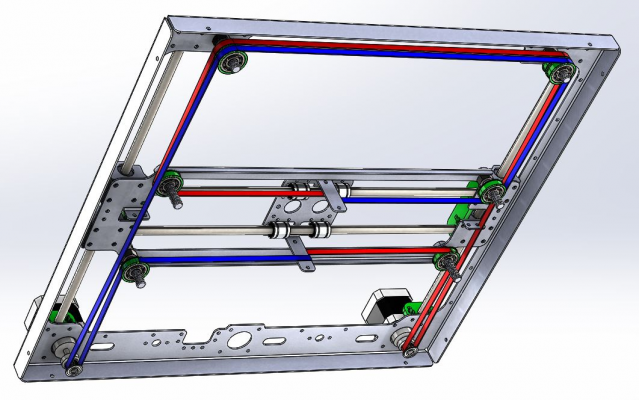

mmmm.... this doesn't inspire me with confidence that you understand how critical the belts need to be directly in line, in both X Y *and* Z on all four points where the belt comes out of the x-ends. Alex_F's Fusebox is what tipped me off to a good design: to give you an idea of what *not* to do, i found a photo online of someone's smartrapcore alu, here it is:

now take a look in the top left corner, at the left GT2 gear. trace the belt: i realise it's hard to tell from photos, but can you see that the belt in that photo is sloping *downwards*? on the right side you can see the belts get closer together! now, i believe it may actually be the outer part of the belt - non-critical - that's not aligned, but this one, oh my god....

please for god's sake don't do that

can you see how, when the carriage would be on the right, the right (shorter) belt would, due to pythagoras theorem, actually need to be *longer* due to the offset??? this is what i was talking about where, if you get this wrong the belts will be slack at one point and over-tight at the ends.

can you see how, when the carriage would be on the right, the right (shorter) belt would, due to pythagoras theorem, actually need to be *longer* due to the offset??? this is what i was talking about where, if you get this wrong the belts will be slack at one point and over-tight at the ends.wark-wark... faillll....

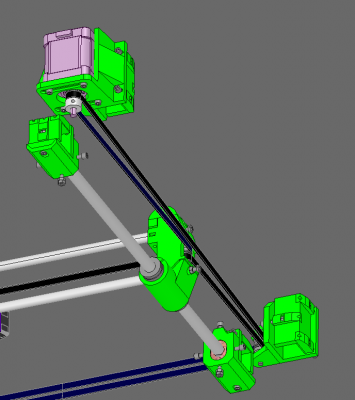

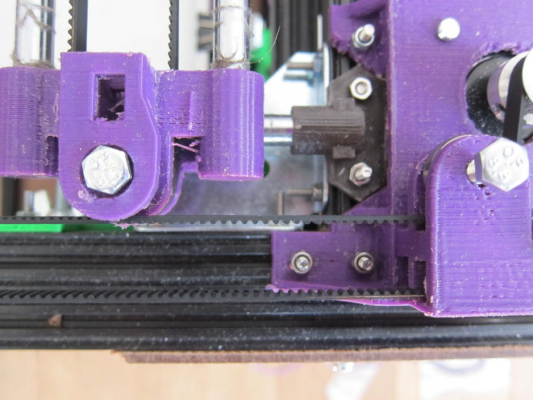

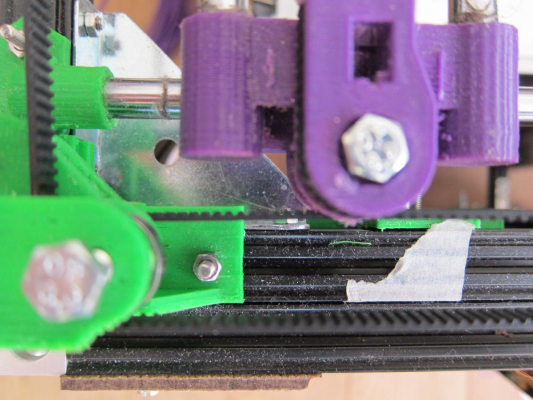

ok so here's 2 dead-straight belts, both pictures are taken from above, you can see that at either end the belt as it comes out of the x-end goes *exactly* 90 degrees. this is absolutely, absolutely, 100% cast-iron absolute without fail absolute, absolute critical.

then, also, this is taken from the side (sorry the perspective is distorting things slightly), but again, you can see, no Z-direction drop in the belts. again, this is absolutely critical on the inner belt... which (doh) is hidden behind the outer one because i took the photo dead-level with the top belt... sorry. anyway you can see this is the "offset" design, which i copied from Alex_F's Fusebox - the left belt is offset by some 16mm from the right belt, but they DO NOT drop AT ALL. both belts are ENTIRELY in the XY plane.

this one, then, shows that the one belt (top one) doesn't drop at all (stays in the XY plane), look towards the end of the photo, notice how the belt remains parallel with its return path (as it heads towards the idler in green)

but yes, you're right: you *can* "dip" the outer part of the belt, or make it go non-perpendicular.... it's the parts of the belt that go into the x-ends that is critical and must be perfectly aligned... but with an offset design, why bother risking it?

Quote

2) If both lengths of belt are equal and the frame is square then adjusting them independently would only make room for error (ex: different tensions in each of them due to human error, like thinking you hear the same tone when "striking the chord"

well... there's 2 belts, so that's kinda an unavoidable procedure. personally i'd be happy with, if the belt came from the same source, if the note was the same after pulling them both equally a bit hard (to even out any inequalities), to "punnggg" them. i know purists and engineers who would freak out at that, but hey

Quote

3) I have a lot of adjusting elements, from the clamps themselves that can "slide" on the square tubing to the Y Rod hole which is larger than the diameter of the rod and fine adjustment can be done by turning the screws in the 3(or 4)-point-adjusting mechanism.

The design challenge I have now is designing a jig (3d printed + metal bushings) to drill the tubes at precise positions and at straight angles so that when fastening the frame everything comes up square.

The other challenge is developing a "procedure" to make everything straight and square.

yyyeah, you made life a bit harder for yourself that it needs to be, and you're setting people up for getting it wrong by not copying or following the procedure. much better to get the design right and hard-code the correct setup into the actual parts, don't you think?

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 11:59AM |

Registered: 9 years ago Posts: 1,035 |

Yes, a bit harder, but I like that  . It also gives the possibility to overcome many build errors, which I believe a DIYer with a hacksaw and a cordless drill will make. Not everybody will have factory cut aluminum extrusions and maybe they are not absolutely needed in all situations... but hey, if they are cheap enough people will not complicate their lives with ALU tubes anyway.

. It also gives the possibility to overcome many build errors, which I believe a DIYer with a hacksaw and a cordless drill will make. Not everybody will have factory cut aluminum extrusions and maybe they are not absolutely needed in all situations... but hey, if they are cheap enough people will not complicate their lives with ALU tubes anyway.

Regarding the dead straight lines of belt I admit they look good, but they are again not necessary. As I said, as long as the teeth don't catch on each other it's fine.

Regarding having the belts give the same "note" when punged, thus needing separate adjustment mechanisms, I will at least try the single/common tensioning system because I really believe that having the same length of belts and crocheting them symmetrically through the CoreXY pathway and gripping them at the same teeth at the X Carriage will ultimately end up with them being the same tension. Then one only has to tension them even more to ensure a smooth operation.

Anyway, my question is answered. Just to summarize, it's better to have belts at the same tension than t use them at different tensions to made up for un-square frames. Better to have other mechanisms to adjust frame squareness.

Thanks all for your answers, this can continue as a discussion for the finer details and other related issues, of course.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

. It also gives the possibility to overcome many build errors, which I believe a DIYer with a hacksaw and a cordless drill will make. Not everybody will have factory cut aluminum extrusions and maybe they are not absolutely needed in all situations... but hey, if they are cheap enough people will not complicate their lives with ALU tubes anyway.

. It also gives the possibility to overcome many build errors, which I believe a DIYer with a hacksaw and a cordless drill will make. Not everybody will have factory cut aluminum extrusions and maybe they are not absolutely needed in all situations... but hey, if they are cheap enough people will not complicate their lives with ALU tubes anyway.Regarding the dead straight lines of belt I admit they look good, but they are again not necessary. As I said, as long as the teeth don't catch on each other it's fine.

Regarding having the belts give the same "note" when punged, thus needing separate adjustment mechanisms, I will at least try the single/common tensioning system because I really believe that having the same length of belts and crocheting them symmetrically through the CoreXY pathway and gripping them at the same teeth at the X Carriage will ultimately end up with them being the same tension. Then one only has to tension them even more to ensure a smooth operation.

Anyway, my question is answered. Just to summarize, it's better to have belts at the same tension than t use them at different tensions to made up for un-square frames. Better to have other mechanisms to adjust frame squareness.

Thanks all for your answers, this can continue as a discussion for the finer details and other related issues, of course.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 12:59PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Yes, a bit harder, but I like that. It also gives the possibility to overcome many build errors, which I believe a DIYer with a hacksaw and a cordless drill will make. Not everybody will have factory cut aluminum extrusions and maybe they are not absolutely needed in all situations... but hey, if they are cheap enough people will not complicate their lives with ALU tubes anyway.

Regarding the dead straight lines of belt I admit they look good, but they are again not necessary. As I said, as long as the teeth don't catch on each other it's fine.

let me be absolutely clear: the statement that you have made is 100% wrong. if you do not believe me, and cannot work it out in your mind that the tension in the belts will vary as the carriage goes back and forth if the belts are not directly aligned and at 90 degrees when coming out of the x-ends, then you will find out *why* this matters so much when it comes to actually trying to print.

i have that ability to visualise in 3 dimensions: most of the time i can apply it correctly and not make mistakes, but having *already* made the mistake of not aligning the belts i can tell you that it is a simple and undeniable fact of physics and mechanics that in order to have constant tension without variation on the two belts, the belts *MUST* go through *EXACTLY* 90 degrees when going round the x-end idler bearings and they MUST be ABSOLUTELY dead-level in the XY plane at all times.

i realise you may feel that it doesn't matter: i'm telling you, you're 100% wrong. been there, done it, cursed a lot at the waste of PLA from a faulty set of idler bearing holders, and started again.

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 03:15PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

let me be absolutely clear: the statement that you have made is 100% wrong. if you do not believe me, and cannot work it out in your mind that the tension in the belts will vary as the carriage goes back and forth if the belts are not directly aligned and at 90 degrees when coming out of the x-ends, then you will find out *why* this matters so much when it comes to actually trying to print.

I thought I was pretty clear that the lines of belt that come and go from the X carriage should be straight. That is common sense I never disputed that. I have them dead straight in my design. I am talking about the outer line, the line that goes from motor to idler... . If you are saying that that one should be dead straight too then I can't argue because I don't have hands-on experience but I can't see how that one would cause any change in tension.

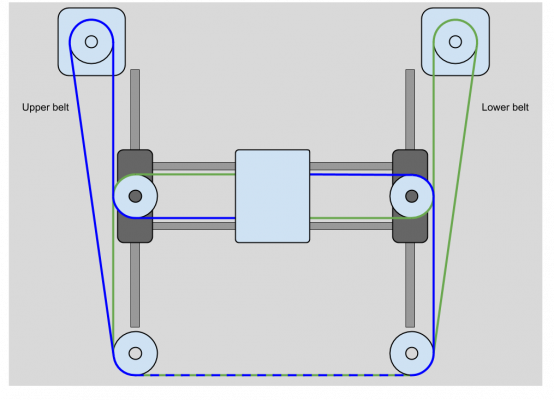

The system I am using is exactly this one:

Smartracore, Frax 3D and several others seem to use this design:

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 08:21PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Quote

lkcl

let me be absolutely clear: the statement that you have made is 100% wrong. if you do not believe me, and cannot work it out in your mind that the tension in the belts will vary as the carriage goes back and forth if the belts are not directly aligned and at 90 degrees when coming out of the x-ends, then you will find out *why* this matters so much when it comes to actually trying to print.

I thought I was pretty clear that the lines of belt that come and go from the X carriage should be straight.

apologies, you didn't. now you have.

Quote

That is common sense I never disputed that. I have them dead straight in my design. I am talking about the outer line, the line that goes from motor to idler... .

okay. good. because that guy making the smartrapcore alu... well... he's been told, but didn't listen.

Quote

If you are saying that that one should be dead straight too then I can't argue because I don't have hands-on experience but I can't see how that one would cause any change in tension.

the outer bearings (the outer return path), are fine, but for goodness sake make sure they're dead level with all the other bearings. only put the bearings for one belt in the exact same XY plane, absolutely no variation in height.

Quote

The system I am using is exactly this one:

Smartracore, Frax 3D and several others seem to use this design:

well, looking up "smartrapcore" designs, two out of two that i found online were a complete f***-up as far as actually being capable of printing anything accurately. i worked out that one of them i found would actually have a whopping FOUR PERCENT variation in the length of objects it printed as the head moved from one end of travel to the other. the other one was also a f***-up a the guy had put the GT2-20 motor gear higher than the idler bearings. it was hard to tell from the photos if he'd got them level with the x-ends but at the very least the upper and lower edges of the belt will be under different tensions by a tiny amount - tiny but enough to cause the belt to "ride" up and down on the bearing during travel. the consequences of that are well-known but include wear-and-tear on the belts, as well as minor variations in belt tension, and in extreme cases the belt coming *off* the idlers.

now, on that smartrapcore forum, the guy who posted "i designed a smartrapcore alu", that was over eight months ago. he has lots of people saying "wow, cool! yeah i'm making one!" and "yeah i'm copying your design!", it's not until months later that someone pointed out that the belt layout is f*****d. and did he listen? no. he said "surely that's not important, is it???" and the reply was "you can work that out with some calculations". no response - no questions, no "thank you".

so you say that you are going to copy "smartrapcore" - i am not really sure that's a very good idea, as there appear to be too many people who are completely clueless. just like with the original reprap, where to "fix" the z-issues the guy doing the demo stuck his thumb on the printbed in the middle of a print and went "there! it's fixed!".... let me be diplomatic and not finish the sentence...

in short, what i'm saying is, it's best that you know *why* you're doing what you're doing, from engineering principles, as opposed to copying someone else without understanding why they chose to do what they're doing. and picking a design that has *no background* - no explanation as to the decisions and provenance - is really, really asking for trouble. so, for this "smartrapcore", can you actually find a document which describes in full how it was designed and why the various design decisions were made?

with the Fusebox, there was at least some description of the design decisions, and they made sense to me. Alex_F had documented much of what he'd done, and had documented the revisions he'd made. the bits where he was having trouble after 4 revisions, turns out we're still discussing how to fix those on page 7 of the Fusebox forum.... but hey, that's the way it goes.

btw, on that Frax3D picture, the distance between the blue "start" and "end" are so far apart that i'd be concerned about "twisting" - which would manifest as side-wall loading on the linear bearings. the red will be the same. on the sandwich200v2 i endeavour to take this into account by lining up the "start" and "end" points of the belts directly underneath each other. it means that the "blue" and "red" bearings are slightly offset on the X-End (by the width of one bearing) so that the "blue" and "red" belts travel directly one above the other. i'm doing a vertical x-rod arrangement for the v2 so i feel it matters more.

i seem to recall that you've chosen a vertical x-rod arrangement as well, so this is something that you should probably look at, as well.

... in other words, for the design that you've chosen, neither of those two are good examples for you to follow. in the Fusebox, Alex_F chose to use one bolt to hold 2 bearings in each X-end. the distane between the two belts as they head towards the carriage is therefore 16mm (he uses 625 bearings). and that's.... i feel that that's close enough not to cause side-wall loading on the carriage's linear bearings, especially as he uses LM8LUUs. with two LM8UUs, you *will* get side-wall loading, resulting in clatter, wear, and, ultimately, damage to the bearings *and* the bars. i've heard of at least one person managing to do that.

Edited 1 time(s). Last edit at 04/23/2016 08:24PM by lkcl.

|

Re: Do CoreXY belts need to be of equal tension? April 23, 2016 11:08PM |

Registered: 9 years ago Posts: 1,035 |

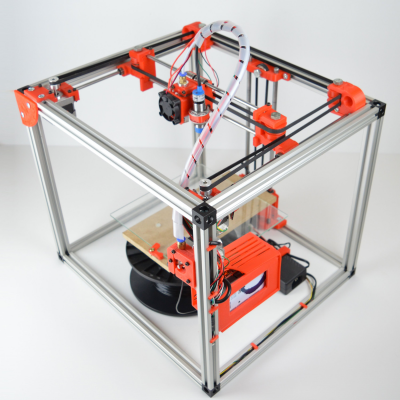

OK, your concerns are valid with different builds. So, to stop linking other designs and make room for deviating the discussion, here's the Sketchfab link to my printer STL:

[sketchfab.com]

I am in the process of moving the corexy steppers' vertical members (columns) outside to have a symmetric arrangement so I will upload a slight variation soon but this one is good enough to see what's straight, what's level, etc. I can tell you from the start that the line of belt coming/going to the X Carriage bearings are dead straight and that the bearings on X carriage, Idler and motor pulley are perfectly arranged vertically.

Whatever observations you have please let's make on the actual design as I am not building neither a smartrapcore nor the frax

Edit: btw, both motor mounts and idler mounts can be adjusted vertically by sliding them on the vertical members before tightening the square clamp on the alu tubing.

Cheers.

Edited 1 time(s). Last edit at 04/23/2016 11:21PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

[sketchfab.com]

I am in the process of moving the corexy steppers' vertical members (columns) outside to have a symmetric arrangement so I will upload a slight variation soon but this one is good enough to see what's straight, what's level, etc. I can tell you from the start that the line of belt coming/going to the X Carriage bearings are dead straight and that the bearings on X carriage, Idler and motor pulley are perfectly arranged vertically.

Whatever observations you have please let's make on the actual design as I am not building neither a smartrapcore nor the frax

Edit: btw, both motor mounts and idler mounts can be adjusted vertically by sliding them on the vertical members before tightening the square clamp on the alu tubing.

Cheers.

Edited 1 time(s). Last edit at 04/23/2016 11:21PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 24, 2016 02:51AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

OK, your concerns are valid with different builds. So, to stop linking other designs and make room for deviating the discussion, here's the Sketchfab link to my printer STL:

[sketchfab.com]

niiiice. oo, triple linear z-rails and dual z-threaded rods, niice. oh. left and right z-rails: you'll get seesaw effects on those, around the back z-rod. push one side down, the other will go up. take a look at page 7 of the Fusebox forum for some discussion on how to arrange an aluminium L-shape across the back, to stop that happening. the other way, which would work well, would be to put in 3 z-threaded rods (and use a belt at the bottom instead of 2 or 3 steppers - save on a stepper motor.

sooOoo... you have at the front bar-rod-bar and at the back rod-bar-rod, drop a GT2-20 onto the NEMA17 then a flexible 5-to-8 coupler on top of that (check it but i think there should be room...) - something like that... then the 2 threaded rods on one side will stabilise the corners... you miiight not need the middle linear rods at the back... because the 2 linear rods at the front would stop shear and sideways motion...

sorry i'm thinking out loud here

Quote

I am in the process of moving the corexy steppers' vertical members (columns) outside to have a symmetric arrangement so I will upload a slight variation soon but this one is good enough to see what's straight, what's level, etc. I can tell you from the start that the line of belt coming/going to the X Carriage bearings are dead straight and that the bearings on X carriage, Idler and motor pulley are perfectly arranged vertically.

aaawesome.

Quote

Edit: btw, both motor mounts and idler mounts can be adjusted vertically by sliding them on the vertical members before tightening the square clamp on the alu tubing.

mmm... that's just a temptation for people copying the build to get it utterly wrong. if you've no intention of having people copy your design then that need not be a concern. up to you.

|

Re: Do CoreXY belts need to be of equal tension? April 24, 2016 06:08AM |

Registered: 9 years ago Posts: 1,035 |

Sometimes I wonder what link have I directed you to  ...or that I'm lost in translation.

...or that I'm lost in translation.

I have no threaded rods, I only have belts for X, Y and Z.

X&Y are CoreXY arrangement.

Z is GT2 belt with 0.9deg motor and 3 linear rods guides for the bed.

XY stage has several adjustment options: Y Rods square clamps and the 4-point-adjustment for the moving parts and also XY motors square clamps that can go up and down on Z and left to right on their mounts.

Z stage is 3 rods which are inserted right into the square tubing for their upper ends and have the 4-point-adjustment screws at the lower end, for adjusting vertical and parallel position. The Bed Platform is also having some features that can take lots of errors, from Z Smooth Rods misalignment due to drill bits run-off while drilling the square tubes to the Bed Support T(ee) build errors. Anyways those are more difficult to spot unless I'll someday make a video about it.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

...or that I'm lost in translation.

...or that I'm lost in translation.I have no threaded rods, I only have belts for X, Y and Z.

X&Y are CoreXY arrangement.

Z is GT2 belt with 0.9deg motor and 3 linear rods guides for the bed.

XY stage has several adjustment options: Y Rods square clamps and the 4-point-adjustment for the moving parts and also XY motors square clamps that can go up and down on Z and left to right on their mounts.

Z stage is 3 rods which are inserted right into the square tubing for their upper ends and have the 4-point-adjustment screws at the lower end, for adjusting vertical and parallel position. The Bed Platform is also having some features that can take lots of errors, from Z Smooth Rods misalignment due to drill bits run-off while drilling the square tubes to the Bed Support T(ee) build errors. Anyways those are more difficult to spot unless I'll someday make a video about it.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 29, 2016 01:08AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Sometimes I wonder what link have I directed you to...or that I'm lost in translation.

I have no threaded rods, I only have belts for X, Y and Z.

sorry - i don't use proprietary software (so am not going to download a file i can't edit or view... because it's proprietary), and likewise a proprietary browser plugin is required to view the model in a web browser, so i got a very unclear 2D render - from a fixed perspective - which i could not do any zoom or rotate on.

understandable then that without any kind of specifications in the usual places (best place for which is the reprap wiki) i would assume quite a lot. sorry!

Quote

Anyways those are more difficult to spot unless I'll someday make a video about it.

yes. imagine you have a 2560x1600 screen, images come out very small (even if they're hi-res) you've allocated about 10-15 seconds to look at an image. it's late at night, so the brightness on the LCD is turned right down. the only way to get detail to people is to zoom *right* in, filling the entire image with really rather boring close-ups of exactly and pretty much only the part that you want to grab their attention with. repeat that quite a lot

Edited 1 time(s). Last edit at 04/29/2016 01:11AM by lkcl.

|

Re: Do CoreXY belts need to be of equal tension? April 29, 2016 03:38AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

sorry - i don't use proprietary software (so am not going to download a file i can't edit or view... because it's proprietary), and likewise a proprietary browser plugin is required to view the model in a web browser, so i got a very unclear 2D render - from a fixed perspective - which i could not do any zoom or rotate on.

You only need a modern open source browser with OpenGL ...or something like this. I use latest Firefox, so open source too.

There is no need for proprietary plugins to see the Sketchfab 3d model.

I don't dare to write in a wiki about something I haven't yet demonstrated or prototyped...soryy it might be a while until I have one.Quote

lkcl

understandable then that without any kind of specifications in the usual places (best place for which is the reprap wiki) i would assume quite a lot. sorry!

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 29, 2016 07:14PM |

Registered: 8 years ago Posts: 776 |

[editorial note: many apologies for the huge number of edits, the word p a n d o r a, which is used in the open project known as o p e n p a n d o r a . org, is apparently BANNED by the reprap sysadmins! not f***. not bulls*** - all words i used and then edited out - but p a n d o r a - a word used in an open hardware project! utterly ridiculous. i had to use a binary search on save-edit-save, cutting out 1/2 the reply, then 1/4, then 1/8th, then down to individual sentences, finally homing in on the quotes prohibited quotes word. so, anyway, that's why there are 4 - now 5 - edits. 4 iterations of a binary-search algorithm to find one word in a few hundred. not bad  anyway. sysadmins: wtf?? ]

anyway. sysadmins: wtf?? ]

i use debian (iceweasel) - i've never had it work with opengl.

the wiki's there so that you can dare to do exactly that. i put about 3 entries of 3d printers that i was contemplating building (and then abandoned) before i finally settled on the sandwich200. i've worked in public for about 20 years, now, on mailing lists, then wikis when they became popular, and i find them *really* important as a tool for *me* to keep track of things.

the abandoned entries: they're not even demonstrated or prototypes. it's a very common mistake made by people who are not familiar with libre and open concepts, to assume that people are going to... shock-horror... they criticise you because... shock-horror, you *didn't provide a fully working product*!!! f that: it's nonsense. people *want* to know how you went through the design process. look at what's happening here on the forum: you're getting a huge amount of advice and help, right?

... but forums are, frankly, a effing pain to actually track down information - they're actually worse than useless. google the "akula device". on a wiki somewhere that i found (with difficulty) someone refers you to a schematic on page SEVEN HUNDRED AND THIRTY of a similar forum (same source code) to this one. page 730 for god's sake! and there's another 300+ pages of discussion after that one. how in god's green earth is anyone going to *ever* find anything useful amongst a THOUSAND pages - pages! not comments - a thousand PAGES of comments. it's AOL BBS "me-too" postings all over again.

basically unless you happen to be reading and happen to be involved directly at the time, finding anything useful on a forum is either vastly time-consuming or is completely useless. it's utterly disorganised, and it's hit-and-miss even to try to use google to find proper advice.

and that's why we have articles, wiki's and... i really don't like the word ever since it took over from the straightfoward simple word called "diary" - quote blogs quotes. in those, we have comprehensive information, which doesn't move about, and is reasonably organised. wikis in particular are *really* important because the information is structured, and can be evolved over time to reflect the development process as it progresses, whereas articles and quotes blogs quotes cannot really be changed (or moved) without causing a great deal of hassle right across the entire internet.

people *want* to see the progress that you're making - look up the open p a n d o r a project some time, to see the incredibly valuable mistakes that they documented, saving others doing similar projects *enormous* amounts of time, money and more, and helped reduce risk.

to learn is to make mistakes and correct them, and people in this community *really* want to collaborate and help each other out: it's exciting, and it's a pretty exclusive thing we're doing. how are you going to do that if A you haven't told anyone what you're doing because you're "afraid" of wikis and B you use the forums in an unstructured way (as we all do) but *only* the forums, so that it's impossible for anyone to "catch up" with what you've done? that severely limits the scope of the number of people who are ever going to help you - or learn from what you did - or improve on it, doesn't it?

apologies, i'm not just speaking to you when writing this

Edited 5 time(s). Last edit at 04/29/2016 07:23PM by lkcl.

anyway. sysadmins: wtf?? ]

anyway. sysadmins: wtf?? ]Quote

realthor

Quote

lkcl

sorry - i don't use proprietary software (so am not going to download a file i can't edit or view... because it's proprietary), and likewise a proprietary browser plugin is required to view the model in a web browser, so i got a very unclear 2D render - from a fixed perspective - which i could not do any zoom or rotate on.

You only need a modern open source browser with OpenGL ...or something like this. I use latest Firefox, so open source too.

i use debian (iceweasel) - i've never had it work with opengl.

I don't dare to write in a wiki about something I haven't yet demonstrated or prototyped...soryy it might be a while until I have one.[/quote]Quote

lkcl

understandable then that without any kind of specifications in the usual places (best place for which is the reprap wiki) i would assume quite a lot. sorry!

the wiki's there so that you can dare to do exactly that. i put about 3 entries of 3d printers that i was contemplating building (and then abandoned) before i finally settled on the sandwich200. i've worked in public for about 20 years, now, on mailing lists, then wikis when they became popular, and i find them *really* important as a tool for *me* to keep track of things.

the abandoned entries: they're not even demonstrated or prototypes. it's a very common mistake made by people who are not familiar with libre and open concepts, to assume that people are going to... shock-horror... they criticise you because... shock-horror, you *didn't provide a fully working product*!!! f that: it's nonsense. people *want* to know how you went through the design process. look at what's happening here on the forum: you're getting a huge amount of advice and help, right?

... but forums are, frankly, a effing pain to actually track down information - they're actually worse than useless. google the "akula device". on a wiki somewhere that i found (with difficulty) someone refers you to a schematic on page SEVEN HUNDRED AND THIRTY of a similar forum (same source code) to this one. page 730 for god's sake! and there's another 300+ pages of discussion after that one. how in god's green earth is anyone going to *ever* find anything useful amongst a THOUSAND pages - pages! not comments - a thousand PAGES of comments. it's AOL BBS "me-too" postings all over again.

basically unless you happen to be reading and happen to be involved directly at the time, finding anything useful on a forum is either vastly time-consuming or is completely useless. it's utterly disorganised, and it's hit-and-miss even to try to use google to find proper advice.

and that's why we have articles, wiki's and... i really don't like the word ever since it took over from the straightfoward simple word called "diary" - quote blogs quotes. in those, we have comprehensive information, which doesn't move about, and is reasonably organised. wikis in particular are *really* important because the information is structured, and can be evolved over time to reflect the development process as it progresses, whereas articles and quotes blogs quotes cannot really be changed (or moved) without causing a great deal of hassle right across the entire internet.

people *want* to see the progress that you're making - look up the open p a n d o r a project some time, to see the incredibly valuable mistakes that they documented, saving others doing similar projects *enormous* amounts of time, money and more, and helped reduce risk.

to learn is to make mistakes and correct them, and people in this community *really* want to collaborate and help each other out: it's exciting, and it's a pretty exclusive thing we're doing. how are you going to do that if A you haven't told anyone what you're doing because you're "afraid" of wikis and B you use the forums in an unstructured way (as we all do) but *only* the forums, so that it's impossible for anyone to "catch up" with what you've done? that severely limits the scope of the number of people who are ever going to help you - or learn from what you did - or improve on it, doesn't it?

apologies, i'm not just speaking to you when writing this

Edited 5 time(s). Last edit at 04/29/2016 07:23PM by lkcl.

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 03:05AM |

Registered: 9 years ago Posts: 1,035 |

no worries, those are good points. I'll try to learn how to use the wiki and start a page for ScoutCore.I'd rather document and change a single page than cluttering the forums anyway.

it's a confusing environment to choose between instructables, github, reprap wiki, thingiverse, etc ... Is there a CoreXY category in the wiki? I might need some guidance to it :-s

BTW:: @lkcl : the sketchfab model is downloadable should you want to study it in your STL renderer of choice. Here's the download link again: [sketchfab.com]

Edit: as far as I can see, the reprap wiki is very poor with the documentation of the successful builds I am seeing on the forums (G&C, Vulcanus, FuseBox, etc ...none of these already built, tested and proven ones is there)

Edited 6 time(s). Last edit at 04/30/2016 04:34AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

it's a confusing environment to choose between instructables, github, reprap wiki, thingiverse, etc ... Is there a CoreXY category in the wiki? I might need some guidance to it :-s

BTW:: @lkcl : the sketchfab model is downloadable should you want to study it in your STL renderer of choice. Here's the download link again: [sketchfab.com]

Edit: as far as I can see, the reprap wiki is very poor with the documentation of the successful builds I am seeing on the forums (G&C, Vulcanus, FuseBox, etc ...none of these already built, tested and proven ones is there)

Edited 6 time(s). Last edit at 04/30/2016 04:34AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 01:32PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

no worries, those are good points. I'll try to learn how to use the wiki and start a page for ScoutCore.I'd rather document and change a single page than cluttering the forums anyway.

it's a confusing environment to choose between instructables, github, reprap wiki, thingiverse, etc ... Is there a CoreXY category in the wiki? I might need some guidance to it :-s

BTW:: @lkcl : the sketchfab model is downloadable should you want to study it in your STL renderer of choice. Here's the download link again: [sketchfab.com]

Edit: as far as I can see, the reprap wiki is very poor with the documentation of the successful builds I am seeing on the forums (G&C, Vulcanus, FuseBox, etc ...none of these already built, tested and proven ones is there)

que? eh?? no comprenndo! [reprap.org] and search in there for "tag:CoreXY". i believe it's just that you're not familiar with wikis, whereas i've been using them for... errr... 15 years i think, am a contributor to wikipedia, and even wrote a wiki server in python a long time ago... anyway, yes, FuseBox is definitely there: it's how i found it.

basically, the way i see it is, if someone can be bothered to actually document their build properly, it says to me that they have a sound and responsible engineering and project management head on their shoulders (even if they're only project-managing themselves).

can i suggest start by literally cut/pasting either the Fusebox or the Sandwich200 page - don't for goodness sake bother typing out all that crud yourself - and then just wipe 98% of the words, leave the headings you want, change a few words in the description and intro, and then fill in the rest later. save the page often (because you can). you have the right (under the terms of the license of material on the wiki) to do exactly that, so copy away.

and, honestly, don't be concerned - at all - about "being in the public eye" - very few people actually notice when people edit wiki pages, you actually have to go and poke people with a stick to get them to notice, such as blogging about it (blerrrgh, still can't get used to that word...).

so just use it for your own sanity, just like you clearly noticed already: the "info" around the forums quickly gets unmanageable. oh - another suggestion, use the "Discussion" link to store any amount of notes you want (don't pollute the actual page), drop http links to forum messages you particularly want to keep track of and so on. it's there as a publicly-accessible resource, but so few people understand that they have the absolute freedom to use it and make their lives easier!

instructables: instructables is *definitely* for afterwards. it's as the domain name says: it's to *instruct* others. that *is* for when you've completed the build.

github (or better an actual libre service such as gitlab), that's for version control of the project files. BOM, CAD files (if they actually check in to git properly - don't commit binary files to a git repository!!!!), and so on.

thingiverse.... i really don't like the fact that makerlabs f*****d everyone over by secretly registering patents of *PUBLICLY* discussed ideas in reprap forums - other people's prior art basically - and then used those to pull the wool over the eyes of VCs, then disappeared from all the public forums because everyone in the maker community was *really* pissed with them. f*****rs. at least youmagine is not run by deceitful people.

anyway. youmagine (and other sites like it) are basically exactly the same as instructables, except focussed specifically on 3d printing. so again, one definitely for *after* a build.

but wikis - wikis are specifically there for the collation and sane management of information. work-in-progress documentation, notes, categorisation, comparison, discussion (even with yourself!), and so on. very *very* useful. i mean, take a look here - there's like... 50 edits since 4th april for goodness sake: [reprap.org]

ok enough

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 02:27PM |

Registered: 9 years ago Posts: 1,035 |

Wow, I don't understand anything from there ... I'm completely unfamiliar with wikis. I'll have to do some reading.

Edit: nice documenting there.... trying to get my head around it.

Edit: Do I need to PM an admin to open a page for me? How do I do it otherwise? I'll copy the code from your link and start from there.

Edited 2 time(s). Last edit at 04/30/2016 02:41PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edit: nice documenting there.... trying to get my head around it.

Edit: Do I need to PM an admin to open a page for me? How do I do it otherwise? I'll copy the code from your link and start from there.

Edited 2 time(s). Last edit at 04/30/2016 02:41PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 04:01PM |

Registered: 11 years ago Posts: 5,780 |

If you start posting stuff to wikis every time you make a change to something, you'll be spending all your time posting stuff to wikis and none of it developing your project. I tend to save the documentation at the end of a project so I don't waste time documenting things that change a lot throughout the process.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 09:25PM |

Registered: 9 years ago Posts: 1,035 |

Not changes but Goals, etc ...the bird view stuff ... + a few pictures ...

I believe a git is best to sync with the project folder on my computer. But I don't have experience with git either ... yet

... yet

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I believe a git is best to sync with the project folder on my computer. But I don't have experience with git either

... yet

... yetRepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Do CoreXY belts need to be of equal tension? April 30, 2016 10:27PM |

Registered: 9 years ago Posts: 83 |

[rogerdudler.github.io]

Very, very quick overview of git, git workflow, and common tasks.

Then learn the incredibly simple "markdown" language that is common to github, and you can publish your project with history, documentation and 8x10 color glossy photos with circles and arrows and a paragraph on the back of each one explaining what it is.

Very, very quick overview of git, git workflow, and common tasks.

Then learn the incredibly simple "markdown" language that is common to github, and you can publish your project with history, documentation and 8x10 color glossy photos with circles and arrows and a paragraph on the back of each one explaining what it is.

|

Re: Do CoreXY belts need to be of equal tension? May 03, 2016 05:15AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

If you start posting stuff to wikis every time you make a change to something, you'll be spending all your time posting stuff to wikis and none of it developing your project. I tend to save the documentation at the end of a project so I don't waste time documenting things that change a lot throughout the process.

dd: from 20 years of experience in developing software, i've found that the complete opposite is the case. the more complex the project, the more critical it has been to make even cursory notes about even the smallest change. yes you are right about not going to extremes, but to give you an example, i am deliberately using pyopenscad to auto-generate the scad files which are then shown in 3D in openscad. i am creating the entire model in *python*. to repeat: the entire CAD model of the sandwich200 is an object-orientated PYTHON program. what that means is, i can use a git repository to commit each and every single change, i can add a comment on the commit message, and i can do a "diff" where i can revert each commit, and also see clearly what i did in the past, and why.

so if i make a MISTAKE i can SEE WHAT I DID WRONG. i can correct it... without having to abandon an entire revision which may be inter-dependent on weeks or months of work. i can go, "hmm, i moved that over, that moved as a consequence, that bit had to shrink, it was all 3-4 weeks ago, what did i do, and how can i revert it? oh, i know - i'll look through the git log and find out!"

and you know what? i absolutely cringe at the thought of how people have to do CAD design _without_ this kind of extremely detailed note-taking and easy-to-find change logging. how does everyone else manage: don't tell me.... they have dozens of ZIP archives of the same project or something??? because that's completely insane - how can you do a visual "diff" to find a single set of micro-changes that are needed to be reverted because of a mistake??

then, also, just having notes - for myself - about what i'm doing, why i'm doing it - this is just good project management practice for complex projects.

if however you have a better memory than me, or your build is simpler, then yes, i can see how it would be possible to hold the working design in your head, and to not need to keep any ongoing documentation.

the other perspective i see on this is, it doesn't matter if it "slows things down", it's just a courtesy to others in the community to invite them to take a look, now and in the future. i learned a great deal from reviewing some of the more detailed builds where they had created ongoing notes and photos, and, personally, i'd like to return the favour.

|

Re: Do CoreXY belts need to be of equal tension? May 03, 2016 05:18AM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Wow, I don't understand anything from there ... I'm completely unfamiliar with wikis. I'll have to do some reading.

just experiment. and by copying another page it's pretty obvious what does what - no need to "read" - you can just infer what you need from the clear results shown by copying and iteratively editing a page.

Quote

Edit: nice documenting there.... trying to get my head around it.

Edit: Do I need to PM an admin to open a page for me?

nnope.

Quote

How do I do it otherwise? I'll copy the code from your link and start from there.

usual way that i use is, go to the "edit" button then you'll see a link at the top. change the URL - replace sandwich200 with "{insert your printer name}" in the *actual URL*, then hit "save".

the other ways are a pain i find, things like "go search for the page, first, and you will be presented with an option to create it" - ick

Edited 1 time(s). Last edit at 05/03/2016 05:20AM by lkcl.

|

Re: Do CoreXY belts need to be of equal tension? May 03, 2016 06:27AM |

Registered: 9 years ago Posts: 1,035 |

I can't write python for my CAD  .

.

I am using a proprietary (unfortunately) CAD and I have thousands of objects in the file ...can't easily port it over to OnShape or OpenSCad ... I have no time for that and I barely know this software (DesignSparkMechanical).

I usually just delete whatever objects I notice are bad design or have some fault or need replacing, otherwise I modify that object. Not many options to revert back a change but on the other hand this software is stellar at fast prototyping, it's very easy to redo something, if not very complicated. I haven't had many issues with it so far but I'd like to switch to something open source in the near future ... I have my eyes on Antimony for some time but haven't had the chance to dive into it.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

.

.I am using a proprietary (unfortunately) CAD and I have thousands of objects in the file ...can't easily port it over to OnShape or OpenSCad ... I have no time for that and I barely know this software (DesignSparkMechanical).

I usually just delete whatever objects I notice are bad design or have some fault or need replacing, otherwise I modify that object. Not many options to revert back a change but on the other hand this software is stellar at fast prototyping, it's very easy to redo something, if not very complicated. I haven't had many issues with it so far but I'd like to switch to something open source in the near future ... I have my eyes on Antimony for some time but haven't had the chance to dive into it.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.