Coffeetable CoreXY:: new build :: small apartment rep-strap solutions

Posted by realthor

|

Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 21, 2015 04:48PM |

Registered: 9 years ago Posts: 1,035 |

Hi guys, I am looking for a first 3D printer to get my feet wet. After much pondering I have settled on a corexy configuration as the most cost-effective.

The constrains with these build are:

- small studio apartment (35+sq m) so as quiet as possible

- 300 or sub-300Eur build

- Rep-Strap as much as possible (use wood panels or existing furniture or structures to achieve rigidity)

- least amount of printed parts (I don't have a printer to print parts with, I can ask a friend to print parts or go to the local library but that does not ensure precise parts)

- cheap controller (Mega/Ramps)

- belt or spectra (spectra preferred but belt is ok)

- maybe more, can't tell right now

I tried to find aluminum extrusion of sorts in the area => no avail;

I looked for square alu tubing in the area (EUR8+/m)... too expensive (around 50Eur for 12 pieces of 450mm length)

I realized I had this:

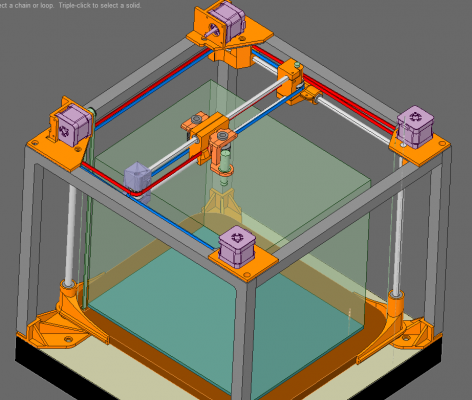

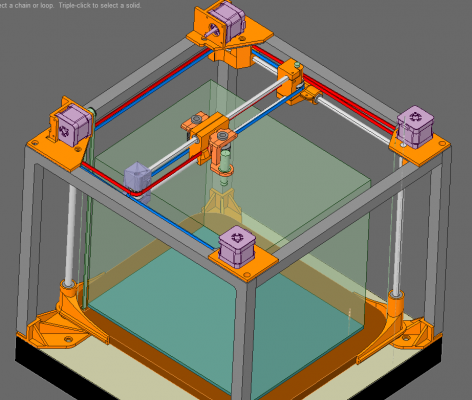

which is 450x450x370 usable area (without the top wooden block)...and that I can do this:

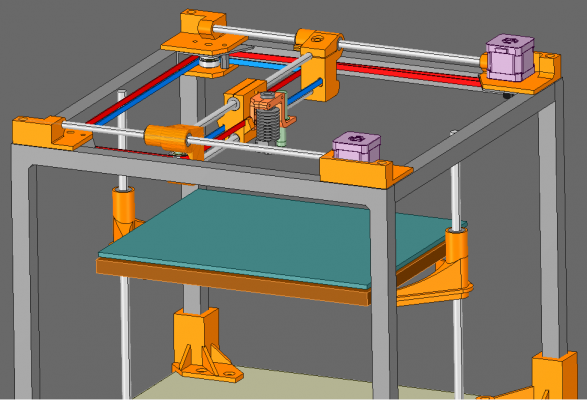

namely take it apart and placing the wooden block below the feet to have the rigid structure atop, which translates to this in CAD format:

This is pretty square (measured it with a level) and square angle.

Please note that I am a big fan of belts and spectra so Rich Rap's Slid3R, Smartfriendz's Smartrap Corexy and this belt-based dual-Z rank high on my prefrences list. I also like to do pretty experimental stuff (see the bot in my sig) so no high expectations here, I can always upgrade to an alu frame of v|t-slot extrusions if unsatisfied

I need as much constructive advice as I can get along this build. I will be ordering the parts from aliexpress so they will take time to arrive, enough time to improve the design.

I will be using:

- Nema17 1.8 stepper motors with 2.5A (the strong ones) [these I already have]

- Arduino Mega/ Ramps 1.4 with some strong current capable steppers (to take advantage of the 2.5A motors)

- GT2 belts for XY and maybe spectra for Z)

- 8mm XY rods/ 10mm Z rods with linear bearings (bushings? maybe for quietness)

- SmartRap CoreXY style corexy configuration (vertically stacked rods for x, vertically stacked bearings for redirection pulleys)

- [more to be defined]

The squareness of the frame will be done by some printed "flanges" that will connect the steel legs to the wooden board using the same holes it used when being in the normal, non-reversed position.

I will have to drill extra holes in the frame and I would like to keep those at a minimum while still achieving the largest print size for the frame.

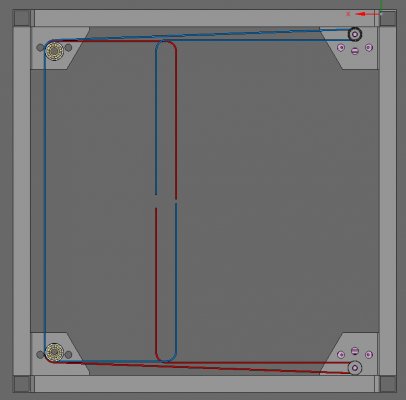

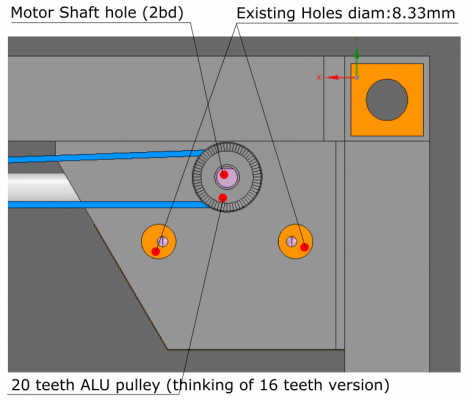

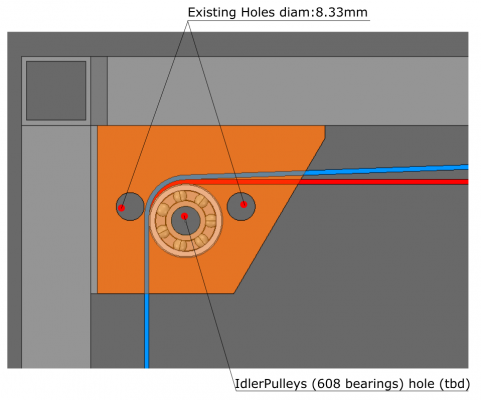

Details of the CoreXY design (design for 20 teeth ALU pulley pushed to the edge of the frame and 608 bearings for idlers):

I am thinking of actually using 16 teeth ALU pulleys and maybe a different size idlers. Anyways one idler will have to be larger to prevent contact of the same color belts' sections at the opposite side to the motors.

This is the part where I will be drilling extra holes in the bracket:

- I am thinking of using the existing holes for the stepper motor mounting and drill one extra hole for the motor shatf to go under the bracket. This will be done in such a way that the chosen pulley (16 or 20 teeth) will keep the belt parallel on the side that attaches to the X carriage):

- I will drill a single hole in the opposite bracket to use for the idlers' bolt (8mm/608 idlers for now, that might change) and use the existing holes to somehow ensure this bolt's vertical rigidity:

More to come I will also wait for feedback to pick a topic and discuss on it.

Thank you.

Edited 2 time(s). Last edit at 11/21/2015 04:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The constrains with these build are:

- small studio apartment (35+sq m) so as quiet as possible

- 300 or sub-300Eur build

- Rep-Strap as much as possible (use wood panels or existing furniture or structures to achieve rigidity)

- least amount of printed parts (I don't have a printer to print parts with, I can ask a friend to print parts or go to the local library but that does not ensure precise parts)

- cheap controller (Mega/Ramps)

- belt or spectra (spectra preferred but belt is ok)

- maybe more, can't tell right now

I tried to find aluminum extrusion of sorts in the area => no avail;

I looked for square alu tubing in the area (EUR8+/m)... too expensive (around 50Eur for 12 pieces of 450mm length)

I realized I had this:

which is 450x450x370 usable area (without the top wooden block)...and that I can do this:

namely take it apart and placing the wooden block below the feet to have the rigid structure atop, which translates to this in CAD format:

This is pretty square (measured it with a level) and square angle.

Please note that I am a big fan of belts and spectra so Rich Rap's Slid3R, Smartfriendz's Smartrap Corexy and this belt-based dual-Z rank high on my prefrences list. I also like to do pretty experimental stuff (see the bot in my sig) so no high expectations here, I can always upgrade to an alu frame of v|t-slot extrusions if unsatisfied

I need as much constructive advice as I can get along this build. I will be ordering the parts from aliexpress so they will take time to arrive, enough time to improve the design.

I will be using:

- Nema17 1.8 stepper motors with 2.5A (the strong ones) [these I already have]

- Arduino Mega/ Ramps 1.4 with some strong current capable steppers (to take advantage of the 2.5A motors)

- GT2 belts for XY and maybe spectra for Z)

- 8mm XY rods/ 10mm Z rods with linear bearings (bushings? maybe for quietness)

- SmartRap CoreXY style corexy configuration (vertically stacked rods for x, vertically stacked bearings for redirection pulleys)

- [more to be defined]

The squareness of the frame will be done by some printed "flanges" that will connect the steel legs to the wooden board using the same holes it used when being in the normal, non-reversed position.

I will have to drill extra holes in the frame and I would like to keep those at a minimum while still achieving the largest print size for the frame.

Details of the CoreXY design (design for 20 teeth ALU pulley pushed to the edge of the frame and 608 bearings for idlers):

I am thinking of actually using 16 teeth ALU pulleys and maybe a different size idlers. Anyways one idler will have to be larger to prevent contact of the same color belts' sections at the opposite side to the motors.

This is the part where I will be drilling extra holes in the bracket:

- I am thinking of using the existing holes for the stepper motor mounting and drill one extra hole for the motor shatf to go under the bracket. This will be done in such a way that the chosen pulley (16 or 20 teeth) will keep the belt parallel on the side that attaches to the X carriage):

- I will drill a single hole in the opposite bracket to use for the idlers' bolt (8mm/608 idlers for now, that might change) and use the existing holes to somehow ensure this bolt's vertical rigidity:

More to come I will also wait for feedback to pick a topic and discuss on it.

Thank you.

Edited 2 time(s). Last edit at 11/21/2015 04:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 23, 2015 12:29PM |

Registered: 9 years ago Posts: 346 |

I am concerned that play in the carriage bearings will allow your nozzle to move and thus you will not give very nice walls.

The bigger the distance from the linear bearing to the nozzle end, the bigger will the resulting movement from play in the linear bearing be. At the same time it seems you will only install one linear bearing so the play can be significant unless you buy very high end components.

Go look at other CoreXY printers and you will see that the nozzle is much closer to the center of the linear bearings

Rest looks fine. You should use bushings instead of ball linear bearings. It will be more silent and have smoother movement. I got some graphite inlaid from China and even though they cost 3 times the ball bearings they are still really low cost and even as I haven't installed them yet, they seem much better when running them with my hand.

How big will it be? Looking at the coffee table photo it looks like it will be huge.

The bigger the distance from the linear bearing to the nozzle end, the bigger will the resulting movement from play in the linear bearing be. At the same time it seems you will only install one linear bearing so the play can be significant unless you buy very high end components.

Go look at other CoreXY printers and you will see that the nozzle is much closer to the center of the linear bearings

Rest looks fine. You should use bushings instead of ball linear bearings. It will be more silent and have smoother movement. I got some graphite inlaid from China and even though they cost 3 times the ball bearings they are still really low cost and even as I haven't installed them yet, they seem much better when running them with my hand.

How big will it be? Looking at the coffee table photo it looks like it will be huge.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 23, 2015 02:14PM |

Registered: 11 years ago Posts: 5,780 |

If you want to verify squareness, all you have to do is measure the diagonals. If the diagonals are the same length, the object is square.

If you're concerned about slop in bearings, I suggest you look into linear guides, at least for the X axis. There is no slop at all and you won't need to use two of them. It will reduce the mass and improve the performance of your X axis at least, and if you use them on the Y axis as well your machine will be about as close to perfect as you can get. You can find good deals on quality, used, linear guides on ebay. I used three in my printer and I recently bought a new-old-stock IKO linear guide, about 630 mm long with bearing block for $34 shipped. You can find deals like that on ebay all the time if you're willing to wade through the multiple pages of listings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're concerned about slop in bearings, I suggest you look into linear guides, at least for the X axis. There is no slop at all and you won't need to use two of them. It will reduce the mass and improve the performance of your X axis at least, and if you use them on the Y axis as well your machine will be about as close to perfect as you can get. You can find good deals on quality, used, linear guides on ebay. I used three in my printer and I recently bought a new-old-stock IKO linear guide, about 630 mm long with bearing block for $34 shipped. You can find deals like that on ebay all the time if you're willing to wade through the multiple pages of listings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 23, 2015 02:57PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

I am concerned that play in the carriage bearings will allow your nozzle to move and thus you will not give very nice walls.

The bigger the distance from the linear bearing to the nozzle end, the bigger will the resulting movement from play in the linear bearing be. At the same time it seems you will only install one linear bearing so the play can be significant unless you buy very high end components.

Go look at other CoreXY printers and you will see that the nozzle is much closer to the center of the linear bearings

Rest looks fine. You should use bushings instead of ball linear bearings. It will be more silent and have smoother movement. I got some graphite inlaid from China and even though they cost 3 times the ball bearings they are still really low cost and even as I haven't installed them yet, they seem much better when running them with my hand.

How big will it be? Looking at the coffee table photo it looks like it will be huge.

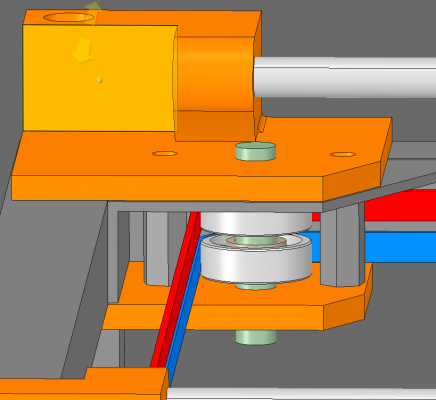

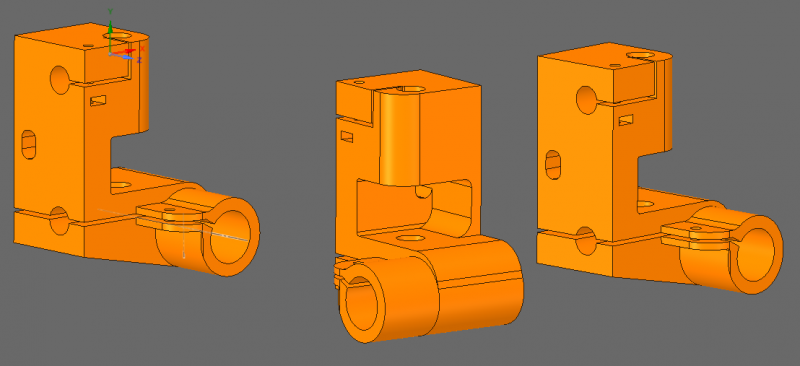

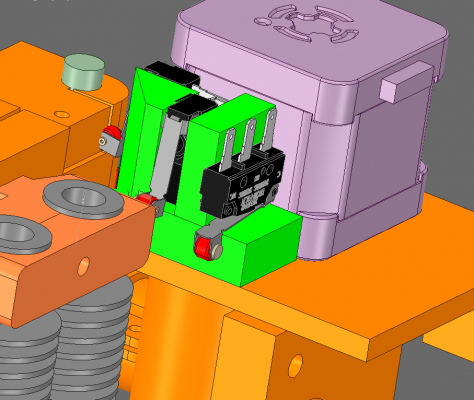

Funny I actually had the same feeling and although i liked very much the design I completely changed it over the weekend, in the way you say. This is the current one:

Still playing with different parts and solutions. BTW, there are 2 bearings on all smooth rods.

Currently the X carriage is based (almost identical in fact) with Smartrap CoreXY design. Now The lower smooth rod is almost in the same plane with the Y rods and the nozzle is much closer so the observerd issue should be gone.

The exterior dimensions are 450x450x370 but if I manage to get the bed to lower very close to the base the build volume is 255x325x285mm but I am pretty sure it will be a tad smaller.

About bushings I don't know, I am tempted but many swear on bearings and I see bearings as a better option for newbies.

@the_digital_dentist: Linear steel rails with block bearings would be great but I've checked on Aliexpress and they cost 4 times as much as the same length smooth rods.

Edited 2 time(s). Last edit at 11/23/2015 03:01PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 23, 2015 06:32PM |

Registered: 9 years ago Posts: 346 |

Hey, looks nice. Good job.

I would maybe be a little worried about part stiffness. For example the vertical brazing from the wood plate to the steel structure and many of the carriage parts. Printed they might not be as strong as you hope for. Maybe reinforce and increase material thickness and surface contact area. It is my experience that with printed parts it is better to have a series of small bolts joining the parts together then one central bigger bolt. The force distribution gets better. So better to use 3 distributed M3 bolts then a single M5 for example.

I would maybe be a little worried about part stiffness. For example the vertical brazing from the wood plate to the steel structure and many of the carriage parts. Printed they might not be as strong as you hope for. Maybe reinforce and increase material thickness and surface contact area. It is my experience that with printed parts it is better to have a series of small bolts joining the parts together then one central bigger bolt. The force distribution gets better. So better to use 3 distributed M3 bolts then a single M5 for example.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 23, 2015 07:05PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

Hey, looks nice. Good job.

I would maybe be a little worried about part stiffness. For example the vertical brazing from the wood plate to the steel structure and many of the carriage parts. Printed they might not be as strong as you hope for. Maybe reinforce and increase material thickness and surface contact area. It is my experience that with printed parts it is better to have a series of small bolts joining the parts together then one central bigger bolt. The force distribution gets better. So better to use 3 distributed M3 bolts then a single M5 for example.

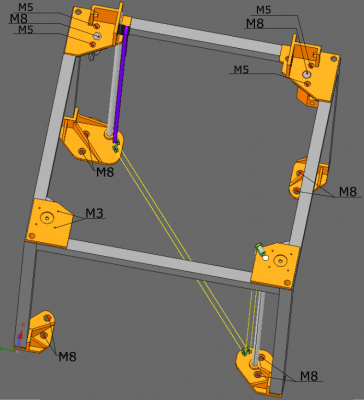

The thickness of all the plastic plates that are being bolted onto the metal frame are 5mm, which from my exp is enough. The following is the bolts' distribution on the current design:

I am also thinking of placing an insert nut just below each metal foot and running a M5 or M6 threaded rod to the top hole where I would put a washer and clamp it tight.

I am a bit worried with the XY motors mounts as the corner plates/brackets will only be held by 2 of those tiny screws (M3 i guess). I might rethink a bit these two brackets because I can only mount the motor with two of the four mounting holes as the other two cover the steel square pipe. My intention was to drill the minimum number of extra holes.

BTW the Smartrap CoreXY mounts the motors with only two screws.

-----------------------

For the other features:

- are 4x8mm shaft for XY and 2x10mm for Z good numbers?

- can you point me to a better X carriage for corexy than the smartrap?

- does the aluminum 16 tooth pulley have any disadvantage (bigger backlash?) then the 20 tooth? Is another one better? I know that the smallest the better resolution but I don't know what has to give...

- I am tempted to use 2 leadscrews for Z instead of the belt/spectra but for that I would need a belt loop of exact dimensions right?

I'll leave other questions for after i get some answers on these ones so I can at least order the parts.

Thank you.

Edited 2 time(s). Last edit at 11/24/2015 06:17AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 07:03AM |

Registered: 9 years ago Posts: 346 |

A number of comments:

1) Your printer is too big for just 8mm linear rods.

2) 5mm material thickness is fine. No need to make that bigger. But material thickness is not all. An unsupported angle even in 5mm thickness will not have much strength. But at this point I think it is better if you make some test prints and try to feel it instead of listening to me trying to be smart based on picture

3) About better ways to do the X carriage; In my opinion there are too few (none, really) reference designs in CoreXY where the performance is documented to a degree that makes me say: THAT is the way to do it. Most often it comes down to the credibility of the person posting or commenting on the design rather then actual data from printed parts. So continue what you have already been doing, look at designs here and on Thingiverse and other sites. Think hard about if the part will have the stiffness and rigidity you want and finally axis of rotations given from play in moving parts. Finally - Start printing some parts to get a feel. Don't spend hours and hours designing a part and then realize that the design won't work because it is overall not stiff enough or can't be printed to the tolerance needed.

4) Using M8 is way overkill unless you are forced by your table to do that- You will crack the plastic before you get any torque put into that kind of bolt.

1) Your printer is too big for just 8mm linear rods.

2) 5mm material thickness is fine. No need to make that bigger. But material thickness is not all. An unsupported angle even in 5mm thickness will not have much strength. But at this point I think it is better if you make some test prints and try to feel it instead of listening to me trying to be smart based on picture

3) About better ways to do the X carriage; In my opinion there are too few (none, really) reference designs in CoreXY where the performance is documented to a degree that makes me say: THAT is the way to do it. Most often it comes down to the credibility of the person posting or commenting on the design rather then actual data from printed parts. So continue what you have already been doing, look at designs here and on Thingiverse and other sites. Think hard about if the part will have the stiffness and rigidity you want and finally axis of rotations given from play in moving parts. Finally - Start printing some parts to get a feel. Don't spend hours and hours designing a part and then realize that the design won't work because it is overall not stiff enough or can't be printed to the tolerance needed.

4) Using M8 is way overkill unless you are forced by your table to do that- You will crack the plastic before you get any torque put into that kind of bolt.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 08:02AM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

1) Your printer is too big for just 8mm linear rods.

the calculated linear rods are X=340mm, Y=360mm, Z=370mm.

Are you saying that I should have 10mm linear rods for X and Y and maybe 12 for Z (considering that I am planning to have only one shaft per side)?

Note: I could barely fit the 10mm Z linear shafts in the corners of the design, I couldn't fit the 12mm because the bearing above and the bearing case will get to a too big diameter that I couldn't fir because it will hit the XY belts. And if I fit the Z rods in between the steel pipes I would reduce the Z travel by more than 30mm.

I don't see too much effort on Z if the bed gets lifted from 2 opposite sides of the bed.

Quote

LarsK

2) An unsupported angle even in 5mm thickness will not have much strength. But at this point I think it is better if you make some test prints and try to feel it instead of listening to me trying to be smart based on picture

Are you referring to the fact that all the bolts are concentrated in the middle thus leaving the edges unsupported? I don't really understand what you want to say here...

Quote

LarsK

3) Don't spend hours and hours designing a part and then realize that the design won't work because it is overall not stiff enough or can't be printed to the tolerance needed.

Unfortunately I can only get some time here and there at the local library which is quite far in fact, so printing parts will be slow. That's why I am mostly dealing with design. I want to order the shafts/bearings/electronics/etc first and then, until they arrive, I'll have time to print bits and pieces.

Quote

LarsK

4) Using M8 is way overkill unless you are forced by your table to do that- You will crack the plastic before you get any torque put into that kind of bolt.

The holes in the metal frame are all 8.33mm ... strange for a metric value, maybe it's something imperial and I don't know but in those 8.33mm holes I plan to put M5 bolts to clamp the above and below plastic parts and the M8 is for the 608 belt-redirect bearings below. 608s take 8mm shaft...hence 8mm bolt. Do you know of a better choice of pulley for the 6mm GT2 belt?

I don't mind suggestions coming... this design will take some time until all the parts will come from China. That's why it's important for me to get all the vitamins right.

Edited 2 time(s). Last edit at 11/24/2015 08:45AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 08:41AM |

Registered: 9 years ago Posts: 346 |

Quote

realthor

Quote

LarsK

1) Your printer is too big for just 8mm linear rods.

the calculated linear rods are X=340mm, Y=360mm, Z=370mm.

Are you saying that I should have 10mm linear rods for X and Y and maybe 12 for Z (considering that I am planning to have only one shaft per side)?

Note: I could barely fit the 10mm Z linear shafts in the corners of the design, I couldn't fit the 12mm because the bearing above and the bearing case will get to a too big diameter that I couldn't fir because it will hit the XY belts. And if I fit the Z rods in between the steel pipes I would reduce the Z travel by more than 30mm.

I don't see too much effort on Z if the bed gets lifted from 2 opposite sides of the bed.

Problem I was pointing to is only the X and Y axis.. On X and Y you should go for 10 or 12 mm. More 12 mm. I don't know about the Z axis, the loads are different.

Quote

realthor

Quote

LarsK

2) An unsupported angle even in 5mm thickness will not have much strength. But at this point I think it is better if you make some test prints and try to feel it instead of listening to me trying to be smart based on picture

Are you referring to the fact that all the bolts are concentrated in the middle thus leaving the edges unsupported? I don't really understand what you want to say here...

You could make the material 3 times thicker on the left bracket and the right bracket would still be the strongest for bending. I think you need more cross support on your individual printed parts. Not just thicker material. But test print would be the best here.

Quote

realthor

Quote

LarsK

3) Don't spend hours and hours designing a part and then realize that the design won't work because it is overall not stiff enough or can't be printed to the tolerance needed.

Unfortunately I can only get some time here and there at the local library which is quite far in fact, so printing parts will be slow. That's why I am mostly dealing with design. I want to order the shafts/bearings/electronics/etc first and then, until they arrive, I'll have time to print bits and pieces.

Honestly, then consider sticking as much as possible to an existing design with as little redesign as possible. Many designs should work just fine with your table structure.

Quote

realthor

Quote

LarsK

4) Using M8 is way overkill unless you are forced by your table to do that- You will crack the plastic before you get any torque put into that kind of bolt.

The holes in the metal frame are all 8.33mm ... strange for a metric value, maybe it's something imperial and I don't know but in those 8.33mm holes I plan to put M5 bolts to clamp the above and below plastic parts and the M8 is for the 608 belt-redirect bearings below. 608s take 8mm shaft...hence 8mm bolt. Do you know of a better choice of pulley for the 6mm GT2 belt?

This sounds correct the but I still think you overall should use more bolts to get more evenly distributed loads on the plastic. But when I compare my builds to others I also see that I use more then most so don't know.

edits: Getting the quote right...

Edited 4 time(s). Last edit at 11/24/2015 09:03AM by LarsK.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 09:54AM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

2) An unsupported angle even in 5mm thickness will not have much strength. But at this point I think it is better if you make some test prints and try to feel it instead of listening to me trying to be smart based on picture

Now I get it I was looking through my parts and I didn't see anything that could resemble an angle so I am not even using corner brackets neither aluminum nor 3d printed ones. I am almost sure I'll have to make the structure more rigid some way. I just don't want to put many holes that would weaken the structure and also don't want holes on the exterior tubings, the ones that are visible. But this can be an afterthought and when will be needed I will act upon it.

Regarding the other parts they are pretty hefty, I feel I exaggerated with the bulkiness of some of the parts, like for example the Y carriages they are much more thick than the Smartrap core ones. We'll see after I print a first round. My design is based a lot after the smartrap core -at least the XY carriages- and most of the parts are bigger/thicker.

Take Y carriage:

Maybe right, maybe wrong, it's a bit overkill but all the important holes are the same with Smartrap core's (as far as I remember).

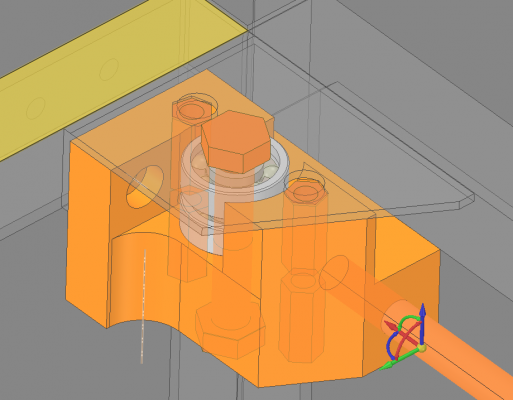

Also compare my belts-redirect corner part:

It is fixed to the above steel bracket (existing in the table design) by the 3 bolts and to the side tube by another bolt and also I have hex couplers inside to provide additional suppport as the belts' tension will try to take the bearings away from the corner.

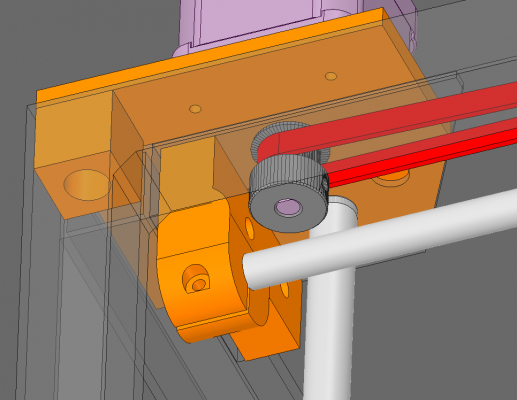

On the other side of the Y rod I have it this way:

Here there are no forces on the Y rod. All the ripping forces are on the motor's shaft as the belt is tensioned and transferred eventually into the metal corner plate/bracket via the stepper's mount bolts.

Ok, now there is enough material here to send me to court

. Bring it on

. Bring it on

Edited 1 time(s). Last edit at 11/24/2015 09:55AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 11:16AM |

Registered: 9 years ago Posts: 346 |

Quote

realthor

Ok, now there is enough material here to send me to court. Bring it on

Hah, well, for my part I'm afraid I have to disappoint. I don't feel I have more constructive input. As you know the Z axis still needs some work and you need to settle on an extruder and how to place the endstops.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 11:44AM |

Registered: 9 years ago Posts: 1,035 |

That's a start

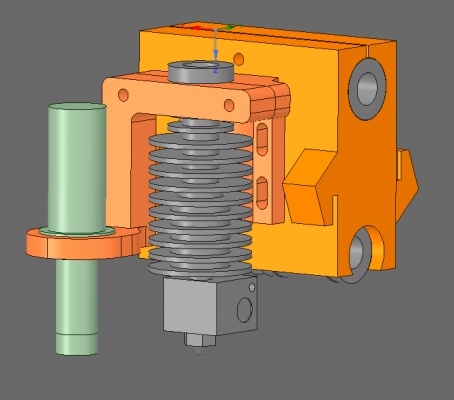

The extruder is ok as is imho. I will change if I find a better one though but that goes from experience and I haven't got so much. I am looking around though. Recently have been going through the assembling instructions for the x400ce 3d printer from germanreprap. Fascinating build and high quality and the extruder is modular, one extruder one bearing:

But what is wrong with the one i've got? It's basically Smartrap core's.

If I can't tell what is wrong I can't improve upon...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The extruder is ok as is imho. I will change if I find a better one though but that goes from experience and I haven't got so much. I am looking around though. Recently have been going through the assembling instructions for the x400ce 3d printer from germanreprap. Fascinating build and high quality and the extruder is modular, one extruder one bearing:

But what is wrong with the one i've got? It's basically Smartrap core's.

If I can't tell what is wrong I can't improve upon...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 12:26PM |

Registered: 9 years ago Posts: 346 |

Where is the motor and the part driving the filament? I know the smartrap-core is direct driven but I can't find the actual extruder in what you show above. Also earlier you showed two hotends in what seemed like a Bowden setup.

Kind reminder: The hot-end is the part that gets hot (the one you showed a screenshot of above) and the extruder is the parts with the motor with a hubbed bolt which drives the filament. Sometimes the hotend and extruder is made in the same assembly (like SmartRapCore) and sometimes it is not, then it is called a bowden setup. If the motor shaft is driving the hubbed bolt directly it is called a direct drive, if there is a gear (like Wades infamous extruder) then it is not

Kind reminder: The hot-end is the part that gets hot (the one you showed a screenshot of above) and the extruder is the parts with the motor with a hubbed bolt which drives the filament. Sometimes the hotend and extruder is made in the same assembly (like SmartRapCore) and sometimes it is not, then it is called a bowden setup. If the motor shaft is driving the hubbed bolt directly it is called a direct drive, if there is a gear (like Wades infamous extruder) then it is not

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 24, 2015 01:05PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

Where is the motor and the part driving the filament? I know the smartrap-core is direct driven but I can't find the actual extruder in what you show above. Also earlier you showed two hotends in what seemed like a Bowden setup.

Kind reminder: The hot-end is the part that gets hot (the one you showed a screenshot of above) and the extruder is the parts with the motor with a hubbed bolt which drives the filament. Sometimes the hotend and extruder is made in the same assembly (like SmartRapCore) and sometimes it is not, then it is called a bowden setup. If the motor shaft is driving the hubbed bolt directly it is called a direct drive, if there is a gear (like Wades infamous extruder) then it is not

Lol, my bad... my brain read hotend/X-carriage for some reason. The extruder is the fourth motor in the corner oposite to the Z motor:

I haven't sketched the actual extruder but I'm planning to use a direct drive extruder like this one.

Endstops are tricky to place I actually have no idea where to put them. But then again that is not critical. I'll think about it.

Edited 1 time(s). Last edit at 11/24/2015 01:06PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 25, 2015 09:00AM |

Registered: 9 years ago Posts: 1,035 |

Catch-up post:

I have opened another thread in hope of getting an easy way to assess the smooth rods diameters that my printer needs but I ended up doing the calculation myself, which in itself was a very interesting journey. I wasn't aware of many things. Anyway my calculations results seem to be:

- 2x8mmx340mm for the X carriage (can take a weight up to 650 grams)

- 2x10mmx360mm for the Y carriage (can take a weight of up to 650 grams per rod but when the carriage is on the extreme side, near the rod, most of the weight of the X carriage is taken by that rod)

- 2x10mmx 370mm for the Z (I will be installing each rod in opposite corners of the printer and most likely drive the Z via belt/Spectra for start, without any gearing and with microstepping activated)

@LarsK: if you are still watching the thread, what bushing did you use? Should i consider bushings for X and Y only and Bearings for Z - noise on Z is not that bothering because of the little movement?

For ont of the previous unanswered questions I haven't found a preper answer yet:

- 10 vs 20 teeth GT2 pulleys. I plan to use the 16 tooth; any disadvantage?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I have opened another thread in hope of getting an easy way to assess the smooth rods diameters that my printer needs but I ended up doing the calculation myself, which in itself was a very interesting journey. I wasn't aware of many things. Anyway my calculations results seem to be:

- 2x8mmx340mm for the X carriage (can take a weight up to 650 grams)

- 2x10mmx360mm for the Y carriage (can take a weight of up to 650 grams per rod but when the carriage is on the extreme side, near the rod, most of the weight of the X carriage is taken by that rod)

- 2x10mmx 370mm for the Z (I will be installing each rod in opposite corners of the printer and most likely drive the Z via belt/Spectra for start, without any gearing and with microstepping activated)

@LarsK: if you are still watching the thread, what bushing did you use? Should i consider bushings for X and Y only and Bearings for Z - noise on Z is not that bothering because of the little movement?

For ont of the previous unanswered questions I haven't found a preper answer yet:

- 10 vs 20 teeth GT2 pulleys. I plan to use the 16 tooth; any disadvantage?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 25, 2015 12:52PM |

Registered: 9 years ago Posts: 346 |

Quote

realthor

I haven't sketched the actual extruder but I'm planning to use a direct drive extruder like this one.

I use the same. On my first Chinese kit printer the bearing holding piece broke and I made my own which is reinforced - That one was injection molded. On my 2nd printer I printed my own and that worked and works fine to this day. On my 3rd printer I had the problem that the thread that you cut in it to hold the fitting broke doing startup. I never liked using cut threads in plastic parts anyways so I also changed it to use a steel M5 bolt that the fitting screws into. I should just redesign the thing to work better with my modifications. On the todo list for some day

click here to see it

Quote

realthor

@LarsK: if you are still watching the thread, what bushing did you use? Should i consider bushings for X and Y only and Bearings for Z - noise on Z is not that bothering because of the little movement?

For ont of the previous unanswered questions I haven't found a preper answer yet:

- 10 vs 20 teeth GT2 pulleys. I plan to use the 16 tooth; any disadvantage?

I think normal ball bearings on the Z axis works nicely, as you said, moves less. I uploaded a small video with a comparison between graphite inlaid linear bearings and the "normal" ball linear bearings. I think the advantage of the graphite is obvious but is it worth the price for you? You decide

For the record; I also think that normal linear rails are better then rods but I understand the price concern.

You can find the video by clicking here, my new printer is running in the background so I guess you can take the background noise as expected noise from fans, etc.

About the pulleys - I use the 20 tooth because that is what is easy to buy. I tried to buy 16 tooth but it was not easy to buy last time I looked. On paper I think the 16 is better as belt slip is not a problem for us (the motor gives up before the pulley / belt) - But at the end of the day I think the difference is insignificant.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 25, 2015 08:21PM |

Registered: 9 years ago Posts: 1,035 |

I kind of found a nice way to have all the endstops in one place (assuming I'll keep the diagonal Z):

It's a rough sketch I am still trying to figure out a good way to adjust the endstops positions without using screws on the XY moving parts.For Z there will be a long bolt activating it from below. On the other hand 3 screws are practically negligible in weight.

I will bundle the wires with the stepper's and will route them through the tubing at the corner.

I posted this to introduce the following question: I've read that it is possible to tell the firmware to home by doing Y first, which is the only way that this setup is feasible. Is that true? I wonder why some solutions out there keep the endstops on the moving parts. It makes no sense.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

It's a rough sketch I am still trying to figure out a good way to adjust the endstops positions without using screws on the XY moving parts.For Z there will be a long bolt activating it from below. On the other hand 3 screws are practically negligible in weight.

I will bundle the wires with the stepper's and will route them through the tubing at the corner.

I posted this to introduce the following question: I've read that it is possible to tell the firmware to home by doing Y first, which is the only way that this setup is feasible. Is that true? I wonder why some solutions out there keep the endstops on the moving parts. It makes no sense.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 26, 2015 12:53PM |

Registered: 9 years ago Posts: 1,035 |

I have to think about the electronics so I can order. If i order from China it will take some time.

I am considering 32 bits but not duet 0.8.5, it is out of the price I would pay for a first 3d printer.

I am thinking:

Due+Ramps-FD (~14+25=39Eur + free shipping from china); a plus that it runs most firmwares

MKS board SBASE board is compatible with Smoothieware V1.2 32 (~52Eur)

Duet 0.6 (from Replikeo: ~70Eur);

I would really like to hear some opinions about sub-80Eur electronics.

Edited 1 time(s). Last edit at 11/26/2015 01:12PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am considering 32 bits but not duet 0.8.5, it is out of the price I would pay for a first 3d printer.

I am thinking:

Due+Ramps-FD (~14+25=39Eur + free shipping from china); a plus that it runs most firmwares

MKS board SBASE board is compatible with Smoothieware V1.2 32 (~52Eur)

Duet 0.6 (from Replikeo: ~70Eur);

I would really like to hear some opinions about sub-80Eur electronics.

Edited 1 time(s). Last edit at 11/26/2015 01:12PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 26, 2015 01:51PM |

Registered: 10 years ago Posts: 14,672 |

There are serous design issues with RAMPS-FD, so don't get it. See the thread in the Controllers section.

The Duet 0.6 from Replikeo has the advantage over the MKS SBASE that it gives you a good web interface without additional hardware. Against that, the Duet 0.6 has 4 stepper drivers compared with 5 for the SBASE, and there have been a few reports of users receiving faulty boards from Replikeo. Replikeo seems happy to replace them, but you have to wait for shipping from China again. I have no idea what the return rate of MKS SBASE boards is.

I though the MKS SBASE and the Replikeo Duet both cost $50. Is the price difference you quote because the MKS board comes with free shipping? With either board, you may have to pay import VAT as well.

There are issues with early MKS SBASE boards, so if you choose it then make sure you get the most recent version - again, there is a thread in the Controllers section about this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The Duet 0.6 from Replikeo has the advantage over the MKS SBASE that it gives you a good web interface without additional hardware. Against that, the Duet 0.6 has 4 stepper drivers compared with 5 for the SBASE, and there have been a few reports of users receiving faulty boards from Replikeo. Replikeo seems happy to replace them, but you have to wait for shipping from China again. I have no idea what the return rate of MKS SBASE boards is.

I though the MKS SBASE and the Replikeo Duet both cost $50. Is the price difference you quote because the MKS board comes with free shipping? With either board, you may have to pay import VAT as well.

There are issues with early MKS SBASE boards, so if you choose it then make sure you get the most recent version - again, there is a thread in the Controllers section about this.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 26, 2015 02:17PM |

Registered: 9 years ago Posts: 1,035 |

They are talking about RAMPS-FD v2 which i can find nowhere. I also was hoping for some black friday offer for 0.8.5 byt they are out of stock...what a bummer

For the Duet... should I decide later on to upgrade to dual extruder, is there an expansion board available and does it make sense compared to purchasing Duet from the start?

Also I have 2.5A motors, do the steppers on the Duet0.6/Duet 0.8.5 support such strong motors?

With Duet I am guessing I can only run RepRap Firmware right? What do I loose from a features pov if I buy Duet0.6 besides the extra stepper? I suppose I can re-upload firmware or config without the hassle of the arduino mega. Also I guess having ethernet it is more convenient to hook it up to a router -although wireless would have been the best for that.

BTW I know it's not really woth it for my build because the frame is not very sturdy so high speeds aren't an option I guess but for future upgrades I believe 32 bits is the way to go.

Thanks.

Edited 3 time(s). Last edit at 11/26/2015 02:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

For the Duet... should I decide later on to upgrade to dual extruder, is there an expansion board available and does it make sense compared to purchasing Duet from the start?

Also I have 2.5A motors, do the steppers on the Duet0.6/Duet 0.8.5 support such strong motors?

With Duet I am guessing I can only run RepRap Firmware right? What do I loose from a features pov if I buy Duet0.6 besides the extra stepper? I suppose I can re-upload firmware or config without the hassle of the arduino mega. Also I guess having ethernet it is more convenient to hook it up to a router -although wireless would have been the best for that.

BTW I know it's not really woth it for my build because the frame is not very sturdy so high speeds aren't an option I guess but for future upgrades I believe 32 bits is the way to go.

Thanks.

Edited 3 time(s). Last edit at 11/26/2015 02:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 26, 2015 03:44PM |

Registered: 10 years ago Posts: 14,672 |

As I understand it, RAMPS-FD version 2 is a design that has never been put into production. If you want a board to add to an Arduino Due, take a look at RADDS.

2.5A stepper motors are a poor choice, because none of the available controller boards can drive them close to their rated current. You should choose stepper motors with rated current in the range 1.2A to 1.7A.

Yes there is an expansion board for the Duet. The DueX4 adds 4 stepper drivers and 4 hot end heaters to either a Duet 0.6 or 0.85. The Duet Shield adds 2 stepper drivers and heaters to a Duet 0.6 only. But a Duet 0.85 would probably costs less than either of these + a Duet 0.6.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2.5A stepper motors are a poor choice, because none of the available controller boards can drive them close to their rated current. You should choose stepper motors with rated current in the range 1.2A to 1.7A.

Yes there is an expansion board for the Duet. The DueX4 adds 4 stepper drivers and 4 hot end heaters to either a Duet 0.6 or 0.85. The Duet Shield adds 2 stepper drivers and heaters to a Duet 0.6 only. But a Duet 0.85 would probably costs less than either of these + a Duet 0.6.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 26, 2015 06:26PM |

Registered: 9 years ago Posts: 1,035 |

I've gone through the whole thread about the SBASE and am more and more drawn to it for its 5 stepper drivers. Also the revision selling currently is 1.2, which solved the jumping temperature reading at the nozzle and they also removed a useless component in a minor revision from 1.1 to 1.2 .

What hardware are you referring to when you say "a good web interface without additional hardware". The SBASE has a card reader as far as I know but misses a LCD. An 12864LCD of the type they also sell goes for about 6Eur on Aliexpress.

Is there any other advantage Replikeo Duet has over SBASE?

I would really buy Duet0.6 but that one extra stepper driver has a dual extruder flavor to it which is very appealing. I've always wanted the second extruder only for two purposes: 0.8 or even 1mm nozzle for infills and (washable) support material. Can't care less for colors and that sort of stuff.

I am a bit worried about quality and missing documentation but overall that extra driver gives it the edge. It's still half the price of a Duet0.8.5 and a third of that of a smoothieboard.

Also about the motors I really can't do anything about it, I already have them. As well as E3Dv6 clones (2 of them). For a first printer I think that the learning curve involved with problematic components is better down the road. Otherwise I'd buy a playstation and conserve my brain

Cheees.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

What hardware are you referring to when you say "a good web interface without additional hardware". The SBASE has a card reader as far as I know but misses a LCD. An 12864LCD of the type they also sell goes for about 6Eur on Aliexpress.

Is there any other advantage Replikeo Duet has over SBASE?

I would really buy Duet0.6 but that one extra stepper driver has a dual extruder flavor to it which is very appealing. I've always wanted the second extruder only for two purposes: 0.8 or even 1mm nozzle for infills and (washable) support material. Can't care less for colors and that sort of stuff.

I am a bit worried about quality and missing documentation but overall that extra driver gives it the edge. It's still half the price of a Duet0.8.5 and a third of that of a smoothieboard.

Also about the motors I really can't do anything about it, I already have them. As well as E3Dv6 clones (2 of them). For a first printer I think that the learning curve involved with problematic components is better down the road. Otherwise I'd buy a playstation and conserve my brain

Cheees.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 04:16AM |

Registered: 10 years ago Posts: 14,672 |

I haven't used Smoothieware, but on a CoreXY machine I am not aware of any significant difference in functionality between RepRapFirmware on the Duet and Smoothieware on the SBASE, other than the web interface. With Smoothieware on the SBASE you get a very primitive web interface, and the upload speed to the SD card is poor. With RepRapFirmware on the Duet, you get the much better DuetWebControl interface which includes fast upload to the SD card. Nearly all Duet users control their printers using the web interface, and upload files to the SD card through it. With the SBASE, if you want a good web interface then you need to add a Raspberry Pi or similar running Octoprint.

Another difference between the boards is the LCD support. The SBASE supports the primitive but cheap 12864 display. Most Duet users don't use an LCD because you can control the printer form a tablet or smartphone over the network, but if you do want one then it supports PanelDue, which is a colour graphics touch control panel. It's much nicer than the 12864 with larger, higher resolutions displays in a choice of sizes and an on-screen keyboard allowing you to enter gcode commands directly, but it costs more. [Full disclosure: I manufacture and sell the PanelDue display controller board.]

If you choose the SBASE, you should factor in the cost of the LCD because you will want one unless you always have a PC right next to the printer. With the Duet, you need not if you have a tablet or smartphone and you can connect the printer to your router.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Another difference between the boards is the LCD support. The SBASE supports the primitive but cheap 12864 display. Most Duet users don't use an LCD because you can control the printer form a tablet or smartphone over the network, but if you do want one then it supports PanelDue, which is a colour graphics touch control panel. It's much nicer than the 12864 with larger, higher resolutions displays in a choice of sizes and an on-screen keyboard allowing you to enter gcode commands directly, but it costs more. [Full disclosure: I manufacture and sell the PanelDue display controller board.]

If you choose the SBASE, you should factor in the cost of the LCD because you will want one unless you always have a PC right next to the printer. With the Duet, you need not if you have a tablet or smartphone and you can connect the printer to your router.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 09:05AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

That's so true. the Duet have many features and is expandable.

Actualy, the price of the Duet is the major restraint for purchase.

If it was Smoothieboard vs Duet, I'll go for the second one, definitely.

But even if you add a screen, a Pi, another screen for the Pi, you're still ways under the price of the Duet with the Sbase.

Otherhand, if you plan to manage several printers, Octoprint/Pi is not a bad idea.

The Sbase, as the AZSMZ, represents a first price 32 bits board.

Obviously it do not offers all the features of the best boards.

But It's ways better than any 16 bits board which does not offers much features too.

This for a third of the price of a genuine Ramps.

You want to take the Sbase just for what it is.

It's personal, but I can't imagine investing 100€ or more in a control board.

I didn't even for my 650lbs CNC mill.

++JM

That's so true. the Duet have many features and is expandable.

Actualy, the price of the Duet is the major restraint for purchase.

If it was Smoothieboard vs Duet, I'll go for the second one, definitely.

But even if you add a screen, a Pi, another screen for the Pi, you're still ways under the price of the Duet with the Sbase.

Otherhand, if you plan to manage several printers, Octoprint/Pi is not a bad idea.

The Sbase, as the AZSMZ, represents a first price 32 bits board.

Obviously it do not offers all the features of the best boards.

But It's ways better than any 16 bits board which does not offers much features too.

This for a third of the price of a genuine Ramps.

You want to take the Sbase just for what it is.

It's personal, but I can't imagine investing 100€ or more in a control board.

I didn't even for my 650lbs CNC mill.

++JM

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 09:13AM |

Registered: 9 years ago Posts: 1,035 |

Quote

J-Max

Hi guys,

That's so true. the Duet have many features and is expandable.

Actualy, the price of the Duet is the major restraint for purchase.

If it was Smoothieboard vs Duet, I'll go for the second one, definitely.

But even if you add a screen, a Pi, another screen for the Pi, you're still ways under the price of the Duet with the Sbase.

Otherhand, if you plan to manage several printers, Octoprint/Pi is not a bad idea.

The Sbase, as the AZSMZ, represents a first price 32 bits board.

Obviously it do not offers all the features of the best boards.

But It's ways better than any 16 bits board which does not offers much features too.

This for a third of the price of a genuine Ramps.

You want to take the Sbase just for what it is.

It's personal, but I can't imagine investing 100€ or more in a control board.

I didn't even for my 650lbs CNC mill.

++JM

Do you own a sbase board? It would be very reassuring if someone actively involved in these discussions would have it running. Currently the only refrain I have with buying this board is the fear of not being able to wire it to a rescued IBM desktop powersource and everything that is required to get it to a functional state.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 09:38AM |

Registered: 8 years ago Posts: 233 |

I have both the Duet 0.6 and the SBase boards. I have mostly run the Duet, but did run the Sbase for a short period of time.

I found the Sbase web interface very inferior to the web interface of the Duet. As a matter of fact, I found the Sbase web interface substantially inferior to running the Sbase with USB connection. So I only ran the Sbase via USB connection and pronterface. The web interface on the Duet is so good, that I NEVER run the Duet via USB connection.

I found the Duet web interface VERY nice to use, better than Pronterface for me. Pronterface IS pretty, and does have some cool additional features... but the DUET web interface is just EASY and very intuitive to use.

For US buyers on the east coast, the Sbase ends up being about $12 cheaper, because Replikeo charges shipping while the Sbase supplier gives free shipping. The Sbase wins as the lowest cost 32bit board for US buyers.

A major Duet advantage to me is the ridiculously fast, personal support for the Duet firmware provided by David/dc42 via this forum.

I ended up choosing the Duet for permanent install, and have been using it for further printer experiments also. If I need to shave $12 from a build, or if there is some development in the web interface for SBASE, I may consider it again.

There is some interesting work using the ESP8266 chip to run the Duet style web interface on MANY boards and adding WiFi into the mix too. That could change the balance toward SBASE if ESP8266 ever gets the bugs worked out of it. I have a bunch of the ESP8266 chips lying around, so I may play with this too if I get a chance.

Edited 1 time(s). Last edit at 11/27/2015 09:43AM by patrickrio.

I found the Sbase web interface very inferior to the web interface of the Duet. As a matter of fact, I found the Sbase web interface substantially inferior to running the Sbase with USB connection. So I only ran the Sbase via USB connection and pronterface. The web interface on the Duet is so good, that I NEVER run the Duet via USB connection.

I found the Duet web interface VERY nice to use, better than Pronterface for me. Pronterface IS pretty, and does have some cool additional features... but the DUET web interface is just EASY and very intuitive to use.

For US buyers on the east coast, the Sbase ends up being about $12 cheaper, because Replikeo charges shipping while the Sbase supplier gives free shipping. The Sbase wins as the lowest cost 32bit board for US buyers.

A major Duet advantage to me is the ridiculously fast, personal support for the Duet firmware provided by David/dc42 via this forum.

I ended up choosing the Duet for permanent install, and have been using it for further printer experiments also. If I need to shave $12 from a build, or if there is some development in the web interface for SBASE, I may consider it again.

There is some interesting work using the ESP8266 chip to run the Duet style web interface on MANY boards and adding WiFi into the mix too. That could change the balance toward SBASE if ESP8266 ever gets the bugs worked out of it. I have a bunch of the ESP8266 chips lying around, so I may play with this too if I get a chance.

Edited 1 time(s). Last edit at 11/27/2015 09:43AM by patrickrio.

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 09:56AM |

Registered: 9 years ago Posts: 1,035 |

Quote

patrickrio

There is some interesting work using the ESP8266 chip to run the Duet style web interface on MANY boards and adding WiFi into the mix too. That could change the balance toward SBASE if ESP8266 ever gets the bugs worked out of it. I have a bunch of the ESP8266 chips lying around, so I may play with this too if I get a chance.

Can you tell us a little bit more about this? Is this planned for a future revision of the SBASE or is it something independent? Do you have any links discussing that?

I am still leaning slightly towards Duet but the two extruders promise of sbase is killing me.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 11:42AM |

Registered: 9 years ago Posts: 346 |

about ESP8266 see this, it is truly great work!

On subject; Why don't you just start out with a RAMPS and the boring 8bit? A lot of people (me included) is still running this antique way and it is fine. Once you get a better feel for where you wanna go and how much money you want to sink into this, you can upgrade.

Yes, in the future you may end up having an unused RAMPS and Arduino Mega - And so what? It is a nice platform to have for experiments, 3d printer or no. The little money you sink into that now, will give you much more time to evaluate what you need - Plus - and not to forget, this is your first printer, and everyone makes mistakes the first time (and 2nd, and 3rd... etc.) - You will cry a lot less if you burn out an Arduino Mega board then a Duet(!).

Finally - Ramps + Arduino just works... It is one less unknown for your build because you can be 99% sure that whatever problem you encounter, someone else will have experienced it before...

On subject; Why don't you just start out with a RAMPS and the boring 8bit? A lot of people (me included) is still running this antique way and it is fine. Once you get a better feel for where you wanna go and how much money you want to sink into this, you can upgrade.

Yes, in the future you may end up having an unused RAMPS and Arduino Mega - And so what? It is a nice platform to have for experiments, 3d printer or no. The little money you sink into that now, will give you much more time to evaluate what you need - Plus - and not to forget, this is your first printer, and everyone makes mistakes the first time (and 2nd, and 3rd... etc.) - You will cry a lot less if you burn out an Arduino Mega board then a Duet(!).

Finally - Ramps + Arduino just works... It is one less unknown for your build because you can be 99% sure that whatever problem you encounter, someone else will have experienced it before...

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 12:34PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LarsK

about ESP8266 see this, it is truly great work!

On subject; Why don't you just start out with a RAMPS and the boring 8bit? A lot of people (me included) is still running this antique way and it is fine. Once you get a better feel for where you wanna go and how much money you want to sink into this, you can upgrade.

Yes, in the future you may end up having an unused RAMPS and Arduino Mega - And so what? It is a nice platform to have for experiments, 3d printer or no. The little money you sink into that now, will give you much more time to evaluate what you need - Plus - and not to forget, this is your first printer, and everyone makes mistakes the first time (and 2nd, and 3rd... etc.) - You will cry a lot less if you burn out an Arduino Mega board then a Duet(!).

Finally - Ramps + Arduino just works... It is one less unknown for your build because you can be 99% sure that whatever problem you encounter, someone else will have experienced it before...

I was thinking about 32bit controller because I am working on a SCARA bot that would take advantage of the 32 bit. But then again that is highly experimental too so I don't know if keeping a 32bit board on that while refining it makes sense. It will mostly stay idle.

Otherwise I already have a sanguinolulu a friend donated when he upgraded and I used it on the SCARA for first tests. My problem is that I also need a somewhat reliable printer to continue work on that one and other projects I have in mind. I am thinking that 32 bit controllers are not there yet (Duet0.8.5 and Smoothieware might be but Smoothieware doesn't support SCARA as far as I know and I also believe their price is still too high for most hobbyists).

I am sooo not decided yet

Edited 1 time(s). Last edit at 11/27/2015 12:36PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Coffeetable CoreXY:: new build :: small apartment rep-strap solutions November 27, 2015 12:34PM |

Registered: 10 years ago Posts: 14,672 |

Quote

LarsK

...

Finally - Ramps + Arduino just works... It is one less unknown for your build because you can be 99% sure that whatever problem you encounter, someone else will have experienced it before...

I think it is more accurate to say that a good quality Ramps + Arduino + LCD (needed for the SD card) just works, provided you don't attach a graphical LCD or a servo (either of which will overheat the voltage regulator on the Arduino), and once you have mastered the art of setting the stepper driver pots using a voltmeter without damaging them in the process. There are posts on these forums every week from users who have overheated the Arduino 5V regulator, and from users who are having difficulty getting the motor currents right.

IMO there are fewer unknowns with a Duet, and probably by now with as SBASE too.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.