Triple-rod supported bed, 8mm shaft enough or go higher?

Posted by realthor

|

Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 06:48AM |

Registered: 9 years ago Posts: 1,035 |

Hello,

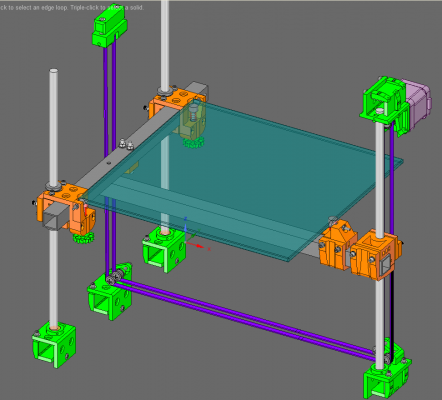

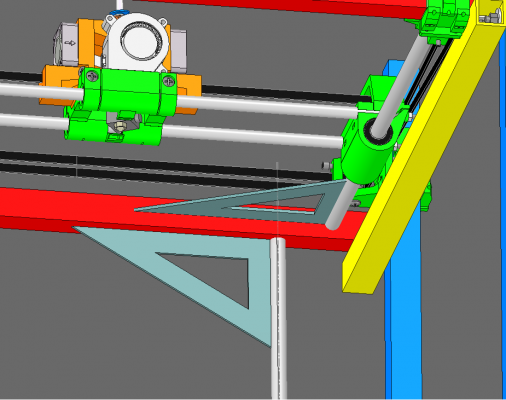

I planned 10mm rods for SCOUTcorexy's dual-supported Z platform but am wondering, as long as the bed is not cantilevered it might be sufficient to have 8mm rods (also considering that I use 3 rods).

Here's a sketch:

Thanks.

Edited 2 time(s). Last edit at 05/25/2016 02:16AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I planned 10mm rods for SCOUTcorexy's dual-supported Z platform but am wondering, as long as the bed is not cantilevered it might be sufficient to have 8mm rods (also considering that I use 3 rods).

Here's a sketch:

Thanks.

Edited 2 time(s). Last edit at 05/25/2016 02:16AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 07:16AM |

Registered: 8 years ago Posts: 346 |

Loved your design, you have put some greats idea where...

more questions:

what is the size of the metal tube? 20x20?

The mema17 motor will have enough force and precision without a reduction?

The belt tension is made by the 2 screw on the top, correct? where do you fix theses 2 screws? looks like is missing one printed piece to fix the screws

Are you planning to share the file of this bed? when?

more questions:

what is the size of the metal tube? 20x20?

The mema17 motor will have enough force and precision without a reduction?

The belt tension is made by the 2 screw on the top, correct? where do you fix theses 2 screws? looks like is missing one printed piece to fix the screws

Are you planning to share the file of this bed? when?

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 09:06AM |

Registered: 9 years ago Posts: 1,035 |

Quote

filipeCampos

Loved your design, you have put some greats idea where...

more questions:

what is the size of the metal tube? 20x20?

The mema17 motor will have enough force and precision without a reduction?

The belt tension is made by the 2 screw on the top, correct? where do you fix theses 2 screws? looks like is missing one printed piece to fix the screws

Are you planning to share the file of this bed? when?

Thanks Filipe. I pasted the screenshot just for rod question

...

... * The tube or the extrusion that it is designed around is 20x20.

* I have Nema17 0.9deg and it will have as a consequence double the precision of the smartrapcore, which works as is. A geared motor is planned down the road.

* The belt is tensioned with two screws and doesn't miss any part.

I will release the design of course, it is already at least in part (and a big WIP) on thingiverse: [www.thingiverse.com]

So, back to my question: are 8mm Z rods enough for this design? SCALU (smartrapcore alu) uses 8mm rods (4 of them) in their latest kit.

Edited 4 time(s). Last edit at 05/25/2016 03:07AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 10:32AM |

Registered: 11 years ago Posts: 5,780 |

The rails are only providing guidance, so the question is: what size will be adequate to prevent lateral flexure that will cause visible layer registration problems? The only thing that would cause lateral flexure of the rails as the bed moves up and down would be misalignment of the rails. How do you intend to align the rails so that each is perpendicular to the X and Y axes?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 11:08AM |

Registered: 9 years ago Posts: 1,035 |

The actual "procedure" is yet to be defined.

There are some features in the design that will help aligning. The upper end of the rods will be inserted in holes in metal, just like solidoodle did it. The lower ends of the rods will float inside a 3-point-adjusting collar where I will work with small bolts to move it so that the bed goes up and down with ease. This should be a first level of getting to a point where the Z stage is usable.

Then there should be some other way to really make sure that is right and that could be done with a digital gauge that slides on the frame's tubes/extrusions and should register the same reading as it goes along the rod, but that is quite challenging.

Would you suggest a better way?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

There are some features in the design that will help aligning. The upper end of the rods will be inserted in holes in metal, just like solidoodle did it. The lower ends of the rods will float inside a 3-point-adjusting collar where I will work with small bolts to move it so that the bed goes up and down with ease. This should be a first level of getting to a point where the Z stage is usable.

Then there should be some other way to really make sure that is right and that could be done with a digital gauge that slides on the frame's tubes/extrusions and should register the same reading as it goes along the rod, but that is quite challenging.

Would you suggest a better way?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 12:13PM |

Registered: 11 years ago Posts: 5,780 |

You might start by getting one rail perpendicular to X and Y, lock it down at both ends, then use the bed carriage to space the rails parallel to each other. I used the frame as a reference for the initial alignment of my printer's axes and it worked well, but all the frame members were milled to matching lengths and I knew from corner to corner diagonal measurements that the frame was square. If you can verify squareness of the frame, you can use metal spacers to set the first rail parallel to the frame. Then start with the carriage at one end of the rails, lock the other two rails down at that end, then move the carriage up (or down) and lock the two rails down at that end.

Edited 1 time(s). Last edit at 05/23/2016 01:08PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 05/23/2016 01:08PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 12:36PM |

Registered: 9 years ago Posts: 1,035 |

That's a good idea but it's pretty difficult to do so ... at least in the current setup:

The Z rods are offset from the Y Rods vertical plane so in order to align them I should move them in the same plane to be able to use a square against their centers.

But if I want to keep them the same width as the bed how can I ensure perpendicularity between them?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The Z rods are offset from the Y Rods vertical plane so in order to align them I should move them in the same plane to be able to use a square against their centers.

But if I want to keep them the same width as the bed how can I ensure perpendicularity between them?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 23, 2016 01:14PM |

Registered: 11 years ago Posts: 5,780 |

It's a pretty rare design where you can just place a square against the rails to align them. For me, using the frame as a reference solved that problem. If the Y rails are aligned to the square frame, you can align the Z rails to the frame and they will then be orthogonal to Y.

Using thin walled tubing without butt joints is going to make getting the frame square and keeping it that way difficult. Each of your frame's joints is free to rotate. You hope to prevent it by adding the third member to the joint, but I don't know if that's going to provide the rigidity needed.

Edited 1 time(s). Last edit at 05/23/2016 01:17PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Using thin walled tubing without butt joints is going to make getting the frame square and keeping it that way difficult. Each of your frame's joints is free to rotate. You hope to prevent it by adding the third member to the joint, but I don't know if that's going to provide the rigidity needed.

Edited 1 time(s). Last edit at 05/23/2016 01:17PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 24, 2016 04:50PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Each of your frame's joints is free to rotate. You hope to prevent it by adding the third member to the joint, but I don't know if that's going to provide the rigidity needed.

realthor and i argued this back and forth in an entertaining way for what... a week? eventually we concluded that yes, amazingly, the triple join does actually create rigidity. it's the fact that each of the joints allow rotation only about one axis and restrict the freedom of movement of the other two axes that does it. so the total number of restrictions of movement totals two restrictions on each of X Y and Z (two provided per bar).

it's quite odd and requires a bit of thought

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 24, 2016 04:59PM |

Registered: 8 years ago Posts: 776 |

realthor, the answer's no.

i went over a "stable" design for robkar, here [forums.reprap.org] but you've chosen belts for Z so it's harder to do 3 Z lifts using belts. so instead you should be looking at treating this like a cantilevered bed. the distance between the left and right rods is too great: LM8UU bearings will have too much play in them (and they're too short), you *will* run into a batch that has insufficient tolerances, and you'll end up with something like *3 millimetres* of travel on the print bed just by putting a 500g weight on one side.

i copied the Fusebox design which is similar to what you have here and i was stunned to find that just putting the screwdriver into the bed levelling spring-loaded M3 bolts was enough to cause 0.2mm of variation in the printbed levelling due to this see-sawing effect.

on pages 6 to 7 of the Fusebox forum we then discussed a range of solutions, which Ax then tested and implemented for the FB2020. we concluded that the "G&C" all-aluminium printer has it right, and that 10 or better 12mm rods with *DUAL* linear bearings PER ROD, mounted directly to a long single aluminium L-shaped bracket, was the way to go. we also concluded i believe that using the cheaper bearings and putting them in plastic housings was in no way sufficient to prevent see-sawing, and that getting the bigger "all-metal" linear bearings and mounting them directly to the L-shaped bracket was much better.

i went over a "stable" design for robkar, here [forums.reprap.org] but you've chosen belts for Z so it's harder to do 3 Z lifts using belts. so instead you should be looking at treating this like a cantilevered bed. the distance between the left and right rods is too great: LM8UU bearings will have too much play in them (and they're too short), you *will* run into a batch that has insufficient tolerances, and you'll end up with something like *3 millimetres* of travel on the print bed just by putting a 500g weight on one side.

i copied the Fusebox design which is similar to what you have here and i was stunned to find that just putting the screwdriver into the bed levelling spring-loaded M3 bolts was enough to cause 0.2mm of variation in the printbed levelling due to this see-sawing effect.

on pages 6 to 7 of the Fusebox forum we then discussed a range of solutions, which Ax then tested and implemented for the FB2020. we concluded that the "G&C" all-aluminium printer has it right, and that 10 or better 12mm rods with *DUAL* linear bearings PER ROD, mounted directly to a long single aluminium L-shaped bracket, was the way to go. we also concluded i believe that using the cheaper bearings and putting them in plastic housings was in no way sufficient to prevent see-sawing, and that getting the bigger "all-metal" linear bearings and mounting them directly to the L-shaped bracket was much better.

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 24, 2016 05:31PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

[...]and that 10 or better 12mm rods with *DUAL* linear bearings PER ROD, mounted directly to a long single aluminium L-shaped bracket, was the way to go. we also concluded i believe that using the cheaper bearings and putting them in plastic housings was in no way sufficient to prevent see-sawing, and that getting the bigger "all-metal" linear bearings and mounting them directly to the L-shaped bracket was much better.

- 3x12mm rods would be too much I believe so I'll stick to my 3x10mm rods plan.

- I have 2xLM10UU per rod but yeah, it's plastic holders all over. I am thinking though of using LM10LUUs.

In the current design those holders are quite complex as they have to perform the functions of the bearings housing, square tube clamp and bed dampening. I really don't want to mess with what I've come up with

... too much to go over again

... too much to go over again

Why do you say that "the distance between the left and right rods is too great"? It is my understanding that a larger footprint makes for a more stable surface.... I was actually thinking to make that distance even larger and place the rods even closer to the frame vertical members...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 24, 2016 06:34PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

Quote

the_digital_dentist

Each of your frame's joints is free to rotate. You hope to prevent it by adding the third member to the joint, but I don't know if that's going to provide the rigidity needed.

realthor and i argued this back and forth in an entertaining way for what... a week? eventually we concluded that yes, amazingly, the triple join does actually create rigidity. it's the fact that each of the joints allow rotation only about one axis and restrict the freedom of movement of the other two axes that does it. so the total number of restrictions of movement totals two restrictions on each of X Y and Z (two provided per bar).

it's quite odd and requires a bit of thought

BTW, this arrangement would work as well, if not even better, for 2020 T-slot extrusion, and, because each overlapping segment provides a "natural" bracket, the costs are reduced with no loss in rigidity.

If T-slot 2020 is used, one can even use one of those three sides corner brackets or even those fancy connector cubes to increase rigidity.

Edited 1 time(s). Last edit at 05/25/2016 04:57PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 29, 2016 03:46PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Why do you say that "the distance between the left and right rods is too great"?

leverage. the 300mm of the left edge is a massive lever which will rotate a tiny 30mm-long bearing on the right. that's a 10:1 force multipler. so a weight of 100 grams on the left end of the printbed now results in 1kg of force on the bearing. 1kg results in 10kg of rotational force - you get the picture?

and because you only have 2 leadscrews, you *will* get a seesaw effect. if you are going to stick with 2 leadscrews you *need* dual bearings per z-rod and a stable force transfer mechanism (made of metal) read the discussion we had on pages 6-7 of the fusebox forum, we looked at the G&C design and went, "yeah that's a good way to do it".

Edited 1 time(s). Last edit at 05/29/2016 03:47PM by lkcl.

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 29, 2016 04:44PM |

Registered: 9 years ago Posts: 1,035 |

Quote

lkcl

Quote

realthor

Why do you say that "the distance between the left and right rods is too great"?

leverage. the 300mm of the left edge is a massive lever which will rotate a tiny 30mm-long bearing on the right. that's a 10:1 force multipler. so a weight of 100 grams on the left end of the printbed now results in 1kg of force on the bearing. 1kg results in 10kg of rotational force - you get the picture?

and because you only have 2 leadscrews, you *will* get a seesaw effect. if you are going to stick with 2 leadscrews you *need* dual bearings per z-rod and a stable force transfer mechanism (made of metal) read the discussion we had on pages 6-7 of the fusebox forum, we looked at the G&C design and went, "yeah that's a good way to do it".

I am sorry I don't follow. Are you suggesting to have the bed wider than the rods?

Wouldn't the 300mm be a masive lever would there be no bearing at all on that side?but there is a bearing (couple of them actually) which prevent that to be a lever...

Moreover, I still feel we're on different pages ... I have no leadscrews... :-/

Edited 1 time(s). Last edit at 05/29/2016 04:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 29, 2016 05:39PM |

Registered: 11 years ago Posts: 5,780 |

Quote

realthor

realthor and i argued this back and forth in an entertaining way for what... a week? eventually we concluded that yes, amazingly, the triple join does actually create rigidity. it's the fact that each of the joints allow rotation only about one axis and restrict the freedom of movement of the other two axes that does it. so the total number of restrictions of movement totals two restrictions on each of X Y and Z (two provided per bar).

it's quite odd and requires a bit of thought

I understand how it should work, but you're assuming a lot of ideals- no flex in the tubing walls which are quite thin, and perfect fit holes that don't allow any play around the screws. I think the actual behavior will not be as good as hoped. This is one of those things that just has to be tried to see if it actually works well.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 29, 2016 05:57PM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

Quote

realthor

realthor and i argued this back and forth in an entertaining way for what... a week? eventually we concluded that yes, amazingly, the triple join does actually create rigidity. it's the fact that each of the joints allow rotation only about one axis and restrict the freedom of movement of the other two axes that does it. so the total number of restrictions of movement totals two restrictions on each of X Y and Z (two provided per bar).

it's quite odd and requires a bit of thought

I understand how it should work, but you're assuming a lot of ideals- no flex in the tubing walls which are quite thin, and perfect fit holes that don't allow any play around the screws. I think the actual behavior will not be as good as hoped. This is one of those things that just has to be tried to see if it actually works well.

One correction... I could have slightly larger holes than bolts ... something around 0.5 to 1M larger. I will start with 5mm and see from there.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 03:46AM |

Registered: 9 years ago Posts: 1,035 |

Quote

realthor

Quote

lkcl

Quote

realthor

Why do you say that "the distance between the left and right rods is too great"?

leverage. the 300mm of the left edge is a massive lever which will rotate a tiny 30mm-long bearing on the right. that's a 10:1 force multipler. so a weight of 100 grams on the left end of the printbed now results in 1kg of force on the bearing. 1kg results in 10kg of rotational force - you get the picture?

and because you only have 2 leadscrews, you *will* get a seesaw effect. if you are going to stick with 2 leadscrews you *need* dual bearings per z-rod and a stable force transfer mechanism (made of metal) read the discussion we had on pages 6-7 of the fusebox forum, we looked at the G&C design and went, "yeah that's a good way to do it".

I am sorry I don't follow. Are you suggesting to have the bed wider than the rods?

Wouldn't the 300mm be a masive lever would there be no bearing at all on that side?but there is a bearing (couple of them actually) which prevent that to be a lever...

Moreover, I still feel we're on different pages ... I have no leadscrews... :-/

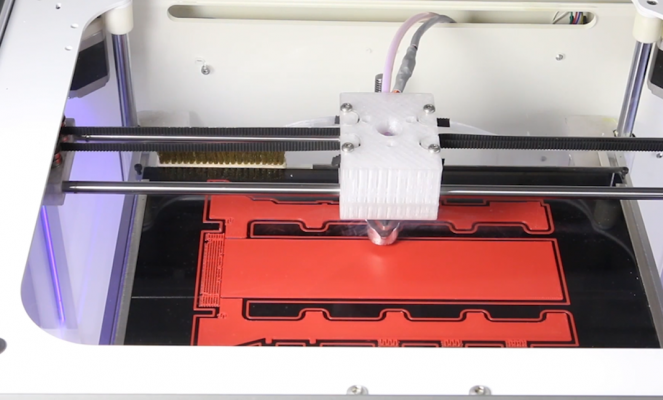

Look at how far Axiom has its cantilevered bed's Z Rods:

...and that's a cantilevered bed. Even if the rods seem like 12mm, I have 3 of 10mm ones.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 04:02PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Quote

realthor

realthor and i argued this back and forth in an entertaining way for what... a week? eventually we concluded that yes, amazingly, the triple join does actually create rigidity. it's the fact that each of the joints allow rotation only about one axis and restrict the freedom of movement of the other two axes that does it. so the total number of restrictions of movement totals two restrictions on each of X Y and Z (two provided per bar).

it's quite odd and requires a bit of thought

I understand how it should work, but you're assuming a lot of ideals- no flex in the tubing walls which are quite thin, and perfect fit holes that don't allow any play around the screws. I think the actual behavior will not be as good as hoped. This is one of those things that just has to be tried to see if it actually works well.

very good points. the original idea came from using extrusion (2020 was the original photo i think) and joining it by drilling all the way through, you remember the idea about drilling through and putting a tapped screw in the end? well this is similar, but use a nut on the end and slot it into the rail... times 3.

returning to the original idea would fix the "flex" problem... if i remember correctly from the analysis i did (weeks ago....) in a counter-intuitive way perfect-fit holes are not actually essential. it's the "pull" of each tube against each other tube that causes them to lock solid: the actual positions and even the size of the holes is completely irrelevant. other than weakening the tube walls massively, the hole size could be completely oversized to an extreme extent, you could put a washer in and as long as each tube was pulled closely against each other tube with absolutely no possibility of separation of the faces on any three bolt locations, you are guaranteed a perfectly triple-perpendicular join.

... *if* as you say the tubing remains perfectly solid.

now, if this was tried with only 2 tubes, it would be a total fail. if the tubes are ever overstretched such that they deform beyond the plasticity point of the metal, it's a total fail of the *entire* corner (because of the critical interdependence of all three tubes for rigidity).

i'm aware there's a lot that could go wrong, here. i won't be using it myself, i'll be sticking to 1515 [at compact sizes below 360mm only!] and will try 2020 on the next design [because it has to be over 360mm].

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 04:10PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

Wouldn't the 300mm be a masive lever would there be no bearing at all on that side?but there is a bearing (couple of them actually) which prevent that to be a lever...

no it would not, and that's the point. the bearing is not perfect: it has travel in it. inside, it's made of plastic, in fact. it's only metal on the outside. take a rod, put a bearing down it, and wiggle the rod sideways: the rod will rotate!! why? because rod bearings are *NOT* designed to prevent rotation, that's why!

the way to try to reduce rotation (not eliminate it) is to have two bearings on the same rod, separated by as much distance as you can stand.... then make absolutely sure that there is a rigid frame around them. if it's plastic, it will be a design fail. i _do_ keep saying to you "read the Fusebox forum pages 6 and 7" and "go look at how the G&C all-aluminium design works"!

Quote

Moreover, I still feel we're on different pages ... I have no leadscrews... :-/

i know. which is why i feel that this design is going to have... issues. not related to the belts, but to the fact that you're not understanding that linear bearings can wiggle about on the rods. just like we discussed on the "carriages" - it's exactly the same thing.

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 04:54PM |

Registered: 9 years ago Posts: 1,035 |

I understand the wiggle in the bearings, I am sorry to prove such a thick skull sometimes but I fail to understand the lever thing. So far I thought you were talking about the bed itself but now I get it you are only talking about the relation between each Z carriage and the bed.

So, if this is right, then on a cantilevered bed one would get the situation you describe, where 100g on the edge of the cantilevered side forces the Z carriages with 10x lever. This is right.

But:

1) I have one front-supported rod, so that situation changes a lot and now I would have a somewhat similar situation if we were talking about the corners of the bed on the side with the center rod.

2) I have dual-bearings on both Z carriages on the side with 2 rods and one bearing on the side with one rod, so any weight that would force the corners of the single-rod-supported-side is taken by a lengthier carriage.

The problem I see now from your posts is that I have the plastic housings for the bearings ... which can be a problem.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

So, if this is right, then on a cantilevered bed one would get the situation you describe, where 100g on the edge of the cantilevered side forces the Z carriages with 10x lever. This is right.

But:

1) I have one front-supported rod, so that situation changes a lot and now I would have a somewhat similar situation if we were talking about the corners of the bed on the side with the center rod.

2) I have dual-bearings on both Z carriages on the side with 2 rods and one bearing on the side with one rod, so any weight that would force the corners of the single-rod-supported-side is taken by a lengthier carriage.

The problem I see now from your posts is that I have the plastic housings for the bearings ... which can be a problem.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 05:32PM |

Registered: 11 years ago Posts: 5,780 |

The wiggle in the bearings problem can be easily solved by using linear guides instead of the round rails and bearings. It will solve other problems such as flexing guide rails, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 05:47PM |

Registered: 8 years ago Posts: 776 |

Quote

realthor

I understand the wiggle in the bearings, I am sorry to prove such a thick skull sometimes but I fail to understand the lever thing. So far I thought you were talking about the bed itself but now I get it you are only talking about the relation between each Z carriage and the bed.

So, if this is right, then on a cantilevered bed one would get the situation you describe, where 100g on the edge of the cantilevered side forces the Z carriages with 10x lever.

yes. 300mm cantilevered bed, 30mm bearing, 100g on the edge turns into a whopping *one kilogram* between the top end of the linear bearing and the bottom end.

[/quote]

Quote

But:

1) I have one front-supported rod, so that situation changes a lot and now I would have a somewhat similar situation if we were talking about the corners of the bed on the side with the center rod.

it changes but is in effect the same thing - the numbers are slightly different but it's still not really okay. let's assume you have only 1 bearing per rod (i know you don't but let's do that). let's take into account that there are 4 rods, so the load is split between all 4.

so it's 150mm of leverage vs 30mm, so that's a 5:1 ratio. but the load is distributed (evenly? let's assume evenly) across 4 rods, so it's a 5:4 ratio, now. maybe linear bearings can take the weight, maybe they can't. *but*, remember even the *distance* is multipled by 5.... and you *can't* have that amount divided by 4 just because there are 4 rods.

in other words, there is literally zero resistance to the force being applied (let's put the printer in zero-g for now, ok?), it's only when the tolerances on the bearings are reached, the bearing begins to resist and the "force" bit comes into action. so we're talking now *only* about the amount of lateral travel in the bearings.

so if there is 0.5mm of play in the top and bottom of each bearing, that's a total of 1mm of play as the top rotates vs the bottom, and that turns into a whopping FIVE MILLIMETRES of potential movement of the print bed EACH WAY! +/- 5mm, man!!

*but*, also, worse than that, you have plastic bearing-holders. which, when that amazing 5mm is reached, those start to bend as well! can plastic bearing-holders *really* take the strain? well, anything that you can quite literally bend in your hand, i wouldn't trust it as far as i could throw it. so, it's not going to be "bearing travel that is multiplied by 5:1, it's going to be "bearing travel PLUS PLASTIC DEFORMATION DISTANCE" that's multiplied by 5:1.

now do you see why i said that there could quite easily be 1cm of see-saw movement on the printbed? i've seen this happen. i have a printer that does it - i based the sandwich200v1 on the Fusebox, and the Fusebox uses a 150mm-long piece of plastic to separate the bearings. it's totally useless.

ok so let's move on to scenario 2...

Quote

2) I have dual-bearings on both Z carriages on the side with 2 rods and one bearing on the side with one rod, so any weight that would force the corners of the single-rod-supported-side is taken by a lengthier carriage.

correct. so, instead of that leverage being 150mm vs 30mm because it's the top and bottom of *one* single bearing, instead now it's 150mm vs top-of-1st-bearing down to bottom-of-2nd-bearing, which iiis... what.... 75mm? so you've got... a leverage effect of 150:75 which is 2:1.

so whilst the force is reduced from 2:1 to only 1:2 by the load distribution on the 4 rods, that's *only* after the full range of travel of the bearings has been reached.... which, again, if you have 0.5mm +/- of play, that's a full 1mm one way in rotation (top goes left 0.5mm, bottom goes right 0.5mm that's 1mm), and 1mm in the other (top goes RIGHT 0.5mm, bottom goes LEFT 0.5mm, that's 1mm). multiplied by 2:1 through the 150:75mm leverage, and the end of the printbed will still be a WHOPPING 2mm of play either way!

and that's from just putting your finger on it and going "boop". not even pressing hard!

Quote

The problem I see now from your posts is that I have the plastic housings for the bearings ... which can be a problem.

yes. ok. hooray. i managed to explain it clearly enough. that's an achievement for me

so, can you see, even if you have the totally-rigid metal arrangement described in the G&C printer, the play in the bearings can *still* result in rotation of the whole arrangement? you cannot rely on the bearings to stop that. thus, logically, the only way to stop rotation of the printbed is: use triple lead (or ball) screws.

so, can you see, even if you have the totally-rigid metal arrangement described in the G&C printer, the play in the bearings can *still* result in rotation of the whole arrangement? you cannot rely on the bearings to stop that. thus, logically, the only way to stop rotation of the printbed is: use triple lead (or ball) screws. actually now i've gone through it i'm going to revise my previous analysis [as being worse than i previously thought]. i'm beginning not to like rods any more, because the same effects that could cause rotation can also result in lateral (sideway) travel. previously i assumed that linear bearings on 2 rods would at least have no lateral travel, whereas i now realised that was an assumption. what would be *less* lateral travel in a 2-rod scenario is if you pulled the 2 rods apart sufficiently to take up any machining-tolerance slack (just as we previously discussed on the "carriage" sub-forum). however that is a less-than-ideal scenario. a 3-rod scenario as long as you pulled all 3 apart (in different directions!) to take up all slack in the machining-tolerances, you *might* be okay.

gaaah i am going to have to check the LM12UUs on the 12mm rods of the sandwich200v2, to make sure that there's no lateral play: i have only 2. it's packed up, now. i'm trying to remember when going "wobble wobble" and pushing it around... did it move? i didn't feel like it was, but then i don't have a micrometer. meh...

Edited 1 time(s). Last edit at 05/30/2016 05:54PM by lkcl.

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 05:57PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

The wiggle in the bearings problem can be easily solved by using linear guides instead of the round rails and bearings. It will solve other problems such as flexing guide rails, too.

yeahhh i didn't really fully appreciate what people were referring to about this, when saying that linear guides were preferable, it didn't really come with a full explanation so i couldn't assess it. things that don't come with explanations, they seem to not "get a grip" on my brain. now i "Get It" so really appreciate the reminder, here, dd, to use linear guides. [p.s edit: i _can_ think of a way to take the slack out of the round rails when using bearings... i described it above: but if i am honest with myself i don't like it]

Edited 1 time(s). Last edit at 05/30/2016 05:58PM by lkcl.

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 30, 2016 06:26PM |

Registered: 9 years ago Posts: 1,035 |

Ultimately one solution is to not push it so hard that it overcomes all these failsafes ...

You can push the limits very far and you'll need better and better parts ... but at some point you have to ask yourself what is it that you are after...

So I try to listen and understand but unless linear guides don't come down in price abruptly I will stay with rods... Frankly I am tempted to go the other way, namely the delrin rollers path ...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

You can push the limits very far and you'll need better and better parts ... but at some point you have to ask yourself what is it that you are after...

So I try to listen and understand but unless linear guides don't come down in price abruptly I will stay with rods... Frankly I am tempted to go the other way, namely the delrin rollers path ...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 31, 2016 07:35AM |

Registered: 11 years ago Posts: 5,780 |

See [www.ebay.com]

There are always deals like this on ebay- you just have to spend some time looking, and be patient enough to wait for the right stuff to show up at the right price.

Back when I used 1/2" round rails, I was using Thomson Super8 bearings. Those bearings have races that tilt inside their little cage allowing you to adjust preload if you put them into the right type of pillow block. I studied Thomson's pillow block and designed a couple printable versions that worked quite well. Those pillow blocks will take almost all the wiggle out of the bearings. You can see them here: [www.youmagine.com]

and here: [www.youmagine.com]

Thomson sells those bearings for $40 each, but I was buying them on ebay for $5 each. I think they make metric equivalents, but the 1/2" size seems to be the most commonly available for low cost.

Edited 1 time(s). Last edit at 05/31/2016 07:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are always deals like this on ebay- you just have to spend some time looking, and be patient enough to wait for the right stuff to show up at the right price.

Back when I used 1/2" round rails, I was using Thomson Super8 bearings. Those bearings have races that tilt inside their little cage allowing you to adjust preload if you put them into the right type of pillow block. I studied Thomson's pillow block and designed a couple printable versions that worked quite well. Those pillow blocks will take almost all the wiggle out of the bearings. You can see them here: [www.youmagine.com]

and here: [www.youmagine.com]

Thomson sells those bearings for $40 each, but I was buying them on ebay for $5 each. I think they make metric equivalents, but the 1/2" size seems to be the most commonly available for low cost.

Edited 1 time(s). Last edit at 05/31/2016 07:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 31, 2016 08:13AM |

Registered: 9 years ago Posts: 1,035 |

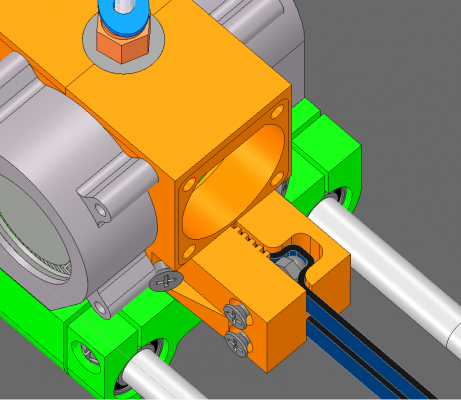

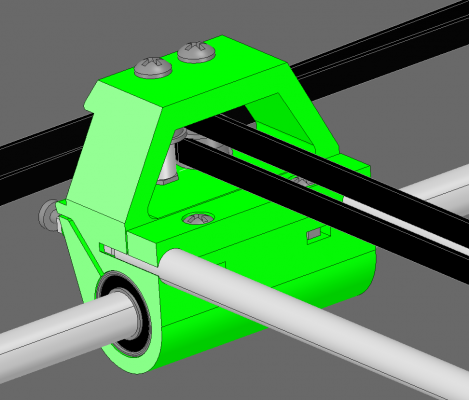

OK, that pillowblock looks ok and it actually looks about the way I am clamping the linear bearings on the XCarriage for Horizontal rods that I am designing (discussion in another thread):

But I will use this with common LM8UU bearings ...so there might be a difference. Also you seem to have the clamping bolt at the center of the bearing while I use the bolt to slightly catch the bearing recess at one side as to prevent axial movement inside the clamp.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

But I will use this with common LM8UU bearings ...so there might be a difference. Also you seem to have the clamping bolt at the center of the bearing while I use the bolt to slightly catch the bearing recess at one side as to prevent axial movement inside the clamp.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? May 31, 2016 09:10AM |

Registered: 11 years ago Posts: 5,780 |

The LM8UU bearings aren't designed for adjustable preloading like the super8s. All you can do with the LM8UUs is hold them in place. The clamps may look similar, but the function is different.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? June 01, 2016 08:20AM |

Registered: 9 years ago Posts: 1,035 |

@d_d: Yeah, I assumed as much.

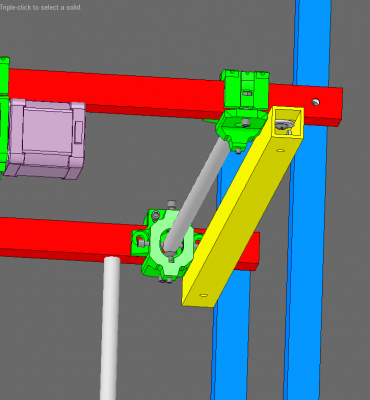

Coming back to the alignment of the rods I've got one idea: have one of the YRods inserted in metal, just as the upper ends of all 3 ZRods. This way I can really align X with Y and with Z with a square angle.

Here's what I am talking about:

So, with YZ I can do a square ruler alignment between Y and the Red tube/extrusion and then another measurement between the Z and the same Red tube/extrusion ... this way that particular ZRod will be perpendicular to that particular YRod.

I have also designed the YCarriages to allow (maybe) easier aligning of the X with Y:

Then, align the YRod to be squared agains the XRod via a similar mechanism (can't define it yet, as I can't use the carpenters square because the rods are offset) ...

Then I will align all other YRods ends' clamps so that XY is square, and all oather ZRods using the moving bed, as we discussed before.

The remaining problem is the play in the ZBearings, which can throw slighlty off the alignment so I should use a way to preload the bearings against the rod maybe...

Makes sense?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Coming back to the alignment of the rods I've got one idea: have one of the YRods inserted in metal, just as the upper ends of all 3 ZRods. This way I can really align X with Y and with Z with a square angle.

Here's what I am talking about:

So, with YZ I can do a square ruler alignment between Y and the Red tube/extrusion and then another measurement between the Z and the same Red tube/extrusion ... this way that particular ZRod will be perpendicular to that particular YRod.

I have also designed the YCarriages to allow (maybe) easier aligning of the X with Y:

Then, align the YRod to be squared agains the XRod via a similar mechanism (can't define it yet, as I can't use the carpenters square because the rods are offset) ...

Then I will align all other YRods ends' clamps so that XY is square, and all oather ZRods using the moving bed, as we discussed before.

The remaining problem is the play in the ZBearings, which can throw slighlty off the alignment so I should use a way to preload the bearings against the rod maybe...

Makes sense?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? June 02, 2016 10:22PM |

Registered: 7 years ago Posts: 51 |

Quote

realthor

Hello,

I planned 10mm rods for SCOUTcorexy's dual-supported Z platform but am wondering, as long as the bed is not cantilevered it might be sufficient to have 8mm rods (also considering that I use 3 rods).

Here's a sketch:

[attachment 78685 SCOUTcorexy_Z-Stage_Overview.png]

Thanks.

The rods are there to prevent XY, rotational(pitch and yaw) movements to the bed. The thicker it is the better it will resist any force from the Z lead screw other than the Z direction.

If you're using belt , then you probably have to worry more on the pitch and Yaw forces. Imagine putting something heavy on just one corner on the bed, will it tilt due to the rods being not stiff enough?

|

Re: Triple-rod supported bed, 8mm shaft enough or go higher? June 11, 2016 06:46PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Vigilant

The rods are there to prevent XY, rotational(pitch and yaw) movements to the bed. The thicker it is the better it will resist any force from the Z lead screw other than the Z direction.

If you're using belt , then you probably have to worry more on the pitch and Yaw forces. Imagine putting something heavy on just one corner on the bed, will it tilt due to the rods being not stiff enough?

I get it about the pitch forces and the slop in the bearing will just allow the bed to tilt even before rods flex but I doubt that kind of flex can be caused by normal functioning. The only cause that I can see for such a tilting force to be a major concern is -in the case of the belt-, the elongation of the belt as the stepper motor pulls the bed from one side and the other side has some lag into following movement.

On the other hand I can't imagine what could cause a Yaw (rotation on Z) force.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.