various XY designs

Posted by printman

|

various XY designs October 08, 2016 07:22AM |

Registered: 11 years ago Posts: 38 |

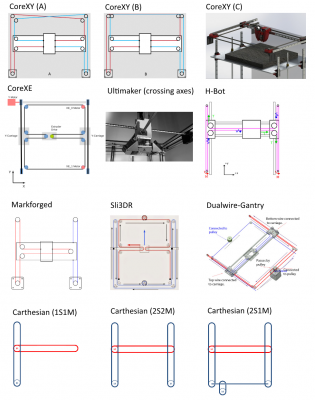

There various XY designs nowadays. Which one is the best in terms of a precision, repeatability, rigidity and speed?

1. CoreXY with crossing - A

2. CoreXY no crossing - B

3. CoreXY - C, http://forums.reprap.org/read.php?397,706869

4. CoreXE

5. Ultimaker - carthesian, crossing axes

6. H-bot

7. Markforged - Markforged Mark design

8. Sli3DR - http://richrap.blogspot.com/search/label/Sli3DR

9. Dualwire Gantry - http://reprap.org/wiki/Dualwire-Gantry_(DW-G)

10. Carthesian (1S1M) - one side driven by one motor

11. Carthesian (2S2M) - two sides driven by two motors (electrically coupled)

12. Carthesian (1S1M) - two sides driven by one motor (mechanically coupled)

1. CoreXY with crossing - A

2. CoreXY no crossing - B

3. CoreXY - C, http://forums.reprap.org/read.php?397,706869

4. CoreXE

5. Ultimaker - carthesian, crossing axes

6. H-bot

7. Markforged - Markforged Mark design

8. Sli3DR - http://richrap.blogspot.com/search/label/Sli3DR

9. Dualwire Gantry - http://reprap.org/wiki/Dualwire-Gantry_(DW-G)

10. Carthesian (1S1M) - one side driven by one motor

11. Carthesian (2S2M) - two sides driven by two motors (electrically coupled)

12. Carthesian (1S1M) - two sides driven by one motor (mechanically coupled)

|

Re: various XY designs October 08, 2016 09:12AM |

Registered: 11 years ago Posts: 5,780 |

Precision is repeatablility, and depends on the rigidity of the construction among other things. Rigidity is usually a function of size/mass (with ordinary materials). For a given input power, speed is inversely proportional to mass, so speed and precision tend to be inversely proportional. Precision, or more specifically, lack of precision, is mainly seen the the finish of the prints.

In comparing different mechanisms, you have to think about potential sources of imprecision. Mechanical rigidity of the frame and axes, the bearings, and the electrical components (motors and drivers) all contribute. You can't have high precision without a rigid frame and quality bearings (linear and rotary). Longer belts (more dynamic stretch) will be less precise than shorter belts (less dynamic stretch). Wider belts (less dynamic stretch) will be more precise than narrower belts (more dynamic stretch). You can minimize dynamic belt stretch effects by keeping moving masses low and/or reducing speed/acceleration. You can eliminate belt type problems entirely by driving with ball screws but then you increase the moving mass (the rotating screw).

Electrically coupling two motors is less precise/reliable than using one motor to provide the same drive. Just look at all the Z axis problem posts in these forums. Almost all of the problems occur in machines that have two Z axis motors driving two screws that lift the ends of the X axis.

In the end, the precision you get is going to depend on how carefully you build the machine and how you operate it and the maximum speed is going to depend on how light you keep the moving masses. Speed and precision are always inversely proportional.

There's no single answer for which mechanism is best. What are you really looking for here?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In comparing different mechanisms, you have to think about potential sources of imprecision. Mechanical rigidity of the frame and axes, the bearings, and the electrical components (motors and drivers) all contribute. You can't have high precision without a rigid frame and quality bearings (linear and rotary). Longer belts (more dynamic stretch) will be less precise than shorter belts (less dynamic stretch). Wider belts (less dynamic stretch) will be more precise than narrower belts (more dynamic stretch). You can minimize dynamic belt stretch effects by keeping moving masses low and/or reducing speed/acceleration. You can eliminate belt type problems entirely by driving with ball screws but then you increase the moving mass (the rotating screw).

Electrically coupling two motors is less precise/reliable than using one motor to provide the same drive. Just look at all the Z axis problem posts in these forums. Almost all of the problems occur in machines that have two Z axis motors driving two screws that lift the ends of the X axis.

In the end, the precision you get is going to depend on how carefully you build the machine and how you operate it and the maximum speed is going to depend on how light you keep the moving masses. Speed and precision are always inversely proportional.

There's no single answer for which mechanism is best. What are you really looking for here?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: various XY designs October 12, 2016 06:49PM |

Registered: 11 years ago Posts: 38 |

You are right. While I write precision I mean rather accuracy.

I'm looking for an advice what is the best type of mechanism. I've read about the H-bot which appears to be worse than CoreXY because of a racking, or Markforged mechanism driving only one side. So there can be an answer or an ordering, CoreXY seems to be definitely better.

I'm thinking of building a next version of my 3d printer. I have a box construction with Hiwin rails and thinking of using CoreXY (2), Ultimaker (5), standard carthesian portal type (MendelMax/Prusa like), or 2S1M (12). Ultimaker type seems to be better than CoreXY for me since there are shorter belts and straight moves are straight, but it requires a bowden extruder and crossing rods are not practical. The classical portal type like printer with lightweight table is good, but I don't like the moving table. CoreXY with a table moving only in Z axis is great, but the belt is longer and straight moves are done by both motors fighting who of them has bigger torque. CoreXY prints on top as well which means more vibrations and the box cannot be closed since the filament is dragged over whole top area.

I'm basically struggling with an idea what is better in terms of quality. I'd like to have layers placed exactly on each other, smooth side walls (no vibrations and ringing).

Edited 1 time(s). Last edit at 10/12/2016 06:52PM by printman.

I'm looking for an advice what is the best type of mechanism. I've read about the H-bot which appears to be worse than CoreXY because of a racking, or Markforged mechanism driving only one side. So there can be an answer or an ordering, CoreXY seems to be definitely better.

I'm thinking of building a next version of my 3d printer. I have a box construction with Hiwin rails and thinking of using CoreXY (2), Ultimaker (5), standard carthesian portal type (MendelMax/Prusa like), or 2S1M (12). Ultimaker type seems to be better than CoreXY for me since there are shorter belts and straight moves are straight, but it requires a bowden extruder and crossing rods are not practical. The classical portal type like printer with lightweight table is good, but I don't like the moving table. CoreXY with a table moving only in Z axis is great, but the belt is longer and straight moves are done by both motors fighting who of them has bigger torque. CoreXY prints on top as well which means more vibrations and the box cannot be closed since the filament is dragged over whole top area.

I'm basically struggling with an idea what is better in terms of quality. I'd like to have layers placed exactly on each other, smooth side walls (no vibrations and ringing).

Edited 1 time(s). Last edit at 10/12/2016 06:52PM by printman.

|

Re: various XY designs October 13, 2016 07:45AM |

Registered: 8 years ago Posts: 601 |

What you've shown in the picture is types of movement systems, not 3D printer designs. Each has its own compromise, but each is able to have highly accurate, precise and repeatable movements. You just need to design your machine with the strengths and weaknesses of each system in mind. For example, H-bot is fine as long as it is designed with the differences in belt tension in mind. CoreXY is 'smarter' in that it uses the belts to its advantage.

Ultimaker type machines can use direct drive. Many have made direct drive extruders for ultimaker. It is now possible to make extruders almost as light as a bowden system (well, nearly). The ultimaker rods are not very beefy either, so larger diameter rods may be needed to support more weight. CoreXY can easily be enclosed, just build it taller.

Basically, you are making assumptions based on machines you have seen rather then what the actual advantages and disadvantages are of each movement system.

Ultimaker type machines can use direct drive. Many have made direct drive extruders for ultimaker. It is now possible to make extruders almost as light as a bowden system (well, nearly). The ultimaker rods are not very beefy either, so larger diameter rods may be needed to support more weight. CoreXY can easily be enclosed, just build it taller.

Basically, you are making assumptions based on machines you have seen rather then what the actual advantages and disadvantages are of each movement system.

|

Re: various XY designs October 13, 2016 09:14PM |

Registered: 11 years ago Posts: 5,780 |

In the coreXY, slightly different torque from the motors shouldn't matter until you push the mechanism right to the edge of its performance limits. The motors step when they are told to step and as long as the mechanism isn't binding and the speed/acceleration isn't excessive, the extruder carriage will go where you expect. At some speed/acceleration, one motor may be able to pull harder than the other and things will start going badly, but that's how you'll know when to turn down the speed/acceleration. In coreXY, 45/135 degree lines are drawn by operating only one motor to move both the Y axis and the extruder carriage. 45/135 degree lines are very commonly used for infill. If you change the infill angle to something like 60/150, you'll get both motors working again which should allow you to run a little faster. In more conventional cartesian printer mechanisms where the moving mass of one axis (usually Y) is greater than the other, the motor pulling the heavier axis will crap out at lower speed/acceleration than the one pulling the lower mass (extruder carriage moving in X axis).

A CoreXY machine can be enclosed- you just have to design it that way. A lot of the examples you see people post here aren't designed for enclosure- they often use the frame members as part of the linear motion system which makes it hard to enclose the machine because of the resulting mechanical inferences. Yes, it needs more room above the XY mechanism than a machine in which the extruder moves in only one axis, but getting a little taller usually isn't nearly as big a problem as getting a bigger foot-print.

Using zero backlash ball screws to drive the axes will eliminate ringing (at least that caused by belt stretch, you may still have some caused by the motor). The high mass of the screws means you'll have to operate the machine pretty slowly. If you compare belt driven results and ball screw driven results at the same slow speeds/accelerations, I'm not sure there would be a big difference in the print quality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A CoreXY machine can be enclosed- you just have to design it that way. A lot of the examples you see people post here aren't designed for enclosure- they often use the frame members as part of the linear motion system which makes it hard to enclose the machine because of the resulting mechanical inferences. Yes, it needs more room above the XY mechanism than a machine in which the extruder moves in only one axis, but getting a little taller usually isn't nearly as big a problem as getting a bigger foot-print.

Using zero backlash ball screws to drive the axes will eliminate ringing (at least that caused by belt stretch, you may still have some caused by the motor). The high mass of the screws means you'll have to operate the machine pretty slowly. If you compare belt driven results and ball screw driven results at the same slow speeds/accelerations, I'm not sure there would be a big difference in the print quality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: various XY designs October 17, 2016 05:36PM |

Registered: 11 years ago Posts: 38 |

Thanks. Good points. I've already decided to go for a box with moving table up and down but still struggling with the xy mechanism.

I've narrowed down all the types to only two of them:

1. Carthesian 2S1M - one motor drives both Y axes, the another one drives X axis.

See: [www.youtube.com]

2. CoreXY (B ) - corexy over two levels without crossing

See: [www.youtube.com]

The type 1 looks more rigid but slower, while the type 2 quicker but loose. What do you think is better for 3d printing in terms of quality? I'm trying to find some deciding arguments.

I'm most likely to use a direct drive extruder (need to find a light one).

I've narrowed down all the types to only two of them:

1. Carthesian 2S1M - one motor drives both Y axes, the another one drives X axis.

See: [www.youtube.com]

2. CoreXY (B ) - corexy over two levels without crossing

See: [www.youtube.com]

The type 1 looks more rigid but slower, while the type 2 quicker but loose. What do you think is better for 3d printing in terms of quality? I'm trying to find some deciding arguments.

I'm most likely to use a direct drive extruder (need to find a light one).

|

Re: various XY designs October 17, 2016 06:58PM |

Registered: 11 years ago Posts: 5,780 |

When it comes to delivering high print quality, the mechanism you select isn't nearly as important as how you build it. Many people say they want high print quality and then immediately focus on minimizing cost. If you focus on minimal cost, you'll end up with just another cheap printer. You can't build a high quality printer without buying high quality components, and high quality parts cost more than low quality parts.

You don't have to mortgage your house, just be careful about how you shop for parts and don't design your printer and then hunt for the parts to build it exactly the way you designed it. Gather parts and design them in as you accumulate them. It takes a little longer to finish your project but you can achieve high print quality for reasonable cost.

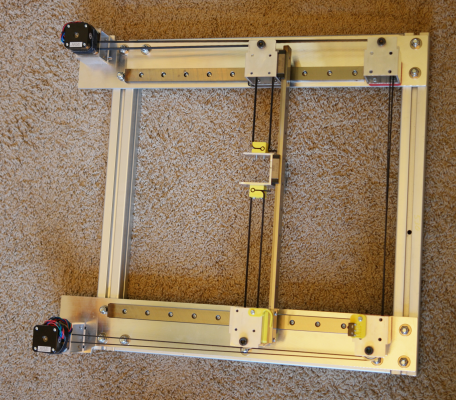

This is my CoreXY mechanism, built for a little over $200:

There's about 18 lbs of aluminum there (purchased at about $2.25/lb), and three used 24 mm linear guides purchased at about $35 each, some hardware and bearings (another $15 or so), and two motors (about $20 each), pulleys and belts (about $10). This thing is rock solid and ready to deliver as much precision as pulleys and belts will allow.

The new part cost of all this would have been astronomical. By shopping carefully I was able to hold the cost down and keep quality very high.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You don't have to mortgage your house, just be careful about how you shop for parts and don't design your printer and then hunt for the parts to build it exactly the way you designed it. Gather parts and design them in as you accumulate them. It takes a little longer to finish your project but you can achieve high print quality for reasonable cost.

This is my CoreXY mechanism, built for a little over $200:

There's about 18 lbs of aluminum there (purchased at about $2.25/lb), and three used 24 mm linear guides purchased at about $35 each, some hardware and bearings (another $15 or so), and two motors (about $20 each), pulleys and belts (about $10). This thing is rock solid and ready to deliver as much precision as pulleys and belts will allow.

The new part cost of all this would have been astronomical. By shopping carefully I was able to hold the cost down and keep quality very high.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: various XY designs October 18, 2016 12:41PM |

Registered: 12 years ago Posts: 548 |

Quote

printman

2. CoreXY (B ) - corexy over two levels without crossing

See: [www.youtube.com]

while the type 2 quicker but loose

I built my corexy with makerslide with the belts setup that way and it's not 'loose' in it's operation. I also use a e3dv6 on a Titan extruder.

I put the printer on Thingiverse: [www.thingiverse.com]

|

Re: various XY designs October 23, 2016 04:16AM |

Registered: 8 years ago Posts: 601 |

As said before, you're not comparing the style of motion here but the build quality.

In theory corexy is more capable then any standard cartesian design as it does not have the added bulk of an X axis motor. This means you can design it to be lighter and faster. However, any machine if well designed is still highly capable.

In theory corexy is more capable then any standard cartesian design as it does not have the added bulk of an X axis motor. This means you can design it to be lighter and faster. However, any machine if well designed is still highly capable.

Sorry, only registered users may post in this forum.