layer shift

Posted by serdar415

|

layer shift May 30, 2018 04:37AM |

Registered: 6 years ago Posts: 48 |

Hi i have updated my slicr software and i tried to print multiple parts at once. Software was printing every part in same layer in old version. But the new version started to print every part individualy. After printing few parts the hotend and fan duct started to crash other parts and all axises forced.

After that i started printing again. The parts on the upper left corner and lower right corner started to show layer shift on x axis.

At the center of the bed there is no problem.

Has the belt tooth torn out?

After that i started printing again. The parts on the upper left corner and lower right corner started to show layer shift on x axis.

At the center of the bed there is no problem.

Has the belt tooth torn out?

|

Re: layer shift May 30, 2018 07:04AM |

Registered: 11 years ago Posts: 5,780 |

Pictures of the printer showing XY belts would help.

It sounds like the mechanism may be binding as you get near the corners of the bed. That implies that the belt paths, which should be parallel to the guide rails, are not parallel to the guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It sounds like the mechanism may be binding as you get near the corners of the bed. That implies that the belt paths, which should be parallel to the guide rails, are not parallel to the guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: layer shift May 30, 2018 07:12AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: layer shift May 31, 2018 02:54AM |

Registered: 6 years ago Posts: 48 |

These are the photos.

The printer started to print normal today.

The steppers get hot or something i think.

The printer started to print normal today.

The steppers get hot or something i think.

|

Re: layer shift May 31, 2018 07:35AM |

Registered: 11 years ago Posts: 5,780 |

If the steppers got hot, it may be because the motor current is set too high. That would cause the drivers to overheat, which would cause their protection circuits to shut them down, which would cause shifted layers.

In my coreXY printer, the XY motors get 5-10C above ambient after hours of operation. If you have to set the current so high that the motors are getting hot, maybe the mechanism is not moving smoothly. It may move smoothly when you take the belts off, but the belt tension may effect the motion and cause it to bind. Manually push the extruder carriage around. Does it take a constant amount of force to move it around the print area?

The photos are almost useless. Post a picture that shows the entire printer from above.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In my coreXY printer, the XY motors get 5-10C above ambient after hours of operation. If you have to set the current so high that the motors are getting hot, maybe the mechanism is not moving smoothly. It may move smoothly when you take the belts off, but the belt tension may effect the motion and cause it to bind. Manually push the extruder carriage around. Does it take a constant amount of force to move it around the print area?

The photos are almost useless. Post a picture that shows the entire printer from above.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: layer shift May 31, 2018 08:35AM |

Registered: 6 years ago Posts: 48 |

Yes it takes constant amount of force around the print area.

I printed parts which took 5 hours of print and there wasnt any problem. I chek the motors and they dont get hot.

Does the motors pull more current when the extruder movement obstructed by the previously printed parts? Instant current increase might heat the steppers and caused layer shift?

Printer is working fine at the moment.

I chek the belt tension and it is a bit loose . And the belt has different tension at different points. On the left side it feels loose and on the right it feels good tension.

By printers belt is under the hood. i ll try to take better photos.

Edited 1 time(s). Last edit at 05/31/2018 08:37AM by serdar415.

I printed parts which took 5 hours of print and there wasnt any problem. I chek the motors and they dont get hot.

Does the motors pull more current when the extruder movement obstructed by the previously printed parts? Instant current increase might heat the steppers and caused layer shift?

Printer is working fine at the moment.

I chek the belt tension and it is a bit loose . And the belt has different tension at different points. On the left side it feels loose and on the right it feels good tension.

By printers belt is under the hood. i ll try to take better photos.

Edited 1 time(s). Last edit at 05/31/2018 08:37AM by serdar415.

|

Re: layer shift May 31, 2018 09:09AM |

Registered: 11 years ago Posts: 5,780 |

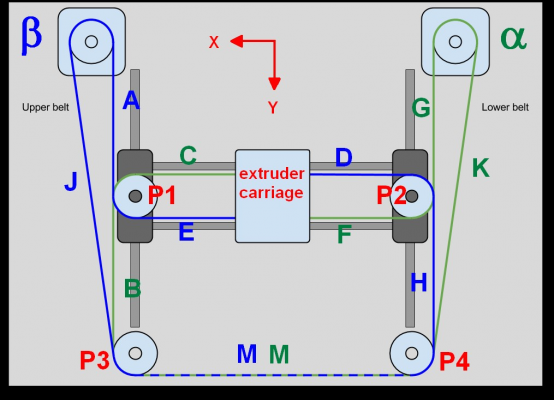

If the belt tension varies as the extruder carriage moves, it means the belts are probably not parallel to the guide rails, or the Y axis rails are not parallel to each other. It also means it will take a variable amount of force to move the extruder carriage, which could result in skipped layers. The Y axis rails must be parallel, the X axis rail(s) must be perpendicular to the Y rails, and the belts have to be parallel to the X and Y guide rails:

In the picture, segments labeled A-H have to be parallel to their respective guide rails. J, K, and M do not have to be parallel to the rails.

How is movement "obstructed by previously printed parts"?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the picture, segments labeled A-H have to be parallel to their respective guide rails. J, K, and M do not have to be parallel to the rails.

How is movement "obstructed by previously printed parts"?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.